B

2

SAGINAW CONTROL & ENGINEERING • A/C USER MANUAL

back to top

1. User Manual

This instruction manual contains information and instructions to enable the user to work safely, correctly and economically

on the unit. Understanding and adhering to the manual can help one:

• Avoid any dangers

• Reduce repair costs and stoppages

• Extend and improve the reliability and working life of the unit

PLEASE ENSURE TO USE THE RIGHT VERSION OF THE INSTRUCTION MANUAL SUITABLE FOR YOUR UNIT

Conditions of Use

The unit is to be used exclusively for the dissipation of heat from control cabinets and enclosures in order to protect

temperature sensitive components in an industrial environment. To meet the conditions of use, all the information and

instructions in the instruction manual must be adhered to.

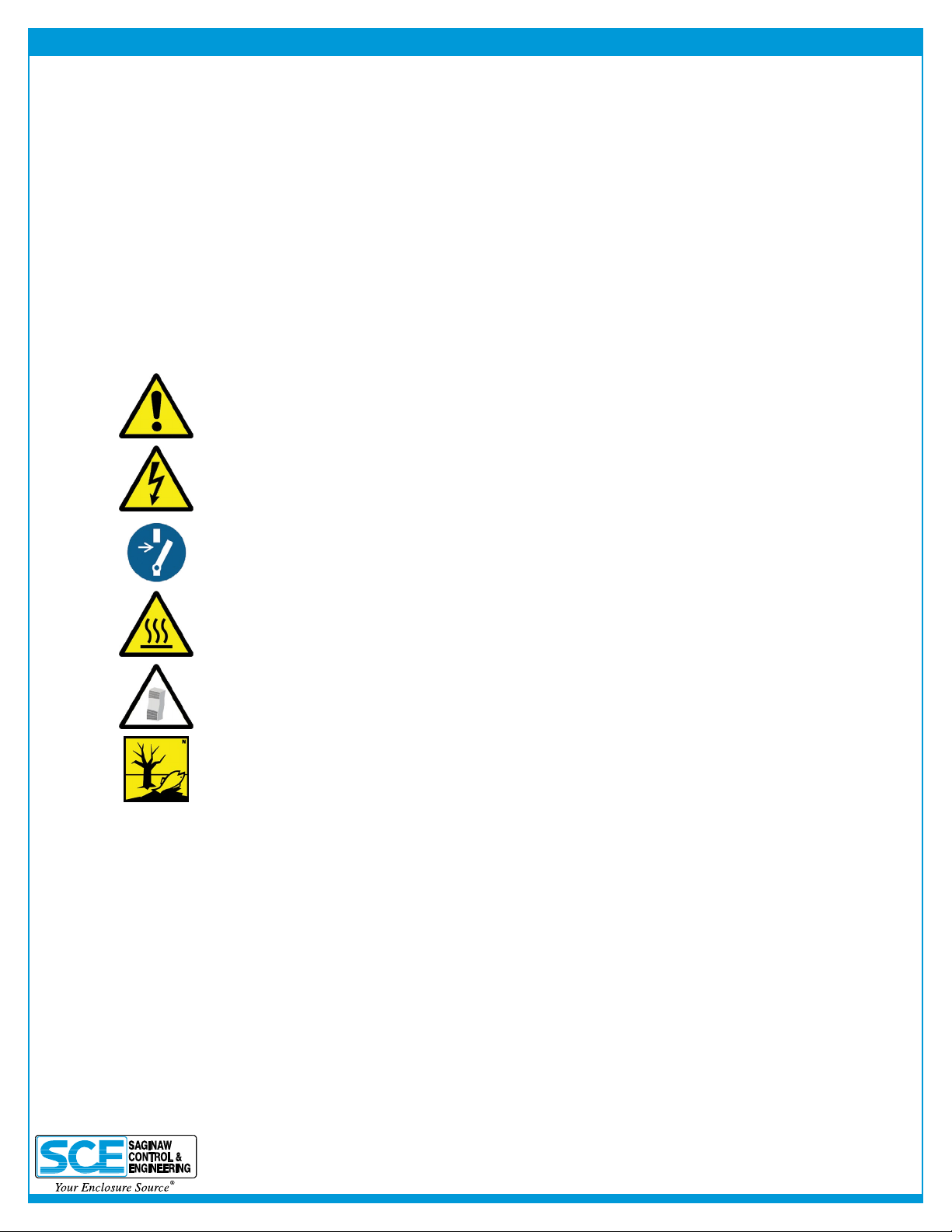

General Danger

Indicates compulsory safety regulations which are not covered by a specic pictogram such

as one of the following.

High Electric Voltage

Indicates electric shock danger.

Important Safety Instruction

Indicates instructions for safe maintenance and operation of the unit.

Attention

Indicates possible burns from hot components.

Attention

Indicates possible damage to the unit.

Instruction

Indicates possible danger to the environment.

2. Legal Regulations

Liability

The information, data and instructions contained in this instruction manual are current at the time of going to press. We

reserve the right to make technical changes to the unit in the course of its development. Therefore, no claims can be

accepted for previously delivered units based on the information, diagrams or descriptions contained in this manual. No

liability can be accepted for damage and production caused by:

• Disregarding the instruction manual

• Operation error

• Inappropriate work on or with the unit

• The use of non-specied spare parts and accessories

• Unauthorized modications or changes to the unit by the user or his personnel

Saginaw Control & Engineering is only liable for errors and omissions as outlined in the guarantee conditions contained in

the main contractual agreement. Claims for damages on any grounds are excluded.