Page 10

Line Scan Camera SK2048USD Manual (v. 7.2012)

A charge-coupled device is a linear array

designed for moving discrete electrical

charges from one element of the array to

the next by successively applying a voltage

to each element in turn. The discrete charge

packets emanating from the end of the

linear array are converted into a voltage and

digitized for further transmission.

A line scan signal is produced by moving

the object to be imaged in a trajectory

perpendicular to the camera sensor.

By synchronizng data acquisition, high

frequencies and resolutions are achieved.

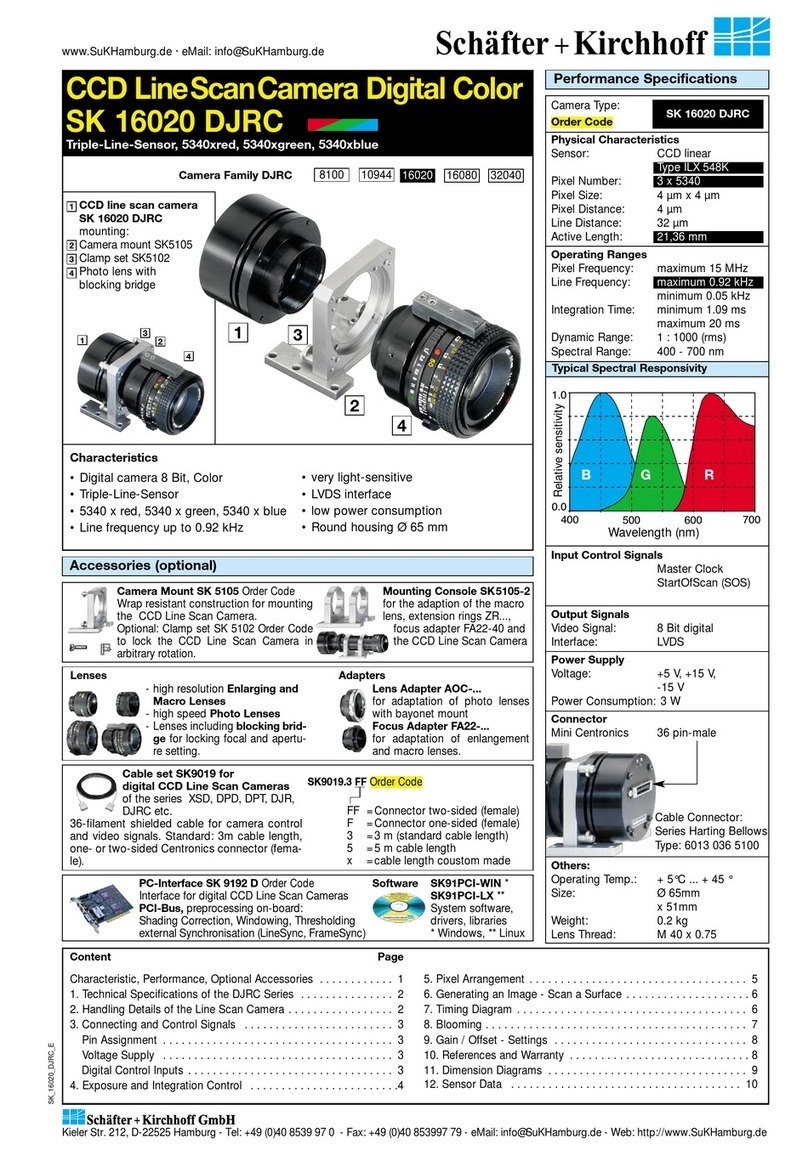

The choice of line scan camera is primarily

determined by the customer application

requirements, which influence sensor length,

pixel number and line scan frequency – see

Imaging Definitions, below.

Our considerable experience in line scan

camera design and software production

allows us to get the best possible imaging

performance within the constraints of the

technology. Potential problems are simply

designed out – or an intrinsic constraint is

tuned away – according to circumstance.

For example, illumination over-exposure of

the sensor causes blooming and signal blur

or loss, from charge leakage across pixels.

Blooming can be either designed out (anti-

blooming) or cut by reducing the integration

time or lens aperture.

Similarly, gain and offset tuning can increase

signal-to-noise ratios, while shading correction

negates any problems of pixel variability, lens

vignetting or inhomogeneous illumination,

whether initially present or not.

Other custom features can be chosen, such

as specialized or filtered illumination, choice

of color or monochrome line sensors as well

as type of interface, with either GigE VisionTM,

Gigabit Ethernet, LVDS, CameraLink® or USB

2.0 interfaces available for data output.

The oscilloscope display facility of the supplied

software is responsive in real-time, and the

zoom function can be used to highlight an

area of interest. The oscilloscope display is

ideally suited for parameterizing the camera,

for evaluating object illumination, for focussing

the image or for aligning the line scan camera

correctly – see Section 7.2 Alignments and

Adjustments.

A line scan camera 2D area scan can easily be

performed by simply specifying the number of

line scans to be integrated.

• Exposure Period and Integration Time

The illumination cycle of a line scan sensor, of

a particular length and number of pixels, for a

set period of time is designated the exposure

period.

Within a single exposure period, the

integration time is the duration designated for

signal accumulation of charges by the sensor.

In continuous mode, the next exposure cycle

is simply begun at the time of read-out of

the previous exposure and, so, the durations

of exposure period and integration time are

identical. Cameras with integration control

are capable of curtailing the integration time

within an exposure period (emulating a shutter

mechanism).

• Pixel and Line Scan Frequencies

The pixel frequency for an individual sensor

is the rate of charge transfer from pixel to pixel

and its ultimate conversion into a signal. The

minimum exposure period of a sensor is the

minimum time required for the read-out of

a whole line scan and is dependent on the

maximum pixel frequency and the number of

pixels (plus a sensor-dependent overhead of

passive pixels).

The line scan frequency is inversely

proportional to exposure period. During the

time the charges from a finished line scan

are read out, the next line scan is being

exposed. Thus, the minimum exposure period

determines the maximum line scan frequency.

• Optical Resolution

The optical resolution of a line scan camera is

determined primarily by the number of pixels in

the linear sensor and secondarily by their size

and spacing, the inter-pixel distance.

Currently available line scan cameras have up

to 12 000 pixels, ranging from 4 to 14 µm in

size and spacing, for sensors up to 56 mm in

length and line scan frequencies up to 83 kHz.

During a scanning run, the effective resolution

perpendicular to the line scan camera is

determined by the velocity of the scan and by

the line scan frequency, i.e. the number of line

scans per second.

Imaging Definitions

7. Line Scan Camera Fundamentals

7.1 Features and Characteristics

Pixel 1

CCD Sensor

Object

structure

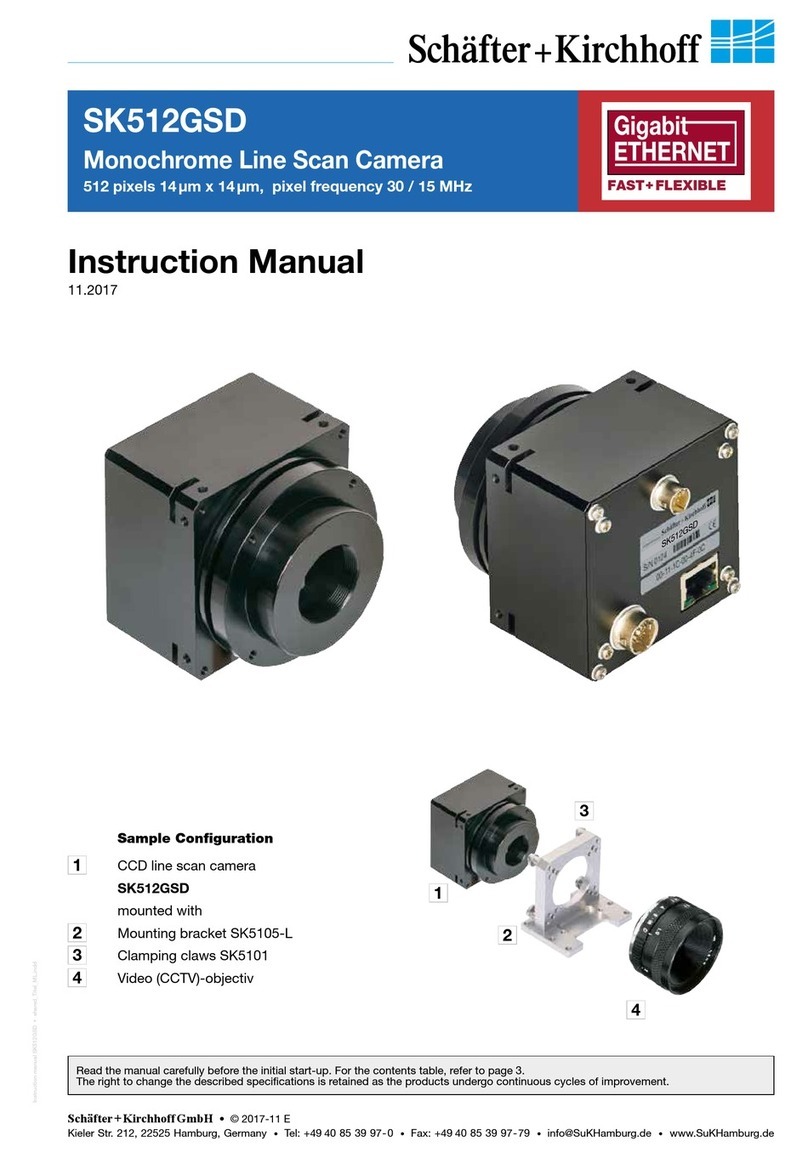

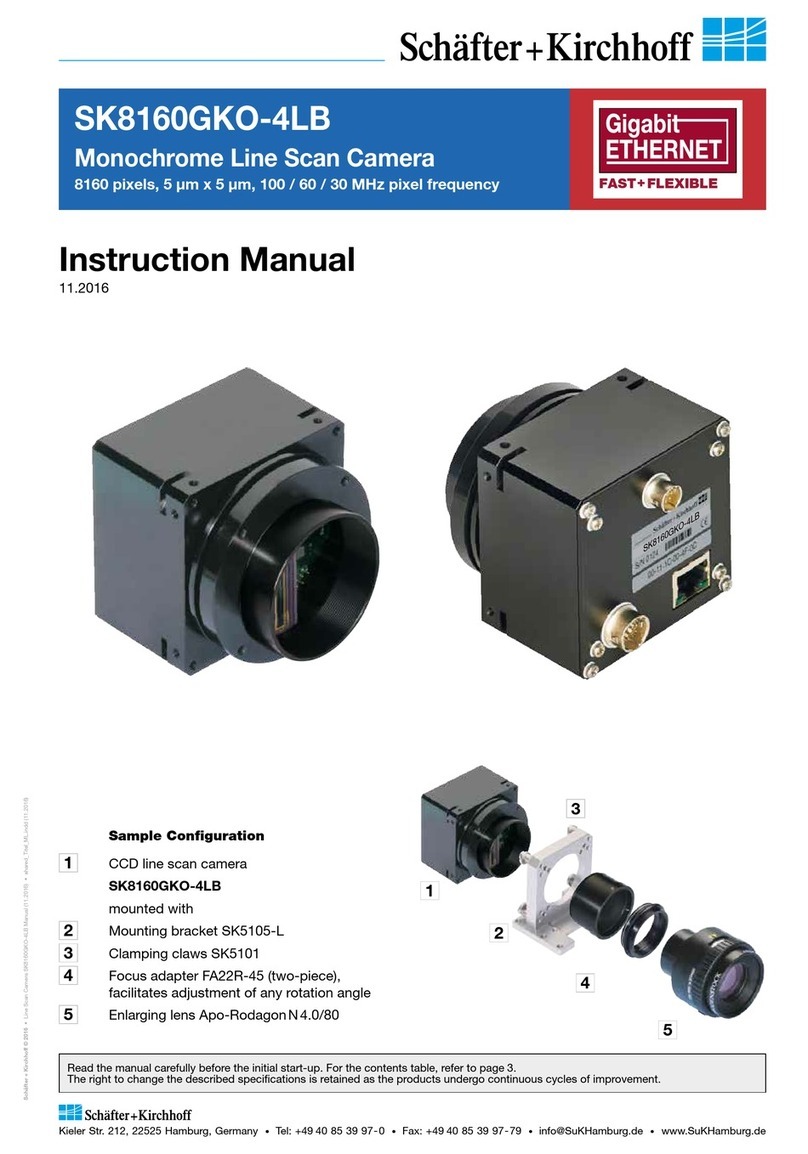

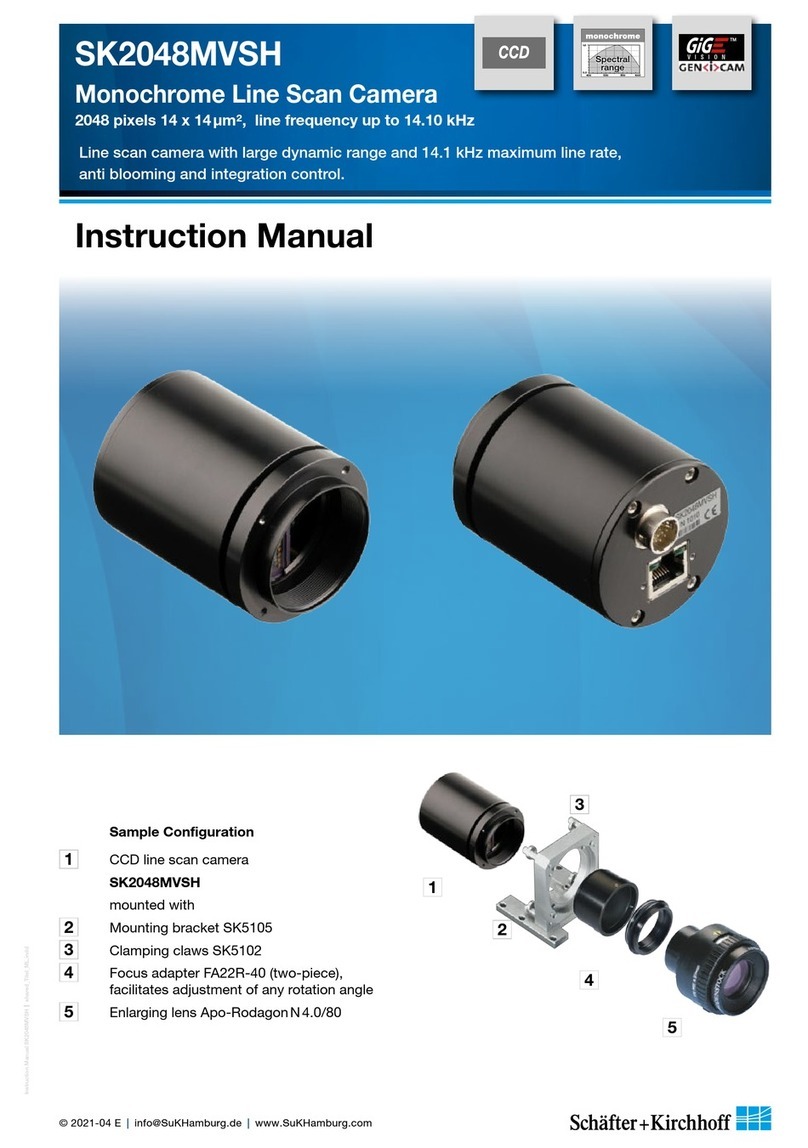

GigE SK7500GTO

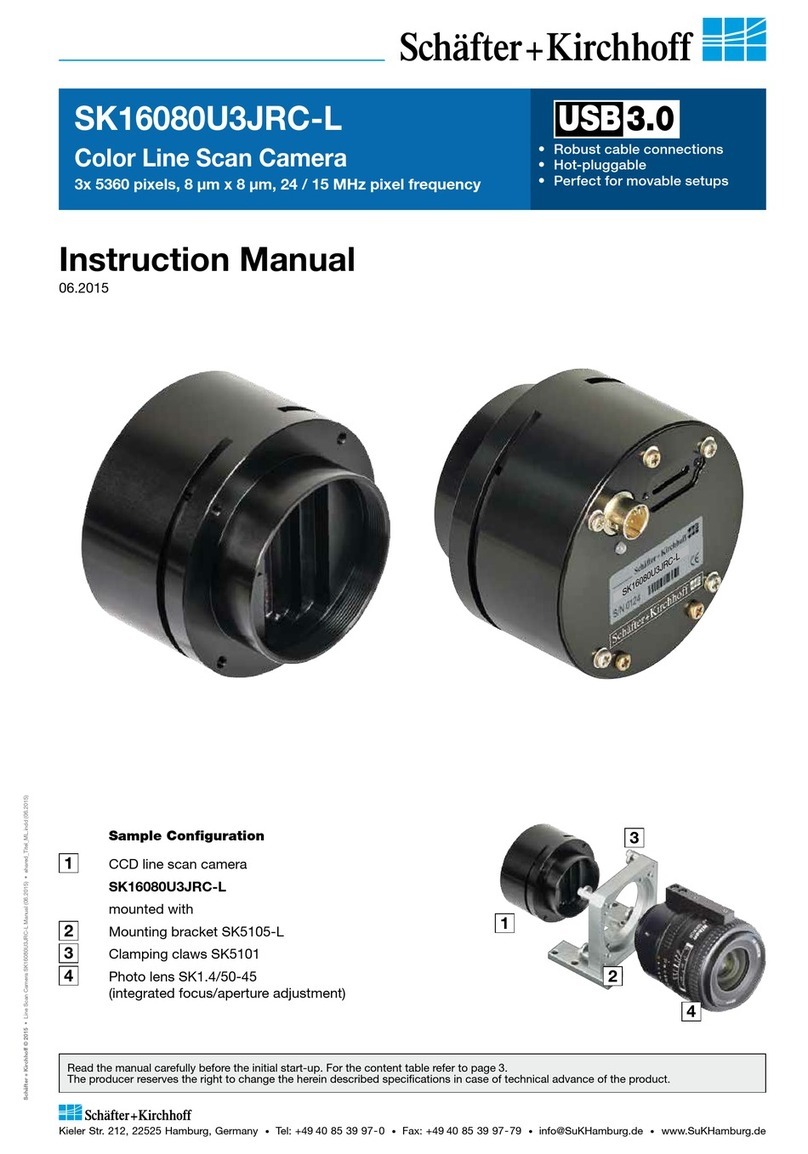

Line scan cameras from Schäfter+Kirchhoff are supplied factory-preset for the particular application, with optional accessories and appropriate

software – for parameterization of the camera or for optimizing signal acquisition. The advantages and constraints of the technology are described

below and some essential aspects of sensor alignment, lens focussing and signal optimization are presented.

• Region of Interest

A freely programmable window (region of

interest, ROI) can be applied to the line sensor

so that only the pixel information within the ROI

can reach the memory.

By only illuminating these ranges, data volume

and data processing is accelerated for both line

and area scan acquisitions.

Constraint: the ROI memory allocation must be

divisible by 8.

Data Reduction and Acquisition Acceleration

• Thresholding (B/W cameras only)

The thresholding process generates a binary

signal from the gray scale data, with values below

the threshold yielding 0 and those above yielding

1. Only the pixel addresses of the location and

threshold transition (from high→low or low→high)

are transmitted, reducing data throughput.

Thresholding is particularly appropriate for

measuring widths or edge positions, by simply

masking the required pixel addresses.

GigE SK7500GTF-XB