GENERAL

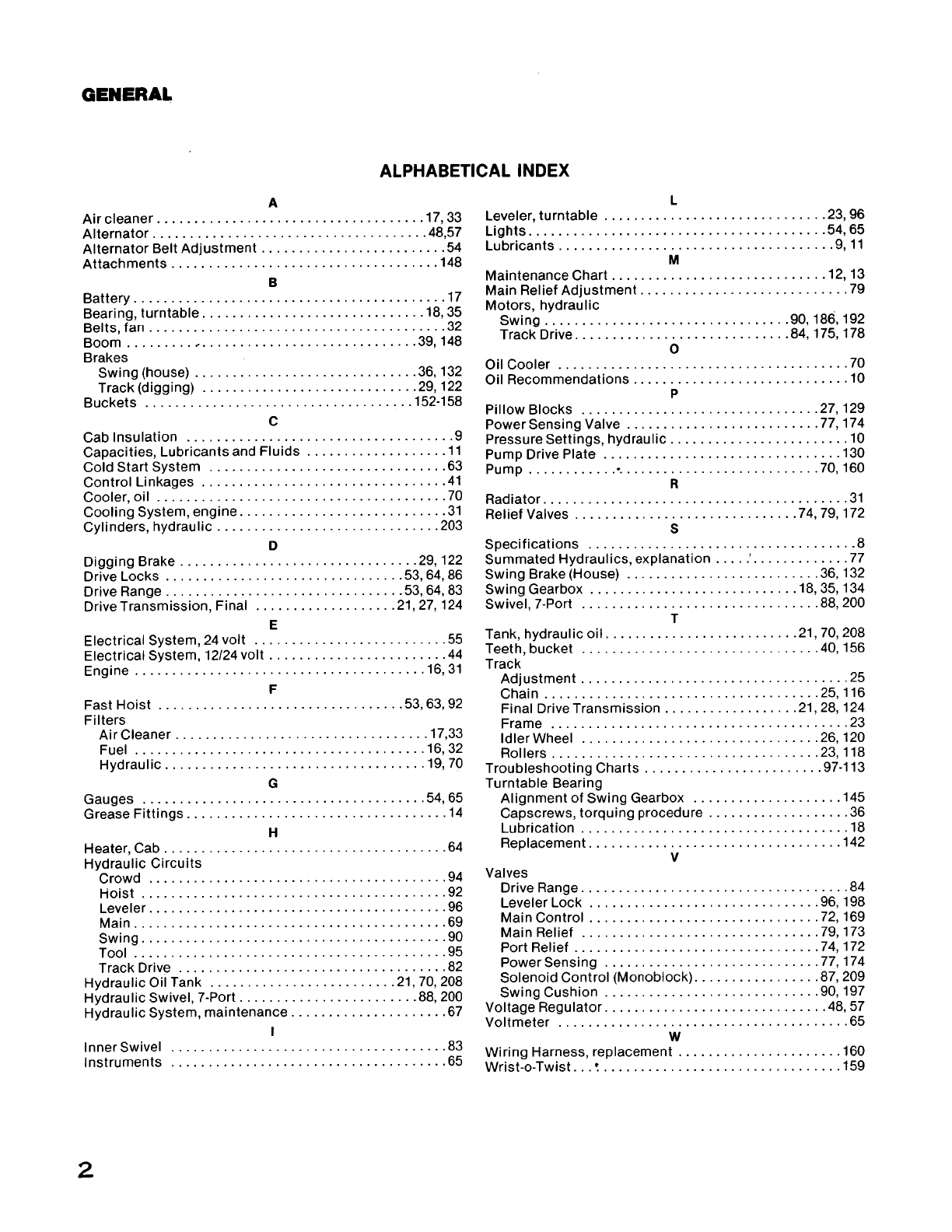

ALPHABETICAL INDEX

A L

Air

cleaner

....................................

17,

33

Leveler,

turntable

..............................

23,

96

Alternator

.....................................

48,57

Lights

........................................

54,

65

Alternator

Belt

Adjustment

.........................

54

Lubricants

.....................................

9,

11

Attachments

....................................

148

M

B

Battery

..........................................

17

Bearing,

turntable

..............................

18,

35

Belts, fan

........................................

32

Boom

.........

,

.............................

39,

148

Brakes

Swing (house)

..............................

36,

132

Track (digging)

.............................

29,

122

Buckets

....................................

152-158

C

Cab

Insulation

....................................

9

Capacities,

Lubricants

and

Fluids

...................

11

Cold Start System

................................

63

Control

Linkages

.................................

41

Maintenance Chart

.............................

12,

13

Main Relief

Adjustment

............................

79

Motors, hydraulic

Swing

.................................

90, 186,192

Track Drive

.............................

84,

175, 178

0

Oil Cooler

.......................................

70

Oil Recommendations

.............................

10

p

Pillow

Blocks

................................

27,

129

PowerSensingValve

..........................

77,174

Pressure

Settings,

hydraulic

........................

10

Pump Drive Plate

................................

130

Pump

............

•

...........................

70,

160

R

Cooler, oil

.......................................

70

Radiator

.........................................

31

Cooling

System, engine

............................

31

Cylinders, hydraulic

..............................

203 Relief Valves

..............................

74, 79,

172

s

D

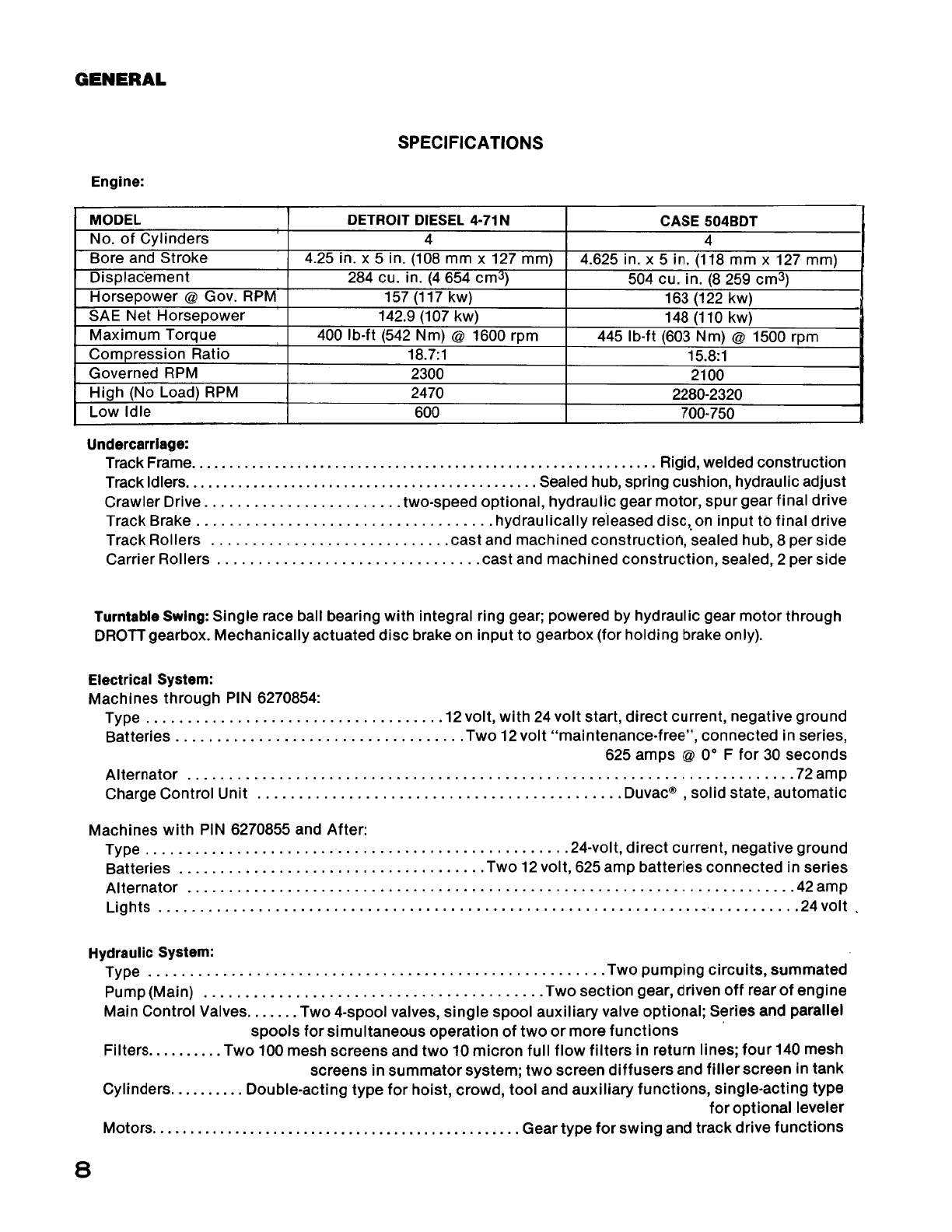

Specifications

....................................

8

Digging

Brake

................................

29,

122 Summated Hydraulics, explanation

....

.'

.............

77

Drive Locks

................................

53,

64,

86

Swing

Brake (House)

..........................

36,

132

Drive Range

................................

53,

64,

83

Swing Gearbox

............................

18,

35,

134

Drive Transmission, Final

...................

21,

27,

124

Swivel, ?-Port

................................

88,

200

E

Electrical System,

24

volt

..........................

55

Electrical System, 12/24 volt

........................

44

Engine

.......................................

16,31

F

Fast

Hoist

.................................

53,

63,

92

Filters

Air

Cleaner

..................................

17,33

Fuel

.......................................

16,

32

Hydraulic

...................................

19,

70

T

Tank, hydraulic

oil

..........................

21,

70,208

Teeth, bucket

................................

40,

156

Track

Adjustment

....................................

25

Chain

.....................................

25,

116

Final Drive

Transmission

..................

21, 28,

124

Frame

........................................

23

ldlerWheel

................................

26,

120

Roilers

....................................

23,

118

Troubleshooting

Charts

........................

97-113

G Turntable Bearing

Gauges

......................................

54,65

Alignment

of

Swing Gearbox

....................

145

Grease

Fittings

...................................

14

Capscrews,

torquing

procedure

...................

36

H

Lubrication

....................................

18

Heater, Cab

......................................

64

Hydraulic

Circuits

Crowd

........................................

94

Replacement

..................................

142

V

Valves

Hoist

.........................................

92

Drive Range

....................................

84

Leveler

........................................

96 Leveler Lock

...............................

96,

198

Main

..........................................

69 Main Control

...............................

72,

169

Swing

.........................................

90

Tool

..........................................

95 Main Relief

................................

79,173

Port Relief

.................................

74,172

Track Drive

....................................

82

PowerSensing

.............................

77,174

Hydraulic Oil Tank

.........................

21,

70,

208

Hydraulic

Swivel, ?-Port

........................

88,

200

Hydraulic System, maintenance

.....................

67

I

InnerSwivel

.....................................

83

Instruments

.....................................

65

Solenoid

Control

(Monoblock)

.................

87,

209

Swing

Cushion

.............................

90,

197

Voltage Regulator

..............................

48,

57

Voltmeter

.......................................

65

w

Wiring

Harness, replacement

......................

160

Wrist-o-Twist

...

~

................................

159

2

Find manuals at https://best-manuals.com