Schako FKF Operating instructions

SCHAKO KG

Steigstraße 25-27

D-78600 Kolbingen

Telephone +49 (0) 74 63 - 980 - 0

Fax +49 (0) 74 63 - 980 - 200

schako.com

Additional operating instructions

according to ATEX 2014/34/EU

Particle Filter Box Model FKF

Contents

Construction subject to change. No return possible!

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 2 06.12.2021Version:

General conditions ...............................................................................................................................3

General description and instructions .......................................................................................................................................... 3

Personnel qualification and training ........................................................................................................................................... 3

Safety-conscious work ............................................................................................................................................................... 3

Designated use .......................................................................................................................................................................... 3

Delivery and storage .................................................................................................................................................................. 3

Mounting information ................................................................................................................................................................ 3

Maintenance ............................................................................................................................................................................... 3

Hazard caused by non-observance of the safety instructions .................................................................................................... 3

Description ........................................................................................................................................4

Models and dimensions ......................................................................................................................... 5

Dimensions ................................................................................................................................................................................ 5

Dimensions of accessories ...................................................................................................................................................... 10

Installation and maintenance ................................................................................................................. 10

Information regarding assembly and commissioning .............................................................................................................. 12

Information regarding maintenance and inspection ................................................................................................................. 12

Type plate ....................................................................................................................................... 13

Certificate of conformity ....................................................................................................................... 14

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 3

Construction subject to change. No return possible!

06.12.2021Version:

General conditions

General description and instructions

These additional operating instructions must be observed prior

to mounting and commissioning the device.

These additional operating instructions contain basic informa-

tion regarding its use in areas subject to explosion hazards to be

observed during assembly, operation and maintenance.

Prior to mounting and commissioning and during maintenance

work, the present additional operating instructions must be read

by the installer and the responsible skilled personnel/system

operator!

Personnel qualification and training

The personnel for assembly, inspection and maintenance must

have the relevant qualification for this work.

The area of responsibility, competence and monitoring of the

personnel must be exactly regulated by the system operator. If

the personnel does not have the required knowledge, it must be

trained and instructed. Moreover, the system operator must en-

sure that the contents of the additional operating instructions

are understood completely by the personnel.

Safety-conscious work

The safety instructions given in these additional operating in-

structions, the existing national and international regulations on

explosion protection, accident prevention and the system oper-

ator's internal work, operating and safety regulations must be

observed.

Designated use

The devices have been designed for use in ventilation systems

in areas subject to explosion hazards according to ATEX of Cat-

egory II, Zones 1, 2 and Category III, Zones 21, 22.

These devices are not suitable for use in unreleased Ex zones.

The operating safety of the delivered devices is only guaranteed

when used in accordance with their designated use.

Delivery and storage

Upon receipt, the devices must be checked for completeness

and transport damage. If delivered incompletely or damaged,

the forwarding company and the SCHAKO KG have to be in-

formed immediately.

The device must not be exposed directly to weather, solar radi-

ation and moisture.

Mounting information

Mounting, electrical connection work and commissioning must

be carried out by skilled personnel only and in accordance with

the recognised technical rules and the safety and accident pre-

vention regulations.

Maintenance

Only a device subjected to proper maintenance and kept in per-

fect condition can guarantee safe and reliable operation.

When defective parts are replaced with spare parts, only SCHA-

KO original spare parts may be used. The SCHAKO KG cannot

be held liable for any damage caused by using spare parts that

are not original and will not give any warranty.

Hazard caused by non-observance of the safety in-

structions

Non-observance of the safety instructions can result both in

putting persons and the environment and operating units at risk.

Likewise, non-observance of the safety instructions will result in

the loss of any claims for damages.

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 4

Construction subject to change. No return possible!

06.12.2021Version:

Description

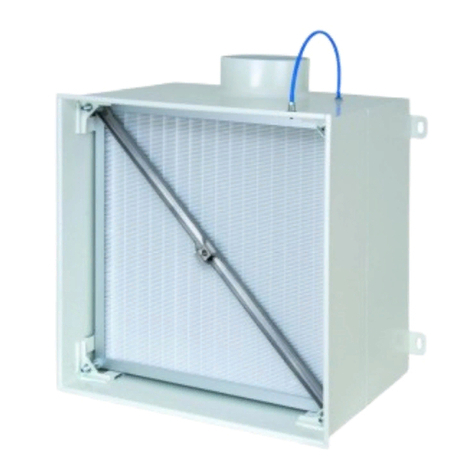

The FKF particle filter box with fluid seal on the filter cell has

been specially developed for use in cleanrooms as required by

the pharmaceutical, electronic, precision mechanical and optical

industries in hospitals and laboratories. The integrated particle

filter (to DIN EN 1822) removes particles, radioactive dust,

mist, bacteria, viruses, etc., from the supply or return air.

This ensures that the incoming and outgoing air flows are ex-

tremely clean and germ-free.

The fluid is located at the filter cell and pressed into a sealing

device especially developed for this purpose in the filter box

when the filter cell is installed. Owing to the properties of the

fluid, the filter cell can be mounted and dismounted several

times without having to change the fluid.

The filter box, type FKF-... , consists of electrolytically galva-

nised sheet steel painted to RAL 9010 (white) or stainless steel

V2A (1.4301) with a round connection spigot for hose connec-

tion while the type FKF-Q-... has a rectangular spigot with con-

nection flange. A filter pressure device in the filter box ensures

a safe seal. As a standard feature, a differential pressure and

aerosol monitoring device is integrated in the particle filter

box.

Optionally, the particle filter boxes FKF-H-... are additionally

equipped with a shut-off damper sealing air-tight. This shut-off

damper can be adjusted manually from below after the air dif-

fuser is removed. Leakage at closed shut-off damper according

to DIN EN 1751, class 4, at a duct pressure of up to 1000 Pa. An

electric actuator is not available. As an alternative, a SCHAKO

DKA-L in ATEX version can be used outside the filter box.

Attention!

We would like to point out that we supply the filter boxes with

integrated spacers for fitting the filter clamps and the diffuser

assembly pole brace. This makes it possible to fit the air diffuser

without additional expense, even when the filter has not yet been

inserted into the filter box.

The assembly of the air diffusers is effected via magnetic fasten-

ing. This allows the air diffusers to be easily taken off for filter

replacement and decontamination without requiring tools. The

following ceiling air diffusers in supply and return air models are

suitable to be fitted to the particle filter box type FKF: FDQJ,

FPIL, FDAV. Magnetic fastening is generally not possible for

FPIL and FDAV and for air diffusers made of aluminium and

stainless steel. These air diffusers are mounted via central fas-

tening (-VM).

If required, the suitable particle filters can be included in the de-

livery.

Sealing on the particle filter

The filter boxes in stainless steel design 1.4301 are

delivered together with the air diffuser FDQJ made of stainless

steel. FPIL and FDAV are not available in connection with parti-

cle filter boxes made of stainless steel.

The particle filter box has the following ATEX marking:

This particle filter box meets the regulations of the ATEX direc-

tives and can be used in ventilation systems in areas subject to

explosion hazards.

The particle filter box has been certified for the explosion pro-

tection group II for Zones 1, 2 and 21, 22.

Zones 1 and 2 represent the application range containing gases,

while Zones 21 and 22 represent the application range contain-

ing dusts.

Classification by zone must be established by the system oper-

ator or planner in compliance with current standards.

Note:

In explosion-protected zones, only devices that have an ATEX

approval for this use may be used.

Technical data, information

- The grounding terminals of the particle filter box must be

connected to the equipotential bonding.

- It rests with the operator to ensure that the products are only

used in zones specified by the product marking.

Fluid

(in filter housing)

II 2G Ex h IIB T6 Gb

II 2D Ex h IIC T80°C Db EPS 09 ATEX 2 154 X

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 5

Construction subject to change. No return possible!

06.12.2021Version:

Special conditions

Note on operation

Type of ignition protection

Quality assurance

-It must be ensured that all metal components, in particular

the filter frame, are properly and permanently connected to

the equipotential bonding.

-In the case of a manually operated shut-off damper, care

must be taken to operate the cable slowly.

-The ignition protection type of the filter box is guaranteed by

its safe design.

-The SCHAKO production facilities are certified according to

the QM procedure EN ISO 9001.

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 6

Construction subject to change. No return possible!

06.12.2021Version:

Models and dimensions

Dimensions

FKF-H-...-M000-D1-...

FKF-H-...-M001-D1-...

Available sizes

Air diffusers for NW 650 consist of a 650x650 mm faceplate having a drill pattern of size 600.

For seal leakage monitoring system/differential pressure device/aerosol monitoring device, see page 8

Detail X, see page 10.

Detail Z, see page 11.

Detail W, earthing, see page 11.

NW Filter dimen-

sions

AøDEE1 R FDQJ-Z / FDQJ-A

(Supply air / return air)

FPIL-A / FDAV-A

(return air)

FPIL-Z / FDAV-Z

(supply air)

JFH HGaHGaHGa

400 357 102 398 148 374 344 10 375 200 75 375 200 75 415 240 115

500 457 102 498 158 474 444 10 385 200 75 385 200 75 425 240 115

600 557 102 598 198 574 544 10 425 200 75 425 200 75 465 240 115

625 575 102 623 198 592 562 12 425 200 75 425 200 75 465 240 115

650 610 102 648 248 627 597 10 475 200 75 475 200 75 515 240 115

800 762 102 798 248 779 749 9 475 200 75 - - - - - -

Mounting bracket with long hole ø 10 x 20

approx.

external

external

external

Connection to earth

approx.

external

Connection to earth

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 7

Construction subject to change. No return possible!

06.12.2021Version:

FKF-V-...-M000-D1-...

FKF-V-...-M001-D1-...

Available sizes

Detail X, see page 10. Detail Z, see page 11.

Detail W, earthing, see page 11.

approx.

external

Connection

to earth

external

approx.

Connection

to earth

NW H1

FDQJ-Z / FDQJ-A

(Supply air / return air)

FPIL-A / FDAV-A

(return air)

FPIL-Z / FDAV-Z

(supply air)

400-650 320 320 360

800 320 - -

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 8

Construction subject to change. No return possible!

06.12.2021Version:

FKF-Q-...-D1-...

Detail Y

Available sizes

Detail Z, see page 11.

Detail W, earthing, see page 11.

approx.

Connection to

earth

Connection flange

suitable for Metu systems

HM 20 and HM 30

NW B H2

FDQJ-Z / FDQJ-A

(Supply air / return

air)

FPIL-A / FDAV-A

(return air)

FPIL-Z / FDAV-Z

(supply air)

400 200

375 375 415

500 250

600 300

625 300

650 300

800 500 - -

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 9

Construction subject to change. No return possible!

06.12.2021Version:

Differential pressure device / aerosol monitoring

device

applies to models -H and -V

FKF-...-D1 (standard)

With measuring spigot inside the box, for hose connection with

an outer diameter of 10 mm.

FKF-...-D2 (at an extra charge)

With measuring spigot inside the box, for hose connection with

an outer diameter of 10 mm. Additionally with 2 measuring

spigots on the box outside, for a hose with an inner diameter of

4 mm.

FKF-...-D3 (at an extra charge)

With measuring spigot inside the box, for hose connection with

an outer diameter of 10 mm. Additionally with 2 measuring

spigots on the box outside, for a hose with an inner diameter of

4 mm and aerosol feeding device in the spigot of the box inside.

1.) Earthing (Detail W, see page 11).

FKF-...-D4 (at an extra charge)

With measuring spigot inside the box, for hose connection with

an outer diameter of 10 mm. Additionally with aerosol feeding

device in the spigot of the box inside.

FKF-...-D5 (at an extra charge)

With measuring spigot inside the box, for hose connection with

an outer diameter of 10 mm. Additionally with aerosol feeding

device in the spigot on the outside.

Available sizes

1.)

1.)

1.)

NW a

FDQJ-Z / FDQJ-A

(Supply air / re-

turn air)

FPIL-A / FDAV-A

(return air)

FPIL-Z / FDAV-Z

(supply air)

400-650 75 75 115

800 75 - -

NW b c d e f

400 75 90 35 150 80

500

125 140 85 200

130

600 180

625 189

650 206

800 129 144 89 204 282

1.)

1.)

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 10

Construction subject to change. No return possible!

06.12.2021Version:

Differential pressure device / aerosol monitoring

device

applies to model -Q

FKF-...-D1 (standard)

With measuring spigot inside the box, for hose connection with

an outer diameter of 10 mm.

FKF-...-D2 (at an extra charge)

With measuring spigot inside the box, for hose connection with

an outer diameter of 10 mm. Additionally with 2 measuring

spigots on the box outside, for a hose with an inner diameter of

4 mm.

FKF-...-D3 (at an extra charge)

With measuring spigot inside the box, for hose connection with

an outer diameter of 10 mm. Additionally with 2 measuring

spigots on the box outside, for a hose with an inner diameter of

4 mm and aerosol feeding device in the spigot of the box inside.

1.) Earthing (Detail W, see page 11).

FKF-...-D4 (at an extra charge)

With measuring spigot inside the box, for hose connection with

an outer diameter of 10 mm. Additionally with aerosol feeding

device in the spigot of the box inside.

FKF-...-D5 (at an extra charge)

With measuring spigot inside the box, for hose connection with

an outer diameter of 10 mm. Additionally with aerosol feeding

device in the spigot on the outside.

Available sizes

1.)

1.)

1.)

NW a

FDQJ-Z / FDQJ-A

(Supply air / re-

turn air)

FPIL-A / FDAV-A

(return air)

FPIL-Z / FDAV-Z

(supply air)

400-650 75 75 115

800 75 - -

NW b c d e f

400 32 90

40

150 80

500 52

140 200

130

600 72 180

625 71 189

650 69 206

800 55 144 204 282

1.)

1.)

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 11

Construction subject to change. No return possible!

06.12.2021Version:

Accessories - dimensions

(at an extra charge)

Rubber lip seal (-GD1)

Detail X

Not for model FKF-Q-...!

Installation and maintenance

Attention:

Please note that the O-rings (seals) of the bulkhead stuffing box

may dry out over the months. Once the O-rings have dried out,

the hoses can only be inserted, applying higher force. A com-

mon method of reoiling these bulkhead stuffing boxes is to im-

pregnate a cloth with a universal oil, for example from Ballistol,

and wipe it across the hose, before inserting it. This small

amount is sufficient to make the bulkhead stuffing boxes run-

ning smoothly again.

Installation situation

Attention:

In case of installation above the ceiling, you have to specify

the thickness of the ceiling "s".

Attention! Before the particle filter unit can be inserted, the

shipping brace clamped by means of the filter clamps must be

removed!

below ceiling

(standard)

above ceiling

Shipping brace Mounting lever

For filter replacement.

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 12

Construction subject to change. No return possible!

06.12.2021Version:

Installation (filter installation Instructions)

Diffusers with magnetic fastening (-MB)

NW 400-650 (NW 800 not available)

Diffusers with pole brace fastening (-VM)

NW 400-800

With built-in spacers for fixing the filter clamps.

Fastening of grounding connection

Detail W

The grounding connection is fastened on the clean air side of the

filter box. 2 M4 riveting nuts are used for fastening.

(Fastening screw on site)

Installation description

Loosen filter clamp (pos. 4) and re-

move it along with shipping brace.

Press the particle filter unit (pos. 6)

with the fluid seal (see detail Z) point-

ing upwards into the filter housing

(pos. 7). Take care that the filter ma-

terial is not irreparably damaged.

The filter unit can be easily locked us-

ing two diagonal filter clamps (pos. 1

and 3). Next, the VM pole brace (pos.

5) is inserted and fastened using the other two filter clamps

(pos. 2 and 4) Care must be taken that the filter clamps are at

first tightened only slightly cross-wise (e.g. in the sequence fil-

ter clamps 1, 3, 2, 4). After tightening the filter clamps slightly,

they can be tightened properly, again cross-wise and evenly un-

til the filter unit has a tight fit. Care must be taken that the filter

clamps are tightened to 2 Nm maximum. A buffer prevents the

immersing sword from severing the fluid.

Dismounting

In case of concealed mounting (-VM), unscrew the air diffuser

(in case of magnetic fastening (-MB), insert your hands into the

air diffusor slots and remove the unit). Loosen the filter clamps

and take off the VM pole brace. The particle filter cell can easily

be taken off downwards with an assembly lever. The assembly

lever is led sideways from the filter upwards and then hooked on

the filter top edge. Gently pulling on the assembly lever removes

the filter from the box.

Attention!

The particle filter cell may fall out of the filter housing when the

filter clamps are removed!

Maintenance

In addition to keeping machines and equipment clean, the main-

tenance of the filters is especially important. A constant control

of the filters is as essential as changing them when the maxi-

mum allowed particle absorption has been reached. The inspec-

tion must take place at short enough intervals to allow faults that

have occurred or become apparent to be eliminated in time. The

necessary intervals are set depending on the local conditions.

The measured variable for the particle intake of the filter is the

pressure difference. Because of this a differential pressure

measure device is attached at every filter step to monitor the op-

erating condition.

The filter is changed upon reaching the final resistance, which is

set in advance when designing the ventilator capacity of the ven-

tilation system. The final resistance is normally twice the start-

ing resistance.

Fluid

(in filter housing)

Detail Z

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 13

Construction subject to change. No return possible!

06.12.2021Version:

Information regarding assembly and commission-

ing

Prior to being installed in the ventilation system, the particle fil-

ter box must be checked for damage. Damaged fire dampers

must not be installed.

The device may only be used in accordance with its designated

use in air ventilation systems for supply air and return air.

Use only approved fastening material for mounting.

No additional parts must be fastened to the particle filter box.

The particle filter box must be connected to the ventilation duct

network in electrically conducting manner.

In order to avoid the risk of static charges, the particle filter box

must be connected to the on-site equipotential bonding on the

grounding connection provided for this purpose.

Make sure that the ventilation systems are not subjected to any

anomalous operating conditions, such as vibrations, pressure

surges or high proportions of solids in the medium.

If required, the electrical connection diagrams can be found in

the respective Schako additional information.

Electrical wiring and commissioning work must be performed

by skilled personnel only.

Information regarding maintenance and inspection

Proper maintenance increases operational safety and the serv-

ice life of the device. This is why the devices should be subjected

to regular inspection.

If inspection dates are prescribed by law, they must be complied

with.

The operating personnel must be informed, prior to starting

maintenance and inspection work.

The personal safety measures must be looked up in the safety

data sheet. Hazard caused by contact or inhaling hazardous sub-

stances must be excluded by taking appropriate safety meas-

ures.

Prior to maintenance or inspection, all system components up-

and downstream of the device must be switched off and secured

against being switched on again.

The following inspection criteria must be observed:

- Visual inspection of the device

- Check the fastening of the device

- Check the grounding connection for tight fit and good contact

- Functional check

- For additional inspections, please refer to the technical docu-

mentation or additional maintenance instructions

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 14

Construction subject to change. No return possible!

06.12.2021Version:

Type plate

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 15

Construction subject to change. No return possible!

06.12.2021Version:

Certificate of conformity

Additional operating instructions according to ATEX 2014/34/EU for FKF particle filter box

07/06 - 16

Construction subject to change. No return possible!

06.12.2021Version:

Table of contents

Other Schako Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Samlex Europe

Samlex Europe BSWM 160 DUAL owner's manual

stefani

stefani UC2 manual

Acuva

Acuva Wanderer 2.0 user manual

Quincy Compressor

Quincy Compressor EWS 20 Instructions for installation and operation

Schenker

Schenker SMART 80 Installation, use and maintenance manual

Living Water

Living Water ESSENTIAL C7 owner's manual