7

BS EN 15287-1

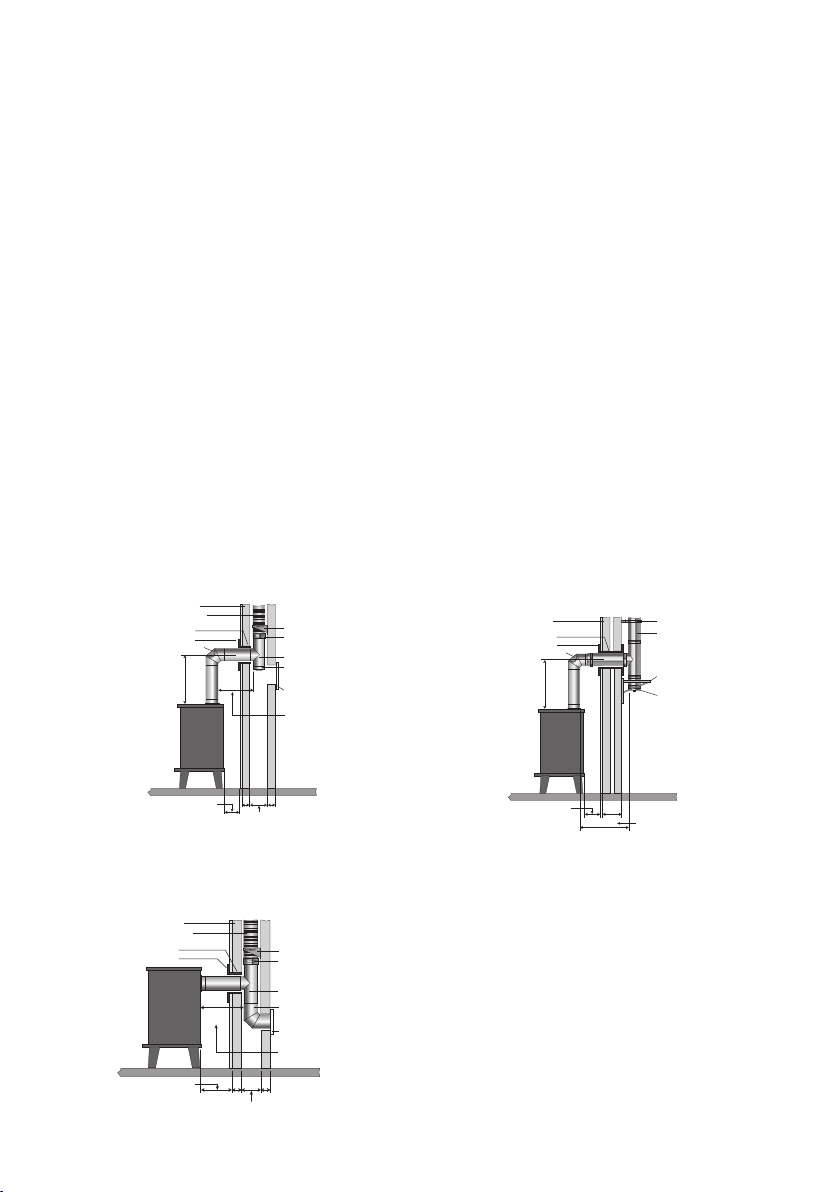

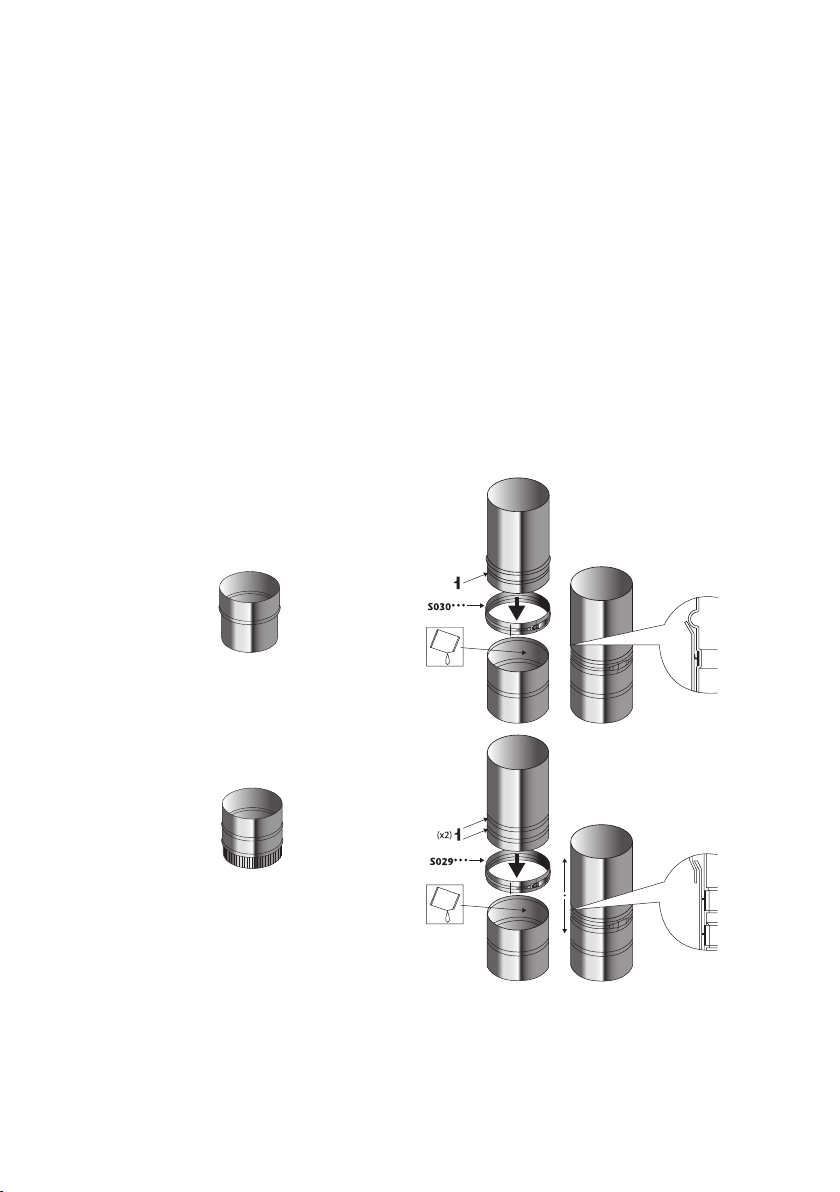

Acceptable alternative Methods of connection

Top Outlet Single Wall Connecting Flue Pipe

into Re-lined Masonry Chimney

Rear Outlet Single Wall Connecting Flue

Pipe into Re-lined Masonry Chimney

Top Outlet Single Wall Connecting Flue Pipe

through Solid Wall into Twin Wall System

Chimney

NB Where the connecting flue pipe from the appliance passes

through any wall other than the existing chimney wall, the

connecting flue pipe must be a System Chimney of twin wall

insulated design.

TOP OUTLET SINGLE WALL CONNECTING FLUE PIPE

INTO RE-LINED MASONRY CHIMNEY

No further bends

allowed on this

configeration

Flexible Twin Wall

Chimney Liner

Inspection/

Cleanout Door

Inspection Bend

Wall Sleeve

Trim Collar

Chimney Wall

Tee Piece

Tee Cap for

Debris Collection/Cleaning Access

100 100

225 square

(9” x 9”)

For minimum distance for

this configuration check

manufacturers distance

to combustibles

600 min

Support Bracket

Single Wall to

Flex Connector

450mm

MAX

Measured from back

of connecting flue pipe

to flue liner

TOP OUTLET SINGLE WALL CONNECTING FLUE PIPE

THROUGH SOLID WALL INTO TWIN WALL SYSTEM CHIMNEY

NB Where the connecting flue pipe from the appliance passes

through any wall other than the existing chimney wall, the connecting

flue pipe must be a System Chimney of twin wall insulated design.

Wall Support

Measured from back

of connecting flue pipe

to outside surface

of chimney

Tee Cap for

Debris Collection/Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

600 min

225

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further bends

allowed on this

configeration

Wall Band

450mm MAX

REAR OUTLET SINGLE WALL CONNECTING FLUE PIPE

INTO RE-LINED MASONRY CHIMNEY

Wall Sleeve

Trim Collar

100100

225 square

(9” x 9”)

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Flexible Twin Wall

Chimney Liner

Chimney Wall

Support Bracket

Swept Elbow

Sweep access

Tee Piece

Single Wall to

Flex Connector

450mm

MAX

Measured from back

of appliance to flue liner

TOP OUTLET SINGLE WALL CONNECTING FLUE PIPE

INTO RE-LINED MASONRY CHIMNEY

No further bends

allowed on this

configeration

Flexible Twin Wall

Chimney Liner

Inspection/

Cleanout Door

Inspection Bend

Wall Sleeve

Trim Collar

Chimney Wall

Tee Piece

Tee Cap for

Debris Collection/Cleaning Access

100 100

225 square

(9” x 9”)

For minimum distance for

this configuration check

manufacturers distance

to combustibles

600 min

Support Bracket

Single Wall to

Flex Connector

450mm

MAX

Measured from back

of connecting flue pipe

to flue liner

TOP OUTLET SINGLE WALL CONNECTING FLUE PIPE

THROUGH SOLID WALL INTO TWIN WALL SYSTEM CHIMNEY

NB Where the connecting flue pipe from the appliance passes

through any wall other than the existing chimney wall, the connecting

flue pipe must be a System Chimney of twin wall insulated design.

Wall Support

Measured from back

of connecting flue pipe

to outside surface

of chimney

Tee Cap for

Debris Collection/Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

600 min

225

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further bends

allowed on this

configeration

Wall Band

450mm MAX

REAR OUTLET SINGLE WALL CONNECTING FLUE PIPE

INTO RE-LINED MASONRY CHIMNEY

Wall Sleeve

Trim Collar

100100

225 square

(9” x 9”)

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Flexible Twin Wall

Chimney Liner

Chimney Wall

Support Bracket

Swept Elbow

Sweep access

Tee Piece

Single Wall to

Flex Connector

450mm

MAX

Measured from back

of appliance to flue liner

TOP OUTLET SINGLE WALL CONNECTING FLUE PIPE

INTO RE-LINED MASONRY CHIMNEY

No further bends

allowed on this

configeration

Flexible Twin Wall

Chimney Liner

Inspection/

Cleanout Door

Inspection Bend

Wall Sleeve

Trim Collar

Chimney Wall

Tee Piece

Tee Cap for

Debris Collection/Cleaning Access

100 100

225 square

(9” x 9”)

For minimum distance for

this configuration check

manufacturers distance

to combustibles

600 min

Support Bracket

Single Wall to

Flex Connector

450mm

MAX

Measured from back

of connecting flue pipe

to flue liner

TOP OUTLET SINGLE WALL CONNECTING FLUE PIPE

THROUGH SOLID WALL INTO TWIN WALL SYSTEM CHIMNEY

NB Where the connecting flue pipe from the appliance passes

through any wall other than the existing chimney wall, the connecting

flue pipe must be a System Chimney of twin wall insulated design.

Wall Support

Measured from back

of connecting flue pipe

to outside surface

of chimney

Tee Cap for

Debris Collection/Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

600 min

225

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further bends

allowed on this

configeration

Wall Band

450mm MAX

REAR OUTLET SINGLE WALL CONNECTING FLUE PIPE

INTO RE-LINED MASONRY CHIMNEY

Wall Sleeve

Trim Collar

100100

225 square

(9” x 9”)

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Flexible Twin Wall

Chimney Liner

Chimney Wall

Support Bracket

Swept Elbow

Sweep access

Tee Piece

Single Wall to

Flex Connector

450mm

MAX

Measured from back

of appliance to flue liner

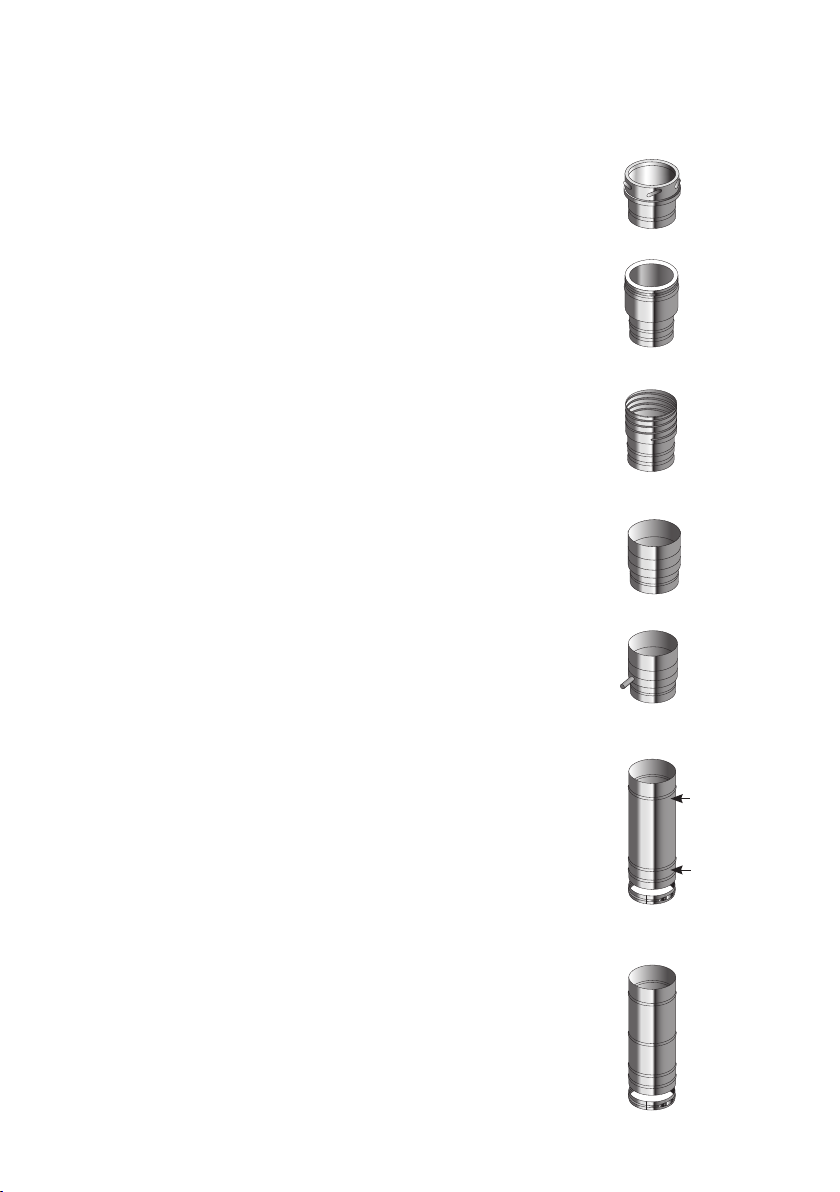

Where a horizontal connecting ue of more than 150mm is required to connect a solid fuel

red appliance to a chimney, an installation method as per the examples below may be used

provided the following criteria is met:-

a. The maximum length of horizontal connecting flue pipe does not exceed 450mm;

b. A Defra exempt appliance or an appliance, which is limited to burning authorised smokeless

fuel only, is installed;

c. A calculation according to BS EN13384-1 has indicated safe operation of the proposed

configuration, and the results of the calculation are left with the householder along with the

appliance installation instructions;

d. The appliance manufacturer agrees in writing to the proposed configuration;

e. The chimney manufacturer agrees in writing to the proposed configuration;

f. The total length of single wall connecting flue pipe is not more than 1.5m;

g. The appropriate distances to combustible materials from both the appliance and the

connecting flue pipe are maintained.