List of contents

Subject Page no.

Introduction 1-1

1. General information..................................................................................1-1

1.1. Guide to symbols.............................................................................................1-1

1.2. Trade marks.....................................................................................................1-1

1.3. Declaration of conformity and EC directives...................................................1-1

2. Safety instructions....................................................................................2-1

2.1. Intended use....................................................................................................2-1

2.2. General information.........................................................................................2-1

2.3. Qualification of personnel ...............................................................................2-2

3. Introduction...............................................................................................3-1

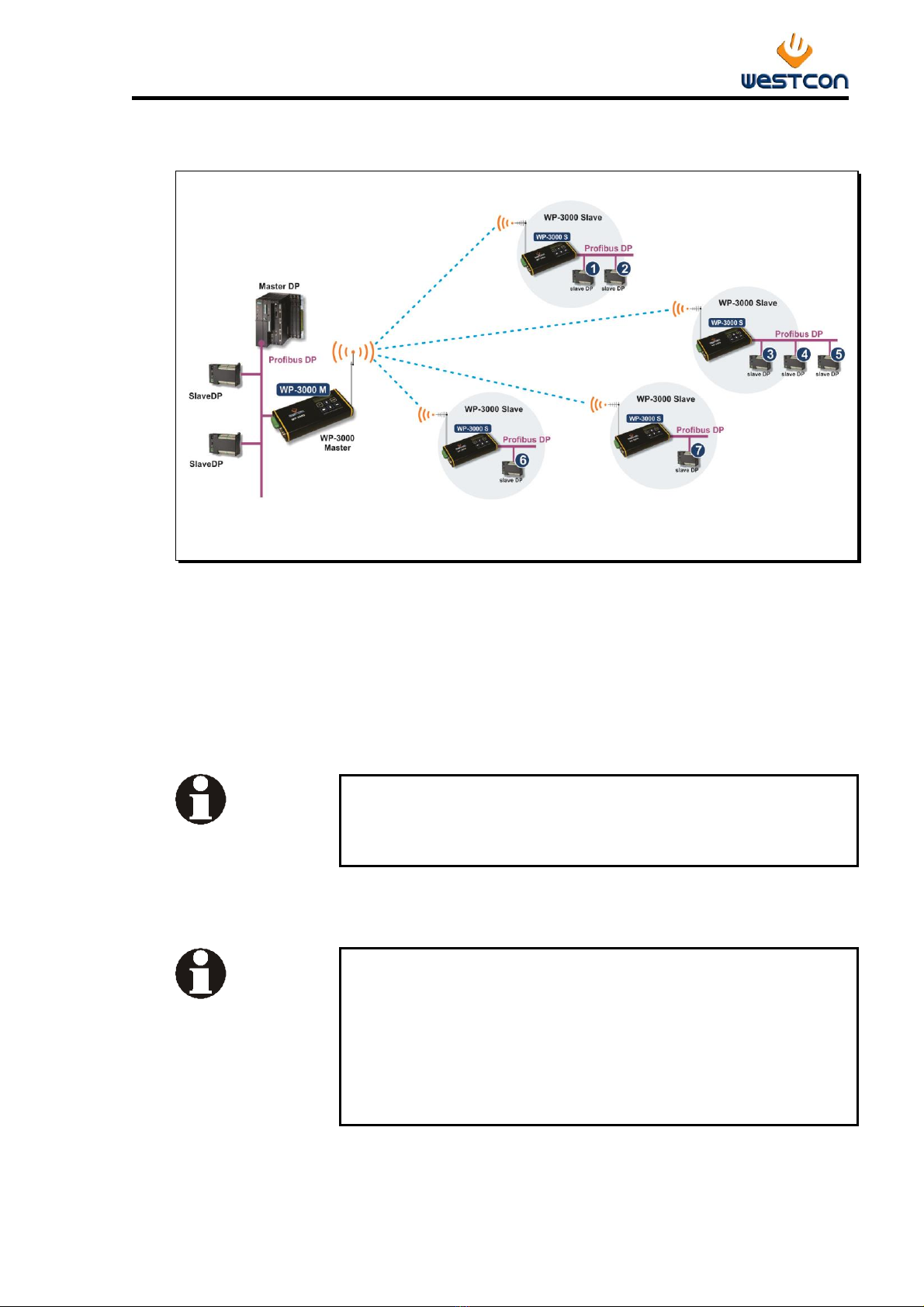

3.1. General information.........................................................................................3-1

3.2. Product family..................................................................................................3-3

3.4. ProfiSafe applications .....................................................................................3-5

3.5. Delay by the radio link.....................................................................................3-6

4. Integrated PROFIBUS diagnostic slave...................................................4-7

4.1. Performance limits...........................................................................................4-7

5. Installation.................................................................................................5-1

5.1. Important information ......................................................................................5-1

5.2. Assembly of wireless modem.........................................................................5-2

5.3. Antenna assembly...........................................................................................5-3

5.4. Electrical connection.......................................................................................5-4

6. Settings .....................................................................................................6-1

6.1. General information.........................................................................................6-1

6.2. System stop prevention...................................................................................6-2

6.3. Basic and PROFIBUS settings.......................................................................6-3

6.3.1. Step 1 –Basic settings at modems..................................................6-4

6.3.2. Step 2 –Test wireless modems .......................................................6-8

6.3.3. Step 3 –PROFIBUS settings .........................................................6-12

6.3.4. Step 4 –Optimization & coexistence setting..................................6-18

7. Working with the diagnostic slave...........................................................7-1

7.1. General information.........................................................................................7-1

7.2. Examples of applications................................................................................7-2

7.3. Mode of operation ...........................................................................................7-3

7.4. Integrate the diagnostic slave into a PROFIBUS network.............................7-4

7.4.1. Integrate GSD file in STEP 7............................................................6-4

7.4.2. Data exchange between PLC program and diagnose slave ...........6-8

7.4.3. Data structure..................................................................................6-12