Contents

1 INTRODUCTION...............................................3

2 INSTALLATION AND SECURITY HINTS........4

2.1 SETUP OF THE MACHINE........................................4

2.2 INTERNET CONNECTION..........................................5

2.2.1 Chiptool...................................................6

2.2.2 CompactFlash Card................................7

2.3 PROTECTION SWITCHES AND PERSONAL SAFETY.........7

2.4 REPAIR AND MAINTENANCE.....................................8

3 PRINCIPLES OF OPERATION........................9

3.1 GENERAL............................................................9

3.2 SYSTEM OPERATION..............................................9

3.3 MECHANICAL CONSTRUCTION.................................10

3.3.1 Testing tub.............................................11

3.3.2 Circulation Unit......................................11

3.3.3 Freeze Resistance................................13

3.4 CUBE TEST.......................................................14

3.5 EY SWITCH.....................................................16

3.6 TRANSPORT OF THE CDF MACHINE.......................16

3.7 EMPTY THE COOLANT LIQUID................................16

3.8 COOLING WATER CONNECTION (OPTION).................17

4 HANDLING THE CONTROLLER...................18

4.1 INTRODUCTION....................................................18

4.2 EYBOARD AND DISPLAY......................................18

4.3 HANDLING.........................................................18

4.3.1 tart.......................................................18

4.3.2 tatus....................................................19

4.3.3 Cycle Time............................................21

4.4 SETUP..............................................................21

4.4.1 Target Value..........................................22

4.4.2 Profile Input...........................................22

4.4.3 Display..................................................24

4.4.4 Clock.....................................................25

4.5 SYSTEM MENU...................................................26

4.5.1 Manual..................................................26

4.5.2 DA Calibration.......................................27

4.5.3 Controller...............................................28

4.5.4 Probes...................................................31

4.5.5 RAM Reset............................................32

4.5.6 Misc.......................................................32

5 TECHNICAL DATA .......................................33

6 SERVICE HINTS.............................................34

6.1 MAINTENANCE CONTROLLER..................................34

6.2 VALUES FOR THE SECURITY DEVICES......................34

6.3 HELP YOURSELF................................................35

7 SCHEMATIC DRAWINGS .............................38

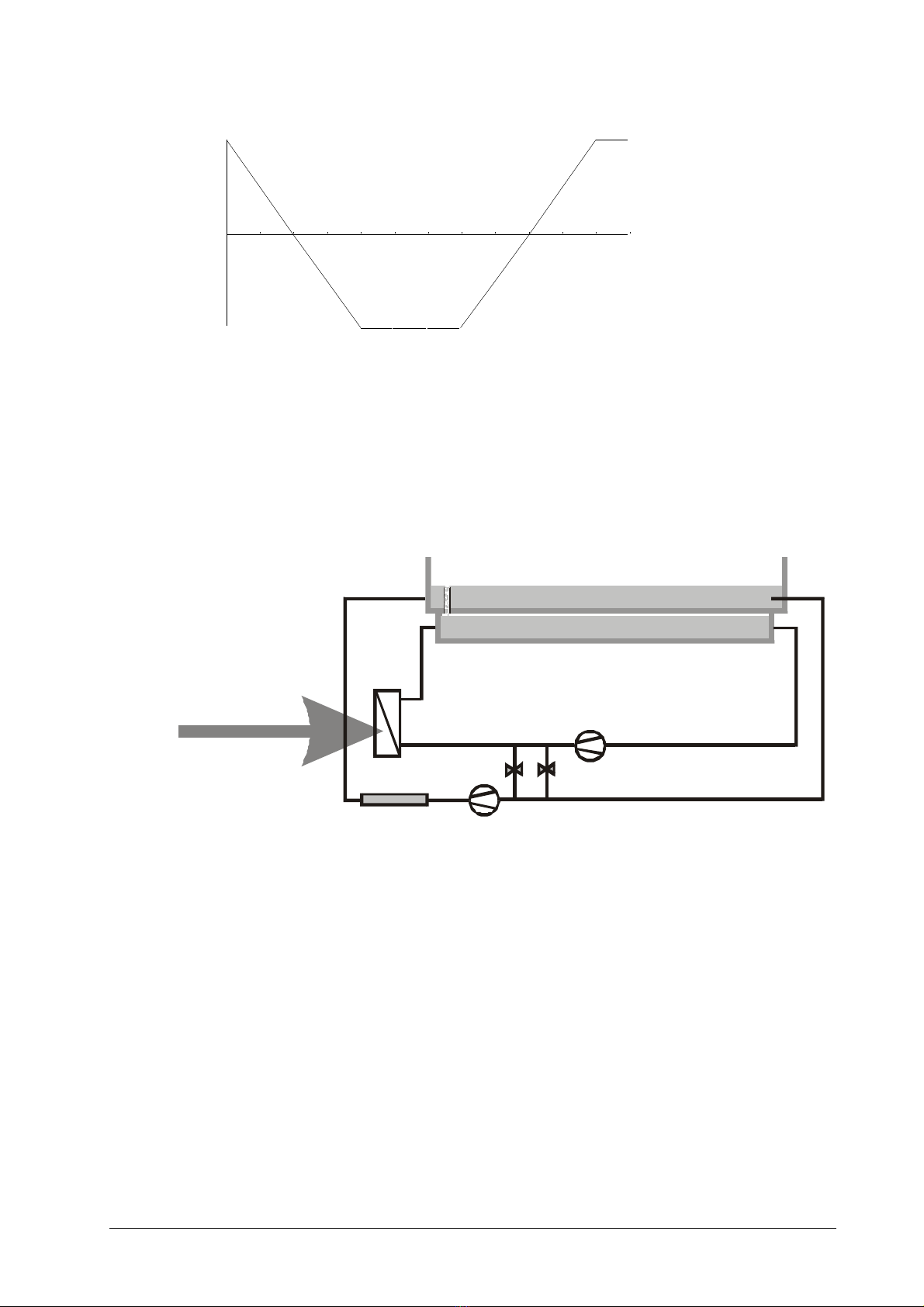

7.1 REFRIGERANT SCHEMATIC.....................................38

7.2 FUSES..............................................................39

8 INDE .............................................................40

CDF-Freeze Thaw- Testing Machine page 2