5

GB

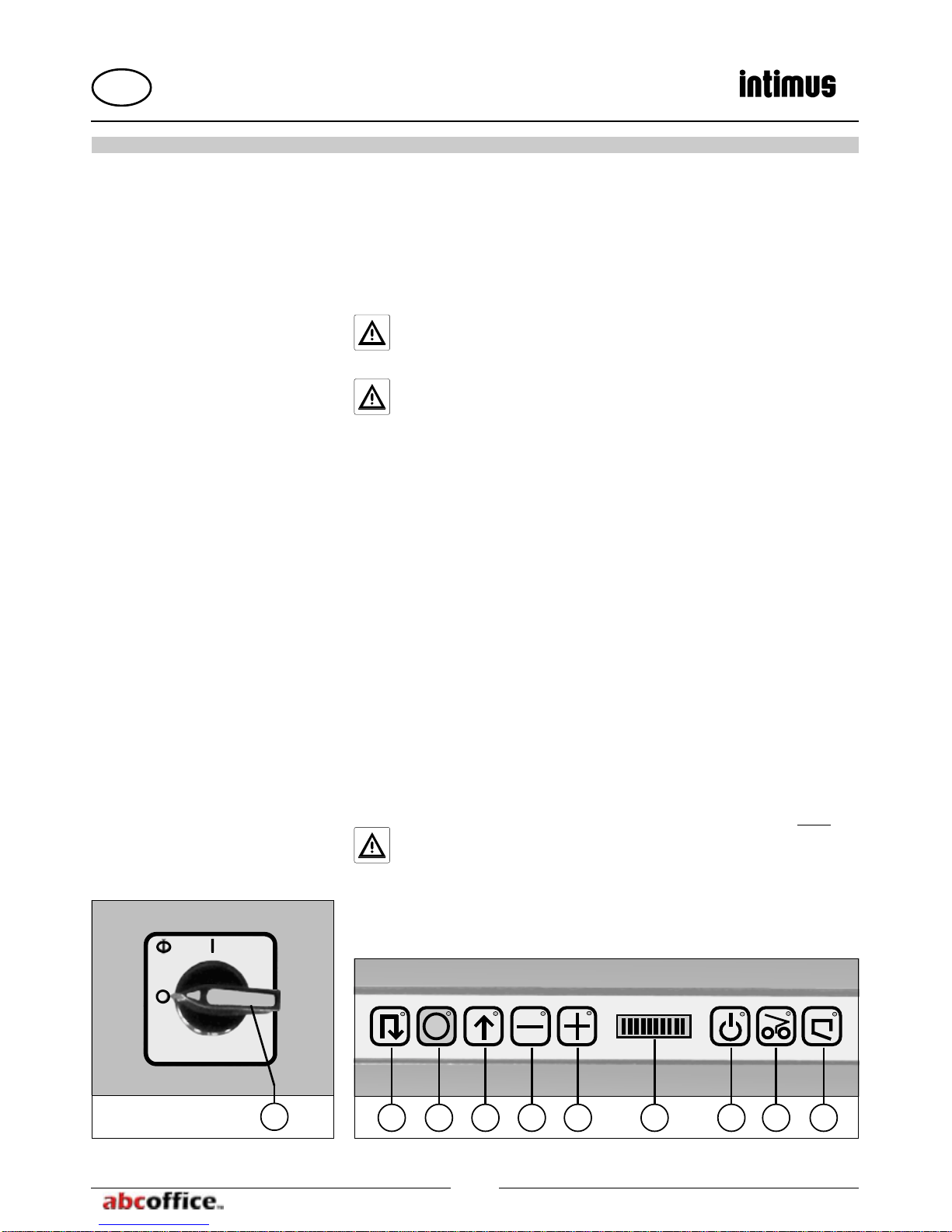

fig. 1

1

MAINS SWITCH

I

S

4 3 2 9 8 10 5 6 7

fig. 2

OPERATING FUNCTIONS (Figs. 1, 2 and 3):

1 = Mains switch (Emergency-stop) (fig. 1)

This switch turns the machine either on

(position „1“) or off (position „0“).

2 = „Cutting system forward“

pushbutton (fig. 2)

Pressingthisbuttonstartsthecuttingsystem.

Material can now be fed to the shredder.

3 = „Cutting system stop“

pushbutton (fig. 2)

Pressing this button switches the shredder

off, thereby halting the cutting system.

4 = „Cutting system reverse“

pushbutton (fig. 2)

Pressingthisbuttonstartsthecuttingsystem

in reverse.

5 = Pilot lamp (fig. 2)

a)„ready“

Continously lights when the mains

switch (1) is operated.

b)„motor protection“

Flashes when the motor is overloaded.

While the motor is cooling down, the

machine cannot be switched on to

„forward“ run.

6 = Pilot lamp „paper jam“ (fig. 2)

Lights when too much paper is fed to the

cutters (see description „AUTOMATIC

RESPONSE IN CASE OF OVER-

LOADING“).

7 = Pilot lamp (fig. 2)

a)„door open“/„hopper open“

Lights when the door is not closed or

when the hopper is open. The machine

then switches off automatically and it

cannot be started as long as the door is

open or the hopper is open.

b)„collecting bag full“ (fig. 2)

Lightsassoonasthecollectingbagis full

and needs to be emptied. At the same

time the machine switches off

automatically.

8 = Vario-Speed Plus Key (fig. 2)

The machine’s cutting speed can be

increased in an infinitely adjustable fashion

by activating the plus key.

9 = Vario-Speed Minus Key (fig. 2)

Themachine’scuttingspeedcanbereduced

inaninfinitelyadjustablefashiontoallowfor

increased cutting capacity by activating the

minus key.

10 = Vario-Speed Display (fig. 2)

Displays the manually selected, current

speed when the cutting system is running.

OPERATION

AUTOMATIC RESPONSE

IN CASE OF „OVERLOADING“:

In case you accidentally overload the shredder, it

willautomaticallyalleviatetheproblemasfollows:

1. Thecuttingsystembecomesjammed.Thepilot

lamp (6) (fig. 2) lights up.

2. The cutting system runs briefly in reverse,

thereby freeing the material to be shredded.

3. Thecuttingsystemautomaticallyswitchesback

to forward mode.

The machine repeats this process until all the

material has been shredded satisfactorily.

AUTOMATIC VARIO-SPEED FUNCTION:

TheVario-Speedoptimizesthemachinepowerin

the different working conditions:

- Theoperating speed isautomatically increased

by up to 50% for small quantities of only a few

sheets.

- Morepower is required atthe cutting systemfor

largerquantitiesofpaper,andthevariablespeed

systemreducestheworkingspeedautomatically

in favour of increased power.

MANUAL VARIO-SPEED FUNCTION:

Inadditiontotheautomaticvariablespeedfunction,

theoperatorcanalsomanuallyselectanydesired,

infinitely adjustable working speed:

- Press the vario-speed plus key (8) (fig. 2), in

order to increase working speed.

- Press the vario-speed minus key (9) (fig. 2), in

order to decrease working speed, and to allow

for increased cutting capacity.

Current cutting speed is indicated at the vario-

speed display (10) (fig. 2).

EMPTYING THE COLLECTING BAG:

When the collecting bag is full, the machine turns

off automatically. The pilot lamp (7) (fig. 2) lights

up. Empty the collecting bag as follows:

- Open the door and take out the sliding frame

with the collecting bag.

- Remove the rubber band, take out the full bag

and dispose of contents.

- Put the empty bag from below through the

sliding frame and put the edges of the bag

approx. 10 cm over the frame outwardly.

- Fixthecollectingbagwiththerubberbandatthe

sliding frame.

- Move back the sliding frame with the collecting

bag and close door.

Note:Themachinewillonlyrunwithcloseddoor!

11 = Light barrier (forward operation) (fig. 3)

The shredding operation is started as soon

asa sheetofpaperpassesthroughthefeed

slot.

OPERATING THE MACHINE:

To start, switch on the unit by operating the main

switch (1) (fig. 1).

Thepilotlampmarked„readyforoperation“(5),as

well as the red stop-button „S“ (3) (fig. 2) will light

toindicatethatthemachineisreadyforoperation.

The paper tray may not be used as a

step ladder or as a seat. Danger of

tipping over!

FEEDING CRUMPLED PAPER:

In order to avoid a reduction of user

safety by increasing the height of the

hopper side panels, and in order to

allow for filling the hopper while

standing on the floor, the height of the

hoppersidepanelsisnotincompliance

with EN 294:1992.

The deviation from EN 294:1992 is

identified with a yellow-black mark.

1. Fill the hopper with crumpled paper.

Note: The crumpled paper can be dropped

directly from the wastepaper basket into the

hopperofthemachine.Theapportioningwings

precedingthe cutting mechanism ensure more

or less uniform distribution of the paper.

Attention:Thewastepaperbasketisnorefuse

tinand should not be emptiedinto the machine

thoughtlessly - in no way can the machine

destroy bottles, pens, pencil sharpeners etc.

2. Press the pushbutton switch „forward“ (2) (fig.

2).Thecuttingsystemrunsandbeginstoshred

the paper.

Note: Do not feed any smooth paper until the

crumpled paper is completely shredded.

3. To switch the machine off press the red stop-

button (3) (fig. 2).

FEEDING SMOOTH PAPER:

- Feed smooth paper through the opening at the

lower part of the hopper to the cutting system.

- Machine switches automatically to forward and

draws paper in.

- The machine switches off automatically after

shredding.

Neverfeedtheshredderwithaquantity

of paper exceeding the maximum

indicated in the technical details.

Should the machine be overfed, follow

the instructions under „AUTOMATIC

RESPONSE IN CASE OF

OVERLOADING“.

Schleicher International

852VS

1-800-658-8788 - www.abcoffice.com