CONTENTS

1Safety instructions............................................................................................. 1-4

Important symbols....................................................................................................................... 1-4

General safety information.......................................................................................................... 1-4

Intended use................................................................................................................................ 1-5

2Start-up................................................................................................................ 2-6

Installation and operation............................................................................................................ 2-6

Electrical connection ................................................................................................................... 2-7

Pneumatic connection................................................................................................................. 2-7

Setting the blow-off volume flow ................................................................................................. 2-8

3Description.......................................................................................................... 3-8

Version overview......................................................................................................................... 3-8

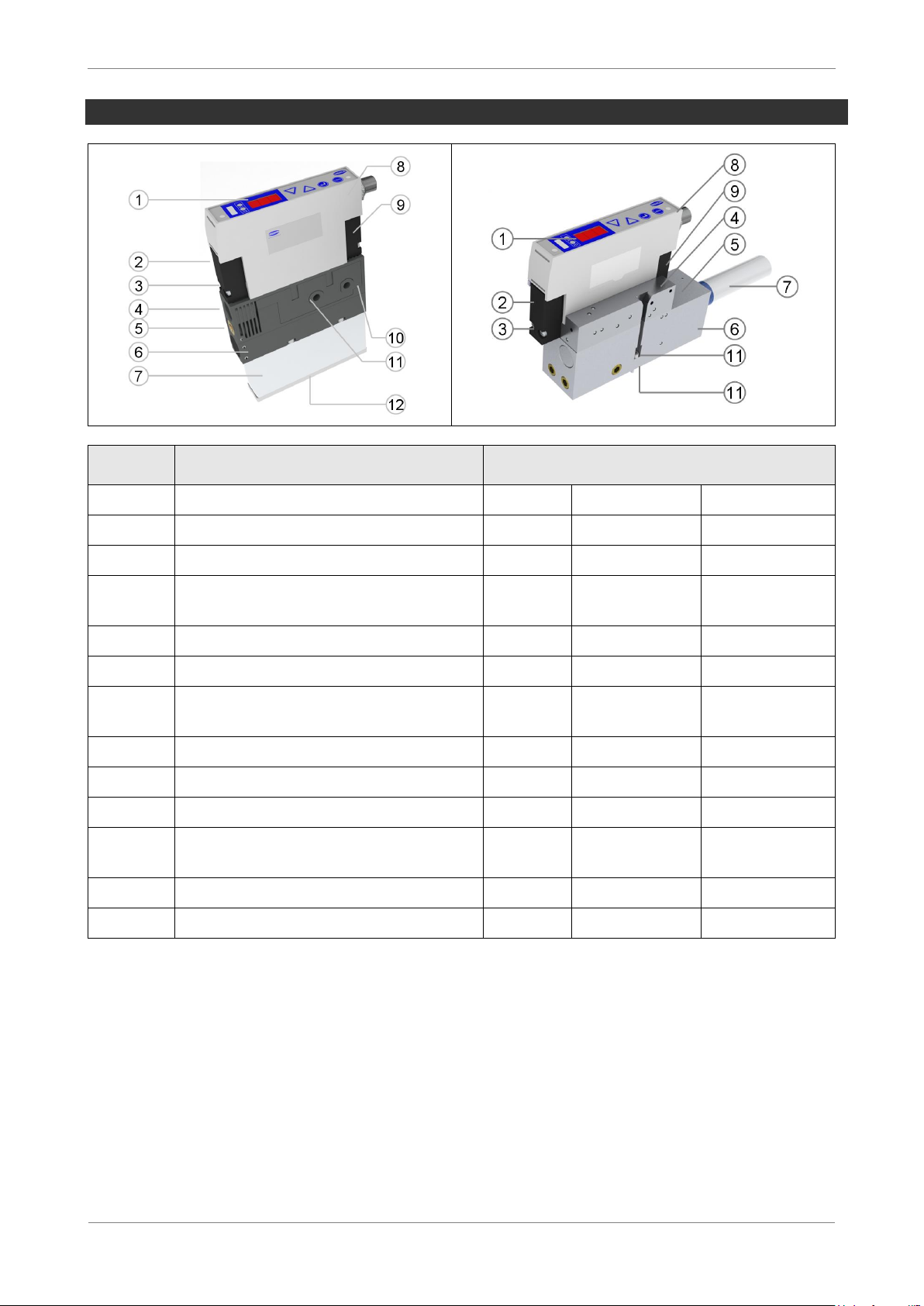

Ejector design.............................................................................................................................. 3-9

Operating and display elements.................................................................................................. 3-10

General function description........................................................................................................ 3-11

Operating modes......................................................................................................................... 3-13

Control concept for IMP ejectors................................................................................................. 3-14

Status display for system vacuum............................................................................................... 3-15

Valve LEDs.................................................................................................................................. 3-17

Monitoring of the valve switching frequency (valve protection function)..................................... 3-17

“Diagnostics” signal output (OUT 1) ............................................................................................ 3-17

4Operating and menu concepts.......................................................................... 4-18

Menu authorisation...................................................................................................................... 4-18

Manual mode............................................................................................................................... 4-19

Basic menu .................................................................................................................................... 4-20

Setting of switching points for the air-saving function with [H-1] and [h-1] ................................ 4-22

Setting of switching points for the signal output with [H-2] and [h-2].......................................... 4-23

Zero-point adjustment (calibration) [CAL] ................................................................................... 4-24

Counters, software versions and serial numbers...................................................................... 4-25

Cycle counters [ct1] and [ct2]...................................................................................................... 4-26

Displaying the cycle counters...................................................................................................... 4-26

Software version [SoC]................................................................................................................ 4-27

Serial number [Snr] ..................................................................................................................... 4-27

Configuration menu ...................................................................................................................... 4-28

Configuration of the vacuum unit [uni]......................................................................................... 4-30

Configuration of the signal output [out] ....................................................................................... 4-30

Configuration of the air-saving function [ctr]................................................................................ 4-31

Configuration of the blow-off function [bLo]................................................................................. 4-31

Rotating the display screen [dPy]................................................................................................ 4-32

Locking the menus using a PIN code [Pin] ................................................................................. 4-33

Resetting to the factory settings (Clear All) [rES]........................................................................ 4-34

5Maintenance........................................................................................................ 5-35

Spare and wearing parts ............................................................................................................. 5-36