Contents

EN-US · 30.30.01.02533 · 00 · 11/20 3 / 42

Contents

1 Important Information ...................................................................................................................................5

1.1 Note on Using this Document ............................................................................................................ 5

1.2 The technical documentation is part of the product ........................................................................ 5

1.3 Type Plate ............................................................................................................................................ 5

1.4 Warnings in This Document................................................................................................................ 5

1.5 Symbol.................................................................................................................................................. 6

2 Fundamental Safety Instructions...................................................................................................................7

2.1 Intended use ........................................................................................................................................ 7

2.2 Non-Intended Use ............................................................................................................................... 7

2.3 Safety Instructions ............................................................................................................................... 7

2.4 Personnel Qualification....................................................................................................................... 7

2.5 Modifications to the Product.............................................................................................................. 7

3 Product Description ........................................................................................................................................8

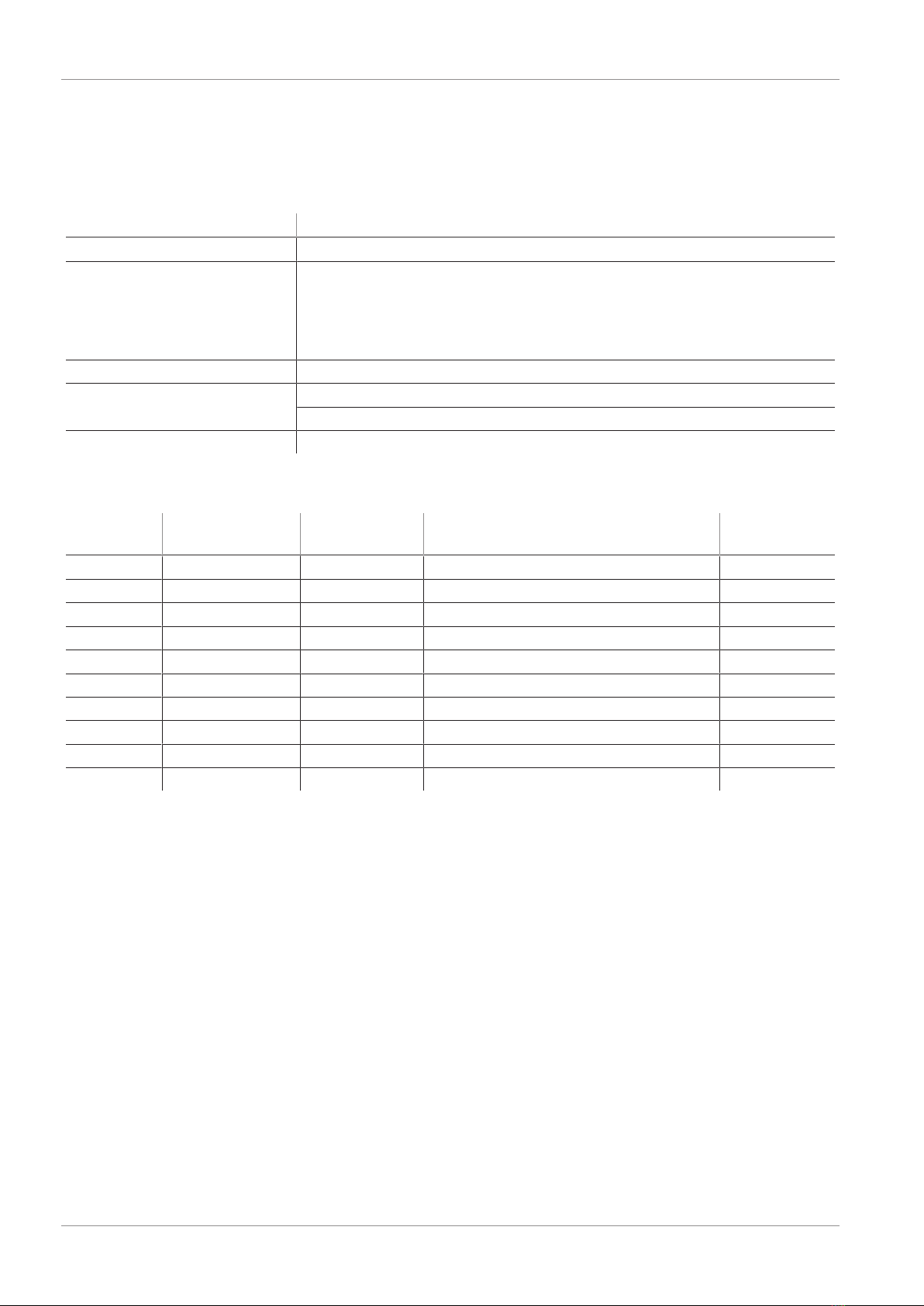

3.1 Designation code................................................................................................................................. 8

3.2 Variants and Type Key ........................................................................................................................ 8

3.3 Design of the flow sensor ................................................................................................................... 9

3.4 Display and Operating Element in Detail .......................................................................................... 9

3.5 Function Instuction............................................................................................................................ 11

3.5.1 Function Setting Mode..............................................................................................................11

3.5.2 Measurement............................................................................................................................. 13

4 Technical Data ...............................................................................................................................................14

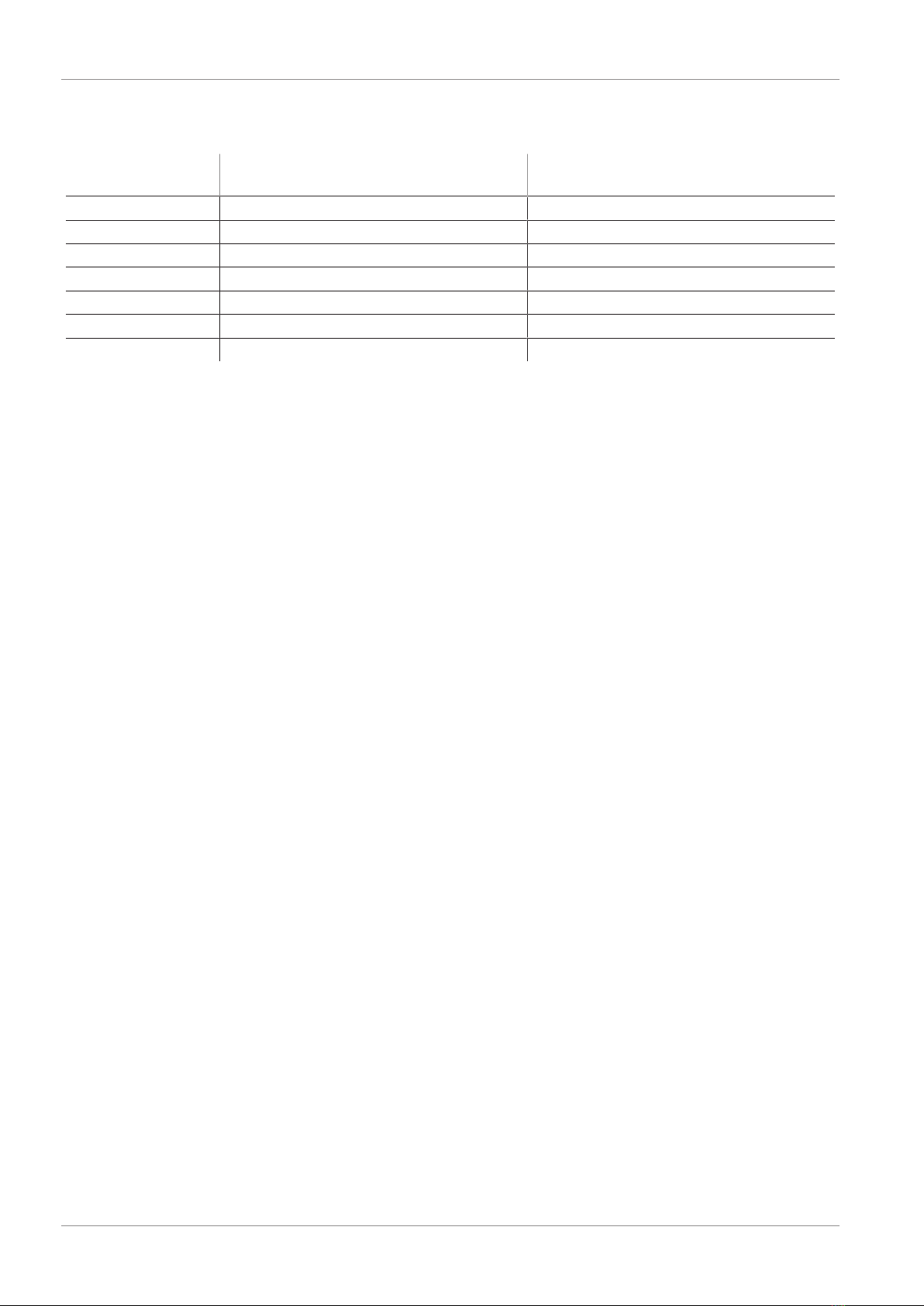

4.1 General Parameters........................................................................................................................... 14

4.2 Dimensions......................................................................................................................................... 16

5 Installation.....................................................................................................................................................17

5.1 Installation Instructions..................................................................................................................... 17

5.2 Mounting Bracket / Optional Parts .................................................................................................. 18

5.3 Piping ................................................................................................................................................. 19

5.4 Electrical Connection......................................................................................................................... 20

6 Operation Instructions..................................................................................................................................22

6.1 Function Selection Mode .................................................................................................................. 22

6.2 OUT1 Setting Selection ..................................................................................................................... 22

6.3 OUT2 Setting Selection ..................................................................................................................... 26

6.4 LCD Display Color Selection .............................................................................................................. 26

6.5 Response Time Selection................................................................................................................... 27

6.6 Display Refresh Time Selection......................................................................................................... 28

6.7 Unit Selection .................................................................................................................................... 29

6.8 Flow Reference Standard Selection.................................................................................................. 29

6.9 Analog Output Selection .................................................................................................................. 30

6.10 Accumulated Value Hold Selection .................................................................................................. 30

6.11 Flow Sensor Display Mode Selection................................................................................................ 31

6.12 Power-Save Mode Selection ............................................................................................................. 31

6.13 External Input Selection.................................................................................................................... 31

6.14 Fine Adjustment Setting ................................................................................................................... 32