4Operating Instructions- The bp408 Safety Circuit - Contents

Contents

Contents..................................................................................................................................4

1General Information....................................................................................................5

1.1 Thank you....................................................................................................................5

1.2 Intended Use ...............................................................................................................6

1.3 Documetation References .........................................................................................6

2Product Certificates....................................................................................................7

2.1 Declaration of Conformity..........................................................................................7

2.2 EU Type Examination .................................................................................................7

2.3 EU Type-Examination Certificate SPL-01 with SMZ ................................................8

3UCM requirements......................................................................................................9

3.1 Requirements regarding certified safety devices....................................................9

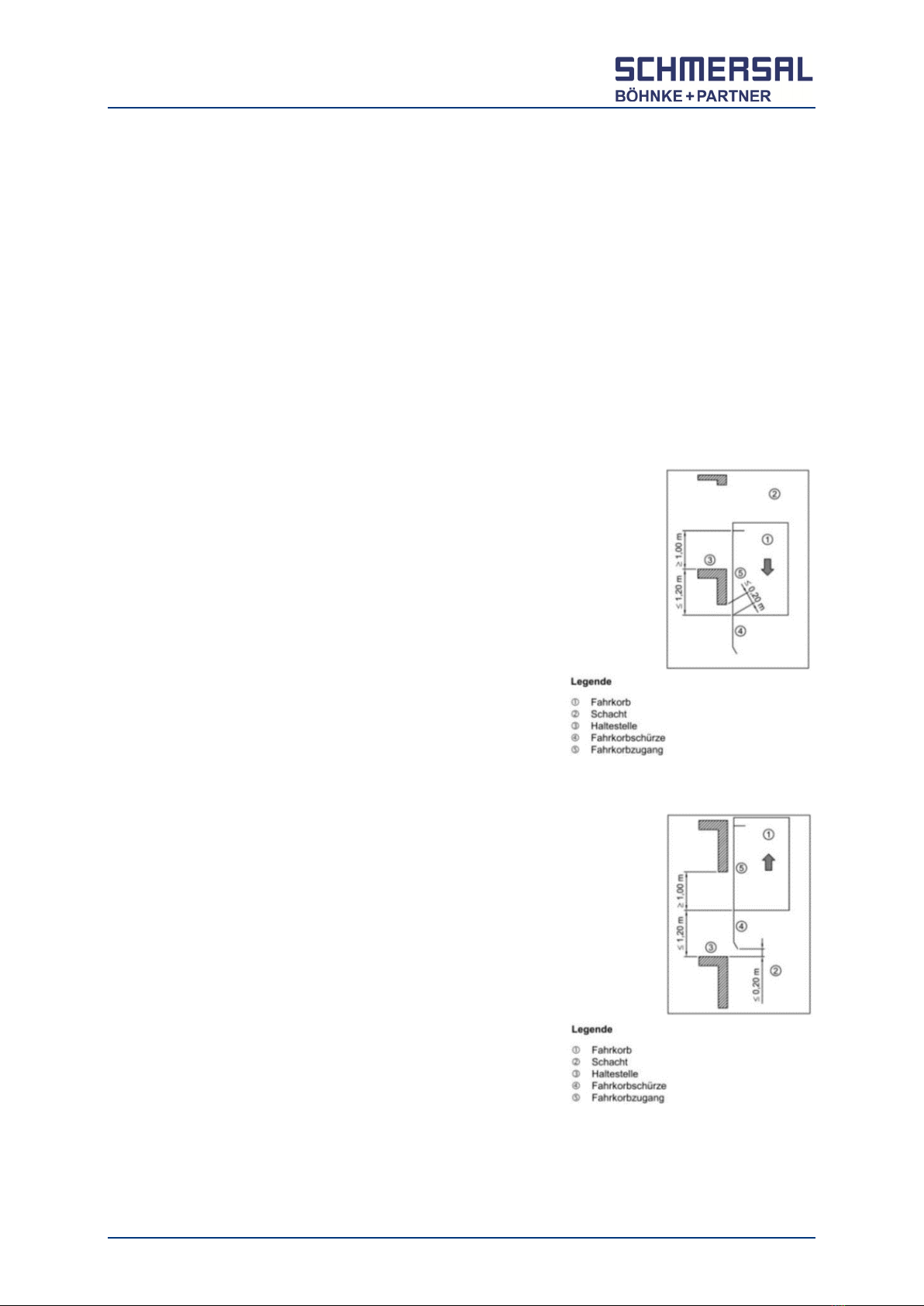

3.1.1 Fig. 1: Cabin moving downward.................................................................................. 9

3.1.2 Fig. 2: Cabin moving upward ...................................................................................... 9

3.1.3 Observation of the situation ...................................................................................... 10

3.2 General Information on UCM Function...................................................................11

3.2.1 Storage, Transport and Operating Conditions .......................................................... 11

3.2.2 Notes on Installation.................................................................................................. 12

3.2.3 Notes on function ...................................................................................................... 12

3.2.4 Notes on test ............................................................................................................. 13

3.3 Bp408 Testing Program ...........................................................................................14

3.3.1 General Testing Sequence ....................................................................................... 14

3.3.1.1 Step 1 ........................................................................................................................ 14

3.3.1.2 Step 2 ........................................................................................................................ 16

3.3.1.3 Step 3 ........................................................................................................................ 17

3.3.2 Extra requirements for UCM testing of traction elevators with gears........................ 18

3.3.3 Extra requirements for UCM testing of hydraulic elevators....................................... 19

3.3.4 Entries in stack memory............................................................................................ 19

4Circuit Board SPL-01................................................................................................20

4.1 Layout ........................................................................................................................20

4.2 Installation Requirements........................................................................................20

4.3 Query Circuit on SPL-01 .........................................................................................-20

4.3.1 Area of Application .................................................................................................... 20

4.3.2 Testing of wiring for query circuit .............................................................................. 21

4.4 Safety Circuit on SPL-01 ..........................................................................................22

4.4.1 Functional description of safety circuit ...................................................................... 22

4.4.2 Error analysis of safety circuit ................................................................................... 22

4.4.3 Testing....................................................................................................................... 23

4.5 Connection of SPL-01 ..............................................................................................24

4.6 Safety circuit status bar on display ........................................................................24

5Tecnical Data.............................................................................................................25