2

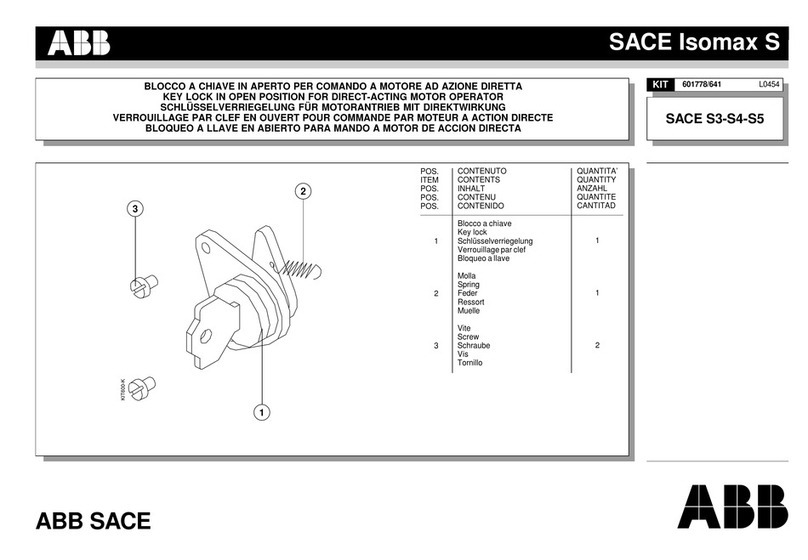

Fig. 1

Caption

A Circuit-breaker rating plate.

B Operating mechanism rating plate.

1 Type of apparatus.

2 Symbols of compliance with Standards.

3 Serial number.

4 Circuit-breaker characteristics.

5 Characteristics of the operating mechanism auxiliaries.

I. Introduction

This publication contains the information needed to install and put the

following medium voltage circuit-breakers into service:

VD4/R - VD4/L - VD4/UniAir - VD4/UniMix, and VD4/S, hereinafter called

VD4.

For correct use of the product, please read it carefully.

Like all the apparatus we manufacture, the VD4 circuit-breakers are

also designed for different installation configurations.

However, this apparatus allows further technical-construction modifica-

tions (at the customer’s request) to adapt to special installation require-

ments. Consequently, the information given below may sometimes not

contain instructions concerning special configurations.

Apart from this manual, it is therefore always necessary to consult the

latest technical documentation (electric circuit and wiring diagrams, as-

sembly and installation drawings, any protection coordination studies,

etc.), especially regarding any variants requested in relation to the

standardised configurations.

Only use original spare parts for maintenance operations.

For further information, please also see the technical catalogue of the

circuit-breaker and the spare parts catalogue.

All the installation, putting into service, running and main-

tenance operations must be carried out by suitably quali-

fied personnel

with in-depth knowledge of the apparatus.

II. Environmental protection programme

The VD4 circuit-breakers are manufactured in accordance with the ISO

14000 Standards (Guidelines for environmental management).

The production processes are carried out in compliance with the Stan-

dards for environmental protection in terms of reduction in energy con-

sumption as well as in raw materials and production of waste materials.

All this is thanks to the medium voltage apparatus manufacturing facility

environmental management system.

A

B

3

4

2

CIRCUIT-BREAKER IEC 62271-100

VD4 ... ... ... CEI 17-1

CLASSIFICATION ... ... ...

SN ... ... ... PR. YEAR ......

M MASS ... kV

Ur

ELECTRIC DIAGRAM ... ... ... ...

FIG. ... ...

.. ... ... ... OPERATING MECHANISM

-MO1 ... ... ... V

Made by ABB

1

5

1. Packing and transport

The circuit-breaker is shipped in special packing, in the open position

and with the springs discharged.

Each piece of apparatus is protected by a plastic cover to prevent any

infiltration of water during the loading and unloading stages and to keep

the dust off during storage.

2. Checking on receipt

Before carrying out any operation, always make sure that

the operating mechanism springs are discharged and that

the apparatus is in the open position.

On receipt, check the state of the apparatus, integrity of the packing and

correspondence with the nameplate data (see fig. 1) with what is speci-

fied in the order confirmation and in the accompanying shipping note.

Also make sure that all the materials described in the shipping note are

included in the supply.

Should any damage or irregularity be noted in the supply on unpacking,

notify ABB (directly or through the agent or supplier) as soon as pos-

sible and in any case within five days of receipt.

The apparatus is only supplied with the accessories specified at the

time of ordering and validated in the order confirmation sent by ABB.

The accompanying documents inserted in the shipping packing are:

– instruction manual (this document)

– test certification

– identification label

– copy of the shipping documents

– electric wiring diagram.

Other documents which are sent prior to shipment of the apparatus are:

– order confirmation

– original shipping advice note

– any drawings or documents referring to special configurations/condi-

tions.