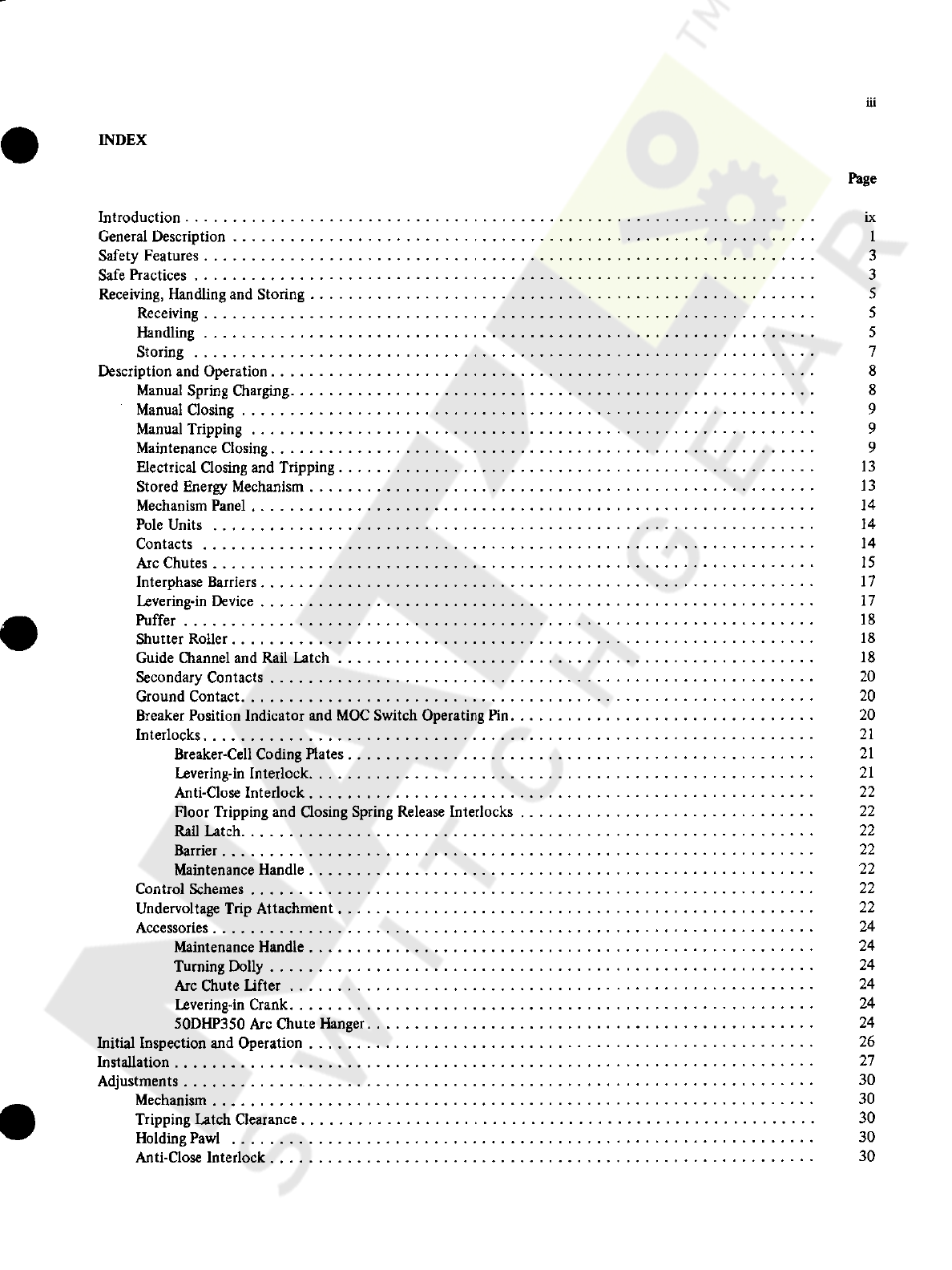

Westinghouse Porcel-line DHP Series User manual

Other Westinghouse Circuit Breaker manuals

Westinghouse

Westinghouse DB-50 User manual

Westinghouse

Westinghouse De-ion DM2R User manual

Westinghouse

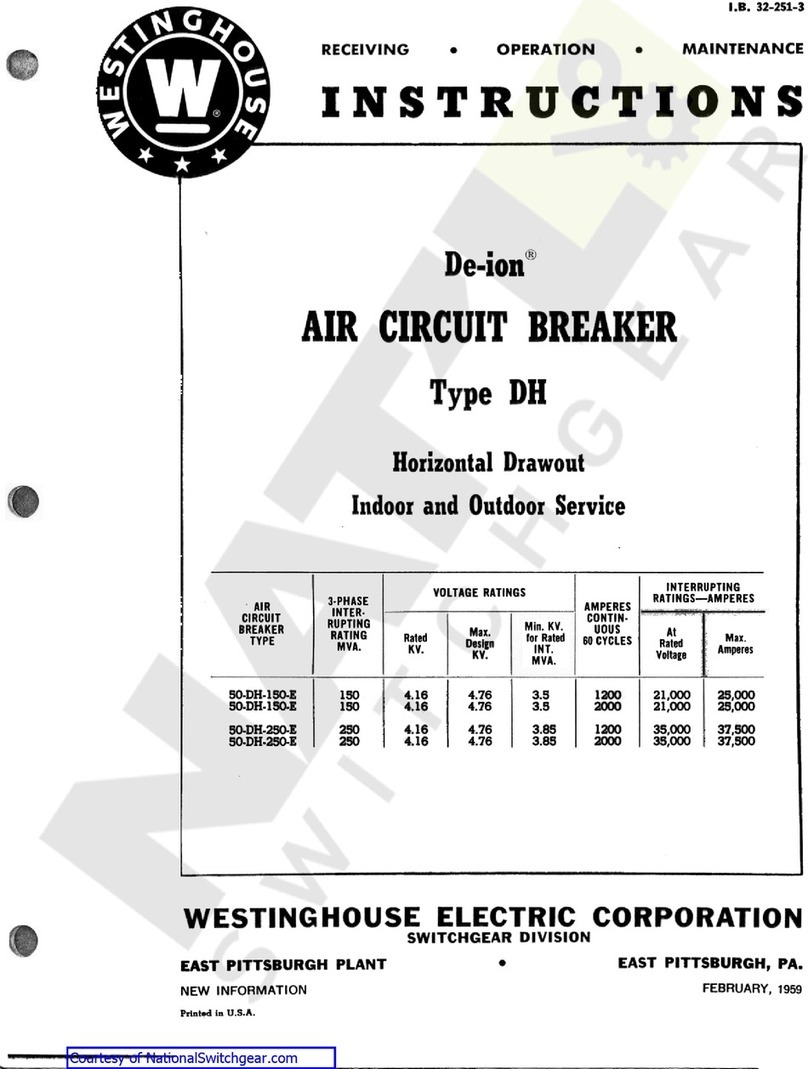

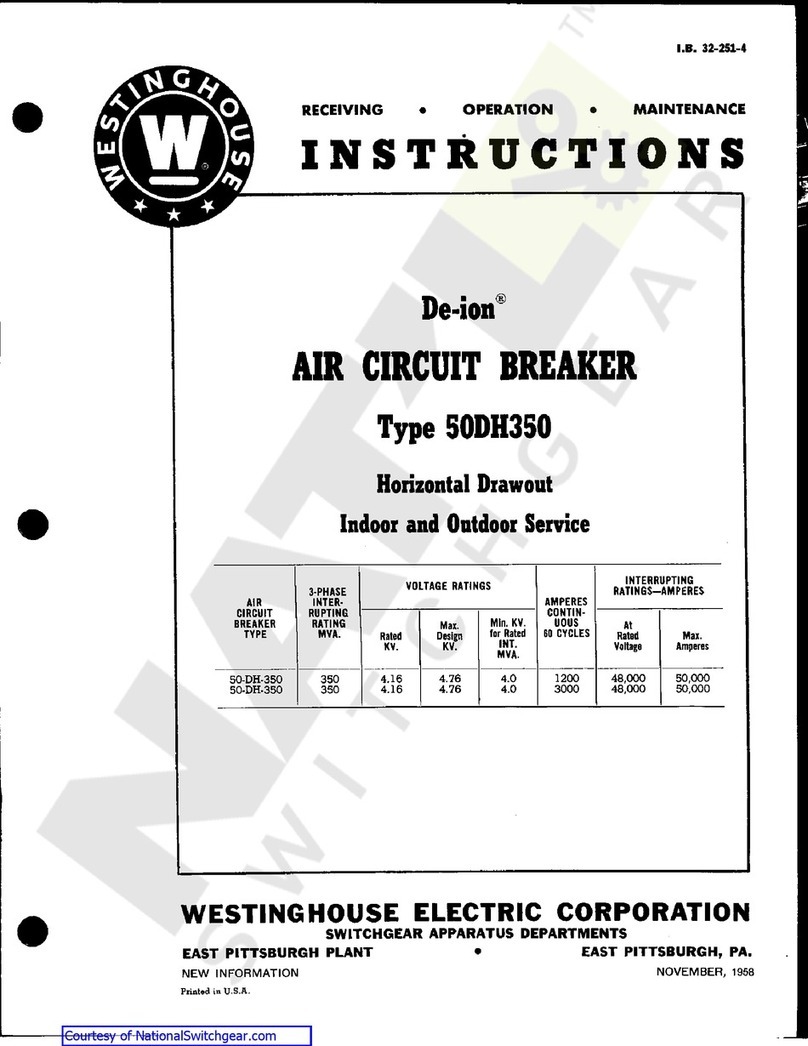

Westinghouse De-ion 50-DH-350 User manual

Westinghouse

Westinghouse F-11 User manual

Westinghouse

Westinghouse De-opn User manual

Westinghouse

Westinghouse De-ion DB-15 User manual

Westinghouse

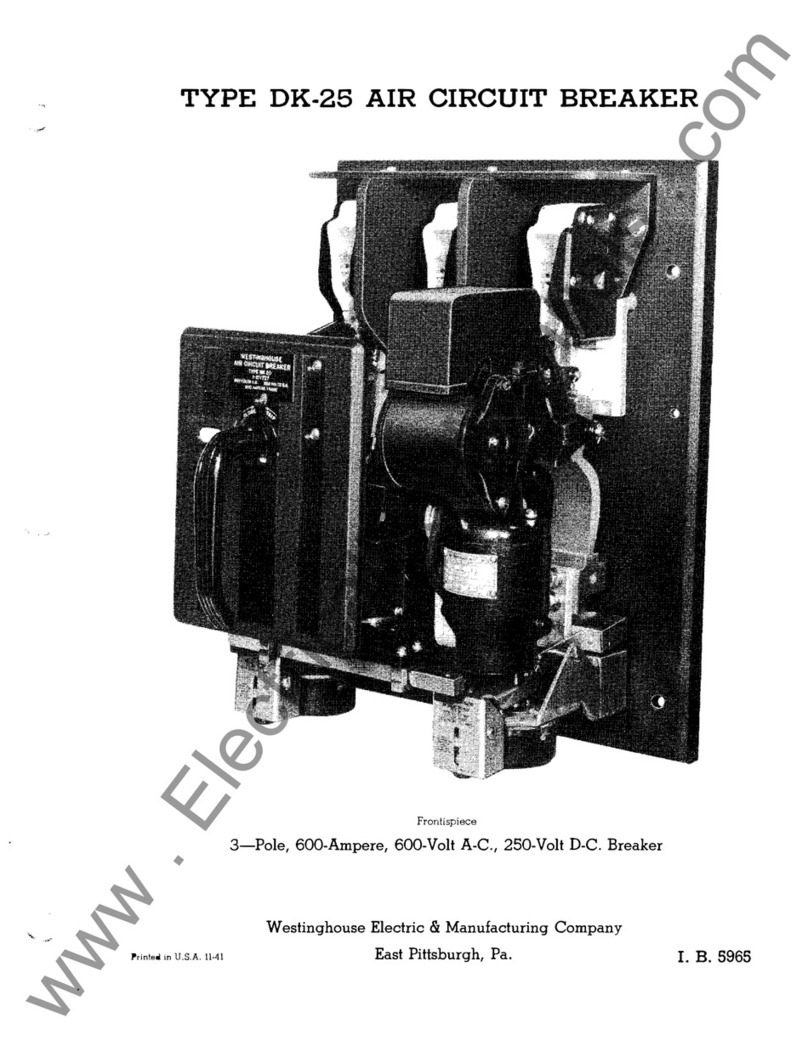

Westinghouse DK-25 User manual

Westinghouse

Westinghouse DBN-1016 User manual

Westinghouse

Westinghouse AB DE-ION Series User manual

Westinghouse

Westinghouse DB-50 User manual

Westinghouse

Westinghouse DB-50 User manual

Westinghouse

Westinghouse F-122 User manual

Westinghouse

Westinghouse DS-206 User manual

Westinghouse

Westinghouse De-ion DB-15 User manual

Westinghouse

Westinghouse DB-75 User manual

Westinghouse

Westinghouse DB-50 User manual

Westinghouse

Westinghouse DK-15 User manual

Westinghouse

Westinghouse DB-75 User manual

Westinghouse

Westinghouse CAS-8 User manual

Westinghouse

Westinghouse De-ion DB-15 User manual

Popular Circuit Breaker manuals by other brands

Siemens

Siemens Sentron 3VA9157-0PK1 Series operating instructions

hager

hager TS 303 User instruction

ETI

ETI EFI-4B Instructions for mounting

nader

nader NDM3EU-225 operating instructions

TERASAKI

TERASAKI NHP TemBreak PRO P160 Series installation instructions

Gladiator

Gladiator GCB150 Installation instruction