3

SRB-E-402FWS-TS

Operating instructions

Fail-safe delay timer / Standstill monitor

EN

To determine the Performance Level (PL) to EN ISO 13849-1 of the

entire safety function (e.g. sensor, logic, actuator), an assessment of all

relevant components is required.

The entire concept of the control system, in which the safety

component is integrated, must be validated to the relevant

standards.

2.4 Technical data

General data

Standards: EN 60204-1, EN 60947-5-1, EN ISO 13849-1,

IEC 61508, EN 62061

EMC rating: to EMC Directive

Air clearances and creepage distances: to EN 60664-1

Mounting: standard rail to EN 60715

Terminal designations: EN 60947-1

Electrical characteristics:

Rated operating voltage Ue: 24 VDC –20%/+20%,

residual ripple max. 10%

Frequency range: −

Mains unit/mains power supply: An ES1 or PELV/SELV mains adapter

must be used as a voltage source or be ensured by means

of additional measures so that the output voltage of the

power adapter in the event of an error does not exceed 60 V.

Mains power supply must harmonise with device safety

(characteristic/melting property) so that triggering is ensured.

Power consumption: 3 W (+ load of the safety outputs)

Fuse rating for the operating voltage: We recommend a circuit

breaker type Z (max. 16 A) or a fine

fuse (max. 15 A, delayed action).

UL Rating of external fuse: max. 16 A, only use fuses in

accordance with UL 248 series

Insulation values to EN 60664-1:

Rated insulation voltage Ui:

- Safety contacts: 250 V

- Safety outputs: 50 V

Rated impulse withstand voltage Uimp:

- Safety contacts 13/14, 23/24: 6 kV

- Safety output Q1/Q2: 0.8 kV

Overvoltage category: III

Degree of pollution: 2

Drop-out delay on "supply failure": < 10 ms

Bridging in case of voltage drops: typ. 5 ms

Readiness after switching on voltage: < 1.5 s

Frequency measurement tolerance: < 2%

Time measurement tolerance: 2% + 30 ms

Control current circuits/inputs:

Inputs S12, S22, S32, S42: 24 VDC / 8 mA

Max. input frequency: 6000 Hz

Inputs X2, X3, X4, X5, X7: 24 VDC / 8 mA

Clock outputs S11, S21, S31, S41: > 20 VDC, 10 mA per output

Cable length: 1500 m with 1.5 mm²

2500 m with 2.5 mm²

Conduction resistance: max. 40 Ω

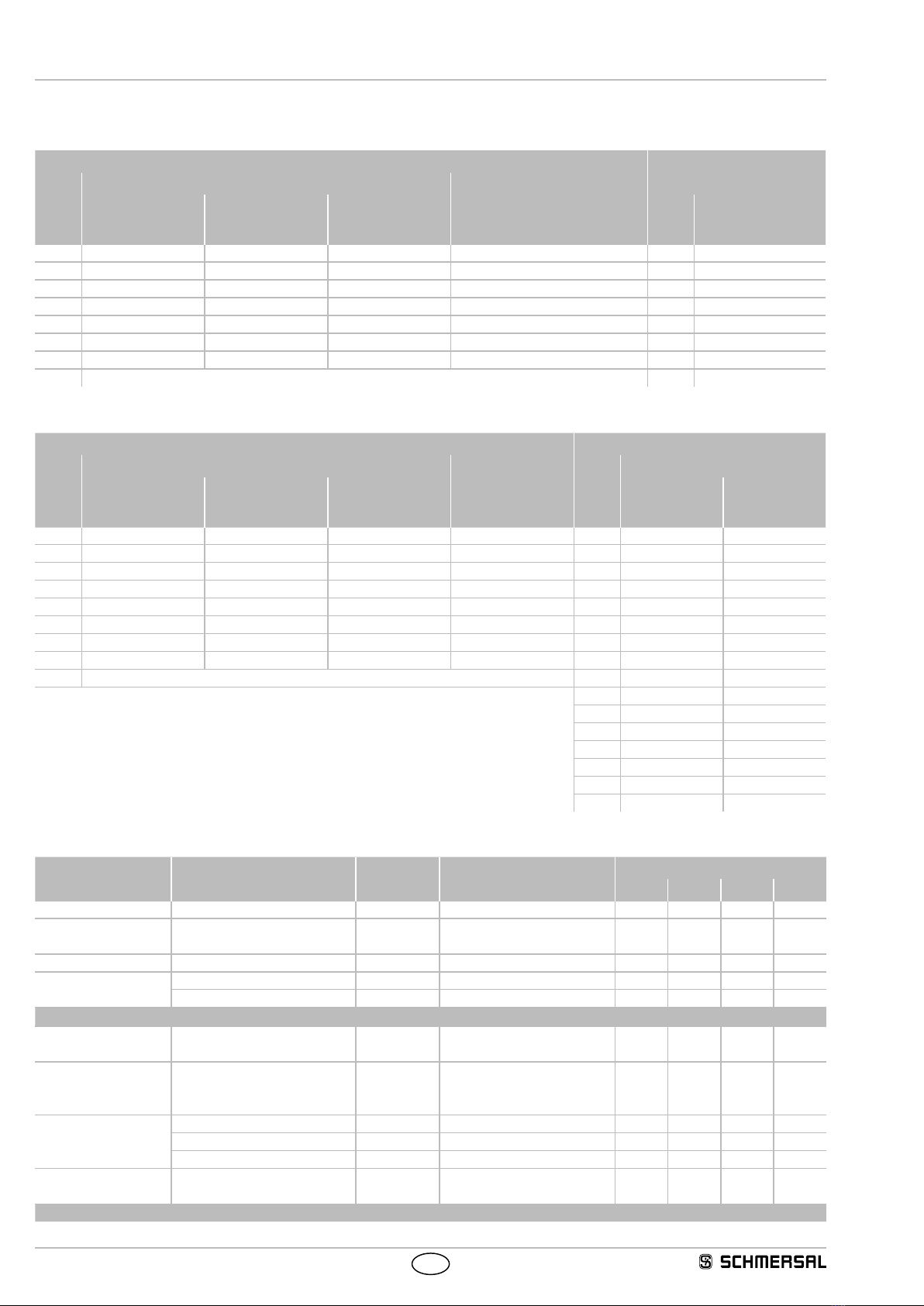

Relay outputs:

Switching capacity of the safety contacts: 13/14, 23/24:

max. 250 V, 6 A ohmic,

min. 10 VDC / 10 mA

(Derating see 2.5)

Fuse rating of the safety contacts: external (Ik= 1000 A)

to EN 60947-5-1

Safety fuse 10 A quick blow, 6 A slow blow

Utilisation category to EN 60947-5-1: AC-15: 230 V / 4 A

DC-13: 24 V / 4 A

Switching capacity of the auxiliary contacts: 41-42: 24 VDC / 1 A

Fuse rating for the auxiliary contact: safety fuse

2.5 A quick blow, 2 A slow blow

Electrical life: refer to 2.5

Mechanical life: 10 million operations

Semi-conductor outputs:

Switching capacity of the safety outputs: Q1/Q2: max. 2 A

Voltage drop: < 0.5 V

Leakage current: < 1 mA

Max. fuse rating of the safety outputs: refer to "Operating voltage"

Test impulse of the safety outputs: < 1 ms (negative),

< 100 µs (positive)

Utilisation category to EN 60947-5-1: DC-13: 24 V / 2A

Switching capacity of signaling outputs: semi-conductor outputs Y1:

24 VDC/100 mA

Fuse rating of the signalling outputs: internal electronic trip,

tripping current > 100 mA

Electrical life: (Derating refer to 2.5)

Max. switching cycles / minute: 20

Inductive consumers: provision is to be made for suitable

protective wiring for suppression.

Mechanical data:

Connection type: refer to 2.1

Cable section: refer to 2.1

Connecting cable: rigid or flexible

Tightening torque for the terminals: 0.5 Nm

Material of enclosure: glass-fibre reinforced

thermoplastic, ventilated

Weight: 180 g

Ambient conditions:

Ambient temperature: –25°C … +60°C

(non condensing)

Storage and transport temperature: –40°C … +85°C

(non condensing)

Degree of protection: Enclosure: IP40

Terminals: IP20

Clearance: IP54

Resistance to shock: 30 g / 11 ms

Resistance to vibrations

to EN 60068-2-6: 10 ... 55 Hz, amplitude 0.35 mm

Altitude: max. 2,000 m

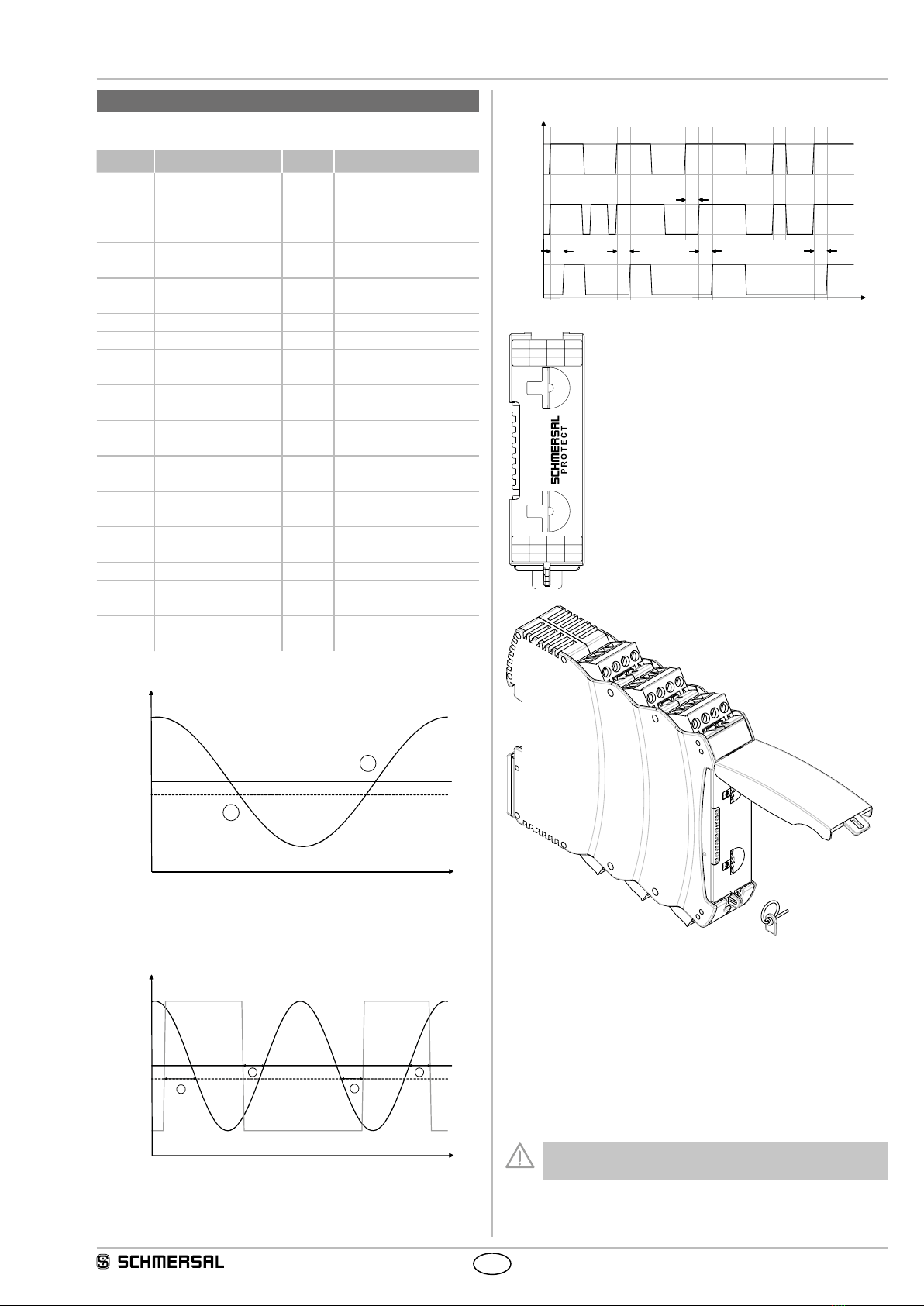

2.5 Derating / electrical lifespan of safety contacts

No derating with individual installation of modules.

Derating on request if several modules are installed one after the

other without spacing and with maximum output load and ambient

temperatures.

Electrical life of the safety contacts

DC13 24V

AC15 230V

AC1 230V

DC1 24V

1.000.000

100.000

10.000

Operations

Contact load in amperes