7

4

4.1. Transport

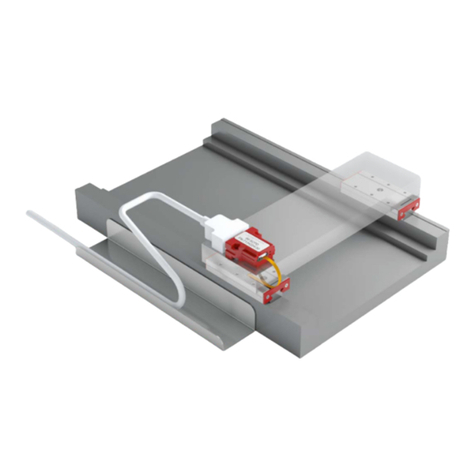

MINISCALE PLUS and MINIRAIL are high-precision components and should be

handled with care. For transportation of these products in-house, the following

points should therefore be noted:

• Transport guideways and accessories in their original packaging

• Protect guideways against impacts

• Always transport MINIRAIL and MINISCALE PLUS carriages on guide rails or on

the protective plastic rail

4.2. Protection

The following instructions should be noted to protect against damage:

• Storage in the original packaging is only possible for a limited period. The

condition of the products should be checked at regular intervals.

• Protect products against moisture/humidity and do not store them out in the

open

(10% - 70%, non-condensing).

• Ensure the correct temperature range:

MINIRAIL -40° C to +80° C.

MINISCALE PLUS -40° C to +80° C.

• Only remove the products from their original packaging at their installation

location and immediately prior to assembly.

• Check the state of lubrication.

• Always store MINIRAIL and MINISCALE PLUS carriages on the guide rail or

protective plastic rail so that the rolling elements are protected.

• MINISCALE PLUS is sensitive to electrostatic discharge! The electronics can be

damaged if precautions are not taken against ESD; ESD regulations should

therefore be observed when handling ESD-vulnerable parts (EN 100015-1).

• The power supply should be switched off prior to connecting or disconnecting

cables, and precautions should be taken to ensure it cannot be switched on

again unintentionally.

Improper handling of the guideways can lead to preliminary damage and thus to

premature failure.

Handling and Storage

3.1 / 3.2 / 3.3 / 3.4 / 4.1 / 4.2 Handling and Storage

Toll Free Phone: 877-378-0240

Toll Free Fax: 877-378-0249

www.servo2go.com

Sold & Serviced By: