CID Bio-Science CI-340 User manual

Table of Contents

Introduction...................................................................................................................................................1

Infrared Gas Analysis (IRGA)................................................................................................................1

Dispersive and Non-Dispersive IRGA....................................................................................................2

Photosynthesis Measurement Using IRGA.............................................................................................2

Technical Information...................................................................................................................................3

Main Components of Gas Exchange Systems ........................................................................................4

Highlights of CI-340...............................................................................................................................4

General Operating Instructions......................................................................................................................7

Using the Keypad....................................................................................................................................7

File Menu................................................................................................................................................8

Installation of the Battery........................................................................................................................9

Interpretation of Parameters..................................................................................................................11

System Setup and Calibration .....................................................................................................................12

Calendar and Time Setup......................................................................................................................13

Leaf/Air Temperature Sensor ...............................................................................................................13

Atmospheric Pressure ...........................................................................................................................13

Flow Rate..............................................................................................................................................14

CO2 and H2O General Overview.........................................................................................................15

CO2 Zero and CO2 Span Procedure.....................................................................................................17

H2O Zero and H2O Span Procedure ....................................................................................................18

Data Transfer...............................................................................................................................................19

Downloading Data................................................................................................................................20

Updating Software................................................................................................................................21

Example of a Data File .........................................................................................................................22

Photosynthesis, Transpiration and Stomatal Conductance..........................................................................23

Taking Measurements...........................................................................................................................23

Closed and Open Systems.....................................................................................................................26

Terminology:...............................................................................................................................................28

Absolute, Differential and Continuous Mode.......................................................................................28

Photosynthesis ......................................................................................................................................28

Photosynthetic Active Radiation (PAR)...............................................................................................29

Transpiration.........................................................................................................................................29

Stomatal Conductance ..........................................................................................................................30

Open and Closed Systems.....................................................................................................................30

Calibrating ............................................................................................................................................34

DATA DISPLAY SCREENS......................................................................................................................36

GRAPH MODE...........................................................................................................................................36

CARE OF THE CI-340...............................................................................................................................37

LEAF CHAMBER CARE AND USE..................................................................................................38

RECHARGING ....................................................................................................................................41

EQUATIONS..............................................................................................................................................44

TROUBLESHOOTING..............................................................................................................................46

SYSTEM SPECIFICATIONS.....................................................................................................................48

CO2 Analyzer:......................................................................................................................................48

H2O Analyzer.......................................................................................................................................48

PAR Sensor...........................................................................................................................................49

Chamber Temperature Measurement....................................................................................................49

Leaf Temperature Measurement...........................................................................................................49

POWER PACK.....................................................................................................................................50

ACCESSORY CONTROL PORT AND CABLE.......................................................................................51

TROUBLESHOOTING..............................................................................................................................52

Technical Support.................................................................................................................................52

Customer Service..................................................................................................................................52

FAQs.....................................................................................................................................................52

APPENDIX A .............................................................................................................................................53

CI-510CS TEMPERATURE CONTROL MODULE ..........................................................................53

APPENDIX B..............................................................................................................................................58

CI-301LA LIGHT ATTACHMENT ....................................................................................................58

APPENDIX C..............................................................................................................................................61

CI-301AD ADJUSTABLE H2O AND CO2 CONTROL MODULE ..................................................61

APPENDIX D .............................................................................................................................................66

CI-301SR SOIL RESPIRATION CHAMBER.....................................................................................66

APPENDIX E..............................................................................................................................................68

CANOPY CHAMBER ASSEMBLY INSTRUCTIONS .....................................................................68

APPENDIX F..............................................................................................................................................73

CI-510CF CHLOROPHYLL FLUORESCENCE MODULE..............................................................73

Warranty Information..................................................................................................................................76

CI-340 Operation Manual rev. 6/7/2017

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

1

Introduction

The CI-340 Hand-held Photosynthesis System is the smallest, fastest and highly accurate infrared gas

analyzer available for both field and laboratory photosynthesis measurements. The CI-340 is

lightweight and utilizes a compact solid-state design concept in which the entire system (display,

keypad, computer, data memory, CO2/H2O gas analyzer, flow control system and battery) is contained

in a single, hand-held durable case. Measurements of photosynthesis, transpiration, stomatal

conductance and internal CO2can be taken with minimal sample degradation because the chamber is

connected directly to the CO2/H2O differential gas analyzer. The short distance between the analyzer

and the leaf chamber decreases the possibility of leaks, water vapor change, or temperature change,

therefore keeping the integrity of the sample high. The unit is designed to perform several

measurements, such as photosynthesis and transpiration rates and stomatal conductance, as well as

measure the absolute and differential CO2concentrations of a leaf or plant. The unit can also be

calibrated easily by the user to ensure quality measurements and data, which can be easily transferred

to a computer using the included USB connector. The functions of the CI-340 are described in further

detail in Table 1 and the following sections.

Table 1: Several different functions of the CI-340 with descriptions of each measurement.

Function

Description

Photosynthesis Rate

Rate at which a known area of leaf assimilates CO2over time

Transpiration Rate

Rate at which water vapor accumulates on a leaf over time

Stomatal Conductance

Overall water loss of the leaf, determined using transpiration

rate and leaf surface temperature

Absolute Mode

Measures CO2 concentration (ppm) from a single source (intake

of the instrument)

Calibration

Allows user to check or adjust unit to known standards,

increasing data quality

Data Transfer

Transfers saved data files from unit to a computer

Infrared Gas Analysis (IRGA)

Infrared gas analysis (IRGA) measures heteroatomic trace gases based on the absorption wavelength of

infrared (IR) light as it passes through an air sample. Heteroatomic gas molecules consist of two or

more different atoms (e.g. CO2, H2O, NH3, CO, NO, N2O). Monatomic gas molecules consist of a single

atom (e.g. O2, N2) and do not absorb IR radiation or interfere with determining the concentration of

heteroatomic gases using infrared light. Carbon dioxide (CO2) strongly absorbs intermediate infrared

wavelengths. Infrared gas analyzers (IRGAs) measure the reduction in the transmission of infrared

wavelengths caused by the presence of a gas between the radiation source and a detector. The

measured reduction in transmission is a function of the concentration of the gas. IRGAs are commonly

used to measure carbon dioxide and water concentrations, as well as photosynthesis. There are two

main types of IRGA, dispersive and non-dispersive, which differ according to the specificity of the gas

type that is being measured.

CI-340 Operation Manual rev. 6/7/2017

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

2

Dispersive and Non-Dispersive IRGA

Infrared gas analyzers can be either dispersive or non-dispersive. Dispersive infrared analyzers

sequentially apply monochromatic radiation, which determines the concentration of various gas

species in a complex mixture of gases. In contrast, non-dispersive analyzers assay the concentration of

a particular species of gas.

Non-dispersive analyzers are commonly used for photosynthesis measurements and function by using

broad-spectrum infrared radiation, made selective for CO2by the use of filters in the optical path.

Typically, detectors designed for CO2exhibit cross-sensitivity to the absorption spectrum of water

vapor. Although filters can minimize this interference, it is necessary to correct the apparent CO2

concentration if there is significant water vapor in the airstream at the intake of the analyzer.

Alternatively, water vapor may be condensed or chemically removed just before the airstream enters

the analyzer.

Photosynthesis Measurement Using IRGA

Photosynthesis is the process by which higher plants transform sunlight into chemical energy. During

this process, plants produce carbohydrates from carbon dioxide and water. This occurs in the presence

of chlorophyll by converting light energy to chemical energy. Measuring photosynthesis is important in

comparing and understanding productivity and biomass accumulation at the leaf, plant and community

(canopy) level as well as in quantifying plant response to environmental stresses and variables, such as

light and temperature.

Most photosynthesis meters are based on the concept of gas exchange on the leaf and typically measure

carbon dioxide and water vapor concentrations. The uptake of CO2 and the release of H2O both use the

stomata as their pathway; therefore most photosynthesis measurements include an estimation of

photosynthetic rate (CO2uptake) and transpiration rate, as well as stomatal conductance.

Carbon dioxide uptake is measured using an IRGA by comparing the CO2concentration of gas passing

into a chamber surrounding a leaf/plant and the CO2leaving the chamber. The CO2concentration of the

gas initially passing into the chamber is measured, and then the gas is pumped through the chamber at

a known flow rate. The concentration in the effluent gas from the chamber is measured using the IRGA

and the difference between this and the input gas is used to measure photosynthetic rate (or

respiration rate if a greater CO2concentration is measured in the effluent gas stream).

Net photosynthesis (Pn) can be determined using the IRGA measurements of the change in CO2. IRGAs

can also be used to measure environmental responses and photosynthetic capacity and determine

other parameters, such as instantaneous gas flux measurements, gas exchange over time (such as for

diurnal cycles), photosynthesis-light response curves, photosynthesis-temperature response curves

and photosynthesis-CO2response curves.

CI-340 Operation Manual rev. 6/7/2017

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

3

Technical Information

The CI-340 is a highly technologically advanced photosynthesis system. It contains a pump along with a

mass airflow sensor. A built-in microprocessor regulates the airflow rate, which is set by the user.

Specifically, the CI-340 is a non-dispersive IRGA in which the infrared light is shone through the gas in

the sampling chamber and then focused on a detector. The energy received at the detector is the total

energy entering the system minus the energy absorbed by the CO2in the sampling chamber. A

technical diagram (Figure 1) illustrates a flow chart for this instrument. An illustration of the CI-340

can be found in Figure 2.

The measurement process starts with the gas or air sample passing a solid-state CO2analyzer. The

output of the analyzer is amplified, sampled by an analog-to-digital (A-D) converter, and sent to the

microprocessor. The processor averages these readings and corrects them for any non-linearity

present in the analyzer. A relative value of CO2concentration is continually updated by the

microprocessor. Each reading reflects a sample being taken every second during a specified time

period. This can be determined by setting the time interval. The rate at which samples are saved in

memory is determined by the “sampling rate” or the time interval input at the beginning of each

measurement session. If you listen carefully during analysis, you can hear the valves switching from

reading the “in” values to the “out” values and the sample number or count will increase by one.

Inlet

Outlet

Figure 1: The pathway of airflow through the CI-340 during measurement. The top figure illustrates

the valve placement and air flow during an “in” reading and the lower figure illustrates the valve

placement and air flow during and “out” reading.

CI-340 Operation Manual rev. 6/7/2017

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

4

When initially performing a measurement, the CI-340 takes gas from the inlet or intake where air is

coming in through a filter. This air is moved through the pump and then next through the flow sensor

where the flow rate is regulated. After that, because the device is measuring in, inlet gas is directed

through the analyzer and then enters into the leaf chamber. The gas leaves the leaf chamber and is

directly exhausted.

The CI-340 will measure the “in” for approximately 20 seconds plus the number of seconds entered for

the time interval. The extra 20 seconds allows the machine to clean out any residual gases that are in

the analyzer and to let the analyzer stabilize. Every time something is changed on the CI-340, the

stability is disturbed and the machine should be allowed a few seconds to stabilize. Once the “in” is

measured, all the valves switch to other position. Now the inlet gas goes straight to the leaf chamber,

and the output of the leaf chamber now goes to the analyzer to be measured before it gets exhausted.

Figure 1 illustrates the pathways of air flow through the CI-340 during both “in” and “out”

measurements.

CAUTION: When attaching a pressurized gas source to the external inlet, use a three-way fitting

(which is provided with each instrument) to allow excess gas to escape. Excess pressure may blow

out internal fittings and tubing, or damage the pump. Do not use a three-way fitting for non-

pressurized gas sources.

Main Components of Gas Exchange Systems

There are several main components making up the CI-340. Each of these components needs to be

functioning properly in order for the combined operation of all the components to produce stable and

accurate photosynthetic measurements. Components include the gas exchange or leaf chamber, the

infrared gas analyzer, the pump and mass airflow sensor, and the flow sensor or meter. Other basic

components include filters, gas lines, the display (LCD) screen, the keypad, and the power source or

battery. The CI-340 utilizes a built-in microprocessor to regulate the airflow rate, which is determined

by the user in the range of 0.2 lpm to 1.01 lpm, with the default setting at 0.3 lpm.

Several things can affect the performance and accuracy of photosynthesis measurement systems, such

as leaf chamber architecture and leaf chamber seal quality. The CI-340 has various leaf chamber

attachments for use with different leaf types and whole plants. The leaf chambers are made from

materials which have a low adsorption of water and CO2in order to provide tight seals and accurate

readings. A common problem with infrared gas analyzers is poor discrimination between CO2and H2O

(water vapor) because both gasses absorb energy at similar wavelengths. This problem is relieved by

using a desiccant to dry the gas sample to a stable (constant) water vapor content before reaching the

analyzer. The CI-340 also allows precise control of temperature, CO2concentration, humidity and light

when taking measurements through use of the accessories. The CI-340 also includes computer

software programs giving the user instant access to data in the field. This allows the user to detect and

correct any errors during the measurement.

Highlights of CI-340

The CI-340 is the most sensitive and most stable hand-held IRGA photosynthesis system. It is also

small and very light-weight. The CI-340 is easy to calibrate, remains stable longer after calibration and

warms up faster than previous IRGA models. This is because the CI-340 incorporates a single IRGA to

perform both intake and outtake measurements. Using a single IRGA to measure (versus two or more),

CI-340 Operation Manual rev. 6/7/2017

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

5

gives the users less drift in measurements because the equations are based on differentials. With fewer

components involved, there are fewer errors and less instrument drift.

The CI-340 can measure chlorophyll fluorescence and photosynthesis simultaneously, has modular

attachments for light and temperature control, CO2/H2O supply and chlorophyll fluorescence, as well as

addition attachment capabilities for soil respiration and plant canopy photosynthesis measurements.

CI-340 Operation Manual rev. 6/7/2017

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

6

Figure 2: Parts of the CI-340

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

7

General Operating Instructions

This section will familiarize you with start-up procedures and guide you on how to move from one

function to another. Specific instructions for each separate function will be found under their individual

heading in the main body of the manual.

For greatest accuracy, the instrument should be turned on 30 minutes prior to any calibrations to allow

it to be fully warmed up. Measurements can be made about 3 minutes after the displayed CO2value

starts to drop from its maximum.

1. The instrument needs to warm up awhile before it is used to measure. The warm up is

measured from the time the instrument is powered on (it does not matter if it is measuring or

not). A warm up of about 4 minutes would be the minimum time to get measurements and

about 20 minutes for more precise measurements.

2. It is best to put the leaf into the chamber before you start the measurement so the leaf has time

to acclimate to the leaf chamber conditions and the instrument has time to react to the changes

the leaf causes. The "Working" display is a period that the instrument uses to stabilize

itself. The actual measurement starts when the display changes from "Working".

3. Variations in the CO2 readings or Pn readings can often be caused by changes in the air stream

going into the instrument. The CO2content of the stream must be very stable. Some

researchers use a long tube to get the intake away from human activity. Some use compressed

air (with a pressure regulator and a T in the hose). Some use a volume buffer (a 2 liter bottle or

larger with the hose from the instrument drawing air from inside that is vented to allow outside

air in) that will average out CO2changes over time. If the experiments are done near a road

with vehicles, it is difficult to get stable CO2readings. If you do not have a source of compressed

air, you may try putting several volume buffers in series (the instrument draws from the first

bottle that draws from the second which then draws from the third which is vented) The

instrument is sensitive enough to detect fires that are hundreds of meters away if they are

upwind.

4. The flow rate can be reduced when the photosynthesis is minimal. Try 0.3 lpm for most

situations and 0.25 lpm if the readings are low.

Using the Keypad

The keypad for the CI-340 consists of 20 keys to enter commands and data. Figure 3-1 illustrates the

keypad. Pressing a key makes a “beeping” sound. A key should be pressed individually each time a

command or letter is asked for. Refer to the TROUBLESHOOTING chapter if problems occur.

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

8

Figure 3: CI-340 Keypad

These characters are not usable: [ +,-,(,*,/,) ]

File Menu

The CI-340 has a file system that allows a great range of data to be stored internally. It has been

designed to emulate the familiar DOS of personal computers. Note that this menu will not be accessible

when there are no files stored in memory; the message “no files” on the top display line will be briefly

displayed when this situation occurs.

To use the File Menu or check if any files are stored, press the key when

“ENTER file menu” is displayed.

Press the key to access the “file menu” when the instrument is first turned

on.

Use the and keys to view all stored files. Pressing the key will

exit this menu.

Enter File menu 13:05:49

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

9

Files are stored in chronological order, with the names and data affiliated accordingly. Up to 1200 files

or 4 MB of data are allowed for storage. Be sure to transfer important data before deleting it from the

CI-340. Refer to the DATA TRANSFER section for related information.

Press the + key (for the letter “D”) to delete the last file saved, or

+ key (for the letter “Y”) to delete all files saved.

The shift and keys will have to be pressed again to confirm erasure of all

files. Deleting a file removes it permanently!

Installation of the Battery

The CI-340 is dependent upon a properly charged power source for efficient and reliable

measurements and calculations. The included battery/battery eliminator is designed to provide the

necessary power. The system is designed to operate from 7.2V rechargeable Li-Ion batteries. Check

with the nearest representative or manufacturer if the included system does not include one or more of

the above items.

If the rechargeable battery should ever fail to charge properly, please recycle it. Many waste processing

systems do not allow Li-Ion batteries to be simply thrown in the trash. Refer to the RECHARGING

chapter for further information on how to take care of the battery and for how to power the CI-340 in

the lab without using the Li-ion battery.

Proper installation of the battery is as follows:

Align the contacts of the battery with the contacts of the CI-340 (Figure 4).

Line up the battery so that it is about 7 mm “off” its final position within the battery mounts

in the direction shown in Figure 4.

Press the battery toward the contacts and slide in the direction shown (Figure 4) until

firmly in place. By pressing the battery toward the contacts, the CI-340 will make necessary

connections with the battery and the battery will be in the correct position.

To remove the battery, slide it in the opposite direction that is shown in Figure 4.

Note: The CI-340 should only be used in low RF ambient areas. Do not use near radio/TV

transmitting antennas or near electrical arc welders.

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

10

Figure 4: Battery installation: Press the battery toward the contacts.

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

11

Interpretation of Parameters

CO2(in)

The amount of CO2(in ppm) at the inlet of the analyzer

CO2(out)

The amount of CO2(in ppm) at the outlet of the leaf chamber

CO2(dif)

The difference between the CO2in and CO2 out values.

H2O (in)

The amount of H2O (in kPa) at the inlet of the analyzer

H2O (out)

The amount of H2O (in kPa) at the outlet of the leaf chamber

H2O (dif)

The difference between the H2O in and H2O out values.

PAR

Photosynthesis Active Radiation in terms of цmol/m2/s

FLOW

The set flow rate of the analyzer (in lpm)

W

Mass flow rate in terms of mol/m2/s

T (air)

Temperature of the ambient air (in °C) in the leaf chamber. This requires the temperature

sensor to be installed for meaningful results.

ATM

Atmospheric pressure (in kPa)

Pn

Net photosynthesis rate in terms of цmol/m2/s

InTCO2

Internal CO2 цmol/mol

T (leaf)

Temperature of the leaf as measured by infrared temperature sensor (in °C)

C

Leaf Stomatal conductance mmol/m2/s

Internal T

Temperature of the analyzer environment (in °C)

E

Transpiration Rate mmol/m2/s

“EXIT to quit”

Aborts current operating function to the default menu

“ENTER file menu”

Allows the user to enter the file menu system:

“SHIFT 2 (D) = del”

Command to delete an existing file; press +

“EXIT file menu”

Returns to the default menu

“Y = delete ALL”

Command to delete all existing files; press + . This must be confirmed

before the instrument will erase all the files.

“Date”

Current running date

“Time”

Current running time

“START/ENTER to go”

Reminds the user that pressing will start the measurement process.

“ENTER to select”

Notifies the user to press to perform the listed functions:

“Change clock”

Allows the user to change the time and date settings

“Calibrate CO2”

Allows the user to calibrate the zero and span for CO2measurements.

“Calibrate H2O”

Allows the user to calibrate the zero and span for H2O measurements using external

sources

“Calibrate Temp”

Allows the user to set the TSCAL1 and TSCAL2 parameters of the temperature sensor.

“Calibrate Flow”

Allows the user to calibrate the flow meter to external standards.

“Calibrate ATM Pr”

Precisely adjusts atmospheric pressure (in kPa)

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

12

System Setup and Calibration

The system is shipped from the factory calibrated for immediate use. The user can perform most

system calibrations if necessary.

To start the CI-340, press . After a brief warm-up time, the instrument will display the basic

display as follows:

Fri 12 Mar 2004 16:06:38

CI-340 version 5.004

©Copyright CID Inc., 1997 - 2004

All rights reserved.

The following screens are accessed in order by pressing the arrow keys, to move up and to

move down:

ENTER to select Calibrate Temp.

ENTER to select Calibrate Flow

ENTER to select Calibrate ATM Pr

ENTER->file menu

Starting Screen: Fri 12 Mar 2004 16:06:38

START/ENTER to go 16:06:38

ENTER to select Change clock

ENTER to select Calibrate CO2

ENTER to select Calibrate H2O

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

13

Calendar and Time Setup

The purpose of these functions is to provide the user current information of local date and time. This

method can be extremely useful to further establish when measurement data are collected or saved, or

simply another form of time keeping. The factory-calibrated date and time are the default values.

ENTER to select Change clock

To change the date and time:

Scroll to choose “Change clock” under the “ENTER to select” function (press the key twice

from the initial display). The time function will be the first selection.

Use the or keys followed by the or keys to adjust and move to the hour,

minute and second of choice.

With the time function set, the date function will follow. Once again, use the or keys

followed by the or keys to adjust and move to the month, day and year of choice.

Press the key to save your selection and continue. Note that at any point of this setup,

Pressing the key will suspend any further actions and return to the screen display above.

Leaf/Air Temperature Sensor

Suggested Calibration Schedule: None.

This function sets the calibration values for a given leaf/air temperature sensor. The included

temperature sensor has been initially tested and calibrated by the manufacturer.

ENTER to select Calibrate Temp

No further calibration is allowed.

Atmospheric Pressure

The CI-340 pressure sensor is capable of measuring absolute atmospheric pressure. This value is used

in calibrations for Photosynthesis, Transpiration and Stomatal Conductance values. The sensor is

calibrated at the factory, and normally does not need to be recalibrated.

ENTER to select Calibrate ATM Pr

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

14

To change the atmospheric pressure (ATM) value:

Scroll to choose the “Calibrate ATM Pr” under the “ENTER to select” function.

Enter the desired ATM value in K Pa. Press to accept the entered value or to abort

the process, and continue to another step.

Flow Rate

The CI-340 is capable of maintaining a steady airflow once the unit begins taking measurements. After

the initial warm-up time (one minute), the instrument will generate the entered flow rate to regulate

the accuracy of the measurements. The instrument is capable of automatically controlling the flow rate

from 0.2 ~ 0.999 lpm. Flow rates of 0.3 lpm give increased accuracy to photosynthesis measurements

unless very active leaves are being measured.

Figure 5: Flow meter setup to measure flow rate.

The flow meter is calibrated by the manufacturer but can be calibrated again by the user. Suggested

calibration schedule is once every six months. Scroll to choose the “Calibrate flow rate” under the

“ENTER to select” function.

ENTER to select Calibrate flow rate

The instrument will briefly run through stabilizing steps and then ask the user to adjust the flow, using

the keys for major changes or the keys for minor changes, over steps from .2 to

1 lpm. For calibration, the flow MUST be measured by the calibrated external flow meter at the port on

the end of the instrument where the leaf chamber plugs in (upper left part as you read the keypad). For

this calibration, the flow rate is measured at the input to the leaf chamber (see figure 5-0). A well-

calibrated flow meter with little backpressure should be used as the standard. If for any reason an error

was made during the calibration procedure pressing the key will also return back to the

beginning of the flow calibration procedure without saving any changes made. Once the calibration

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

15

procedure is competed, in a few moments the instrument will reset and return back to the above screen

display.

CO2 and H2O General Overview

H2O and CO2 Zero should be calibrated every week, unless there are very significant changes in

ambient conditions or the relative humidity values seem erroneous. The H2O Span should be

calibrated annually, and with heavy use every six months. CO2 Span should take place once every six

months. Set Zero is a one point calibration, set Span is a two point calibration.

Calibrating the H2O Span can be done with ambient air using a hygrometer to measure humidity and a

thermometer to measure temperature. These values are entered into the DOS program to calculate the

kPa to enter into the instrument. H2O levels of air are not as easily affected as CO2 concentrations,

therefore as long as the temperature and humidity of the gas being fed through the instrument are

known, the H2O Span can be correctly calibrated. The calibration will be as accurate as the sensors

used to determine the humidity/temperature of the gas.

NOTE: For greater changes in ambient temperatures between sample measurements, it may be

necessary to recalibrate to CO2 “zero setting” at each temperature (i.e. O°C sample and 40°C sample).

This instrument allows calibration with a range of CO2from 200 to 1000 ppm, and H2O from 1 to 7.5

kPa.

ENTER to select Calibrate CO2

To change the calibration of CO2, scroll to choose the “Calibrate CO2” under the “ENTER to select”

function. While the instrument stabilizes to the setup state, it will first ask if you want to calibrate zero.

Start to set zero, else Exit

Press the key to calibrate the zero or press the key to skip the calibrate zero function.

Use 0 ppm CO2gas Press START/ENTER

Connect dry nitrogen or soda lime and allow the zero ppm CO2gas (dry nitrogen or soda lime) to flow

for approximately one minute (three minutes for soda lime) prior to pressing the key to flush the

system completely. Always use a “T” connector. A small amount of flow out of the one-meter tube

ensures a sufficient quantity of gas is flowing to the system (see Figure 6) in the gas line when

supplying gas from a low-pressure regulator in order to avoid excessive flow through the system.

Alternately, use soda lime connected between the intake and exhaust with the small plastic tube where

the chamber usually goes to form a closed loop. (See Figure 7)

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

16

Figure 6: Configuration using compressed gas.

After the system zero is established, use a gas with known concentration of CO2 to calibrate span.

Use the key to skip the “calibrate the span” setting.

Use known CO2

Press the key to proceed.

Enter the concentration of CO2in ppm at the following display:

Concentration ?

__ ppm

The known concentration should flow for approximately one minute.

Press to save your selection. The system will then return to the following screen display and

reset:

ENTER to select Calibrate CO2

H2O calibration follows similar procedures. Dry nitrogen gas or silicon gel (Figure 8) can be used for the

H2O zero, and a known partial pressure of H2O is used for the known H2O. A “DOS” program is provided

to convert relative humidity and temperature to kPa partial pressure. Run RH2KPA.EXE under DOS or in

a DOS window on a PC. Windows XP will automatically launch a DOS window if you double click on the

file name in Windows Explorer.

NOTE: H2O span setting should be checked once every six months. It be checked often by conducting a

photosynthesis test with the “loop back” tube in place of a leaf chamber and sampling a known

humidity of the atmosphere.

CI-340 Operation Manual

CID Bio-Science

1554 NE 3rd Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

www.cid-inc.com

17

Figure 7: Configuration using Soda Lime for CO2 Zero calibration.

Figure 8: Configuration using Silica Gel for H2O calibration

CO2 Zero and CO2 Span Procedure

Tools required: CI-340, Soda Lime external conditioning tube, filter, hose barbs, a CO2 standard gas

ranging from 200-1000 ppm, a t-junction, and a flow regulator.

1. Power on the instrument

2. Connect the soda lime tube, filter and green loop-back tube (Fig.1&2) (for Control Modules: set the

AD CO2 and H2O to zero)

3. Use the up/down arrow to navigate to “Calibrate CO2”

4. Press start/enter

Table of contents

Other CID Bio-Science Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

moovo

moovo MU Installation instructions and warnings

Hanna Instruments

Hanna Instruments HI99111 instruction manual

WIKA

WIKA TR10-B operating instructions

IFM

IFM efector300 SI0102 operating instructions

Contrec

Contrec 505 Series Operation manuals

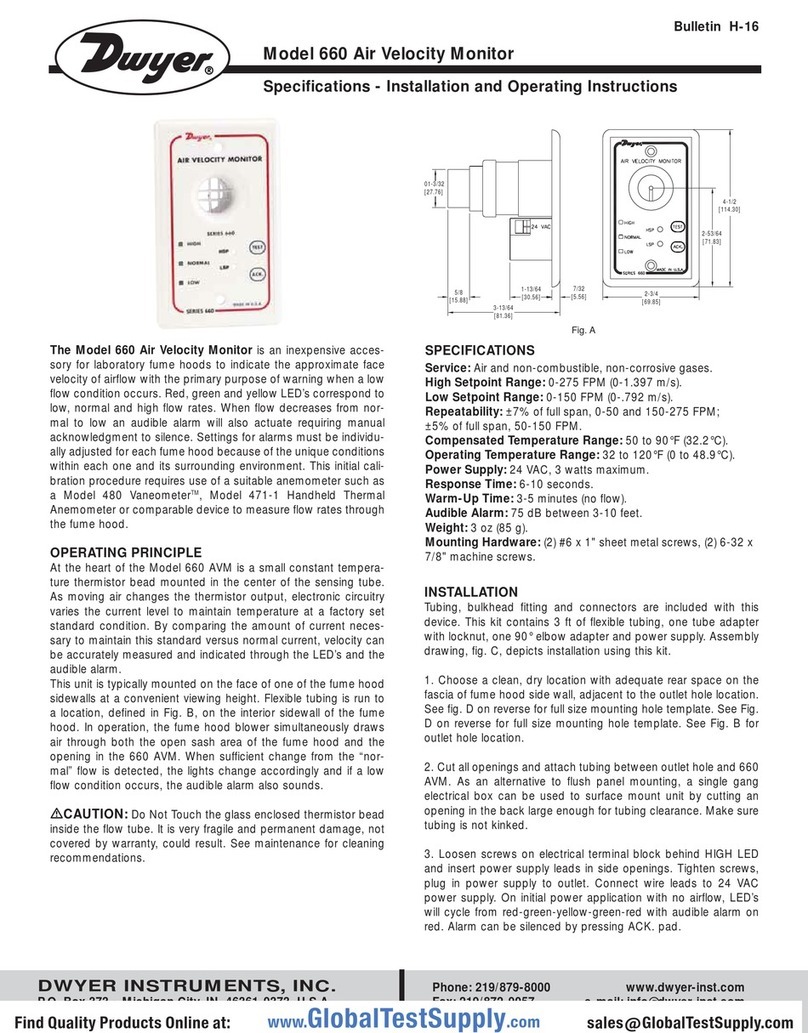

Dwyer Instruments

Dwyer Instruments 660 Installation and operating instructions