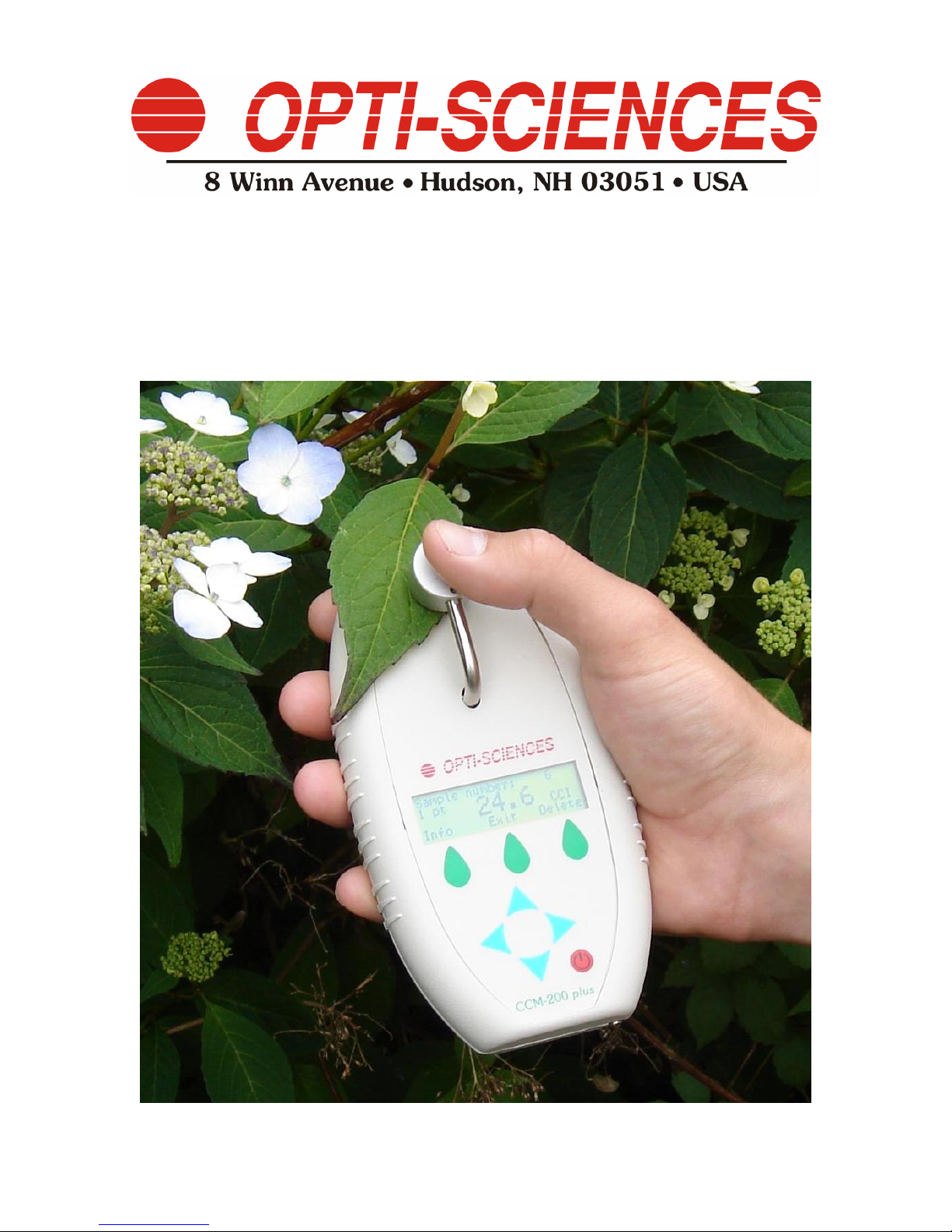

Opti-Sciences, Inc. CCM-200 plus operator's manual

2

Table of contents

TABLE OF CONTENTSINTRODUCTION ............................................................................................................2

INTRODUCTION.......................................................................................................................................................3

WELCOME!................................................................................................................................................................3

LIST OF EQUIPMENT...................................................................................................................................................3

ABOUT THE INSTRUMENT ..........................................................................................................................................3

APPLICATIONS &FEATURES......................................................................................................................................4

Applications.......................................................................................................................................... 4

Features................................................................................................................................................ 4

How it Works........................................................................................................................................ 5

PHYSICAL FEATURES .................................................................................................................................................6

OPERATION OVERVIEW .......................................................................................................................................6

SYSTEM SETTINGS .....................................................................................................................................................7

MEASUREMENT &OPERATION ..................................................................................................................................7

MEASUREMENTS........................................................................................................................................................8

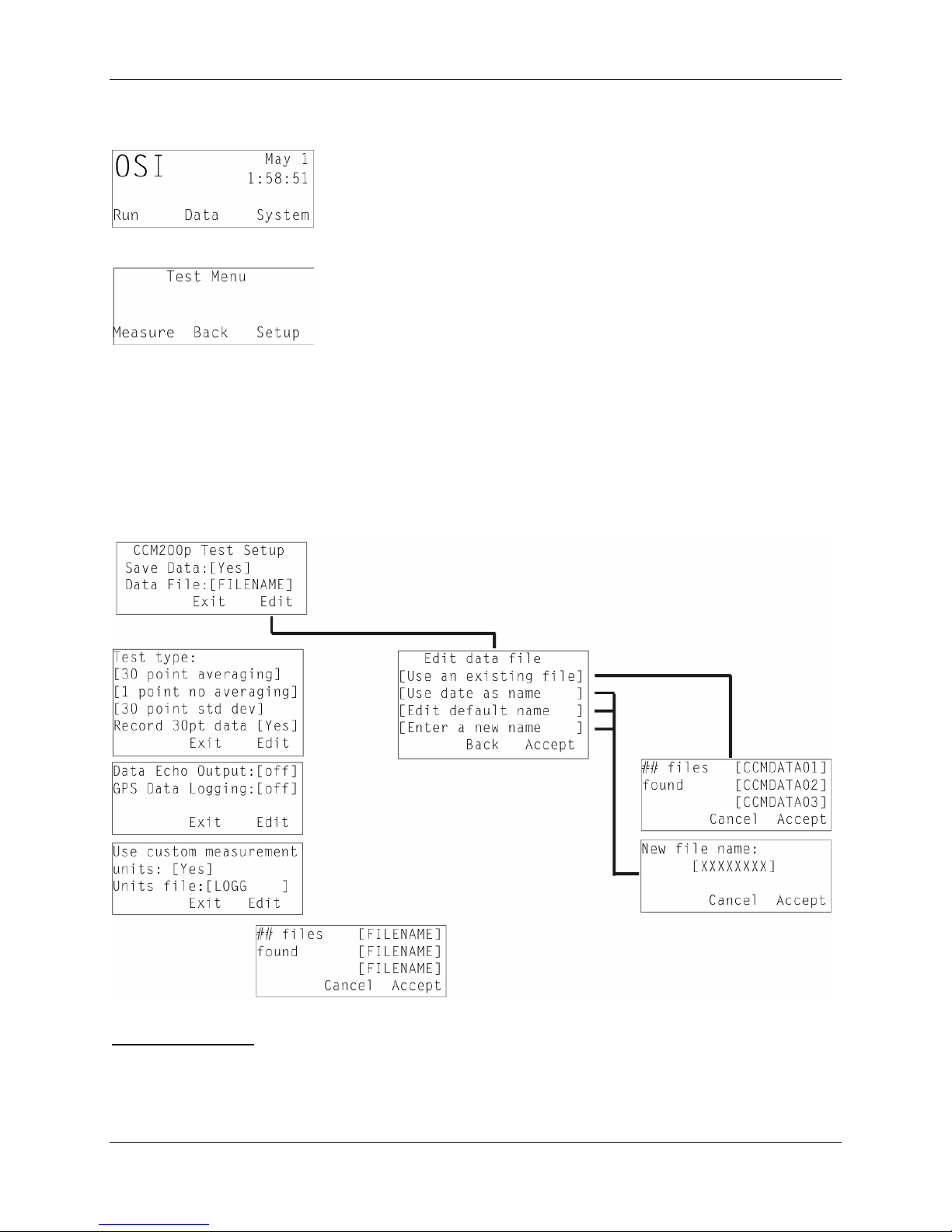

Setup..................................................................................................................................................... 8

CALIBRATION ............................................................................................................................................................9

TEST TYPES .............................................................................................................................................................10

Single point measurement.................................................................................................................. 10

Multi-Point averaging........................................................................................................................ 10

Multi-Point averaging with std. deviation flyer removal................................................................... 10

ENTER COMMENTS FOR MEASUREMENTS ................................................................................................................12

DATA MANAGEMENT...........................................................................................................................................14

TRANSFER DATA BY USB ........................................................................................................................................14

SENDING DATA BY RS232. ......................................................................................................................................14

Communication Settings.................................................................................................................... 15

TECHNICAL SPECIFICATIONS..........................................................................................................................16

ERROR CODES........................................................................................................................................................17

TECHNICAL SUPPORT .........................................................................................................................................22

REFERENCES:.........................................................................................................................................................23