INTRODUCTION

Thank you for choosing our product.

Our company is highly specialised in the development and production of uninterruptible power supplies (UPS).

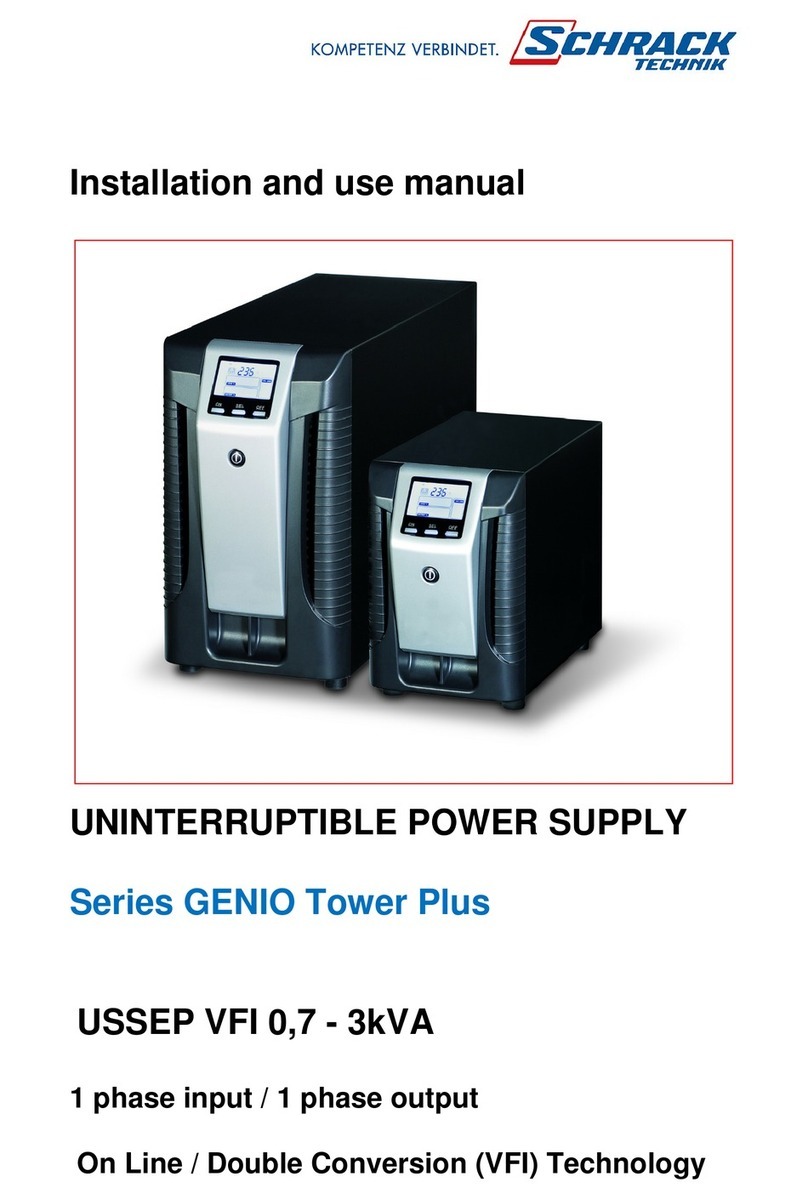

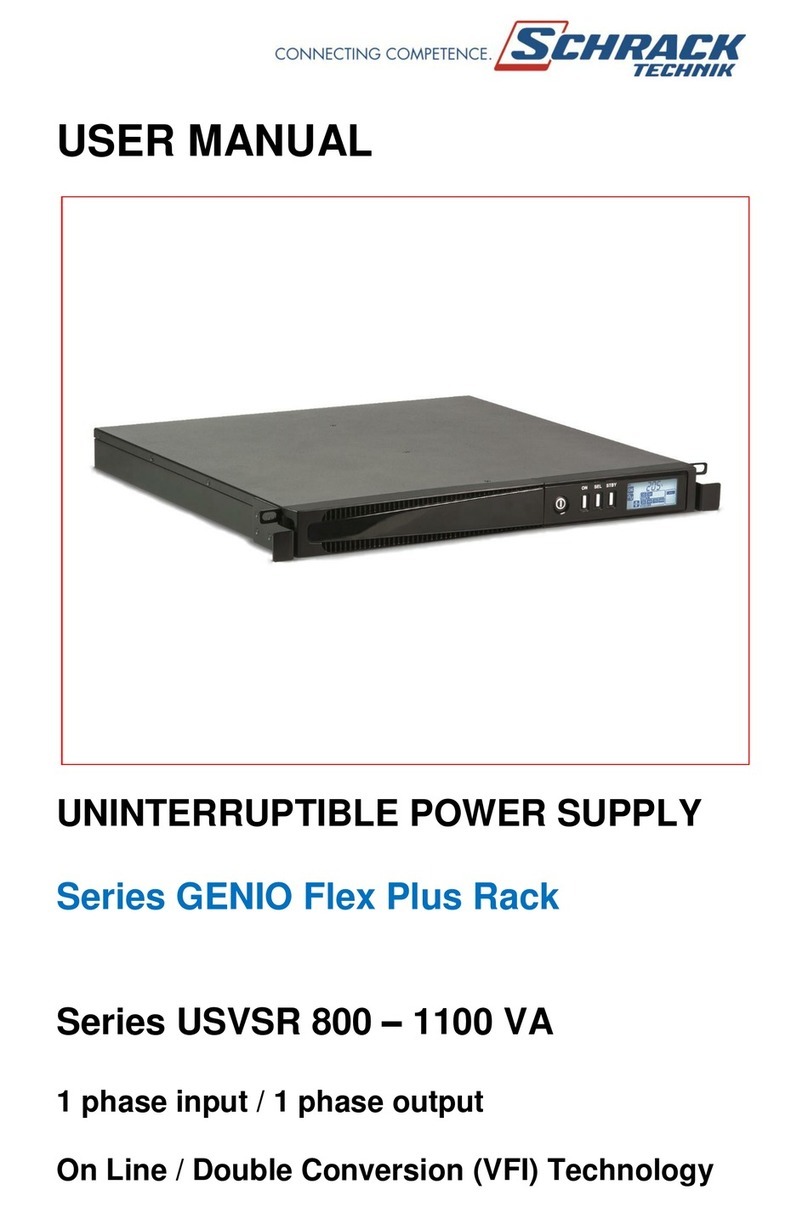

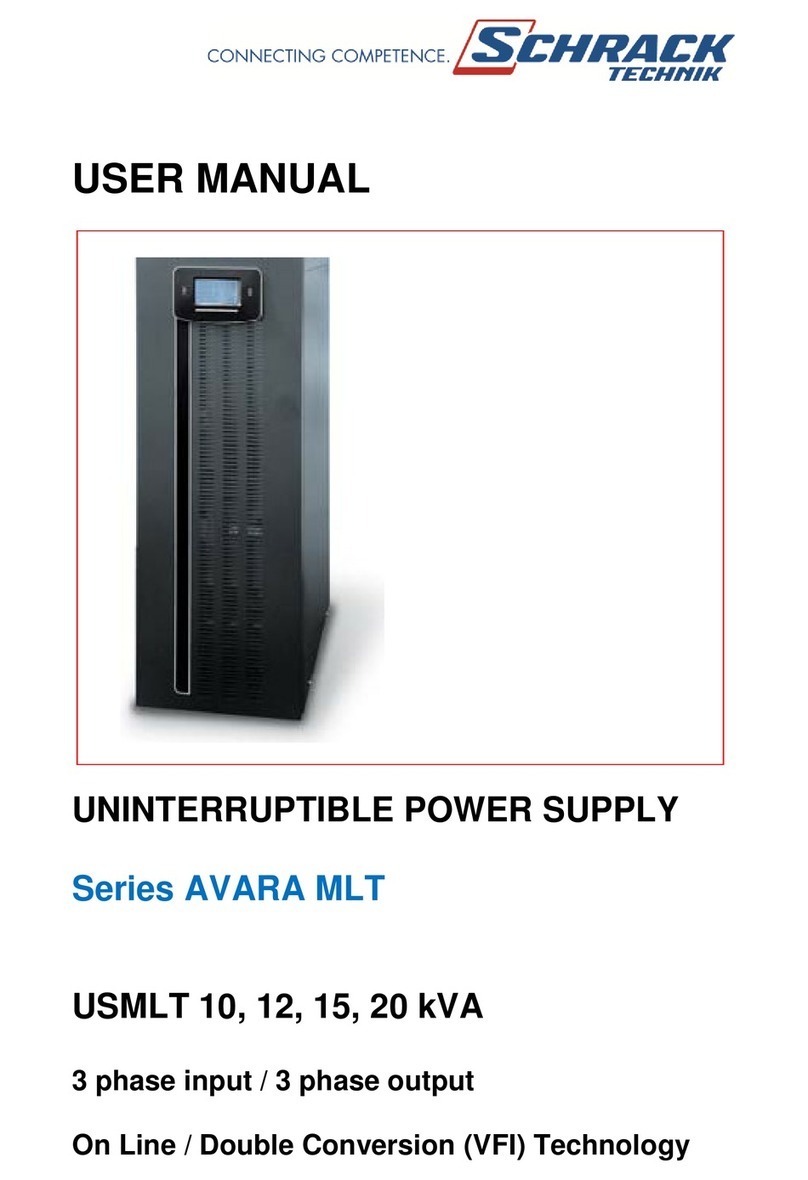

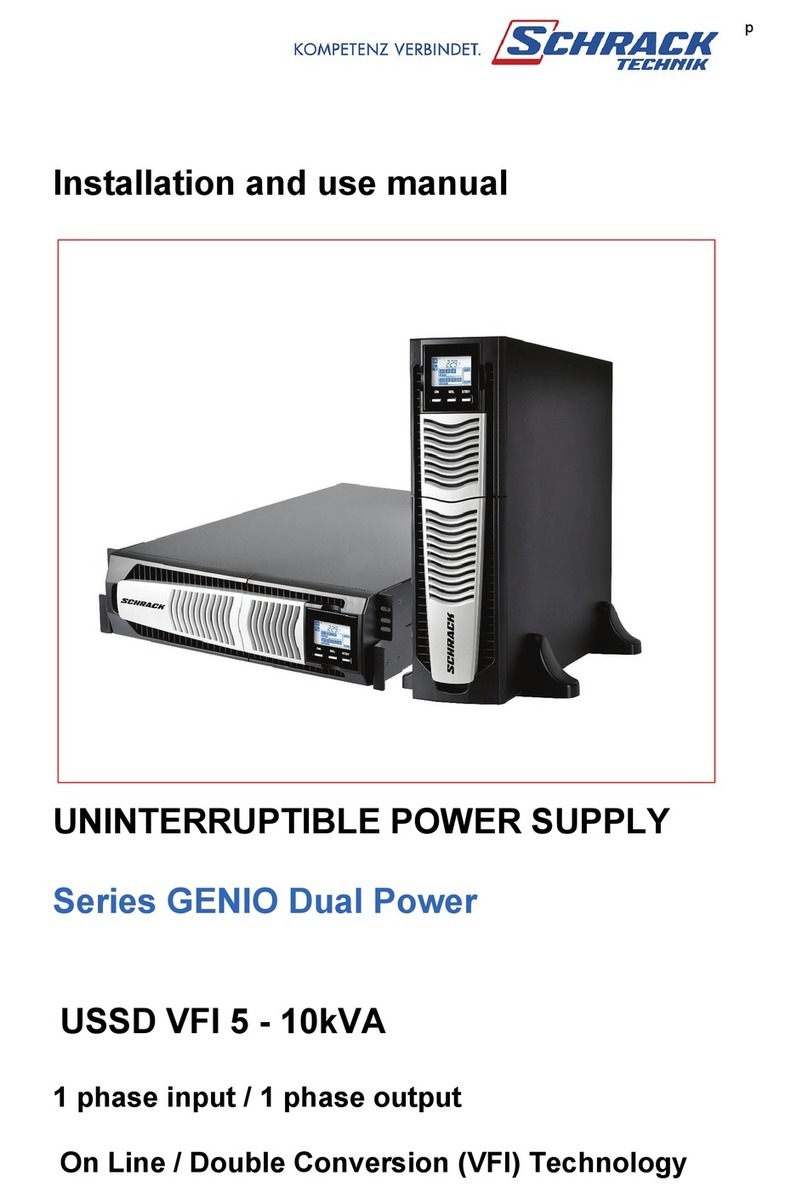

The UPS device described in this manual is a high quality product that has been carefully designed and manufactured to

guarantee optimal performance.

This manual contains detailed instructions for product use and installation.

This manual must be stored in a safe place and CONSULTED BEFORE DEVICE USE for proper usage instructions

as well as maximum performance from the device itself.

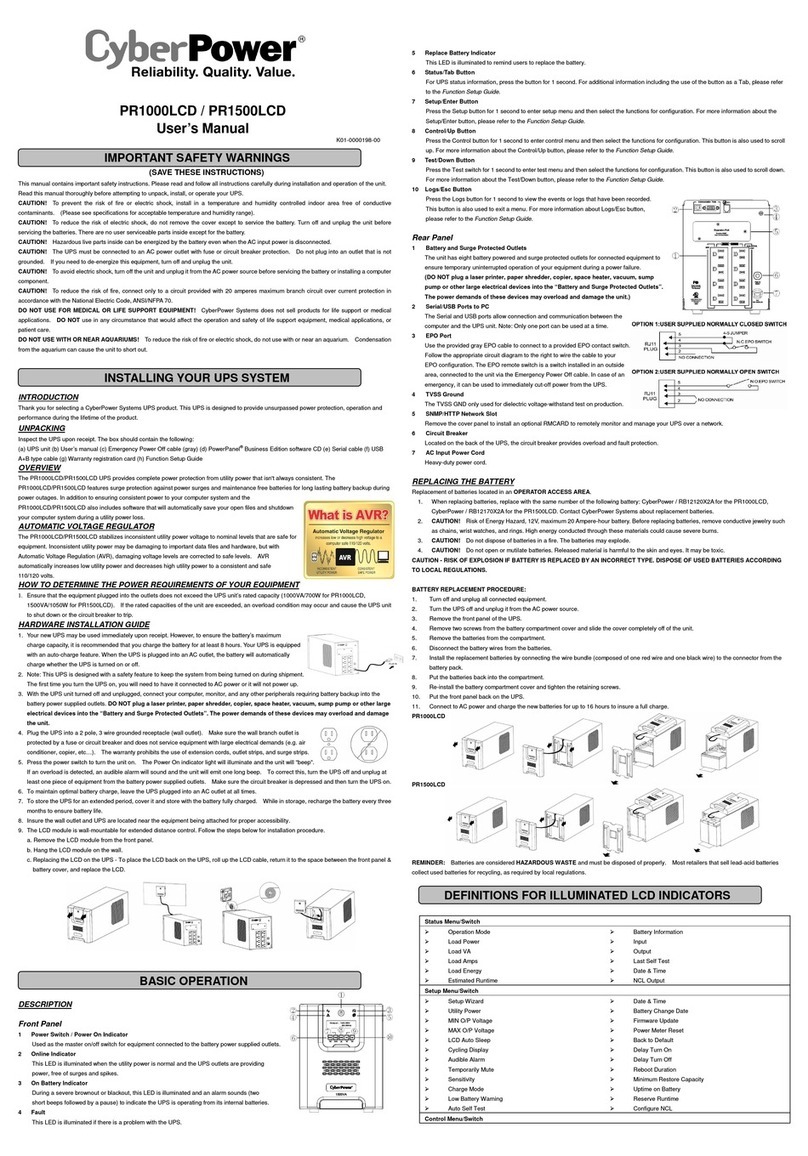

NOTE: Some images contained in this document are for information purposes only and may not faithfully demonstrate the

parts of the product they represent

ENVIRONMENTAL PROTECTION

Our company devotes abundant resources to analysing environmental aspects in the development of its products. All our

products pursue the objectives defined in the environmental management system developed by the company in compliance

with applicable standards.

Hazardous materials such as CFCs, HCFCs or asbestos have not been used in this product.

Packaging is composed of RECYCLABLE MATERIALS. Dispose of all material in compliance with applicable standards in the

country in which the product is used. Refer to the following table to identify materials:

DISPOSING OF THE PRODUCT

The UPS contains internal material which (in case of dismantling/disposal) are considered TOXIC AND HAZARDOUS

WASTE, such as electronic circuit boards and batteries. Treat these materials according to the laws in force, contacting

qualified centres. Proper disposal contributes to respect for the environment and human health.

© The reproduction of any part of this manual, even in part, is prohibited unless authorised by the Manufacturer.

The manufacturer reserves the right to change the product described at any time without prior notice for improvement purposes.