5

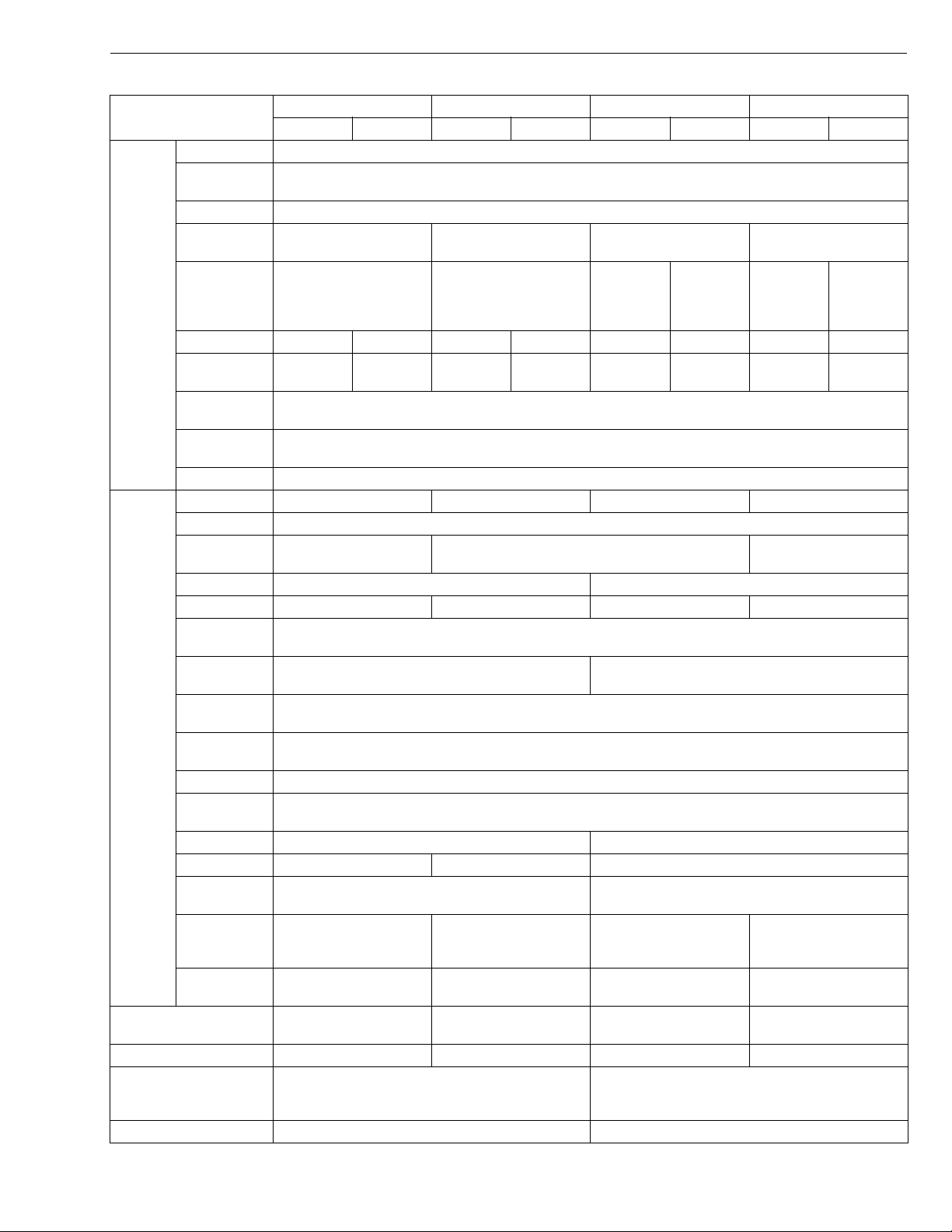

SPECIFICATIONS

J SERIES, WSM

SPECIFICATIONS

[50Hz]

W10275180

Model J106 J108 J112 J116

-STD -AUS -STD -AUS -STD -AUS -STD -AUS

Generator

Type Revolving-field, brush type, separate and self - excitation system, AC generator

Insulation

class Rotor coil: F Stator coil: B

Frequency 50 Hz

Standby

output 6.0 kVA (6.0 kW) 8.8 kVA (8.8 kW) 13.2 kVA (13.2 kW) 17.6 kVA (17.6 kW)

Prime output 5.5 kVA (5.5 kW) 8.0 kVA (8.0 kW) 12 kVA (12 kW) 16 kVA (16 kW)

Voltage 220 V 240 V 220 V 240 V 220 V 240 V 220 V 240 V

Rated

amperage 25.0 A 22.9 A 36.4 A 33.3 A 54.5 A 50.0 A 72.7 A 66.7 A

Number of

phases Single

Number of

poles 2

Power factor 100 %

Engine

Model Z482-B-SEC D722-B-SEC D1005-BG-SEC V1305-BG-SEC

Design Vertical, liquid cooled, 4 cycle, diesel engine

Number of

cylinders 234

Bore x Stroke 67 x 68 mm (2.52 x 2.68 in.) 76 x 73.6 mm (2.99 x 2.90 in.)

Displacement 479 cm3(29.23 cu.in.) 719 cm3(43.89 cu.in.) 1001 cm3(61.08 cu.in.) 1335 cm3(81.46 cu.in.)

Combustion

system Spherical combustion chamber

Compression

ratio 23:1 22:1

Cooling

system Pressurized radiator, forced circulation with water pump

Lubricating

system Forced lubrication by trochoid pump

Lubricating oil Higher than CD class (API)

Starting

system Electric type

Stop solenoid Energized to stop Energized to run

Battery 38B20R 55B24R 80D26R (S)

Fuel tank

capacity

37 L

(9.8 U.S.gals, 8.1 Imp. gals.)

79 L

(20.9 U.S. gals, 17.4 Imp. gals.)

Cooling

system

capacity

2.3 L

(2.4U.S.qts.,2.0 Imp.qts.)

3.0L

(3.2U.S.qts.,2.6 Imp.qts.)

3.3 L

(3.5U.S.qts.,2.9 Imp.qts.)

3.5 L

(3.7U.S.qts.,3.1 Imp.qts.)

Crankcase oil

capacity

2.2 L

(2.3U.S.qts.,2.0 Imp.qts.)

3.4 L

(3.6U.S.qts.,3.0 Imp.qts.)

4.3 L

(4.6U.S.qts.,3.8 Imp.qts.)

5.7 L

(6.0U.S.qts.,5.0 Imp.qts.)

Continuous operating

hours (at 3/4 load) 19.0 Hr 13.5 Hr 20.0 Hr 16.5 Hr

Net weight 225 kg (496 lbs) 255 kg (562 lbs) 340 kg (750 lbs) 380 kg (838 lbs)

Emergency stop

mechanism

During engine operation, automatic shutdown will

occur when either the oil pressure or the water

temperature is abnormal.

During engine operation, automatic shutdown will

occur when either the oil pressure or the water

temperature is abnormal or when the fan belt breaks.

With Caster Option None