5

Operation

CPC III Manual

(PPPT)

I/O Harness

(PIOE)

Oil Temperature

(POTS)

- Plug in the connector labeled “Keypad” to the

Rear Keypad.

- If Installed: Concrete Pressure Sensor: Plug in

the M12 connector to the Concrete Pressure

Sensor.

- One of the connectors you disconnected from

the Rear Control Panel will plug into the I/O-E

Harness (PIOC).

Note: On the early C32 rear panels, only one

connector was used. I this case PIOC will not be

used.

6. Connect the supplied connector jumper to the

remaining connector from the old Rear Control

Panel. (Item 60 on BOM 98458427)

Clean up the harnesses and nish securing all equip-

ment. (Item 270 on BOM 98458427)

Initial Setup

1. Turn on PTO but do not run the engine.

2. Turn on the Maintenance Switch. Inspect F9 fuse

in the PDM. If F9 fuse blows (or is already blown)

then nd the Quick Disconnect (PQD1) on the

harness located next to Cable C and disconnect

it. Tape the connector ends.

- Reset the circuit breaker by cycling the power.

- Turn o the maintenance switch.

Maintenance Switch

(PMS)

OFF

ON

Figure 8

Maintenance switch

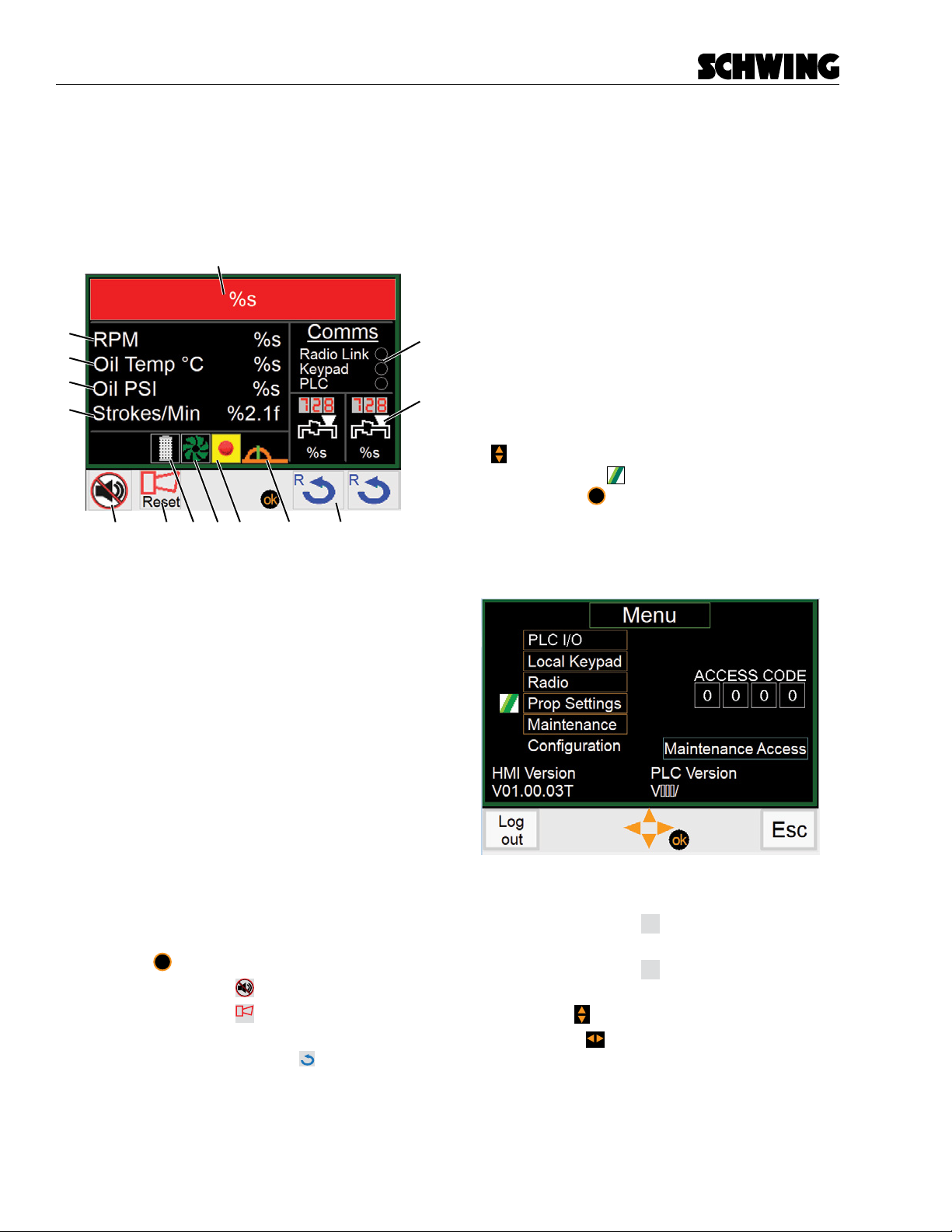

3. Ignore all error messages for now. Go to the

Conguration screen using the system password

and adjust the system settings.

Screen Settings

1Channel E-stop Only select this option if the system you are

replacing had single channel E-Stops.

CPC2 Compatible Only select this option if the system you are

replacing was a CPC2 type machine.

Stroke Counter Select if the unit has a Stroke Counter.

Oil Pressure Sensor Select if the unit has an Oil Pressure Sensor

Agitator Disable Select this option if the unit does NOT have

an electrically controlled agitator.

Boom Horn Disable Select this if the unit does NOT have a

Boom Horn.

Boom Type Choose the Boom Type: 3 Section, 4 Sec-

tion, etc.

Max Engine RPM Max engine RPMs allowed.

Important Notes

1. On some units the Agitator Forward and Reverse

buttons may be backwards. If yours is backwards,

swap the agitator forward and reverse connec-

tors at the valve.

2. All agitator forward and reverse buttons will need

to be removed from the unit as they will no longer

work. Use the rear keypad or radio remote.

3. If fuse F9 blows go to the initial setup instructions.

Fully test the system and Teach the boom using the fac-

tory login.