Watkiss DigiVAC User manual

Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04

Watkiss DigiVAC

Service Manual

Issue Date:29 November2004

Issue Number: 2

Part Number: 969-251

Watkiss Automation Ltd

1 Blaydon Road

Middlefield Industrial Estate

Sandy, Bedfordshire

SG19 1RZ U.K.

Tel: +44 (0)1767 682177

Fax: +44 (0)1767 691769

Email: [email protected]

Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04

Conventions

The following conventions are used in this manual:

WARNING Warning messages alert you to a specific procedure or practice which, if

not followed correctly, could cause serious personal injury.

CAUTION Caution messages appear before procedures which, if not observed, could re-

sult in damage to equipment.

© Watkiss Automation Limited 2002-2004

All Rights Reserved.

Reproduction, adaptation, or translation without prior written permission is prohibited, except as allowed

under the copyright laws.

Warranty

The information contained in this document is subject to change without notice.

Watkiss Automation Limited makes no warranty of any kind with regard to this material, including, but not

limited to, the implied warranties of merchantability and fitness for a particular purpose.

Watkiss Automation Limited shall not be liable for errors contained herein or for incidental or consequential

damage in connection with the furnishing, performance or use of this material.

Contents

Watkiss DigiVAC Service Manual - Edited 29/11/04 c-1

CONTENTS

1Overview

1.1 Introduction ........................................................... 1

1.1.1 Safety..................................................................................1

1.1.2 Operation............................................................................1

1.1.3 Orientation..........................................................................2

1.1.4 Test Paper...........................................................................2

1.1.5 Metric and Imperial measurements ....................................2

1.1.6 Moving the DigiVAC............................................................2

1.2 Modules & Configuration ........................................... 3

1.2.1 DigiVAC Standard ...............................................................3

1.2.2 DigiVAC+.............................................................................3

1.2.3 Modules..............................................................................3

1.3 System Overview ..................................................... 6

1.4 Fuses ................................................................... 8

2 Tools & Materials

2.1 Recommended Tools ...............................................11

2.2 Consumables ........................................................12

2.3 Service Aids ..........................................................12

3 Service Procedures

3.1 General Service Procedures .......................................13

3.1.1 Bin Test Mode...................................................................13

3.1.2 Removing the Rear Conveyor Assembly...........................14

3.1.3 Removing the Rear Deflector Plates .................................14

3.1.4 Removing L/H Side Plates ................................................15

3.1.5 Bin Addressing..................................................................15

3.1.6 PCB Removal, Fitting and Adjustments -

General Comments.........................................................16

3.2 Top Module ..........................................................16

3.2.1 Replacing the Top Drum & Conveyor Belts.......................16

3.3 Control Panel (DigiVAC Standard) ................................17

3.3.1 Removing the Control Panel (DigiVAC Standard)..............17

3.3.2 Engineering Mode.............................................................18

3.4 GUI Control Panel (DigiVAC+) .....................................19

3.4.1 Introduction......................................................................19

3.4.2 Operation..........................................................................19

3.4.3 Care of the GUI Screen .....................................................19

3.4.4 Operating the GUI Screen .................................................19

3.4.5 Cleaning the GUI Screen...................................................19

3.4.6 Adjusting the GUI Screen Display .....................................20

c-2 Watkiss DigiVAC Service Manual - Edited 29/11/04

Contents

3.4.7 Calibrating the GUI Screen Display .................................. 20

3.4.8 GUI Access Levels ........................................................... 20

3.5 Feeder Modules ..................................................... 21

3.5.1 Removing the Feeder Assembly....................................... 21

3.5.2 Feed Band Removal ........................................................ 23

3.5.3 Replacing a Feeder Clutch................................................ 23

3.5.4 Checking and Lubricating the Feeder Clutch

Pulley Bearing................................................................ 24

3.5.5 Replacing Bin Emitter/Sensor .......................................... 25

3.5.6 Bin Emitter/Sensor Calibration......................................... 26

3.5.7 Replacing Tray Sensor..................................................... 27

3.5.8 Set the Separator Stop Plate ............................................ 28

3.5.9 Replace Vacuum Air Filters .............................................. 29

3.5.10 Cleaning/Replacing Vacuum Valve................................. 29

3.5.11 Replacing Bin Feeder Drive Belts.................................... 30

3.5.12 Setting Bin Feeder Drive Belt Tension ............................ 31

3.5.13 Replacing Bin Module Drive Belts ................................. 33

3.5.14 Tensioning Bin Module Drive Belts ................................ 33

3.5.15 Replacing the Rear Conveyor Belts ................................ 33

3.5.16 Replacing Worn Conveyor Wheels................................. 34

3.5.17 Removing the Pinch Wheel Idlers .................................. 35

3.6 Base Module ......................................................... 36

3.6.1 Replacing Drive Motor ..................................................... 36

3.6.2 Checking the Vacuum Pressure ....................................... 38

3.6.3 Replacing the Vacuum Pump Motor ................................ 38

3.6.4 Replacing Motor Tacho Sensor........................................ 39

3.6.5 Replacing or Cleaning the Main Air Filter ......................... 40

3.6.6 Adjusting the Air Blow Pressure....................................... 40

3.6.7 Replacing Blower Motor................................................... 41

3.6.8 Replacing the SMD 8200 Inverter .................................... 42

3.6.9 Removing and Replacing Main Drive Belt ........................ 43

3.6.10 Tensioning Main Drive Belt ............................................ 43

3.6.11 Converting the DigiVAC from 50Hz to 60hz

Supply Frequency ........................................................ 44

3.7 Rear Door ............................................................ 46

3.7.1 Removal of Rear Door Conveyor Belts 433 Long

(Lower).......................................................................... 46

3.7.2 Removal of Rear Door Conveyor Belts 1085 Long

(Upper).......................................................................... 46

3.8 Front Outfeed Conveyor ............................................ 47

3.8.1 Removing the Front Outfeed Conveyor ............................ 48

3.8.2 Replacing Front Outfeed Conveyor Belts.......................... 48

3.9 X-Jogger .............................................................. 49

3.9.1 X-Jogger General Inspection............................................ 50

3.9.2 X-Jogger Sidelay/Endlay Screw Adjustment/Cleaning...... 50

3.9.3 X-Jogger Control PCB/Fuse Replacement........................ 51

3.9.4 X-Jogger Pivot Shaft Cleaning/Lubrication ...................... 52

3.9.5 X-Jogger Power Adjustment ............................................ 52

3.9.6 X-Jogger Vibrator Coil Replacement................................ 53

Contents

Watkiss DigiVAC Service Manual - Edited 29/11/04 c-3

3.9.7 X-Jogger - Park Position Adjustment................................54

3.9.8 X-Jogger Diagnostic Procedure........................................55

3.10 Straight Jogger / Adjustable Height Straight Jogger ..........56

3.10.1 Description .....................................................................56

3.10.2 Jogging Power Adjustment.............................................57

3.11 Tower B Top Module & Two-Tower DigiVAC Systems .........57

3.11.1 Adjusting Inter Tower Distance.......................................57

3.11.2 Removing the Tower Link Assembly...............................58

3.11.3 Removing the Top Module and Tower Link Assembly ....59

3.11.4 Replacing the Tower B Top Module Conveyor Belts........60

3.11.5 Replacing the Tower Link Assembly Conveyor Belts.......61

4 Electronics & Software

4.1 Connection Diagrams ...............................................63

4.1.1 DigiVAC Block Diagram....................................................64

4.1.2 Transformer Tappings ......................................................65

4.1.3 DigiVAC High Voltage Connections

(S/Nos. up to DIG/0000149)...........................................66

4.1.4 DigiVAC High Voltage Connections

(S/Nos. up to DIG/0000149)...........................................67

4.1.5 DigiVAC High Voltage Connections

(S/Nos. DIG/0000150 onwards) .....................................68

4.1.6 DigiVAC High Voltage Connections

(S/Nos. DIG/0000150 onwards) .....................................69

4.1.7 DigiVAC Standard Low Voltage Connections

(S/Nos. up to DIG/0000149)...........................................70

4.1.8 DigiVAC Standard Low Voltage

(S/Nos. DIG/0000150 onwards) .....................................71

4.1.9 Connections......................................................................71

4.1.10 DigiVAC+ Low Voltage Connections

(S/Nos. up to DIG/0000149).........................................72

4.1.11 DigiVAC+ Low Voltage Connections

(S/Nos. DIG/0000150 onwards) ...................................73

4.1.12 900-190a DigiVAC Output Interface PCB ........................74

4.2 PCBs ...................................................................75

4.2.1 900-103c Transformer Input PCB.....................................75

4.2.2 900-104e X-Jogger Control PCB.......................................75

4.2.3 900-121 Straight Jogger Control PCB...............................76

4.2.4 900-140b DigiVAC Standard (Eco-Vario)

Control Panel PCB ..........................................................77

4.2.5 900-174f DigiVAC Feed Control PCB.................................78

4.2.6 900-176h DigiVAC Base PCB ...........................................79

4.2.7 900-187e DigiVAC Air/Blow Control PCB .........................81

4.2.8 900-192b DigiVAC Base Power PCB.................................81

4.2.9 900-205a DigiVAC Release B Base Power PCB.................82

4.3 SMD 8200 Inverter ..................................................82

4.4 Software - GUI Control Panel ......................................82

4.4.1 Installing New Software....................................................83

c-4 Watkiss DigiVAC Service Manual - Edited 29/11/04

Contents

4.4.2 Updating Software With a Memory Card.......................... 87

4.4.3 Installing Software Via an RS232 Connection.................. 89

4.4.4 Installing Software Via an Ethernet Connection................ 93

4.4.5 Networking DigiVACs....................................................... 99

4.4.6 Troubleshooting Network Connections .......................... 102

4.4.7 GUI Boot Firmware Commands...................................... 103

4.4.8 Software Update Summary ............................................ 103

4.4.9 Error Bleeps ................................................................... 104

5 Machine Inspections

5.1 DigiVAC - After-Build Inspection ................................106

5.2 DigiVAC - Pre-Delivery Inspection ..............................110

6 Routine Maintenance

6.1 DigiVAC Routine Maintenance Schedule .......................113

6.2 DigiVAC X-Jogger Routine Maintenance Schedule ...........114

7 Installation

7.1 Prior to Installation ................................................115

7.2 Unpacking and Installing a DigiVAC ............................115

7.3 Upgrade an 8 DigiVAC to a 12 DigiVAC .........................117

7.4 Upgrade a DigiVAC Standard to a DigiVAC+ ...................118

7.5 Installing the Front Outfeed Conveyor ..........................120

7.6 Installing a Second Tower ........................................122

8 Trouble Shooting

8.1 Trouble Shooting Chart ...........................................125

8.2 Fuse Failure ........................................................128

8.3 SMD Inverter Error Codes ........................................128

9 Appendix

9.1 Specifications ......................................................131

9.2 Conversions .........................................................132

9.3 Technical Documentation Feedback Form .....................133

Overview • Introduction

Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04 1

Chapter 1 Overview

1.1.1 Safety

Please observe good Health and Safety practices when lifting or moving

machinery. When it is necessary to have power connected to the machine

whilst covers are removed, always ensure that extreme caution is taken to

avoid personal injury.

The following service aids are available and must be used where indicated:

950-042 DigiVAC Rear Door Gear Cover

If a service procedure requires the DigiVAC to be operated with the rear door

open, exposed gears are a hazard to the engineer. This gear cover MUST be

fitted.

950-043 DigiVAC Rear Door Safety Switch Bypass

If a service procedure requires the DigiVAC to be operated with the rear door

open, the safety switch on the door must be bypassed. Note: the gear cover

must also be fitted.

1.1.2 Operation

Operating instructions are included in the relevant Operating Manual. They

are not repeated here in this Service Manual.

1.1 Introduction

Rear Door

Gear Cover

Rear Door Safety

Switch Bypass

2Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04

Overview • Introduction

1.1.3 Orientation

Where procedures refer to the R/H (right hand) or L/H (left hand) side of the

machine, this is always as viewed from the front, feed bin end of the machine.

Figure 1:1

1.1.4 Test Paper

Ensure that a supply of paper is available for testing purposes. This should ide-

ally be A4 and A3 (or 8½ x 11” and 11 x 17”). Check that the paper is cut

square and to the correct size before making any changes to the machine.

1.1.5 Metric and Imperial measurements

In most cases metric measurements and specifications are used in this manual.

A conversion chart is included in this manual (see Section 9.1). The DigiVAC

control panels can be set to use either metric or imperial measurements, refer

to the relevant operating manual.

1.1.6 Moving the DigiVAC

Over small distances, the DigiVAC can be moved by raising the jacking screw

and pushing it on its integral wheels. For longer distances, the DigiVAC is

supplied with transport wheels which should be used (see Section 7.2).

Figure 1:2

Front of the DigiVAC

Overview • Modules & Configuration

Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04 3

Warning The DigiVAC is extremely heavy. Please observe good Health and Safety

practices when lifting or moving machinery.

The Watkiss DigiVAC Collator is a modular, vertical paper collating system,

built from a range of compatible modules. Two different versions are availa-

ble, the DigiVAC Standard and the DigiVAC+.

1.2.1 DigiVAC Standard

The DigiVAC Standard is available with 8 or 12 bins. It has a 5-digit counter

with total count and preset count.

Compatible accessories: X-Jogger, Straight Jogger, BookMaster range of

bookletmakers and trimmers.

1.2.2 DigiVAC+

The DigiVAC+ is available with 8 or 12 bins. Two towers can be linked

together (three towers at a future date). It has a Graphical User Interface (GUI)

comprising an 8.2" colour touch-screen, connecting cable and central process-

ing unit (CPU).

Compatible accessories: X-Jogger, Straight Jogger, BookMaster range of

bookletmakers and trimmers, Watkiss Automatic Stitch-Fold & Trim.

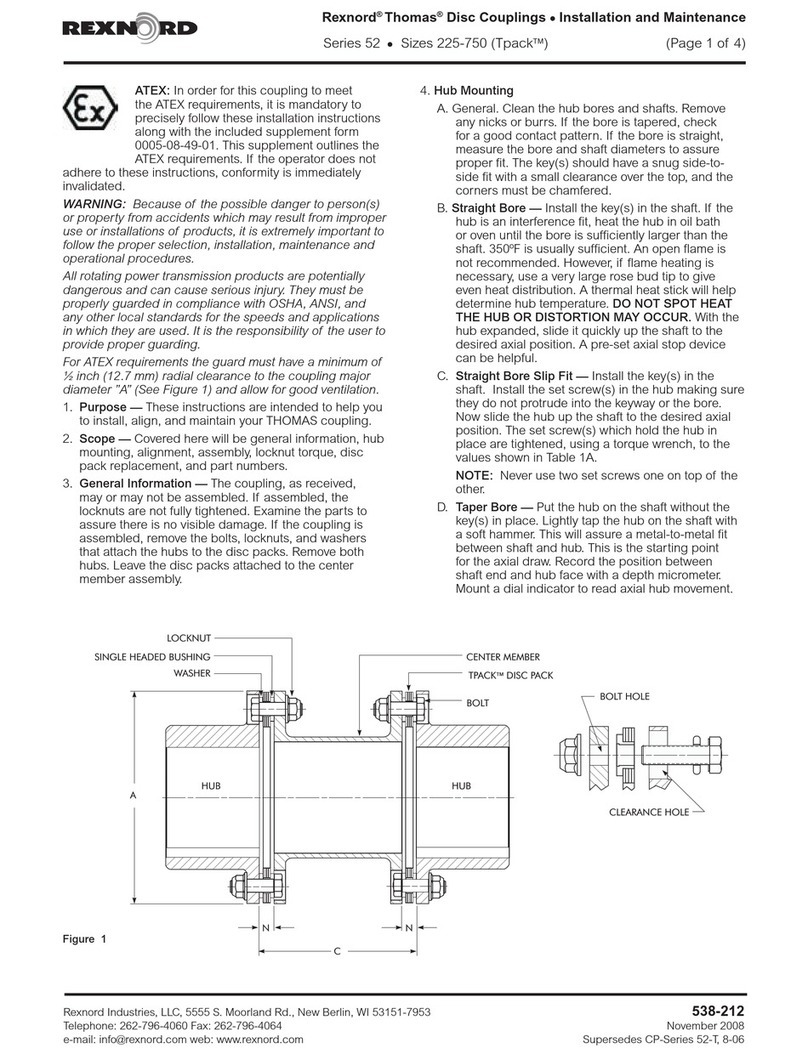

1.2.3 Modules

The illustration below shows the modules which make up a DigiVAC collating

system.

1.2 Modules & Configuration

4Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04

Overview • Modules & Configuration

Figure 1:3

The table below lists the modules available for the DigiVAC Collator, some

of these are modules that may be used independently of the Watkiss DigiVAC

(e.g. BookMaster). The table gives the product abbreviation, the name, the fac-

tory part number and the module software address for each complete module

assembly.

Service information for ancillary equipment is provided in separate service

manuals:

• BookMaster Service Manual - part no. 969-240

• Automatic Stitch Fold & Trim - part no. 969-270

• SpineMaster Service Manual - part no. 969-230

Module Address: The module address is used by the system software to iden-

tify and control certain modules. The individual feed bins are identified by an

address number from 1 to 12, whilst the other modules use 17 upwards. Not

all modules need a module address.

Tower A Tower B

!

!

"#$

%

&

'

(

)

*

)

+

+Rear Door (DRDR or DNRD)

"Booklet Maker (DBMS, DBMP or DASF)

%Trimmer (DTMS, DTMP or DATR)

'Outfeed Conveyor (DBOC or DCNV)

!Tower B Top Module, including bridge

,(not illustrated) Straight Jogger

#Base Module (DBAS)

&First 4 Feeders (DF4F)

)Add-on 4 Feeders (DA4F)

*Control Panel (DCTL or DGUI)

(Top Module (DTOP)

$X-Jogger (DXJG)

Overview • Modules & Configuration

Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04 5

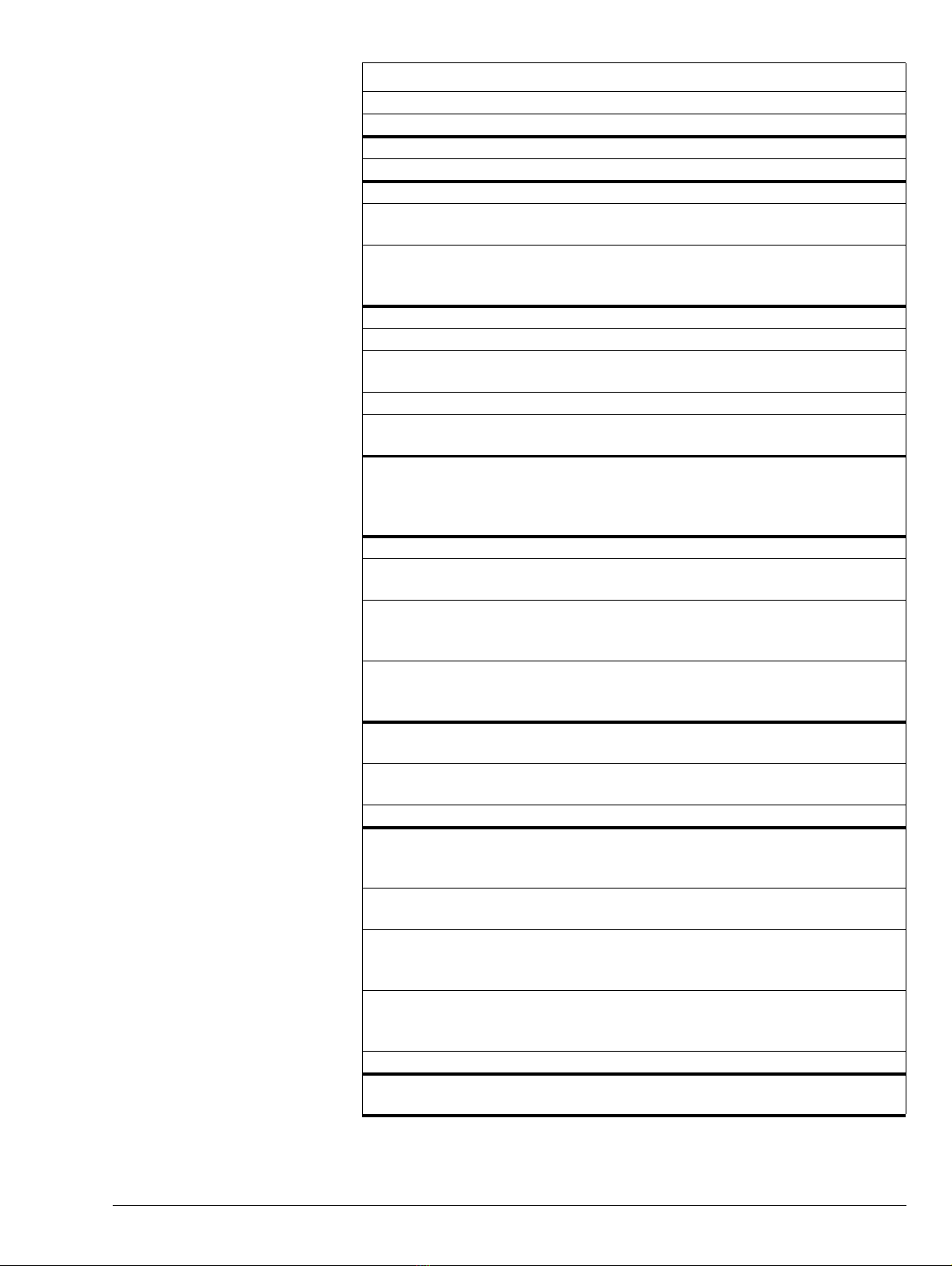

CODE MODULE NAME PART NO. ADDRESS

DTOP DigiVAC Top Module 032-100

DTWB DigiVAC+ Tower B Top Module 032-101 21

DCTL DigiVAC Standard Control Panel 032-130

DGUI DigiVAC+ GUI Control Panel 032-131

DF4F DigiVAC First 4 Feeders 032-150 1/2/3/4

DA4F DigiVAC Add-on 4 Feeders 032-151 5/6/7/8 &

9/10/11/12

DigiVAC Add-On 4 Feeders

(incl Installation Kit, comprising conveyor and

rear door extensions)

032-152 5/6/7/8 &

9/10/11/12

DRDR DigiVAC Rear Door - to suit 8 bins 032-160

DigiVAC Rear Door extension to suit 12 bins 032-161

DNRD DigiVAC Rear Door, for connection to Nagel

BookletMaker 032-163

DigiVAC+, Tower B Rear Door to suit 8 bins 032-164

DigiVAC+, Tower B Rear Door extension to suit

12 bins 032-165

DBAS DigiVAC Base Module 200V, 50/(60)Hz

210V, 60Hz

230V, 50Hz

240V, 50Hz

032-200

032-201

032-203

032-204

17

DXJG DigiVAC X-Jogger 032-320

DigiVAC X-Jogger including Front Outfeed

Conveyor 032-321

DJGR DigiVAC Straight Jogger 110V

(Discontinued from July 2003) 115V

230V

032-322

032-323

032-324

AJGR Straight Stack Jogger, Adjustable 110V

Height (from July 2003) 115V

230V

050-050

050-051

050-052

DASF DigiVAC Automatic Stitch/Fold 115V

230V 041-533

041-534

DATR DigiVAC Automatic Trimmer 115V

230V 041-543

041-544

DCNV DigiVAC Stitch/Fold/Trim Outfeed Conveyor 041-524

DBMP DigiVAC BookMaster Pro incl. BCP

& Interface Kit 230V

115V 041-564

041-565

DTMP DigiVAC TrimMaster Pro 115V

230V 041-593

041-594

DBMS DigiVAC BookMaster Standard 100V

115V

230V

041-566

041-567

041-568

DTMS DigiVAC TrimMaster Standard 100V

115V

230V

041-584

041-585

041-586

BOC BookMaster Outfeed Conveyor 041-570

DASM DigiVAC Automatic SpineMaster 115V 60Hz

230V 50Hz 062-011

062-012 DASM

6Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04

Overview • System Overview

The major elements of the DigiVAC modular collating system are shown

below.

Figure 1:4 The DigiVAC System

All systems comprise:

• Base Module

• Top Module

• Control Panel - GUI or Eco

• First 4 Feeders Module

• 1 or 2 x Add on 4 Feeders Module

Base Module: The Base Module houses the drive motor, vacuum and blow

pumps and associated electronics required for the DigiVAC’s operation. The

base also includes a toroidal transformer on all except 240V machines - see

Section 4.1.2 on 65 for details of transformer tappings.

The DigiVAC Base Module Rel.B was introduced at Serial No. 150 (Techni-

cal Bulletin 150 refers). The Rel.B base includes a 3-phase motor and

SMD8200 Inverter. The inverter takes a single-phase 50/60Hz 180-264V AC

electrical supply and inverts it to 230V AC 50Hz three-phase output for the

1.3 System Overview

SMD 8200 INVERTER

905-386 (S/N150+)

MOTOR DRIVE PCB

900-192 (S/N<150)

DRIVE

MOTOR

(S/N150+

3 PHASE)

Overview • System Overview

Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04 7

Drive Motor. This ensures consistent revolution speed regardless of load

exerted on the machine and is essential for two-tower operation. Rel.B bases

require software V2.1a or later.

Top Module: The top module transports the collated sheets over the top drum

and down into the rear conveyor. In two tower configurations, Tower B has a

different top module which includes the connecting bridge.

DigiVAC Standard Control Panel: The DigiVAC Standard is fitted with a

touch membrane control panel which includes the display, control panel keys,

and speed control. In order to change the software of the DigiVAC Standard,

the Eprom must be changed.

DigiVAC+ Control Panel: The DigiVAC+ is fitted with a Graphical User

Interface (GUI). This consists of a Central Processing Unit (CPU) housed in

the Base Module, a link cable and a touch-screen. The CPU holds the boot

firmware and application software that controls the DigiVAC+ and the opera-

tion of the touch-screen.

System Power: Power enters the Base Module via the input fuses next to the

input connector, EMI filters and double pole isolation on/off switch. From

here it goes via the torroidal transformer (except on 240V machines) which

supplies the Interface PCB in the Base Module. The Interface PCB distributes

power throughout the machine.

Drive Motor: The drive motor turns the drive belts which in turn drive the

feed system in each bin. The feed timing is controlled by a clutch on the clutch

drive shaft of each bin. A tachometer located on the end of the drive motor

shaft provides the master timing signal for the whole system.

Communications: The Interface PCB is connected by separate power and

communications cables to each of the feed modules. Each 4-bin feeder module

has its own PCB. The feeder module PCB interprets instructions from the Con-

trol Panel. The feed bin PCB controls each bin clutch so that drive is engaged

at the exact moment and for the correct duration required.

Paper Sensors: Sensors on each bin provide feedback via the PCB to the

Interface PCB/Control Panel for the detection of double feed, miss feed and

empty bin conditions. A message is displayed on the control panel relating to

each condition.

System Air: The blower motor delivers air throughout the system for sheet

separation. Air passes to each bin through connected vertical pipes (sealed

with ‘O’ rings). The air blow in each bin can be controlled using the air taps

(see operating manual). The air blow is regulated by the 900-187 Air Blow

Control PCB.

The vacuum pump delivers vacuum throughout the system through connected

vertical pipes. Each feed bin has an individual valve and filter. The valve is

switched on and off by the main interface PCB. The vacuum pressure is fac-

tory set.

Paper Transport: Sheets are transported by dual conveyor belts upwards,

over a wide diameter drum at the top of the machine, and then down into jog-

ger or booklet-maker. Transporting the sheets upwards gives the paper a long,

straight path into the online finishing equipment.

8Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04

Overview • Fuses

Paper Feeding: In each bin, the stack of paper is elevated on an air bed. The

bottom sheet of the stack is separated by means of air separation, and it is then

transported forwards by a vacuum conveyor. The sheet passes through a spe-

cially shaped gate and into the conveyor system. There are no operator adjust-

ments to the gate, the air blow, the vacuum or the tray height. The only

adjustment is to the profile of the vacuum conveyor.

Jogging: Two joggers are available for the DigiVAC. The X-Jogger stacks

and jogs sets either straight or with a 20° offset. It fits onto mounting pegs on

the front of the DigiVAC. The Straight Jogger is free standing, at either the

front or rear of the DigiVAC.

Note: To deliver sets to the front of the DigiVAC, the Front Outfeed Conveyor

must be fitted.

Multi Tower Systems: Multi-tower systems are only possible with the Digi-

VAC+. Two DigiVAC+ towers can be linked to give up to 24 bins. The top

module of Tower B includes connecting bridge which transports paper and

carries the communication between the two towers. The rear door on Tower B

is also different. The control panel is located on Tower A.

Figure 1:5

Fuses on the PCBs protect the motors and the voltage rails in the system.

Warning When changing a fuse, always ensure that the power is switched off and the

mains disconnected. Also ensure that the fuse holder grips the fuse firmly. A

loose fuse holder may cause connection problems. If needed, bend the tabs on

the holder to tighten the fit.

1.4 Fuses

LOCATION FUSE FUNCTION RATING

Mains input

socket - 12.5A Ceramic, Anti-surge, T

DigiVAC Base PCB F1 3.15A Glass, Anti-surge, T

F2 6.3A Glass, Anti-surge, T

DigiVAC Base

Power PCB F4 X-Jogger 2.0A Glass, Anti-surge, T

F5 Drive Motor 3.15A Glass, Anti-surge, T

X-Jogger PCB F1 X-Jogger 2.0A Glass, Anti-surge, T

Transformer Transformer 3.15A Ceramic, Anti-surge, T

Overview • Fuses

Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04 9

FUSE SYMPTOMS OF FAILURE

DigiVAC Standard DigiVAC+

Mains input socket No mains switch illumination No mains switch illumination

Machine Dead Machine Dead

DigiVAC Base PCB F1 Control Panel Dead Control Panel Dead

Transformer LED on Transformer LED on

Machine Dead Machine Dead

DigiVAC Base PCB F2 Machine will start, but no

feed occurs showing up on

the bin as a Jam

‘PSU VOLTAGE ERROR: 28v’

message is displayed

No Jog or Oscillate Function

is available

DigiVAC Base Power

PCB F4 No Jog function ‘No Power to Stacker’ mes-

sage displayed

No Oscillate function selecta-

ble from the panel XJOG Mimic shows yellow

DigiVAC Base Power

PCB F5 Motor Stalled Error Motor Stalled Error

X-Jogger PCB F1 No Oscillate function ‘No Power to Stacker’ mes-

sage displayed

XJOG Mimic shows yellow

Transformer Mains switch is illuminated Mains switch is illuminated

LED on the transformer is

not illuminated LED on the transformer is

not illuminated

Machine Dead Machine Dead

10 Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04

Overview • Fuses

Tools & Materials • Recommended Tools

Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04 11

Chapter 2 Tools & Materials

It is recommended that Watkiss engineers carry the following tools and mate-

rials with them. Watkiss part numbers are included where relevant, although

many of the recommendations are standard tools which are readily available.

Some of the tools listed are not required directly for servicing the DigiVAC,

but are be required for DigiVAC accessories such as the Automatic Stitch-

Fold & Trim units and the BookMaster and TrimMaster range.

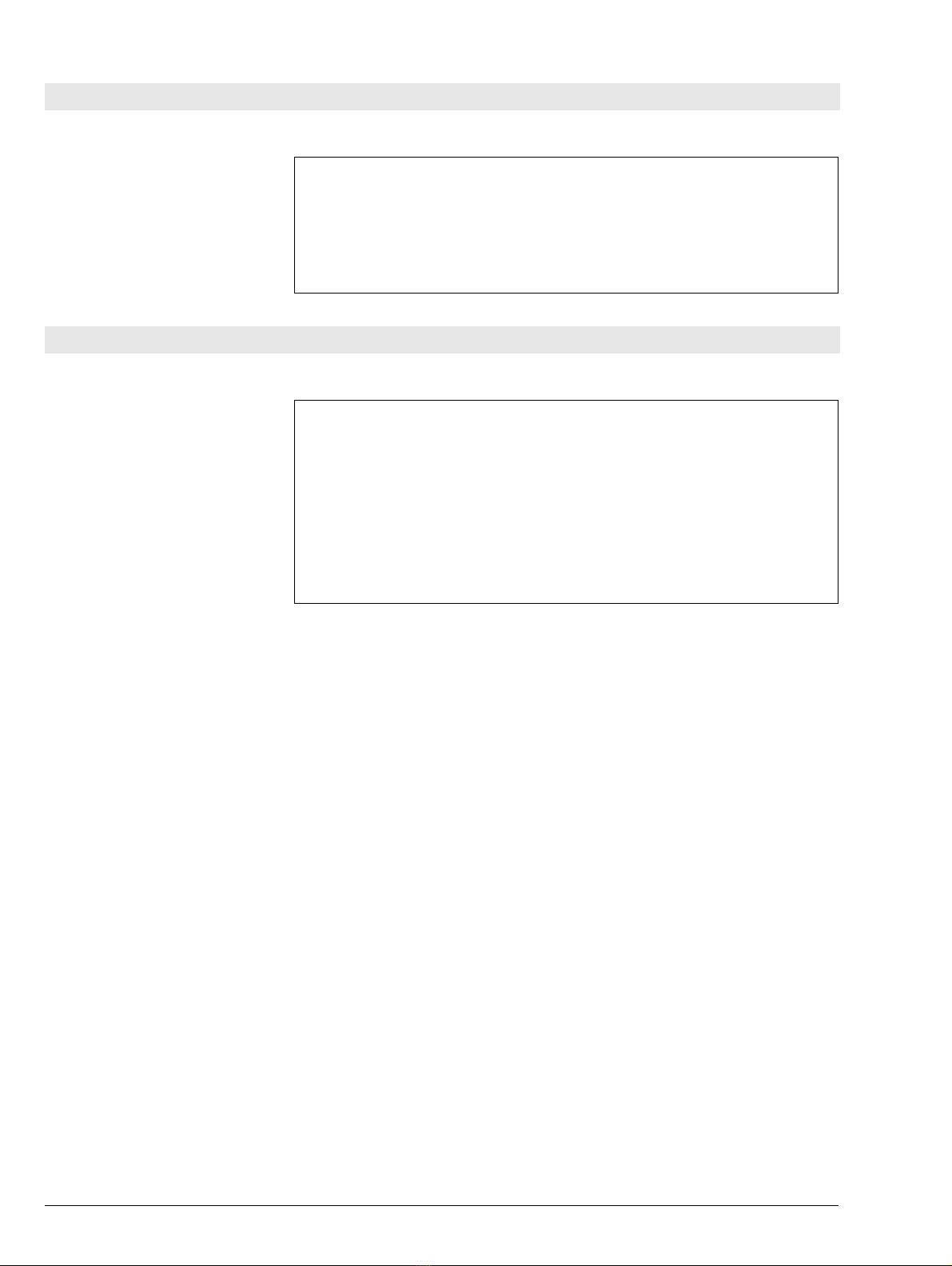

2.1 Recommended Tools

WATKISS

PART NO. DESCRIPTION

952-030 Screwdriver - POZI, No 3 - long

952-026 Screwdriver - Electrical + Neon

952-060 Spanner - Combination, 5.5mm

952-062 Spanner - Combination, 7mm (M4)

952-063 Spanner - Combination, 8mm (M5)

952-066 Spanner - Combination, 10mm (M6)

952-067 Spanner - Combination, 13mm (M8)

952-002 Special Tool - Spanner - single end, 17mm (M10)

952-003 Special Tool - Nut Spinner - short, 10mm (M6)

952-053 Pliers - Long Nose, small

952-056 Pliers - Side Cutters, small

952-043 Allen Key ‘L’ - 2.0mm

952-044 Allen Key ‘L’ - 2.5mm

952-045 Allen Key ‘L’ - 3.0mm

952-046 Allen Key ‘L’ - 4.0mm

952-047 Allen Key ‘L’ - 5.0mm

952-093 Handled Allen Key - 2.0mm

952-092 Handled Allen Key - 2.5mm

952-091 Handled Allen Key - 3.0mm

952-090 Handled Allen Key - 4.0mm

Ball Ended Allen Key - 1.5mm

952-096 Ball Ended Handled Allen Key - 3.0mm

952-006 Knife - Scalpel Handle

952-007 Knife - Scalpel Blade (10A)

952-004 6” Rule

952-193 M5 Tap

Tap Wrench

3,4,5mm Pin Punches

952-404 3/4LB Ball Pein Hammer

955-001 7mm AF Nut Runner

12 Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04

Tools & Materials • Consumables

2.2 Consumables

WATKISS

PART NO. DESCRIPTION

Lint Free Cloth

951-007 Loctite 242 (thread locking compound)

951-023 Loctite Retainer 641 (weak retaining compound)

Light Oil (SA30/40)

2.3 Service Aids

WATKISS

PART NO. DESCRIPTION

Digital Multi Meter

370-052 Bin Sensor Calibration Stock

950-041 Tray Gauge - 2 off

950-042 Rear Door Gear Cover

950-043 Safety Switch Bypass

950-044 Blow Gauge

950-045 Vacuum Gauge

Service Procedures • General Service Procedures

Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04 13

Chapter 3 Service Procedures

Service Aids for Safety

The following service aids are available and must be used where indicated:

950-042 DigiVAC Rear Door Gear Cover

If a service procedure requires the DigiVAC to be operated with the rear door

open, exposed gears are a hazard to the engineer. This gear cover MUST be

fitted.

950-043 DigiVAC Rear Door Safety Switch Bypass

If a service procedure requires the DigiVAC to be operated with the rear door

open, the safety switch on the door must be bypassed. Note: the gear cover

must also be fitted.

3.1.1 Bin Test Mode

For some service procedures, it is necessary or helpful to put individual bin

modules, into test mode. This allows some functions to be tested without using

whole-machine communications including:

• Detector function

• Tray empty sensor function

• Clutch function

• Valve function

• Feed drive belt tension

Procedure

1. Switch off the DigiVAC at the mains ON/OFF switch.

2. Press and hold one of the bin ON/OFF switches on the relevant module

whilst switching the mains power back on. The bin module is now in Test

Mode.

Tip: To put all bin modules into Test Mode, press one of the bin ON/OFF

switches on each bin module whilst switching on the power.

3.1 General Service Procedures

Rear Door

Gear Cover

Rear Door Safety

Switch Bypass

14 Watkiss DigiVAC Service Manual - Issue 2 - 29/11/04

Service Procedures • General Service Procedures

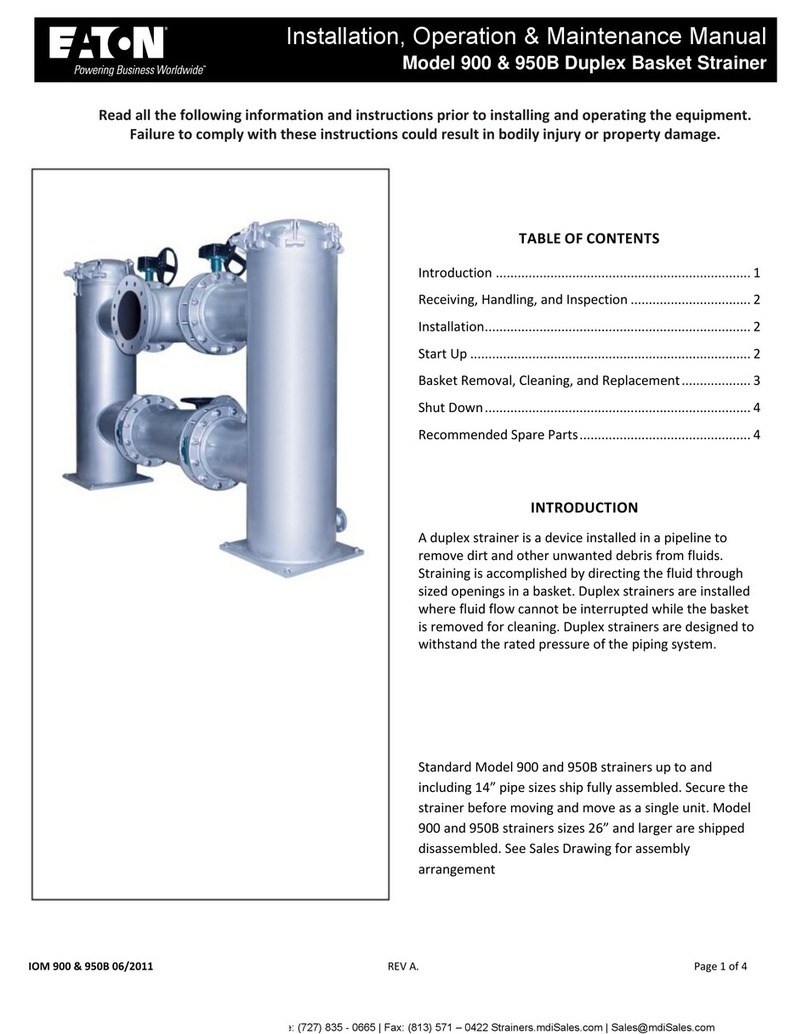

3.1.2 Removing the Rear Conveyor Assembly

For many service procedures it is necessary to remove the rear conveyor

assembly.

Procedure

1. Push conveyor to the left against the spring pressure

2. Pull the right edge of the conveyor outwards

3. Ease the conveyor assembly downwards and lift it clear of the collator

Figure 3:1 Removing the rear conveyor assembly

After refitting the rear conveyor, make sure all the conveyor belts are correctly

aligned.

3.1.3 Removing the Rear Deflector Plates

For many service procedures it is necessary to remove the rear deflector plates.

Figure 3:2 Rear Deflector Plates

There are two possible methods of removing a rear deflector plate:

• Remove both M5 button head screws and lift the plate clear.

• Remove the M5 button head screw on the R/H side of the machine (this

is the left hand screw when viewed from the rear of the machine). Then

loosen the L/H screw and the plate can be eased out.

1

2

3

1. Push conveyor to the left against

the spring pressure

2. Pull the right edge of the con-

veyor outwards

3. Ease the conveyor assembly

downwards and lift it clear of the

collator

Deflector Plates

Conveyor Wheels

Table of contents

Other Watkiss Industrial Equipment manuals