Service Manual

Remote Control Cable/Radio

555

•Under all circumstances, keep the boom suffi-

ciently away from obstacles such as boom cranes,

scaffolds, buildings, etc.

• The placing boom must never be used as a

crane for lifting materials.

• The length of the end hose must not exceed 4

meters (13 feet) in length. The end hose should not

be kinked during pumping operations. The safety

cable between the boom pipeline and the end hose

must be in place and attached.

• If end hose is replaced with a combination of

reducers and hoses (for example, a 5-4 reducer and

4” hose), then all hoses, reducers, etc. must be fas-

tened with safety cables and may not exceed the

weight of the recommended end hose. Any of the

above mentioned items should be capable of han-

dling the pumping pressures of the specific equip-

ment.

• Perform regular maintenance and lubrication

of boom at 1 year prescribed intervals and do a

complete check of the boom and tower annually

using Schwing America’s “Regular Check-Up

Concrete Placing Booms” form, SAE-510. This

form is supplied with all units and is available from

Schwing America.

Pipelines

•PIPELINE AND CLAMPS MUST BE SUFFI-

CIENT FOR PUMP CAPABILITY.

• The pipeline connections must not be opened

under working pressure. Before the pipeline is

opened, pressure must be relieved by sucking back

the concrete. Secure couplings after assembly of

the pipeline.

• Because of the increased danger of accidents,

the following important points must be adhered to

when blowing out the pipeline with compressed

air:

a. Blowing-out should be performed under the

supervision of an expert.

b. No pipe bends or hoses should be connected to

the end of the pipeline during the blow-out

process.

c. No person is allowed to be next to the concrete

discharge end.

d. A catch basket must be fitted to the concrete

outlet.

e. The concrete outlet should be positioned high

enough to permit easy discharge of the con-

crete.

f. The pipe cleaning head must be equipped with

a working gauge and a properly sized air regu-

lator hand valve.

g. The plug must be long enough to ensure air

tight sealing of the pipeline at the catch basket

after the pipeline has been blown out.

h. The plug must be tight-fitting to prevent com-

pressed air from flowing around the plug and

into the concrete.

i. Work at the pipeline is allowed only after the

pipeline has been relieved of compressed air.

Ensure that the air pressure has been com-

pletely relieved.

j. Single pipe sections and short pipes up to a

length of 40 feet must not be blown out. Great

danger of accidents exists because of rapid

expulsion due to too little mass!

• When laying pipeline, use as few bends as pos-

sible. Horizontal pipelines must be adequately sup-

ported. When installing a vertical pipeline, the best

method is to use upright struts supporting the low-

est vertical pipe. Each succeeding pipe should then

be anchored to the building.

• It is preferable to install pipelines within build-

ings whenever possible. See operator’s manual and

“Pumping Concrete” booklets for more informa-

tion on pipeline installation.

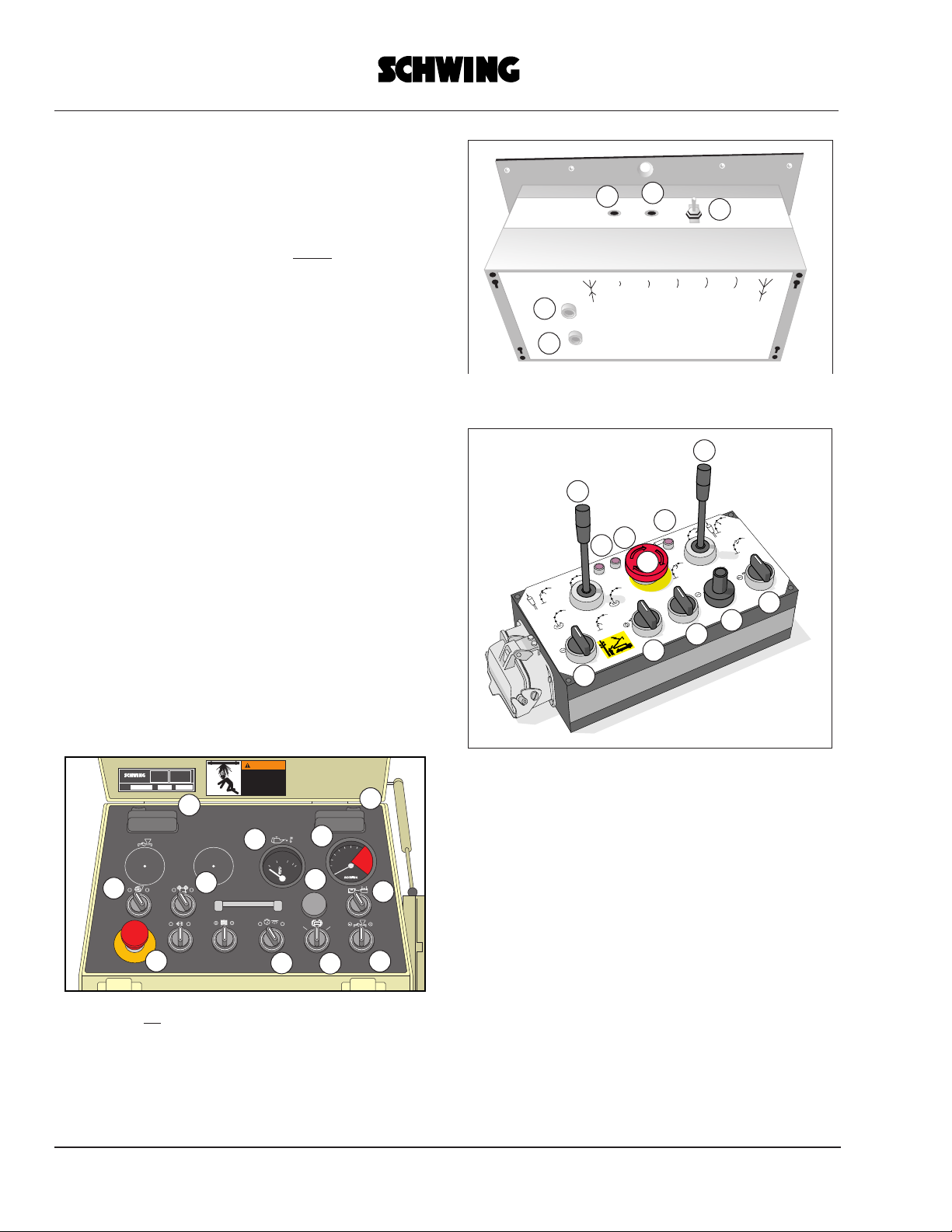

Remote Controls

•To avoid unintended operating movements of

the machine, set all control levers or switches in

the operator’s cabin and on the remote control

panel to the neutral position prior to any switch-

over to local or remote control and prior to discon-

nection of the remote control line.

Electrical Connections on the site-

Hydraulic Power Packs, etc.

•The power supply connection for electrically

driven stationary concrete pumps or the electric

power packs for pumps or booms has to be

arranged by the contractor.

• The power supply on construction sites,

according to VDE 0100 paragraph 55, may be

taken only from a special feed point, e. g. an elec-

trical distribution box with current-operated