SCORPIO TECHNOLOGY TRANSISTOR TESTER User manual

1

TRANSISTOR TESTER

CONTENTS:

Section 1: General and Planning Information

Section 2: Components and Material Required

Section 3: Assembly

Section 4: Wiring

Section 5; Testing

Section 6: Theory –How the Circuit Works

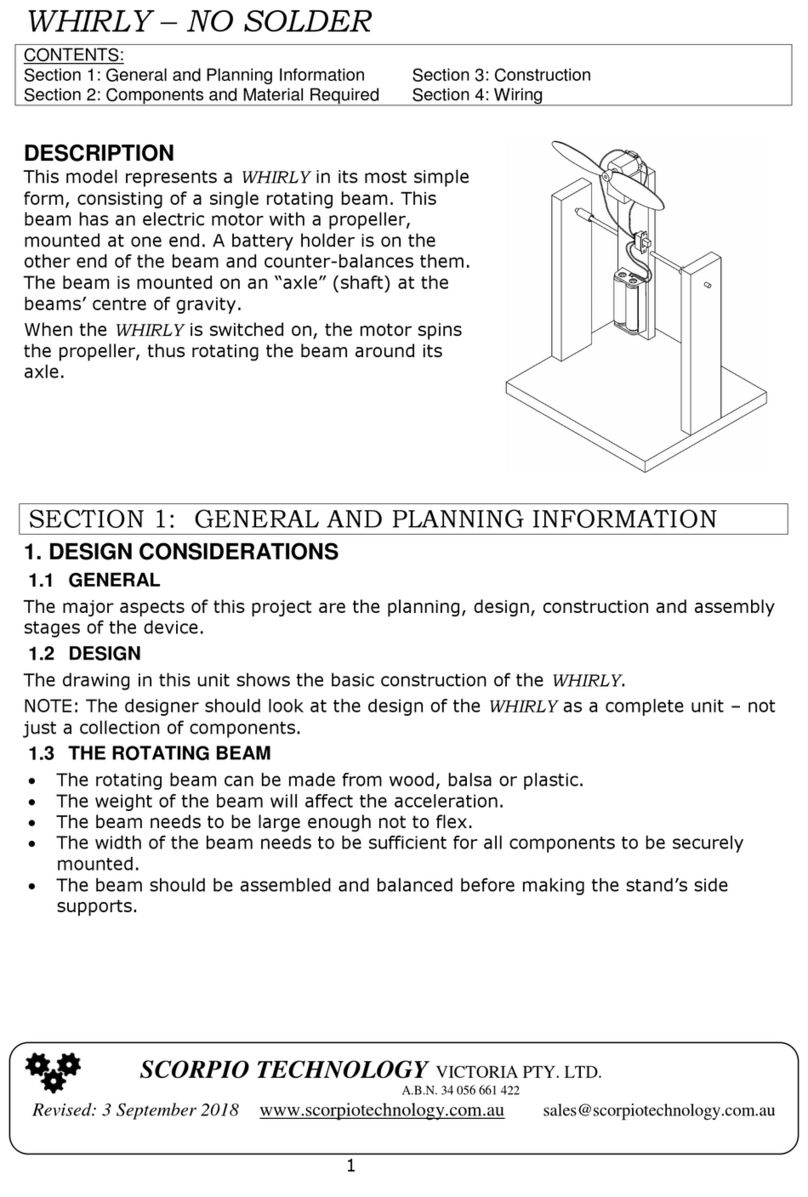

DESCRIPTION

This device is used to detect a faulty

transistor, within an assembled PCB.

The testing can be carried out on the

PCB's components, so that only the

faulty transistor needs to be removed

and replaced. The TRANSISTOR TESTER

PCB and components are small

enough to fit into a small plastic box,

making it very portable.

SECTION 1: GENERAL AND PLANNING INFORMATION

1. DESIGN CONSIDERATIONS

1.1 GENERAL

Locating a faulty transistor on a circuit board, crowded with soldered in place

components, can be a difficult proposition. With an in-circuit TRANSISTOR TESTER,

however, the component's general quality can be determined, while avoiding damage

to other components and/or the foil pattern, due to excessive soldering iron heat. The

TRANSISTOR TESTER described here will indicate whether a suspect transistor is good or

faulty and, as bonus, tell you the component's type (PNP or NPN).

A pair of flashing LED’s indicates the transistor's condition. One LED flashes if the

transistor is a functional PNP type, while the other LED flashes if the transistor is a

good NPN type. If the transistor is faulty, either both LEDs will flash or neither will

flash, depending on the type of failure.

SECTION 2: COMPONENTS & MATERIAL REQUIRED

2.1 COMPONENTS SUPPLIED

The following components are supplied in the kit:

SCORPIO TECHNOLOGY VICTORIA PTY. LTD.

A.B.N. 34 056 661 422

17 Inverell Ave., Mt. Waverley, Vic. 3149 Tel: (03) 9802 9913 Fax: (03) 9887 8158

Revised: 11 September 2015 www.scorpiotechnology.com.au sales@scorpiotechnology.com.au

Issued: 17 February 2013 www.scorpiotechnology.com.au

sales@scorpiotechnology.com.au

2

2.2 ADDITIONAL REQUIREMENTS

The following material is to be supplied by the student / designer:

Battery - 9V

Electric hook-up wire –Multi-strand in assorted colours

2.3 TOOLS REQUIRED

The following tools are required:

Assorted hand tools

Soldering equipment and solder

Drill bit –1.5mm

Drill bit –7.0mm

SECTION 3: ASSEMBLY

3.1 PCB ASSEMBLY

Insert components onto

the PCB from the non-

track side, with the leads

coming out on the track

side. Slightly bend the

leads, to keep the

components in place.

Always check to ensure

that the components are

oriented correctly (as

per the PCB and

instructions).

Incorrect orientation of

components will cause

the TRANSISTOR TESTER to

malfunction. It may also

cause damage to some

components.

Mount the resistors (R1

to R5). Use the colour

coded bands to identify

each resistor. Place them

in the positions shown

on the PCB overlay.

3

Mount the diodes (D1 to D4): these have a glass body, with a black band near one

end to identify the negative end. Make sure the ends with the bands around them

are placed in the same direction as shown on the diagram.

Insert the two Integrated Circuit (IC) sockets. The notch at the end of the socket

must be facing the same direction as shown in the overlay diagram.

Insert the electrolytic capacitor (C1). The negative lead is marked with a stripe on

the body and is also the longer of the two leads.

Check the components on the circuit board against the diagram. Ensure that all the

components are in their proper positions and are correctly oriented.

Solder the components in place.

Insert the two integrated circuits into the sockets. It is important that the sockets

are facing in the correct direction. The notches on the integrated circuits must face

in the same direction as the notch on the socket and as shown on the diagram. If

available, use an IC inserter to insert IC2 (4027).

3.2 MAKING THE FRONT PANEL

Cut three different coloured wires, each 300 mm long. Strip about 15mm of

insulation from both ends of each wire, and twist the bared strands.

Remove the top covers from the three test clips, and slide the covers onto the

wires. Solder them to the test clips. Push the covers back onto the test clips.

Cut out one of the "Front Panel" pictures

(at the end of this unit). Position this Front

panel on the cover of the slide box. Using

a sharp scriber mark the positions for the

six holes, which have to be drilled in the

top of the slide box.

Place a piece of wood underneath the slide

box lid. The wood must fit up against the

inside of the lid, so when you drill the lid,

it will not crack. Drill the holes using a

slow drilling speed. Clean up any burrs

around the holes.

Glue the cut out of the front panel in

place, making sure the hole positions line

up with the drilled holes. Cover the paper

panel with clear contact, cut out the holes

and trim to size with a sharp knife.

3.3 ASSEMBLY TO THE FRONT PANEL

Press the LED holders into place on the cover.

WARNING: If the ICs are placed the wrong way around, the IC's will be permanently

damaged when the battery is connected to the circuit.

WARNING: The 4027 IC is a CMOS type and can easily be damaged by static

electricity from your fingers. If you do not have an IC inserter, you must first

make sure that any static build up in your body is discharged. To do this you must

touch the metal body of an earthed appliance immediately before handling the 1C.

This should be done at the location you are working in.

Walking across the room, touching the earthed appliance and walking back to your

work bench will NOT work. Static buildup can occur during this time.

4

Solder the wires from the PCB to the pushbutton switch. Fit the pushbutton switch

into position on the cover, in the hole marked "Test".

Fit the push button switch on the cover.

Feed the test clips wires through the holes marked C, B and E (refer front panel

drawing). Pull through about 50 mm of wire and tie a knot in each wire (from

underneath). This is to prevent the wires being pulled back through the holes, and

stops them from being broken from the circuit board.

Solder the test clips wires to the PCB, taking care that the wires for C, B and E go

to their correct positions.

Push the LED holders into the holes

above where PNP and NPN are

marked.

Carefully push the two LEDs into the

LED holders. Make sure the LEDs for

NPN and PNP go in their correct

positions.

Push the LEDs up into their holders as shown below. Slide up the ring over the

LED’s legs and push it up until it snaps into place.

Solder the wires from the two LEDs to the PCB. The positive and negative leads

must be correctly positioned

Carefully check the components, orientation and wiring against the layout diagram.

3.3.1. IDENTIFYING A LED’s NEGATIVE LEAD

LEDs have a positive (Anode) and negative (Cathode) lead and

may use one or more methods to identify the negative lead.

These are shown in the diagram.

The methods are:

The flag (the larger connection inside the body) identifies the

negative lead. This is visible when the LED is held up to the

light. Most types of LEDs use this method.

The shortest leg is negative.

A flat on the ridge around the base of the LED is on the

negative side.

SECTION 4: WIRING

4.1 ASSEMBLING THE PCB TO THE TESTER

Cut two wires, each no longer than 100 mm. Strip about 10 mm of the plastic

insulation from both ends.

Solder these 2 wires to the PCB for the push button switch (these wires will be

attached to the switch later).

Connect the battery clip to the PCB. Make sure that the red (positive +) and black

(negative -) leads go to the appropriate positions on the PCB.

Cut two Red and two Black leads, each 100 mm long. Strip about 10mm of

insulation from one end of each, and about 20 mm from the other end.

WARNING: Take care when soldering the wires to the switch terminals - overheating

can damage the plastic body of the switch.

NOTE: When working with fine multi-strand wires, the bare wires of each end

should be tightly twisted together and “tinned” before being soldered to any

component.

5

Wrap the 20mm length of one black lead around the negative leg of LED1.

Similarly, connect one red wire to the positive leg of that LED.

Repeat the above step for LED2, using the second red and black wires.

Solder these wires to the LEDs. Slide a short piece of 2mm plastic tubing up over

at least one of the legs on each LED, to prevent the wires from touching each other

and shorting out.

SECTION 5: TESTING

5.1 TESTING

Connect a 9 volt battery.

Select the NPN transistor and connect the transistor's Collector, Base and Emitter

leads to the C, B and E test clips (respectively). When the "Test" button is pressed,

the NPN LED should flash on and off to indicate the NPN transistor is functioning.

Repeat the above using a PNP transistor.

If the TRANSISTOR TESTER is working correctly, fit the battery inside the unit and

attach the lid. The TRANSISTOR TESTER is now complete, and ready for fault finding.

5.2 TROUBLESHOOTING

Check that that positive (red) and negative (black) battery leads go to their correct

positions on the PCB.

Check if the battery has adequate charge.

Check if the positive and negative leads to an LED or both LED's are reversed.

Check that bare wire ends do not touch.

Check if the wiring is connected as per the PCB overlay.

Check that all the components are in the right positions and facing in the correct

directions.

Check for short circuits, especially where solder connects across from one track to

another. Note that pins 1 through to 8 on IC2 are connected.

Check that there are no solder bridges between the terminals.

Check your soldering. Make sure there are no dry joints - the soldering may look

dry or lumpy or you may notice the solder around a lead does not actually connect

to the lead. This will look like a dark ring around the lead: try pulling the

component up to see if the lead comes out or moves, (a magnifying glass or eye

piece will help)

If you have checked all of the above, there may be a faulty or damaged component.

Test them individually or replace them.

SECTION 6: THEORY - HOW THE CIRCUIT WORKS

The TRANSISTOR TESTER circuit is based on a 555 (IC1) timer operating as a 12 Hz

multivibrator. The output at pin 3 drives one flip-flop of IC2. This flip-flop divides the

WARNING: When using the

TRANSISTOR TESTER

, power to the circuit under test must

be removed. Failure to do so will either result in incorrect readings or damage to

the TESTER.

NOTE: One of each transistor type - i.e. an NPN and a PNP - should be used to test

your

TRANSISTOR TESTER

. If you have a known faulty transistor available, it also can

be used.

6

input frequency by two, but more importantly, delivers complementary voltage

outputs at pins 15 of 1C1 (Q) and 14 (not-Q).

These complementary outputs are connected to indicators LED1 and LED2 via current-

limiting resistor R3. The LED's are arranged so that when the polarity across the

circuit is one way, only one LED will be illuminated, and when the polarity is the

reverse of that, the other LED is illuminated. Thus, when no transistor is being tested,

the LEDs flash alternately. The IC2 complementary outputs are also connected to

resistor network R4 and R5. The junction of these two resistors is connected to the

base of the transistor being tested.

With a good transistor connected to the B, C and E (Base, Collector and Emitter) clips,

when the correct voltage is applied to the three connectors, the transistor will turn on.

This produces a short circuit across the LED pair. For example, when a PNP transistor

is under test, during the interval when the Q output is low and the Q (not-Q) output is

high, the PNP device will turn on. In this mode, LED1 is shorted, LED2 is reverse

biased and, for that half cycle, neither LED will be illuminated. On the next half cycle,

the conditions of Q and not-Q are reversed with Q high and not-Q low. Under these

conditions, LED1 is off because it is reverse biased, and since the PNP transistor is cut

off, it does not prevent LED2 from being illuminated. Thus, when testing a good PNP

transistor, LED2 will flash, and when testing a good NPN type, LED1 will flash.

If the transistor under test is open circuit, both LEDs will flash. If the transistor has an

internal collector-to-emitter short circuit, neither LED will flash.

To compensate for low-valued resistors that may be present in the circuit being

tested, R4 is selected to supply a large amount of base current to the transistor under

test. This makes it possible to overcome in-circuit resistances across the collector-

base or base-emitter junctions of as little as 40 ohms.

Diodes D1 through D4 become important if the transistor being tested has an internal

short between its collector-base or base-emitter junctions. In such a case, half of the

transistor acts like a diode and would normally conduct and indicate a good transistor.

To overcome the possibility of this type of problem occurring, diodes D1 through D4

are added in series with the collector.

Other SCORPIO TECHNOLOGY Microcontroller manuals