Windup Torch Kit Essentials

www.kitronik.co.uk/2164

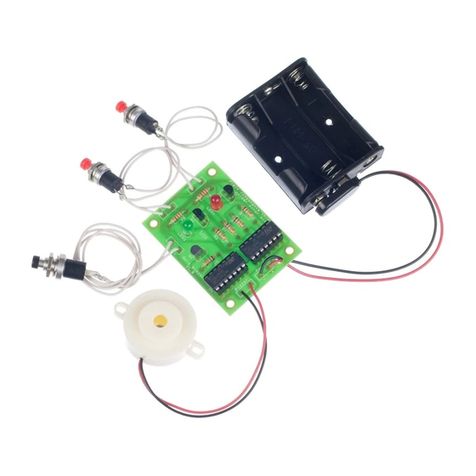

Checking Your Windup Torch PCB

Check the following before you wind up the torch for the first time.

Check diode 1 and 2 are positioned correctly, with the bands towards the version text

Check the Zener Diode (D2, marked 1N750) is positioned closest to the capacitor

Check that the capacitor is positioned correctly, with the -ve stripe on the side where the --- is indicated on

the PCB.

Check the LED is attached with the correct polarity.

Check the bottom of the board to ensure that:

All holes (except the two large mounting holes and one strain relief hole) are filled with the lead of a

component or wire.

All these leads are soldered.

Pins next to each other are not soldered together.

Using your torch

To use your torch simply wind the generator handle. After a few seconds of winding the LED should light up.

If it doesn’t try turning the handle the other direction.

The gearbox attached to the motor has a built in, self-resetting, clutch mechanism. This makes a clicking noise when

it is activated. Stop winding if you hear clicking and the clutch will reset. Try winding more gently if the clutch

continues to activate.

If your torch doesn’t stay lit long check the solder joints on the capacitor. A dry joint or a short will prevent the

capacitor from storing charge, and keeping the LED lit.

Some of the winding energy goes to lighting the LED directly, and the excess is stored in the capacitor. Winding

faster will increase the amount of stored energy, meaning the LED will stay lit for longer after winding stops.