Scotchman SHEARMASTER 610 User manual

You have downloaded a manual for our

Model SHEARMASTER 610.

www.scotchman.com

01

MODEL

SHEARMASTER

610

24" PLATE SHEAR

MARCH 2022

SERIAL # 2094A & UP

SECTION

1.0

2.0

TABLE OF CONTENTS

DESCRIPTION

INTRODUCTION

2.1

3.0

4.0

4.1

4.2

4.3

4.4

4.5

4.6

5.0

5.1

5.2

6.0

6.1

6.2A

6.2B

7.0

7.1

7.2

8.0

8.1

8.2

8.3

PAGE 2

SAFETY PRECAUTIONS

WARRANTY

WARNING LABELS

INSTALLATION AND SET-UP

Physical Dimensions

Machine Moving Procedures

Physical Inspection

Electrical Requirements

Machine Start-Up

Machine Stroke Inspection and Adjustment

MAINTENANCE

Lubrication

Scheduled Maintenance

MACHINE OPERATION

Bar Shear Operation

Shear Blade Adjustment

Shear Arm Adjustment

ELECTRIC BACK GAUGE

Setting The Length Stop To The Machine

Using Touch And Cut

TROUBLE SHOOTING GUIDE

Electrical Trouble Shooting-Motor

Limit Switch Inspection Procedure

Control Valve Inspection

PAGE #

4

4

5

6

7-13

7

8

9

10

12

12

14-16

14

15

16-20

16

19

20

21

21

22

24-29

24

26

26

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE #

8.4 Hydraulics 27

8.5 Seal Replacement-Cylinder 28

9.0 PARTS LISTS 30-51

9.1 Shear Arm Assembly 30

9.2 Shear Table Assembly 32

9.3 Upper Panel 33

9.4 Sheet Metal 34

9.5 Electrical Unit 36

9.6 Power Unit 38

9.7 Hold Down Assembly 40

9.8 Cylinder Assembly 41

9.9 Material Conveyor 42

9.10 48" Electric Back Gauge 44

9.11 Tiger Stop Adapter 46

9.12 Electrical & Hydraulic Schematics 48

PAGE 3

Page 4

The Scotchman 610 Shear is a versatile, shearing machine engineered for trouble free operation.

The design of the machine combines simplicity of operation with smooth, full stroke control.

The ability of the operator to control the machine’s direction of movement at any point in the stroke,

(stop, jog or reverse), gives the Scotchman Shear a tremendous advantage over mechanical shears.

There is no chance of the Scotchman being "accidentally tripped".

The Hydraulic system operates at a maximum pressure of 3,300 PSI (228 BAR) and is protected from

overload by a relief valve.

1.0 INTRODUCTION

1. The operators of this machine must be qualified and well trained in the operation of the machine.

The operators must be aware of the capacities of the machine and the proper use of the hold down

devices and guards provided with the machine.

2. All of the guards, adjustable restricters and awareness barriers must be installed on the machine

and kept in good working order. Promptly replace worn or damaged parts with authorized parts.

3. Never place any part of your body into or under any of the machine’s moving parts.

4. Wear the appropriate personal protective equipment. Safety glasses are required at all times,

whether operating, setting up or observing this machine in operation. Since heavy pieces of metal

with sharp edges can be processed on this machine, the operator should also wear steel-toed shoes

and tight fitting leather gloves.

5. Strictly comply with all warning labels and decals on the machine. Never remove any of the labels.

Replace worn or damaged labels promptly.

6. Always disconnect and lock out the power when performing maintenance work or setting up any

tooling on the machine. Follow the procedures outlined in the operator’s manual for setting up,

changing or aligning any tooling on this machine.

7. Never operate this machine with dull or damaged tooling. Replace worn blades promptly.

8. Practice good housekeeping. Keep the area around the machine clear and well lit. Do not obstruct

the operator’s position by placing anything around the machine that would impede the operator’s

access to the machine.

9. Never modify this machine in any way without the written permission of the manufacturer.

10. Never leave this machine running unattended.

2.0 SAFETY PRECAUTIONS

11.Never operate any of the work stations from a sitting or kneeling position.

12. Set up a program of routine inspections and maintenance for this machine. Make all repairs and ad-

justments in accordance with the manufacturer’s instructions.

13. A safety tape or CD was mailed to you or shipped with the machine. If you did not receive it, please

contact the factory or your local dealer immediately and one will be sent to you at no charge. If this

machine was purchased used, please contact the factory for a safety tape.

2.1 WARRANTY

Scotchman Industries, Inc. will, within three years of the date of purchase, replace F.O.B. the factory or

refund the purchase price for any goods which are defective in materials or workmanship, provided the

buyer , at the seller’s option, returns the defective goods freight and delivery prepaid to the seller, which

shall be the buyer’s sole and exclusive remedy for defective goods.

Hydraulic and electric components are subject to their respective manufacturer’s warranties.

This warranty does not apply to machines and/or components which have been altered, changed or mod-

ified in any way or subjected to abuse and abnormal use, inadequate maintenance and lubrication or

subjected to use beyond the seller’s recommended capacities and specifications.

In no event shall the seller be liable for labor cost expended on such goods or consequential damages.

The seller shall not be liable to the purchaser or any other person for loss or damage directly or indirect-

ly arising from the use of the goods or from any other cause.

No officer, employee or agent of the seller is authorized to make any oral representations or warranty of

fitness or to waive any of the foregoing terms of sale and none shall be binding on the seller.

Any electrical changes made to the standard machine due to local electrical code variation must be paid

by purchaser. As we constantly strive to improve our products, we reserve the right to make changes

without notification.

This warranty is effective December 1, 2009.

PAGE 5

3.0 WARNING LABELS

ITEM PART # DESCRIPTION

A 003100 MAIN WARNING LABEL

B N/A CAPACITY LABEL

C 003120 DANGER: VOLTAGE

D 003105 FINGERS BEYOND (SHEAR)

PAGE 6

FIGURE 1

A

B

C

D

4.0 INSTALLATION AND SET-UP

ÖCAUTION: THIS SECTION DISCUSSES INSTALLATION AND SET-UP PROCEDURES.

PLEASE READ THOROUGHLY BEFORE OPERATING THIS MACHINE.

4.1 PHYSICAL DIMENSIONS

INCHES CM

F. Floor To Bottom Of Base 3-1/2 8.9

G. Floor To Bar Shear 32 81.2

K. Height 70 178

L. Width 33.5 85

N. Length 49 125

Weight 4,550 lb. 2,068 KG.

PAGE 7

FIGURE 2

32.0

32.0

70.0

49.0

4.2 MACHINE MOVING PROCEDURES

ÖCAUTION: BE SURE THAT ANY LIFTING DEVICE HAS ADEQUATE CAPACITY BEFORE

ATTEMPTING TO MOVE THIS MACHINE. THIS MODEL WEIGHS 3,0100 LB. (1,368 KG.). IT

IS DESIGNED TO BE MOVED BY A FORKLIFT OR AN OVERHEAD CRANE. THERE ARE

FORKLIFT SLOTS DESIGNED INTO THE BASE OF THE MACHINE FOR THIS PURPOSE.

SEE FIGURE 3 BELOW.

PAGE 8

FIGURE 3

5(029($&&(66&29(5

/,)7:,7+)25.67+58&+$11(/621/<

Page 9

Any damage to the machine during shipment should be reported to the delivery carrier immediately.

A damage report must be made so that a claim can be placed. The carrier is responsible for shipping

damage, but it is the customer’s responsibility to immediately report damages, external or internal.

After the machine has been located, remove the side shrouds and inspect the interior of the machine for

possible shipping damages.

CHECK SPECIFICALLY THE FOLLOWING ITEMS:

1. The stroke control handles.

2. The jog switch.

3. The selector switch.

4. The emergency stop buttons.

5. Hydraulic hoses and fittings.

6. A general inspection of machine shrouds, guards and awareness barriers.

7. Check the re-pack box for all accessory items ordered with the machine.

The reservoir is full of oil. The recommended oil is a lightweight, non-foaming, anti-wear

hydraulic oil such as Mobil DTE 25 or equivalent. The reservoir capacity is twenty-four

U.S. gallons (91 liters).

The fluid level should be approximately 2 inches (50mm) below the top of the reservoir.

4.3 PHYSICAL INSPECTION

CAUTION: DO NOT OVER FILL!!

4.4 ELECTRICAL REQUIREMENTS

ÖCAUTION: TO PREVENT DAMAGE TO THE MOTOR AND DANGER TO THE OPERATOR,

ALL ELECTRICAL CONNECTIONS SHOULD BE MADE BY A LICENSED ELECTRICIAN.

All machines are wired for three phase electrical power unless otherwise specified by customer. The sup-

ply voltage should be (+ or -) 10% of the motor voltage rating, to insure satisfactory machine perfor-

mance. Check the motor data tag for full load current requirements.

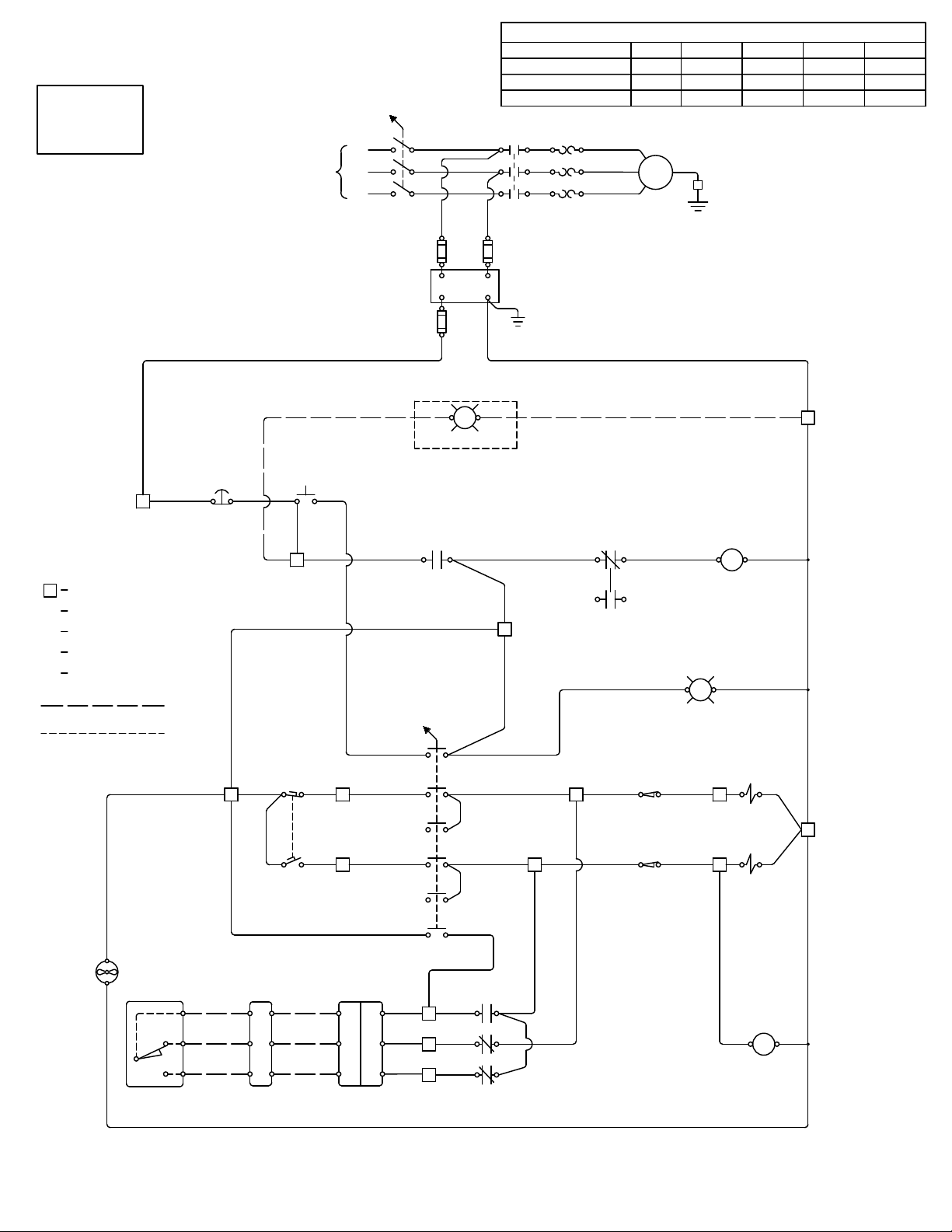

The electrical diagram for the machine is inside the cover of the control box. THE DIAGRAM IS ALSO

IN FIGURE 4. For electrical supply lines ten feet (3 m) or shorter, we recommend at least 12 and prefer-

ably 10, gauge wire. For longer supply lines, use at least 10 gauge and preferably, 8 gauge.

We do not recommend supply lines longer than twenty five feet (7.5 m).

POWER REQUIREMENTS:

Motor frame 3PH=182T 1PH=184T

MOTOR VOLTAGE FULL LOAD CURRENT

(VAC) (AMPS)

208 31

230 29.6

460 14.8

575 12

230 (single phase) 40

Motor power rating: 10hp Speed 1,725 RPM

KVA power rating: 7.9 KVA Frequency 60 HZ

Starting Current: 210% Full Load

PAGE 10

Page 11

3-PHASE

POWER

TERMINAL STRIP #

WIRE #

WIRE COLOR

COMPONENT TERMINAL #

NORMAL POSITION

OPTIONAL EQUIPMENT

COMPONENT

1

(2)

BLK

3

(XO)

FIGURE 4

LEGEND

SEE MOTOR TAG

FOR DETAILS

GND

T1

1FU

3FU

L3

L2

L1

1T

2FU

T3

T2 MTR

1DISC

1M 1OL

INCOMING SUPPLY

(BY CUSTOMER)

PROVIDE MAXIMUM

UPSTREAM

PROTECTION PER N.E.C.

CODE 430-52 AND TABLE

430-152.

FUSE REPLACEMENT

1FU & 2FU = FNQ-R-1

3FU = FNM-2

SEE TRANSFORMER FOR

WIRING DATA

OPTIONAL WORK LIGHT

AVAILABLE (1T MUST BE 250VA)

START

95 96

11413

97 98

2PB

A2

1M

A1

LX2

1OL

LED WORK LIGHT

E-STOP

1 2

1PB

2

1M 1413

G

1PL

GRN/YEL

X1 X2

3

RED

WHT

RED

4BLK

1FTS

1

(XOO) 2

3

(OOX) 4

5

(OOX) 6

2LS

7

9 10

9

1LS

2CVC

1CVC

X2

RED

RED

BLK

BLK

5

610

8

MANUALAUTO

(OXO)

START

1SS

BLUE

13

BROWN

GRN/YEL

12

11

1CR

21 22

32

31

4443

SOCKET

PROBE

MALE

FEMALE

BLOCK

TERMINAL

BLUE

BROWN

GRN/YEL

WHT

RED

BLK

SWITCH

PROBE

RUNNING

1FAN

A2

A1

1CR

(31)

(13)

(43)

(23)

(32)

(14)

(44)

(24)

BLK

GRAY

(LEFT)

(RIGHT)

11

(XOO) 12

(WHT)(BLK)

7

(XOO) 8

(32)

PN 017515 RATING TABLE

MAX. HP

MOTOR FLA

OVERLOAD

LINE VOLTAGE (3PH) 230

10

25

ZB32-32

460

10

12.5

208

10

27.6

ZB32-32

575

10

9.6

380

10

15.8

ZB32-16 ZB32-16 ZB32-16

Page 11A

PN 017523 RATING TABLE

MAX. HP

MOTOR FLA

OVERLOAD

LINE VOLTAGE (1PH) 230

10

40

ZB65-57

SINGLE

PHASE

POWER

TERMINAL STRIP #

WIRE #

WIRE COLOR

COMPONENT TERMINAL #

NORMAL POSITION

OPTIONAL EQUIPMENT

COMPONENT

1

(2)

BLK

3

(XO)

SEE MOTOR TAG

FOR DETAILS

GND

T1

1FU

3FU

L2

L1

1T

2FU

T3

T2 MTR

1DISC

1M 1OL

INCOMING SUPPLY

(BY CUSTOMER)

PROVIDE MAXIMUM

UPSTREAM

PROTECTION PER N.E.C.

CODE 430-52 AND TABLE

430-152.

FUSE REPLACEMENT

1FU & 2FU = FNQ-R-1

3FU = FNM-2

SEE TRANSFORMER FOR

WIRING DATA

OPTIONAL WORK LIGHT

AVAILABLE (1T MUST BE 250VA)

START

95 96

11413

97 98

2PB

A2

1M

A1

LX2

1OL

LED WORK LIGHT

E-STOP

1 2

1PB

2

1M 1413

G

1PL

GRN/YEL

X1 X2

3

RED

WHT

RED

4BLK

1FTS

1

(XOO) 2

3

(OOX) 4

5

(OOX) 6

2LS

7

9 10

9

1LS

2CVC

1CVC

X2

RED

RED

BLK

BLK

5

610

8

MANUALAUTO

(OXO)

START

1SS

RUNNING

1FAN

A2

A1

1CR

(31)

(13)

(43)

(23)

(32)

(14)

(44)

(24)

BLK

GRAY

(LEFT)

(RIGHT)

11

(XOO) 12

(WHT)(BLK)

7

(XOO) 8

(32)

BLUE

13

BROWN

GRN/YEL

12

11

1CR

21 22

32

31

4443

SOCKET

PROBE

MALE

FEMALE

BLOCK

TERMINAL

BLUE

BROWN

GRN/YEL

WHT

RED

BLK

SWITCH

PROBE

FIGURE 4A

LEGEND

WWW.SCOTCHMAN.COM

BEST

IN THE

BUSINESS

WARRANTY

S

C

O

T

C

H

M

A

N

4.5 MACHINE START-UP

BEFORE STARTING THIS MACHINE, TAKE TIME TO THOROUGHLY REVIEW THE VHS

SAFETY TAPE OR SAFETY CD AND THE OPERATOR’S MANUAL.

This machine is equipped with a lock-out, disconnect switch as standard equipment. We strongly urge

you to follow the OSHA directive CFR-1910.147 (effective 09-01-90) regarding lock-out, tag-out proce-

dures. BEFORE POWERING THE MACHINE, be sure that all packing materials and tools have been

removedfrom the machine and that all work stations are clear.

TO POWER THE MACHINE:

1. Place the disconnect switch (A) in the ON position and the selector switch (B) in the START position.

2. Power the machine by pushing the green START button.

Once the machine has been powered, it will not move until either RUN or AUTO is selected. If the ma-

chine does not move when the foot pedal is depressed, the motor rotation is not correct. The electrician

will have to switch two of the line wires to change the direction of rotation.

Any time that the power to the machine has been turned off, the selector switch must be placed in the

START position to restart the machine.

4.6 MACHINE STROKE INSPECTION & ADJUSTMENT

The stroke setting is important for the proper operation of the machine. If this setting has changed, the

machine may over-travel and cause the cylinder to "bottom out". This continued condition will eventu-

ally cause the starter overload to open. It can also cause the hydraulic oil to overheat and damage hy-

draulic system components.

A check of the machine’s stroke setting is made at the pivot end of the plate shear.

SEE FIGURE 5 ON THE FOLLOWING PAGE.

1. Set the stroke control handles (C) out to their farthest position.

2. Place the disconnect switch (A) in the ON position and the selector switch (B) in the START position.

3. Turn the run-auto switch (B) to the RUN position and allow the machine to return.

6. Turn the machine’s power off.

7. Check to see if the metering boss has contacted the left limit switch.

8. If it has not, loosen the four mounting plate screws (G) and move the mounting plate to the right until

contact is made.

9. Tighten the screws and re-check the dimensions. Repeat, if needed.

PAGE 12

PAGE 13

FIGURE 5

Page 14

The Scotchman Shear is an exceptionally rugged machine designed for long life with a minimum

amount of maintenance. A regular program of servicing will extend the life of the machine and prevent

costly down time.

5.0 MAINTENANCE

Re-oil the blades every 10 to 15 cuts.

The oil will allow the machine to shear easier and increase tool life considerably.

We recommend cutting oil or motor oil swabbed on with a brush or applied with a squirt can or a spray

applicator.

Grease the main pins daily.

(SEE FIGURE 6 ON THE FOLLOWING PAGE.)

Grease all other fittings twice per week.

Mobil Grease XHP 222 Special is recommended.

Once a month, check the oil level in the reservoir. It should be approximately 2 inches (50mm) below

the top of the reservoir.

The recommended hydraulic oil is a lightweight, non-foaming, hydraulic oil such as Mobil DTE 25 or

equivalent. The reservoir capacity is 24 U.S. gallons (91 liters).

5.1 LUBRICATION

IMPORTANT: Before operating the SHEARMASTER 610, apply oil to the bar shear blades.

Page 15

FIGURE 6

GREASE

POINTS

5.2 SCHEDULED MAINTENANCE

A program of scheduled maintenance should be set up and documented according to your application

and the frequency you use this machine.

The following is a list of some important items that should be included in a scheduled maintenance

program.

Since the 610 Shear can be used for a wide variety of applications, every user must design and implement

a scheduled maintenance program that fits their needs.

1. EVERY 500 HOURS OR SIX MONTHS:

B. Check the condition of all cutting blades on the machine.

C. Check the condition of the bushings in the shear beam. This can be done visually by watching the

beam for vertical movement while the machine is in operation. If vertical movement is noted,

block or support the beam with a lifting device and remove the main pin and check the clearance. If

the clearance exceeds twelve thousandths (.012) of an inch (.3mm), replace the bushing.

2. EVERY 1,500 HOURS OR 1 YEAR:

A. Change the hydraulic fluid in the reservoir and replace the filter. For recommended fluids, SEE SEC-

TION 5.1.

Page 16

When using the bar shear on your Scotchman Ironworker, always use the hold-down device. Never put

any part of your body between the hold-down and the material to be sheared. A maximum clearance of

1/8" (3mm) between the hold-down and the material to be sheared is acceptable.

The maximum tonnage available on the bar shear is to the left, or closest to the pivot point. For

applications that do not require the maximum tonnage, move the material to the right, for minimal

distortion of the drop off piece. Do not attempt to shear pieces that are too short for the hold-down to

grip as this will cause the material to "kick-up" and probably result in damage to the machine.

It is important that the hold-down is correctly adjusted (1/8" above the material) to avoid possible damage

to the machine and injury to the operator. The hold-down is adjustable to cover all thicknesses of material

within the rated capacity of the machine. A shear support table with adjustable guide is fitted to allow the

accurate feeding of material at any angle. The maximum material that can be sheared is 1 x 12 inch (25 x

305mm), 3/4 x 20" (19 x 508mm) mild steel.

The standard shear blades fitted to the machine comprise of two rectangular fixed blades. The shear

blades are symmetrical and each can be rotated to expose four (4) cutting edges. After a period of time

and subsequent dulling of the blades, the blades can be removed, rotated, and reinstalled back on the

machine. Blade Clearance must be checked whenever blades are changed. SEE FIG. 7A on page 18, and

FIG. 8 on page 19 for more information on setting the shear blade clearance.

Also, we have a curved Sabre Blade (P/N 422071) that can be can replace the standard upper shear blade.

The Sabre Blade makes it easier for the machine to shear and will increase it's shearing capacity slightly.

Keep in mind that the Sabre Blade has only two cutting edges (the curved side) and it will damage the

machine if installed upside-down!!

After rotating or grinding worn blades, they must be refitted and adjusted to clearances listed in this

section. But first, always make sure the shear arm is adjusted properly. The upper ’moving blade’ is not

adjustable and the lower ’fixed blade’ must be adjusted to suit. The securing and adjusting screws for the

lower 'fixed blade’ are more accessible when the shear table has been removed. An even clearance

between the ’moving’ and ’fixed blade’ along their entire length is important and attention should be

given to ensuring that the ’fixed blade’ is in a vertical plane. .

REFER TO SECTION 6.2A FOR SHEAR BLADE ADJUSTMENT.

REFER TO SECTION 6.2B FOR SHEAR ARM ADJUSTMENT.

6.1 BAR SHEAR OPERATION

CAUTION: WHEN THE BAR SHEAR STATION IS NOT IN USE, ALWAYS CRANK THE

HOLD-DOWN DEVICE TO ITS DOWN POSITION.

6.0 MACHINE OPERATION

Page 17

080430

080430

080061

080061

USE OUTER STOP PIN HOLES

FOR STORAGE OF GUIDE WHEN

NOT BEING USED

USE INNER STOP PIN HOLES

WITH GUIDE ORIENTATED AS

SHOWN FOR 90° CUTS ON

LEFT SIDE OF TABLE

REVERSE ORIENTATION FOR

USE ON RIGHT SIDE OF TABLE

ALIGN 45° NOTCH

FLUSH WITH EDGE OF

TABLE FOR MITERING

REVERSE ORIENTATION

FOR USE ON OTHER SIDE

FEED MATERIAL

FEED MATERIAL

FEED MATERIAL

FEED MATERIAL

ALIGN FRONT EDGE OF

90° NOTCHES FLUSH WITH

FRONT EDGE OF SLOTS IN

TABLE FOR 90° CUTS

AWAY FROM STOP PIN HOLES

STOP PIN

STOP PIN HOLE

GUIDE

BAR SHEAR GUIDE INSTRUCTIONS

SHEARMASTER 610

FEED MATERIAL

080061

080061

FIGURE 7

Other manuals for SHEARMASTER 610

1

This manual suits for next models

1

Table of contents

Other Scotchman Power Tools manuals

Popular Power Tools manuals by other brands

REED

REED SAWITSD 07615 operating instructions

Orgapack

Orgapack OR-T 200 Operating and safety instructions

Makita

Makita TM3000CX7 instruction manual

Metabo

Metabo BS 18 LT BL Q Original instructions

Campbell Hausfeld

Campbell Hausfeld DG460500CK Operating instructions and parts manual

Makita

Makita 4399D instruction manual

Bomag

Bomag BPR 70/70 D Operating and maintenance instructions

Klauke

Klauke EK 50/18CFB manual

EINHELL

EINHELL TC-CD 18/35 Li Original operating instructions

Rikon Power Tools

Rikon Power Tools 82-100 Operator's manual

Magna-Matic

Magna-Matic MAG-8000-7 operating instructions

DS Produkte

DS Produkte KT-03 instructions