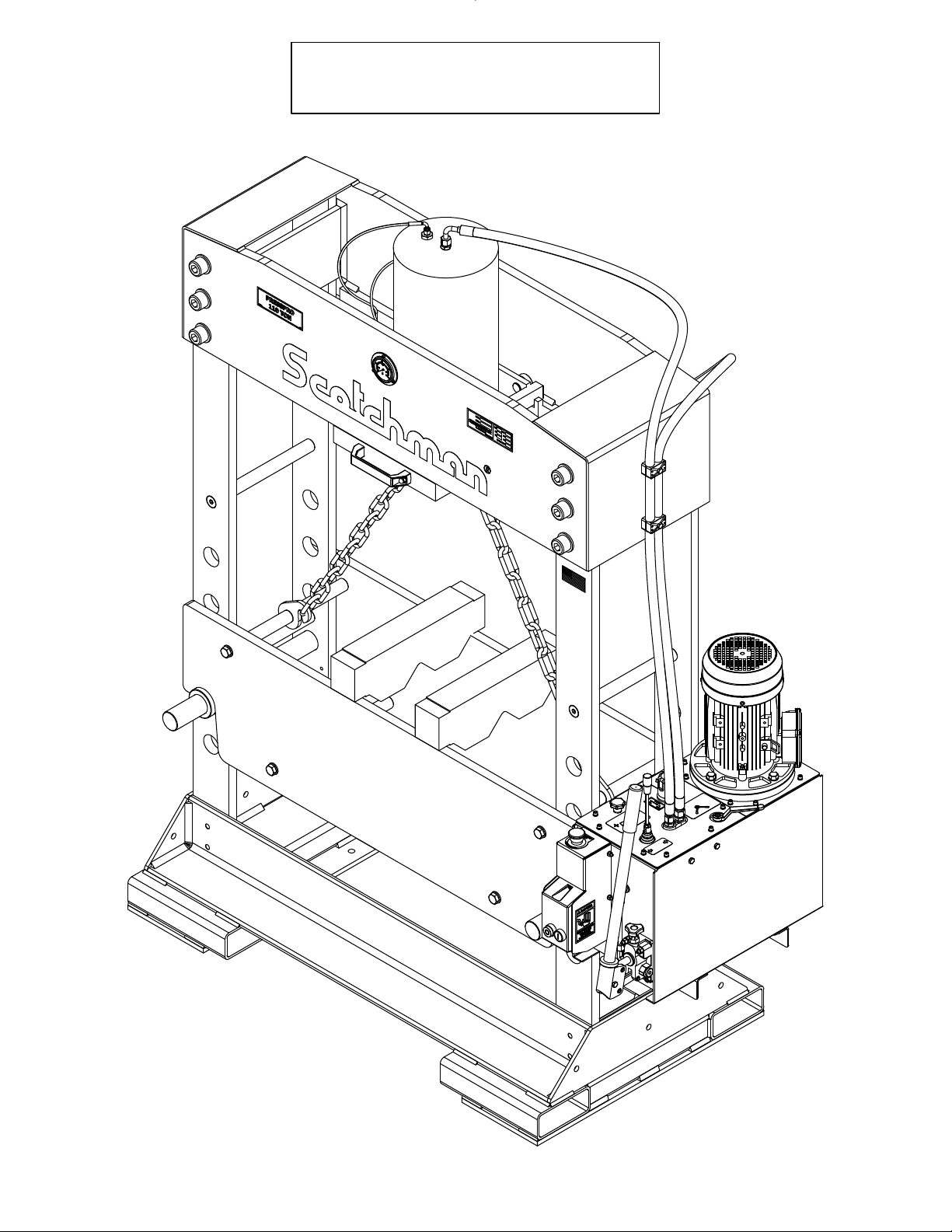

Scotchman PRESSPRO 110 User manual

You have downloaded a

manual for the

SCOTCHMAN

PRESSPRO 110

HYDRAULIC PRESS

www.scotchman.com

PRINTED DECEMBER 2022

PRESSPRO 110

HYDRAULIC

PRESS

SCOTCHMAN INDS. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Phone: 1-800-843-8844 www.scotchman.com

S/N 2000 and higher

Page 2

PRESSPRO 110

SCOTCHMAN INDS. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Phone: 1-800-843-8844 www.scotchman.com

TABLE OF CONTENTS

SCOTCHMAN INDS. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Phone: 1-800-843-8844 www.scotchman.com

Page 3

SECTION DESCRIPTION PAGE #

1.0 INTRODUCTION

1.2

Warranty

Standard Features

2.0

3.0

4.0

3.2

3.3

3.4

INSTALLATION AND SET UP

Machine Moving Procedures

Pallet Jack

Forklift

Securing The PressPro 110

Mounting Brackets For Hydraulic Unit

Installation Of The Hydraulic Unit

Connecting Hydraulic Hoses

Electrical Requirements

Electrical Schematic

MACHINE CONTROLS

On/Off Switch

Emergency Stop Button

Pressure Control Valve

Oil Filler Plug

Speed Setting Valve

MACHINE START UP AND OPERATION

First Start Up

Positioning The Press Cylinder

Positioning The Table

OPERATING THE PRESSPRO 110

V-Block Set

PRESSPRO 110 MAINTENANCE

Changing The Hydraulic Oil

PRESSPRO HYDRAULIC SCHEMATIC

3.5

3.6

3.7

3.8

3.9

5.0

3.11

6.0

4.2

4.3

4.4

4.5

5.1

5.3

5.2

7.0

6.1

7.1

3.1

6.2 Working At Or Near Maximum Capacity

1.1

SAFETY PRECAUTIONS

3.10

4.1

8.0

PRESSPRO 110 PARTS LIST

9.0

9.1 Piston Parts

Cylinder Parts9.2

9.3 PressPro 110 Parts Diagram

Direction Control Valve

Hand Pump

4.6

4.7

4

5

14

13

11

22

21

19

18

17

16

15

26

25

23

22

33

32

31

30

29

27

4

5

7

7

23

23

25

30

34

34

35

36

24

24

10

10

Physical Dimensions & Technical Data

Hydraulic Reservoir

Page 4

1.0 INTRODUCTION

Our 110 ton hydraulic press is equipped with a movable cylinder (left-right) and an in-height adjustable

working table. Equipped with pressure regulation, 2 speeds, joystick and a hand pump for precision

pressing.

Smooth & precise, heavy-duty and versatile; This hydraulic press is industrial-grade and ideal for

assembly, straightening, fabrication, quality control, maintenance, product testing, bending, & forming.

The open side frame design allows for material to pass through and provides flexibility to work on the

longest work pieces. Built for the big jobs as well as the small ones; the adjustable H-frame bed height

offers increased versatility with its ability to raise and lower the table for the best working distance

possible

Meets CE Standards and comes with our 3-year warranty.

1.1 WARRANTY

Scotchman Industries Inc. will, within three years of date of purchase, replace F.O.B. the factory or

refund the purchase price for any goods which are defective in materials or workmanship, provided that

the buyer returns the warranty registration card within thirty days of the purchase date and, at the

seller’s option, returns the defective goods freight and delivery prepaid to the seller, which shall be the

buyer’s sole and exclusive remedy for defective goods.

Hydraulic and electrical components are subject to their respective manufacturer’s warranties.

This warranty does not apply to machines and/or components which have been altered, changed or

modified in any way or subjected to abusive and abnormal use, inadequate maintenance and lubrication

or subjected to use beyond the seller’s recommended capacities and specifications.

In no event shall seller be liable for labor cost expended on such goods or consequential damages.

The seller shall not be liable to purchaser or any other person for loss or damage directly or indirectly

arising from the use of the goods or from any other cause.

No officer, employee or agent of the seller is authorized to make any oral representations or warranty of

fitness or to waive any of the foregoing terms of sale and none shall be binding on the seller.

Any electrical changes made to the standard machine due to local electrical code variations must be paid

by purchaser.

As we constantly strive to improve our products, we reserve the right to make changes without

notification.

SCOTCHMAN INDS. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Phone: 1-800-843-8844 www.scotchman.com

Page 5

2.0 SAFETY PRECAUTIONS

1.2 STANDARD FEATURES

• Heavy duty all-steel construction

• Industrial grade hydraulic system

• Ram moves laterally for added versatility

• 3 Ram speeds

• Joystick operation with hand pump option

• Removable ram cap to accept a variety of tooling

• Adjustable H-frame bed/table height offers increased versatility

• Open side-frame design allows for material to pass through

• Hydraulic-assist for table height adjustment to maximize operator safety

• Set of V-blocks to simplify your pressing jobs

• Pressure gauge to monitor force

• Meets CE standards

• Three year warranty

1. The operator of this machine must be qualified and well trained in the operation of the machine.

The operator must be aware of the capacities of the machine and its proper use. This manual is

not intended to teach untrained personnel how to operate machinery.

2. All of the guards, adjustable restrictors and awareness barriers must be installed on the machine

and kept in good working order. Promptly replace worn or damaged parts with authorized parts.

3. Never place any part of your body into or under any of the machine’s moving parts.

4. Wear the appropriate personal protective equipment. Safety glasses are required at all times,

whether operating, setting up or observing this machine in operation. Since heavy pieces of metal

with sharp edges can be processed on this machine, the operator should also wear steel-toed shoes

and leather gloves.

5. Strictly comply with all warning labels and decals on the machine. Never remove any of the labels

and replace worn or damaged labels promptly.

Page 6

6. Always disconnect and lock out the power when performing maintenance work or repairs. Follow

the procedures outlined in the operator’s manual.

7. Practice good housekeeping. Keep the area around the machine clear and well lit. Do not

obstruct the operator’s position by placing anything around the machine that would impede

the operator’s access to the machine.

8. Never modify this machine in any way without the written permission of the manufacturer.

9. Never leave this machine running unattended.

10. Do not use press when temperature is below 42℉ (+5C) or above 122℉ (+50C)

11. Set up a program of routine inspections and maintenance for this machine. Make all repairs

and adjustments in accordance with the manufacturer’s instructions.

• NEVER TURN OFF THE MACHINE WHEN PRESSING FORCE IS BEING APPLIED

TO THE WORK PIECE.

• UNEXPECTED FORCE EXPANSION WHEN RESTARTING CAN DAMAGE THE

MACHINE OR INJURE THE OPERATOR.

• THEREFORE ALWAYS RELEASE THE FORCE FROM THE OBJECT, MOVE THE

PISTON UPWARDS AND THEN SAFELY TURN OFF THE PRESS.

WARNING: ALWAYS RELEASE JOYSTICK BEFORE TURNING OFF THE PRESS AND

JOYSTICK MUST BE IN MIDDLE POSITION WHEN STARTING THE PRESS.

► NOTE: ANY WELDING OPERATIONS ON THE PRESS TABLE ARE PROHIBITED.

THIS CAN DAMAGE THE MACHINE!!

► NOTE: THE MACHINE MUST BE BOLTED TO THE FLOOR - SEE SECTION 3.5

• NEVER USE A MACHINE UNLESS IT'S BOLTED TO THE FLOOR.

• IT CAN TIP OVER IF HEAVY PARTS ARE LOADED ON THE TABLE.

• THIS CAN CAUSE SEVERE INJURY OR DEATH!!

• USE THE PRESS IN THE VERTICAL POSITION ONLY.

► NOTE: MAXIMUM PRESSING FORCE CAN BE EXERTED FOR A SHORT TIME ONLY.

DO NOT USE MAXIMUM FORCE WHEN THE PISTON IS EXTENDED FURTHER

THAN 3/4 OF ITS LENGTH. THIS CAN DAMAGE THE PISTON - SEE SECTION 6.2

Page 7

3.0 INSTALLATION AND SET UP

CAUTION: THIS SECTION DISCUSSES INSTALLATION AND SET-UP PROCEDURES.

PLEASE READ THOROUGHLY BEFORE OPERATING THIS MACHINE.

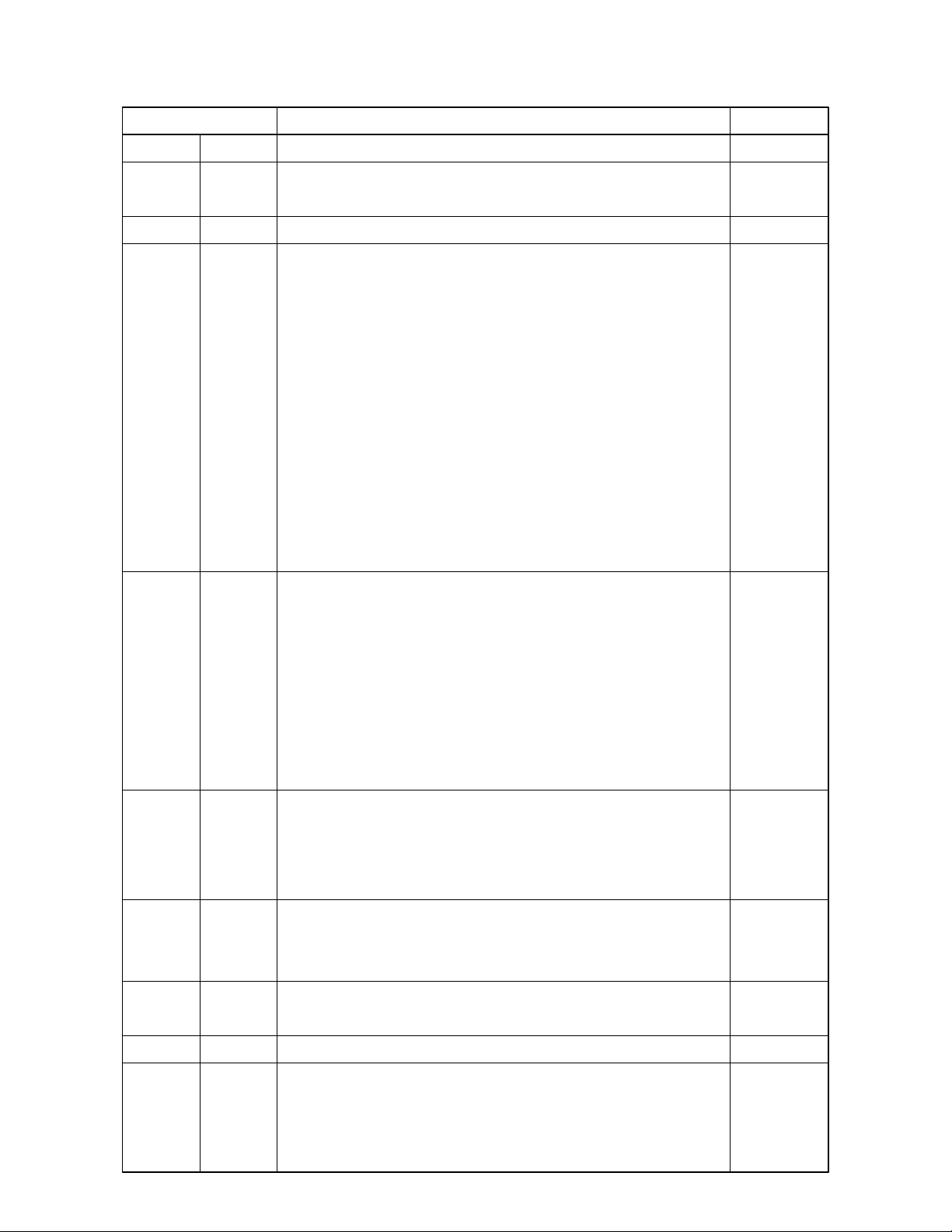

3.1 PHYSICAL DIMENSIONS & TECHNICAL DATA

The following pages show the PressPro 110 physical dimensions, capacities, moving procedures, how to

secure the press in it's final location, mounting the hydraulic unit and hoses, how to fill the hydraulic

system, the electrical requirements and connections, and initial start up procedure. Following these

instructions ensure the press is set up properly and will help to ensure the safe operation and long life of

your new Scotchman PressPro 110 press.

UPON DELIVERY, DO NOT SIGN FOR ANY MACHINE UNTIL YOU HAVE REMOVED THE

PLASTIC AND INSPECTED EVERYTHING FOR DAMAGE!

• It is the customer’s responsibility to inspect the arriving machine.

• Make sure to note any damages on the delivery ticket and then immediately contact Scotchman

Inds. about the damage so we can assist you. Our toll free number is 1-800-843-884.

• If the driver will not wait for you to inspect the shipment, simply mark the shipment as

“damaged” before signing.

• It is unlikely that we can recoup any costs from damages not noted on the delivery ticket.

The press is delivered in the following condition:

• Table is in lowest position.

• Hydraulic unit mounted on the inside of the frame.

• Lifting chain packed in a separate box.

• Cylinder fixed in the middle of the press.

• Hydraulic unit without oil.

FIGURE 1

Page 8

M

L

PLACE V-BLOCKS

OR TABLE HERE

PRESSPRO

110 TON

H

I

A

E

C

J

D

B

F

CROSS BEAM ASSY.

TOP POSITION

CROSS BEAM ASSY.

BOTTOM POSITION

G

O

N

K

A

B

C

D

E

F

G

H

J

K

MM

I

UNITS INCHES

L

M

MM

UNITS INCHES

N

O

84-3/4 2153

54-1/4 1378

30 762

43-1/4 1099

12-1/8 308

66-1/2 1689

1375-3/8

8-11/16 221

21-1/2 546

32-3/4 832

4-3/4 121

16-5/16 414

36414-5/16

34313-1/2

121948

PRESSPRO 110 SPECIFICATIONS

Page 9

CAUTION: MAXIMUM PRESSING FORCE CAN BE EXERTED FOR A SHORT TIME ONLY.

DO NOT USE MAXIMUM FORCE WHEN THE PISTON IS EXTENDED FURTHER

THAN 3/4 OF ITS LENGTH. THIS CAN DAMAGE THE PISTON.

► NOTE: THE GIVEN PARAMETERS OF THE PISTON MOVEMENTS ARE MAXIMUM

VALUES AND CAN BE UP TO 25% LOWER.

PARAMETERS ARE VALID WITH MINIMUM OIL TEMPERATURE OF 86°F (30°C).

Press Force

Maximum Pressure

Cylinder Stroke

Oil Flow (Approaching)

Total Oil Capacity

(Tank and Cylinder Capacity)

Oil Type (See Pg. 13)

Press Speed

Return Speed

Weight

Diameter Cylinder

Diameter Piston Rod

Diameter Piston Head

US tons

psi

in.

gal/min

gallons

in/sec

pounds

in.

in.

in.

in/sec

in/sec

gal/min

Approach Speed

Oil Flow (Press)

kN

-

110 981

3750 260

15 380

415.4

1.4 5.3

12.2 46

HL46

.265 6.74

.091 2.32

8.66 220

3.54 90

4.72 120

3000 1361

bar

mm

ltr/min

liters

mm/sec

Kg

ltr/min

-HL46

mm/sec

mm

mm/sec

.319 8.09

mm

mm

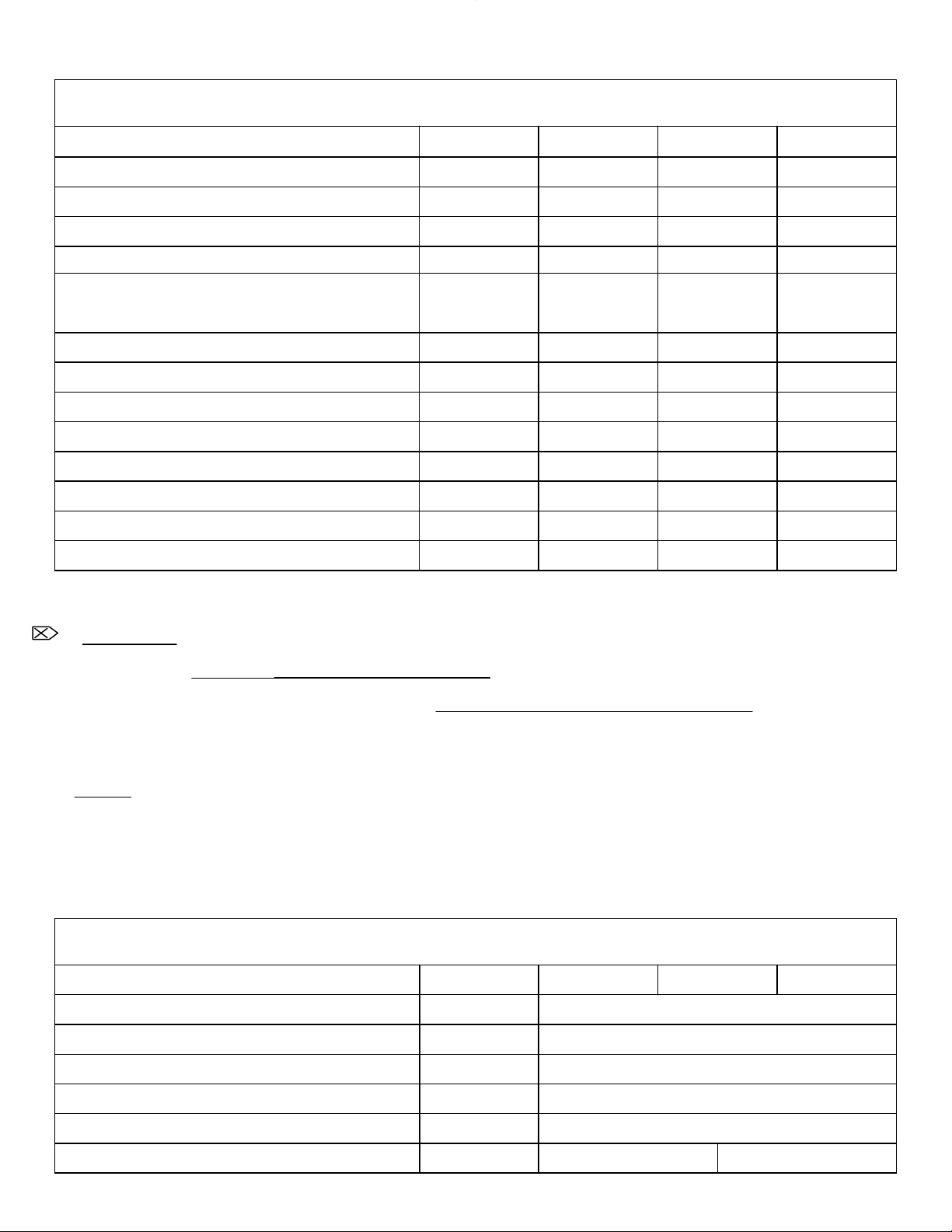

PRESSPRO 110 CAPACITIES

Motor

Voltage

Frequency

Revolutions Per Minute (60Hz)

Insulation Protection

Insulation Classification

hp

V

Hz

IP

230 3ph or 460 3ph All Models

60

1680

55

F

rpm

kW

Full Load Amps FLA 230V - 10A 460V - 5A

IC

2.6

PRESSPRO 110 VOLTAGE SPECIFICATIONS

3.5

Page 10

3.2 MACHINE MOVING PROCEDURES

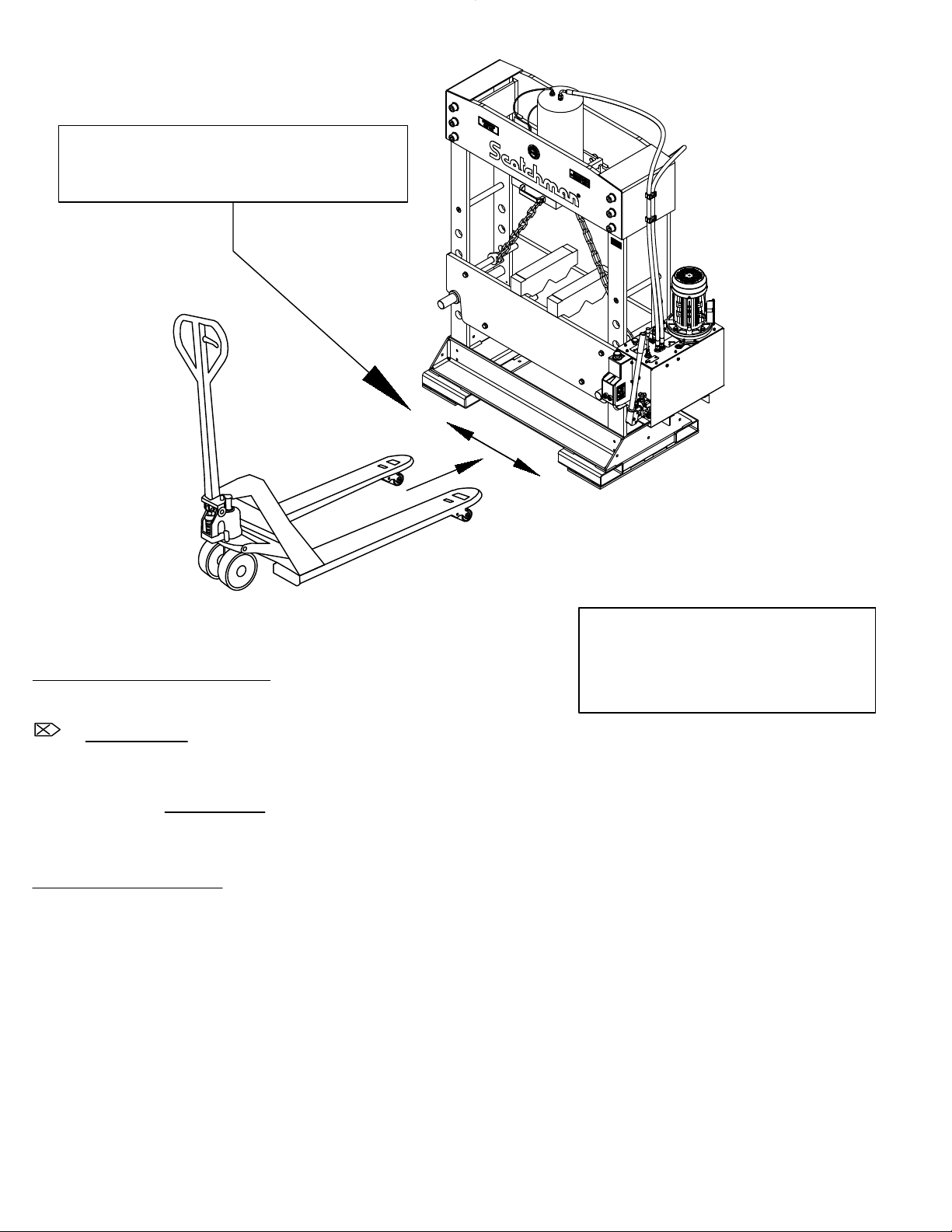

WHEN USING A PALLET JACK, ADHERE TO THE FOLLOWING PRECAUTIONS:

• Place the table in its lowest position.

• Remove the hydraulic unit. (See Sect. 3.7 and 3.8)

• Fix the cylinder in the middle of the press.

• DO NOT USE A NARROW PALLET JACK

• For stability, Pallet Jack must be wide enough to just fit between rectangle tubes.

• See FIGURE 2 on the next page.

The PRESSPRO 110 weighs 3000 lbs. Make sure the pallet jack you use has enough capacity to safely

lift the weight the press and follow the instructions below.

3.3 PALLET JACK

CAUTION: Use extreme caution when moving press as it is TOP HEAVY. When moving the press

with a pallet jack, it must be on a smooth level surface! Have more than one person

help you. Watch the press at all times. Go slowly with smooth movements. Unexpected

movements can make the press tip over and possibly cause serious injury or death.

The most common method of moving the PressPro 110 is with a pallet jack or a fork lift. The following

section shows the correct way to safely move the press without damage or injury.

FIGURE 2

Use a Pallet Jack that just fits

between rectangular tubes

PRESS IS TOP HEAVY!

Use Extreme Caution

when moving!

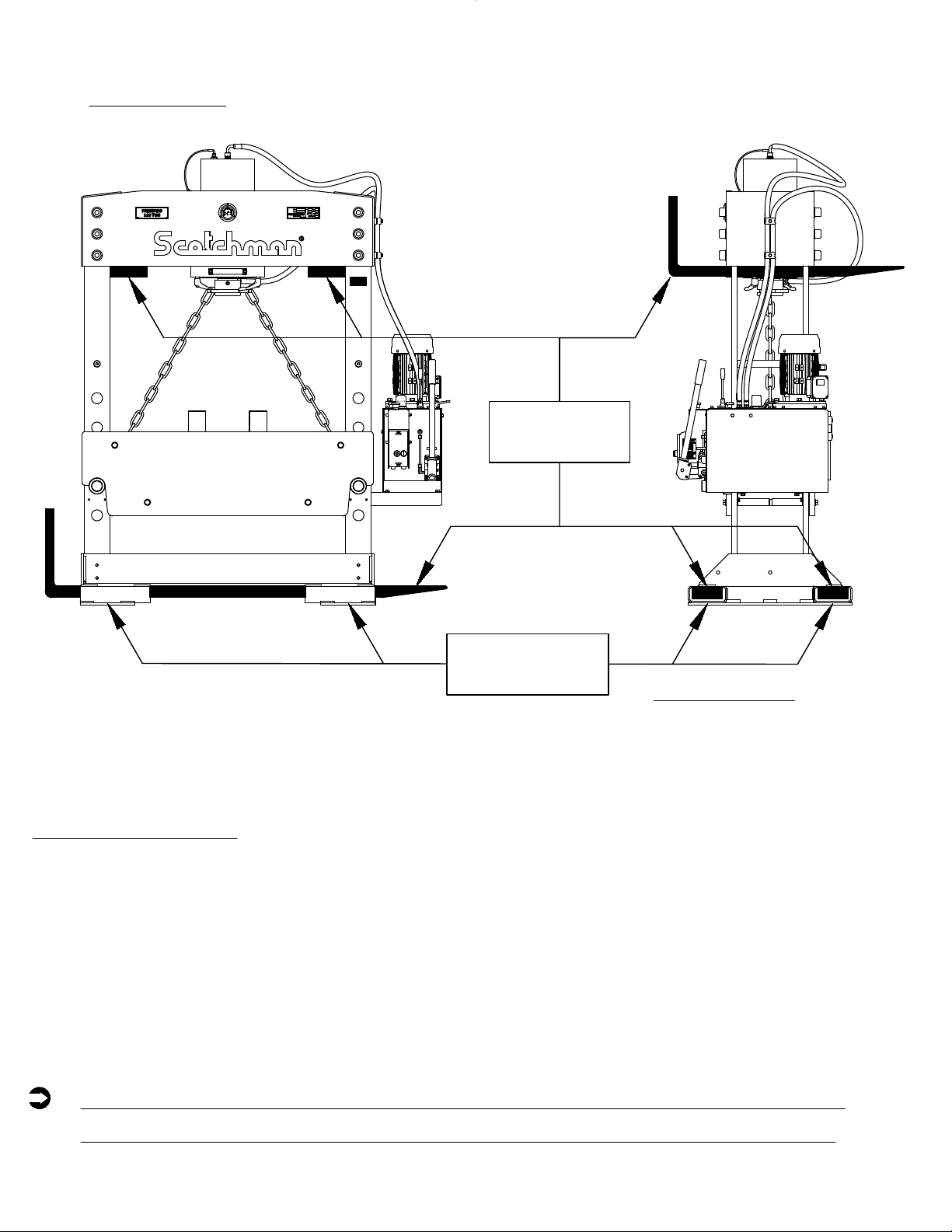

3.4 FORKLIFT

CAUTION: PRESS IS VERY TOP-HEAVY!

Refer to FIGURE 3 on the next page for the below.

Page 11

UPPER SUPPORTS:

• Place the table in its lowest position.

• Keep forks as wide as possible.

• Do not lift the press any higher than needed.

• Go slowly with smooth movements and only on level surface.

• Have another person watch for problems.

FIGURE 3

Upper Supports: Keep forks as

wide as possible as shown below.

Rectangle Tubes:

The safest and

recommended way to

move press

RECTANGLE

TUBES

FORKLIFT

FORKS

Page 12

PLACING THE FORKS THRU THE RECTANGLE TUBES PREVENTS PRESS FROM

TIPPING OVER. THIS IS THE SAFEST AND RECOMMENDED WAY TO MOVE IT.

RECTANGLE TUBES:

• Make sure the forklift forks are long enough to reach through all four rectangle tubes.

• Do not lift the press any higher than needed.

• Go slowly with smooth movements.

• Going straight up or down a slight incline is allowed ONLY if using rectangle tubes.

• Have another person watch for problems.

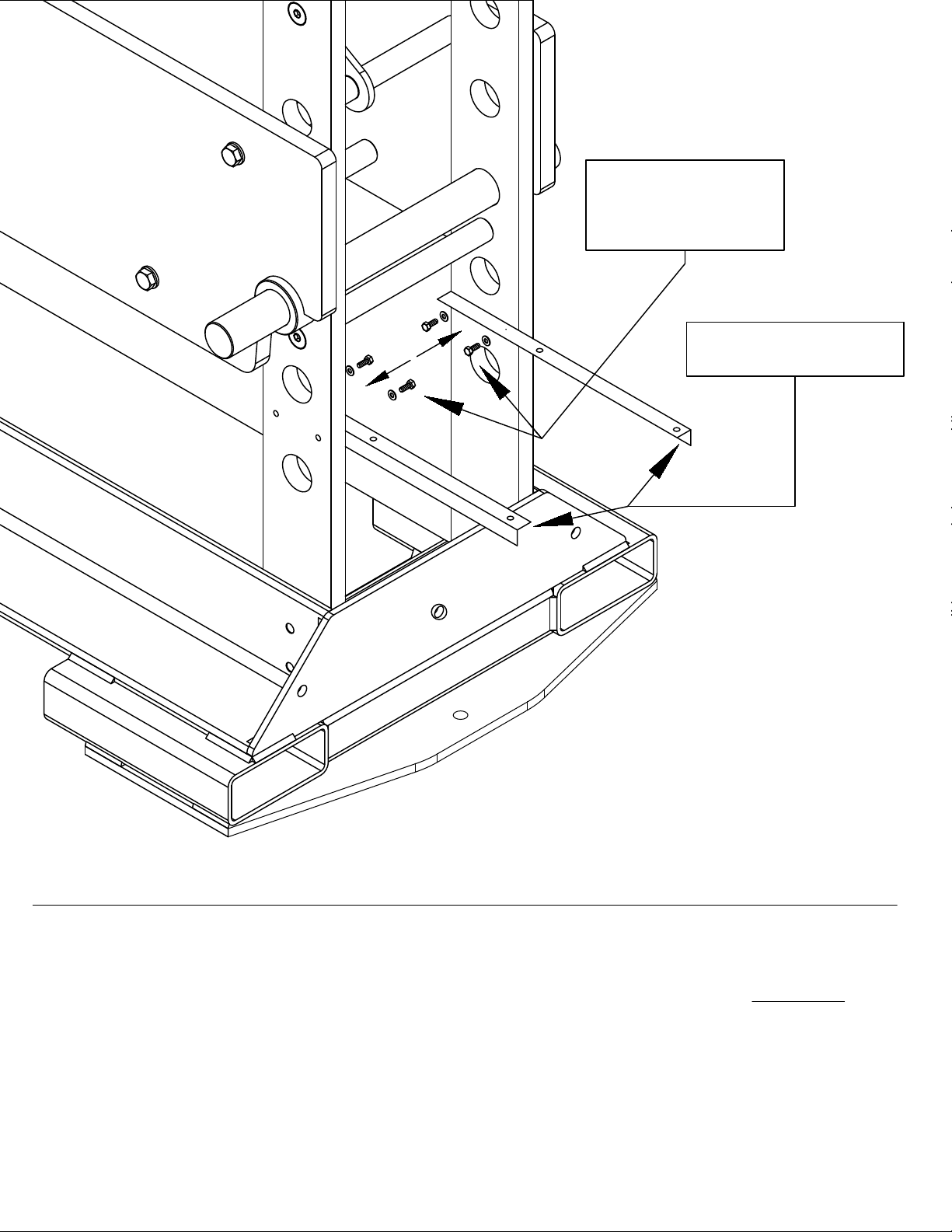

When the machine is positioned in the desired location, it should be bolted to a flat, smooth, level

concrete floor using 10 mm (3/8") screws and plugs (not included). The PressPro 110 has six holes

available in the base for this, three on each side. FIGURE 4 below is a view of the underside of the

machine showing the location of these holes. They are on the inside of the base of the press.

3.5 SECURING THE PRESSPRO 110

Mounting Holes for securing press to concrete floor

Page 13

UNDERSIDE VIEW OF PRESSPRO 110

FIGURE 4

37 in.

6 in.

12 in.

There are two brackets included that are used to mount the power unit on. They need to be installed so

the longer part is pointing to the outside of the machine as shown on the next page in FIGURE 5. Each

bracket should be bolted to a leg with two bolts and two washers.

3.6 MOUNTING BRACKETS FOR HYDRAULIC UNIT

FIGURE 5

BOLTS &

WASHERS

BRACKETS

Page 14

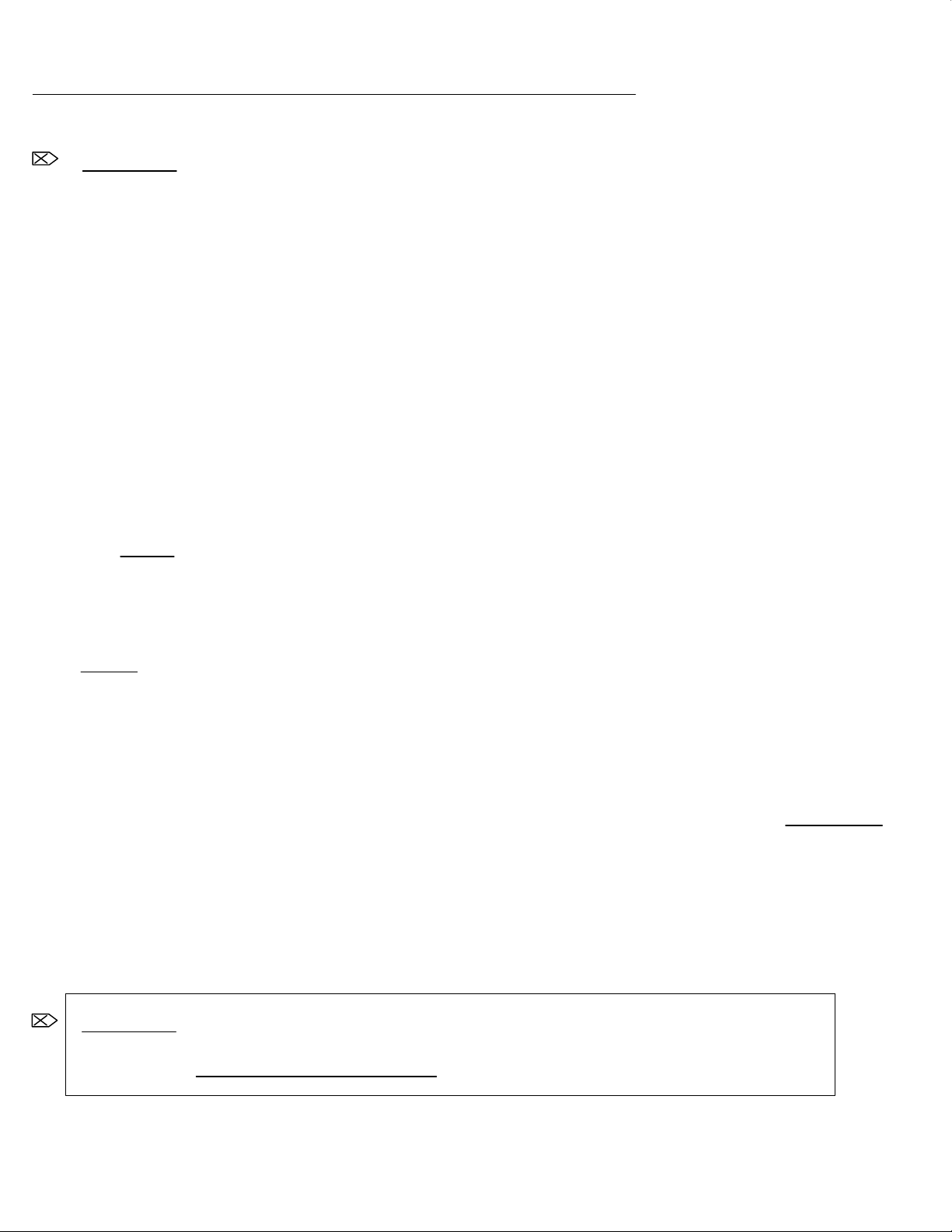

The Hydraulic Power Unit mounts on top of the brackets (shown in the previous section) with four bolts,

four nuts, and eight washers as shown below.

3.7 INSTALLATION OF THE HYDRAULIC UNIT

► NOTE: THE HYDRAULIC UNIT WEIGHS 130 LBS.

WHEN PLACING THE UNIT IN THE

CORRECT POSITION, MAKE SURE TO

USE ENOUGH MAN OR MACHINE

POWER TO LIFT THE UNIT.

HYDRAULIC UNIT

BOLTS TO

BRACKETS AS

SHOWN

ISOMETRIC VIEW OF

HYDRAULIC UNIT AND

MOUNTING BRACKETS

FIGURE 6

Page 15

FIGURE 7

Page 16

Once the hydraulic unit is mounted, the hoses must be attached.

On top of the cylinder there are (2) threaded holes. The centered hole is for the large diameter (18mm)

hose from the reservoir. The other hole is for the small diameter (5mm) pressure gauge hose.

Make sure there are no sharp bends in the hoses between the clamps and connections to the hydraulic

unit as shown below.

3.8 CONNECTING HYDRAULIC HOSES

MAKE SURE ALL HOSES ARE TIGHTENED SECURELY AND CONNECTED IN THE

CORRECT LOCATION BEFORE FILLING RESERVOIR AND OPERATING THE PRESS

FRONT

BACK

A

C

HANDLE AND

SCREW REMOVED

HANDLE INSTALLED IN

CORRECT ORIENTATION

PLACE HOSE MOUNTS ON

SAME SIDE AS POWER UNIT

(SHOWN ON RIGHT SIDE HERE)

IF 2 SPEED HANDLE IS IN AN UNDESIRABLE

POSITION REMOVE HEX HEAD SCREW AND

HANDLE, THEN REASSEMBLE IN CORRECT

ORIENTATION. (MAKE SURE HANDLE CAN

MOVE FROM HIGH SPEED TO LOW SPEED)

PRESSURE GAUGE GOES

IN THE HOLE THAT IS

NOT IN THE CENTER

90° FITTING GOES IN HOLE

CENTERED IN CYLINDER

TOP HOSE GOES TO

FRONT FITTING ON

THE POWER UNIT

BOTTOM HOSE GOES TO

THE BACK FITTING ON

THE POWER UNIT

CAUTION: NEVER RUN THE PRESS WHEN ITS LOW ON OIL. THIS WILL DAMAGE THE

HYDRAULIC UNIT AND CAUSE THE PRESS TO MALFUNCTION.

Oil Tank

Capacity

Gal. / Liter

PressPro 110 8.5 / 32.2

Cylinder

Capacity

Gal. / Liter

Total Oil

Capacity

Gal. / Liter

3.7 / 14 12.2 / 46

Press

Model

Page 17

The press is delivered without oil. Before initial start up, the tank needs to be filled.

Mobile DTE 10 Excel 46 or Mobile DTE 25 or similar hydraulic oil is recommended.

To properly fill the oil tank remove the filler plug on top of the hydraulic unit.

Fill the tank with a sufficient amount of oil. See bottom of page for the capacities of this press.

• The oil level is viewed in the sight glass located in the rear of the hydraulic unit.

• Replace the filler plug.

• Follow the instructions in SECT. 5.1 FIRST START UP to deaerate the hydraulics and

prepare the press for use.

3.9 HYDRAULIC RESERVOIR

• The machine must be connected to 220V 3ph or 440V 3ph power.

• To ensure satisfactory machine performance, the supply voltage should (+ or -) 10% of the motor

voltage rating. Check the machine data tag for full load current requirements.

• For electrical supply lines ten feet (3m) or shorter, we recommend at least 12 gauge, and

preferably, 10. For longer electrical supply lines, use at least 10 gauge, and preferably, 8.

• We do not recommend supply lines longer than twenty five feet (7.5m).

• The electric circuit must be protected by a fuse or circuit breaker with an adequate rating.

• The motor direction can be changed by swapping (2) of the incoming phases - See SECT. 3.11.

• The motor must be running in correct direction before the system can be de-aerated (SECT. 5.1)

3.10 ELECTRICAL REQUIREMENTS

CAUTION: TO PREVENT DAMAGE TO THE MOTOR AND DANGER TO THE

OPERATOR, ALL ELECTRICAL CONNECTIONS SHOULD BE MADE

BY A LICENSED ELECTRICIAN.

Page 18

► NOTE: CHECK WHICH DIRECTION THE MOTOR IS TURNING. LOOKING AT THE

MOTOR FROM ABOVE, MAKE SURE THE MOTOR IS TURNING THE

DIRECTION INDICATED BY THE ARROW.

CAUTION: IF THE MOTOR IS RUNNING IN THE WRONG DIRECTION, IT CAN

DAMAGE THE MACHINE IN A VERY SHORT TIME!!

3.11 ELECTRICAL SCHEMATIC

FIGURE 8

SCHEMATIC

L3

L2

L1 T1

T3

MTR

1M 1OL

T2

INCOMING SUPPLY

(BY CUSTOMER)

PROVIDE MAXIMUM

UPSTREAM

PROTECTION PER N.E.C.

CODE 430-52 AND TABLE

430-152.

GND

95 96

1OL E-STOP

1 2

1PB

START

3

4

2PB

A2

1M

A1

1M

1314

L1

L3

L2

SEE MOTOR TAG

FOR DETAILS

Page 19

Table of contents

Other Scotchman Power Tools manuals