PN: 123-330, Rev. F Page 3of 52

Table of Contents

Warnings..........................................................................................................................2

Application.......................................................................................................................4

Limitations .......................................................................................................................5

System Operations ..........................................................................................................8

Supervisory Pressure Switch.......................................................................................9

Switch Specifications ..................................................................................................9

System Status Indicator Light Operation ....................................................................9

Pressure Relief Assembly (Burst Disk).......................................................................10

Interaction with Engines, Generators and Powered Ventilation (Blowers) ..............10

Diesel Engines or Generators, Powered Ventilation (Blowers) ................................11

Gasoline Engines or Generators ...............................................................................11

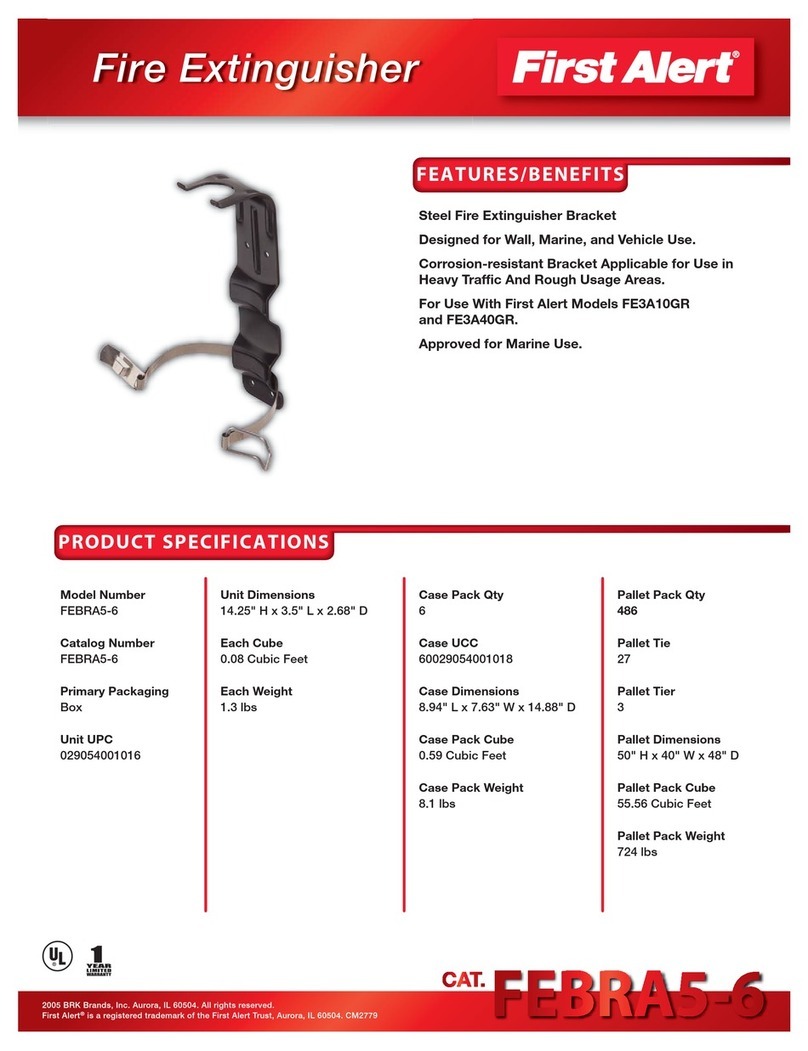

Relationship to Portable Fire Extinguishers ..............................................................11

Manual Discharge Capability ....................................................................................11

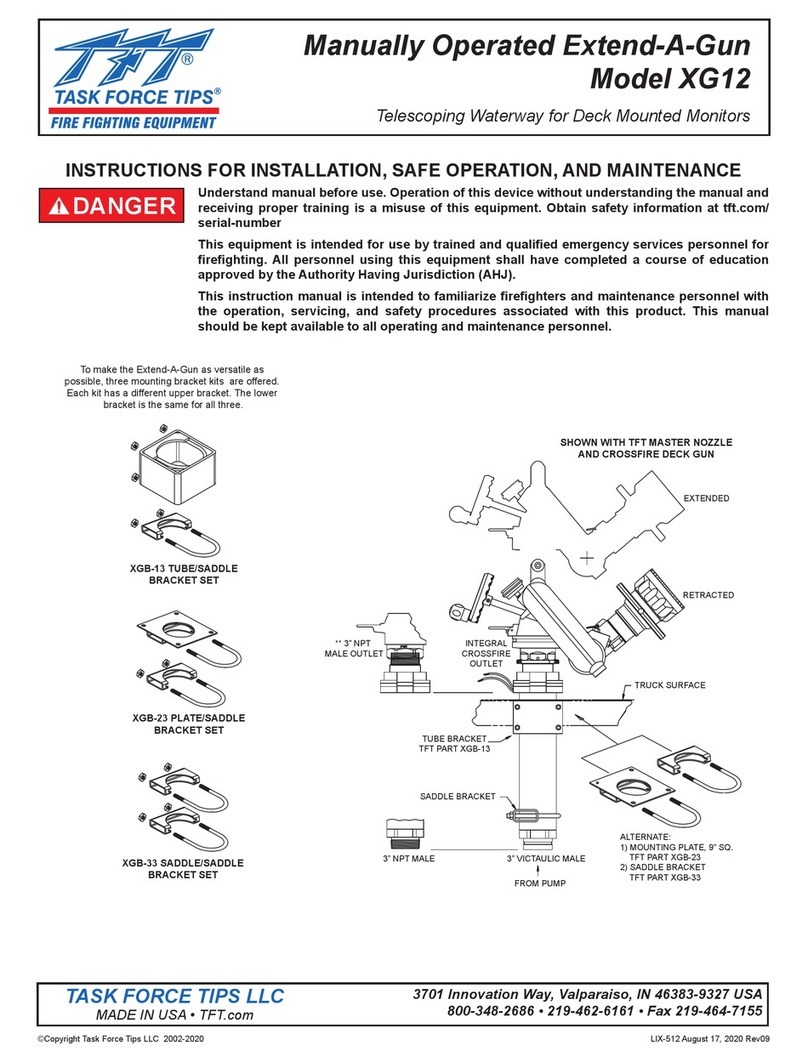

Installation.....................................................................................................................12

I. Cylinder Installation ...............................................................................................12

Wall Mounting ..........................................................................................................13

II. Cable Assembly Installation ..................................................................................15

Test Procedure..........................................................................................................19

III. System Status Indicator Light Installation............................................................23

Installation Requirements .............................................................................................25

System Maintenance / Inspection.................................................................................26

Cylinder Inspection / Cylinder Testing ......................................................................26

Agent Weight Inspection ..........................................................................................29

Pressure Gauge Inspection .......................................................................................30

Reading the Pressure Gauge (Inspection).................................................................30

Pressure vs. Temperature Graphs ............................................................................31

System Status Indicator Light Inspection..................................................................31

Glass Bulb (Temperature Sensor) Inspection............................................................31

Cable Inspection........................................................................................................32

Specification Tables ..................................................................................................32

Table 6: NFG - Automatic and Manual/Automatic Fire Suppression Systems .....32

Table 7A: NFD - Automatic and Manual/Automatic Fire Suppression Systems...33

Table 7B: NFD Automatic and Manual/Automatic Fire Suppression Systems .....35

Two Year NFG and NFD Series Limited Warranty..........................................................36

Conditions......................................................................................................................36

Additional Servicing .......................................................................................................37

Out of Warranty Replacements / Recharges.................................................................37

Safety Data Sheets.........................................................................................................38

Installation Inspection Checklist....................................................................................46