SEAGUARD Sentry multizone User manual

S-SM-11-01f / 1

Sentry multizone instructions

Introduction

Sentry mutizone is a microprocessor based multi-zone corrosion monitor. An LCD display and

LED’s provide indication of the vessel’s level of cathodic protection. The multizone capability of the

Sentry mutizone allows up to three independent zones on a vessel to be simultaneously monitored.

For example, the external hull may represent one zone, other zones may include the insides of sea

chests, ballast tanks, water jet tunnels etc. Each zone requires a reference electrode to be installed.

The Sentry multizone kit comprises a multizone monitor, mounting screws, batteries and an earth

lead.

For our other corrosion monitor products visit our web site atwww.seaguard.co.nz

Sentry multizone installation

1

2

3

zone

under

over

protected

test

Box

outline Box mounting

hole locations

E1

2

3

Connect to hull

Zone 1

ref electrode

Zone 2

ref electrode

Zone 3

ref electrode

83.5

52.5

a. The Sentry can be bulkhead mounted in any

convenient location such as in the engine

room or in the vessel’s bridge/pilot house.

The box dimensions are 115 mm x 65 mm x

40 mm deep.

b. Drill two 3.7/3.8mm diameter holes at 83.5

mm by 52.5 mm centers on the hull bulkhead

or other suitable mounting location.

c. Remove the Sentry lid. Mount the box using

the two 8g x 12 mm self tapping screws

provided.

d. Insert the 3 x AA batteries supplied. Refasten

the Sentry lid making sure that the desiccant

pack remains inside.

e. Connect terminal E to the hull with the black

earth lead provided.

f. Connect terminals 1,2 & 3 to the blue

reference electrode wires for zones 1,2 & 3

respectively.

Note: The reference electrode is purchased

separately.

Sentry test

Mount the Sentry and reference electrode as described above.

Once re-assembled press the ‘test’ button and check that all lights illuminate briefly.

During this lamp test check that the appropriate material is displayed on the LCD (‘ALU’ for

Aluminum, ‘FE’ for Steel or ‘Br’ for bronze).

S-SM-11-01e / 2

Sentry operation

Press the ‘test’ button.

All the LED’s will briefly light in the initial lamp test mode.

The yellow LED corresponding to zone 1 will then light and the protection level for zone 1 will be

shown by two LED’s on the protection level display and the millivolt reading will be indicated on the

LCD.

After a few seconds the yellow Zone 2 LED will illuminate and the protection level LEDs and LCD will

show the protection level within this zone.

After a few seconds more the yellow Zone 3 LED will illuminate and the protection level LEDs and

LCD will show the protection level within this zone.

The cycle will then recommence with the Zone 1 display.

Note. If only two zones have been specified at the time of ordering then zone 3 will not be

displayed.

In order to conserve battery life the unit operates for 30 seconds and then powers down.

In case of low battery voltage a ‘Lo Bat’ indication will appear in the top left corner of the LCD.

The Sentry LED’s indicate the current level of cathodic protection.

Providing that the Sentry has been set up for the correct material being protected then the green

LED indication shows that the material is protected from corrosion. Red LED indication warns of

under protection or over protection. Under protection indicates corrosion can take place. Over

protection can also indicate that corrosion or other problems are occurring.

Extreme over or under protection is indicated by a single flashing red LED.

An extreme over protection indication may also be caused by faulty connection to the electrode or

the electrode being out of the water.

For a particular zone, a reference electrode must be connected to the corresponding terminal on

the

Sentry mutizone and it must be in contact with sea water. Only then will the unit correctly indicate the

cathodic protection level.

Sentry calibration and options

The Sentry has been calibrated prior to dispatch from the factory and needs no further adjustment.

Three material settings are available on this model for correctly displaying the protection level of

Aluminum, Steel or Bronze. This is set at the factory.

Sentry fault finding

In order to test the operation of the Sentry press ‘test’ and check that all lights illuminate for about

one second and that the LCD displays the material being monitored. If this does not happen check

that the batteries are not flat and that they are correctly installed.

Disconnect the electrode wire from terminal ‘1’ and check that the top red led flashes and that the

LCD reads between -1200 and -1300mV when zone 1 is being displayed. Repeat this for electrodes

2 and 3.

Link terminals ‘E’ and ‘1’ and check that the LCD reads between -10 and +-10mV when zone 1 is

being displayed. Repeat this for electrodes 2 and 3.

.

Reconnect terminal ‘E’ to the hull and terminals ‘1’, ‘2’ and ‘3’ to their individual electrodes.

S-SM-11-01f / 3

Seaguard Ltd, P.O.Box 2628, Christchurch, New Zealand

Telephone: +64 (0)3 389 9032 Mobile: +64 (0)25 362 767 Fax: +64 (0)3 389 9042

Cathodic protection levels

The Sentry mutizone has LCD and LED (Light Emitting Diode) indication of the cathodic protection

level. Providing the unit has been set up for the correct material and reference electrode type

(factory adjustable only), green LED indication shows that the material is protected from corrosion.

Red LED indication can indicate under protection or over protection. Under protection indicates

corrosion can take place. The rate of corrosion is influenced by a number of variables such as the

type of material, the oxide layer present, the quality of the electrolyte and the potential relative to the

reference electrode. Moderate over protection can be accepted but may be uneconomic for steel,

bronze and brass. Over protection can cause problems with aluminum due to amphoteric attack.

LCD readings can be evaluated from the table below for Seaguard zinc electrodes and typical

materials in use in the marine sector. For Ag AgCl reference electrodes, subtract 1000 from the

numbers below:

Material Freely corroding Protected Over protected

Carbon steel +390 +150

304 Stainless steel (active) +470 +230

Aluminum +260 +50 -100

Bronze +680 +350

Brass +640 +310

Corrosion Theory

The rate of corrosion is influenced by a number of variables such as the type of material, the oxide

layer present, the quality of the electrolyte and the potential relative to the reference electrode.

Moderate over protection can be accepted but may be uneconomic for steel, bronze and brass.

Over protection can cause paint disbondment and hydrogen embrittlement in high strength steel,

and can cause amphoteric attack to aluminum.

Corrosion rates depend upon many factors and, for this reason, the protection should be monitored

regularly under all operating conditions. These should include measuring the protection whilst the

vessel is moored and whilst under way.

If the anodes on the vessel have been set up for seawater usage and the vessel is used in fresh

water, the protection levels may fall and the Sentry will indicate the vessel is under protected. Under

normal circumstances, this should not be a problem as corrosion rates in fresh water are

significantly less than in seawater.

Care should always be taken where dissimilar metals are used next to one another.

Specifications

Dimensions 115 x 65 x 40mm Battery life 2 years (when used once per day)

Mounting bulkhead Ref. electrode Zinc

Power 3 x alkaline AA cells Zones 1,2 or 3 zones

Operating temp. 0 to 500 CResolution +/-5 mV

Range -1300mV to +1300mV Protection IP 65

Table of contents

Popular Measuring Instrument manuals by other brands

ThermoWorks

ThermoWorks Therma K operating instructions

Eico

Eico 232 instruction manual

PASCO

PASCO ES-9077 instruction sheet

AquaMaster Tools

AquaMaster Tools Combo pen P110 Pro user manual

Heyuan Intelligence

Heyuan Intelligence DZ81-MS3UI7C user manual

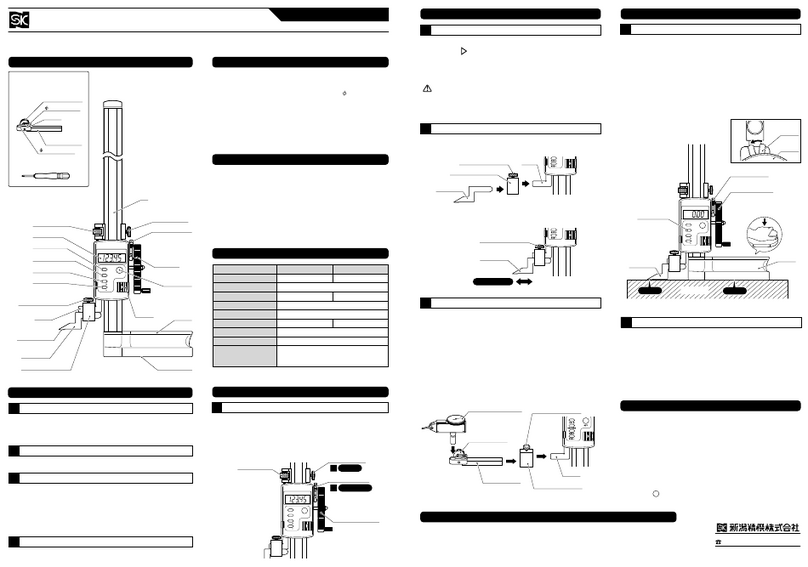

Niigata seiki

Niigata seiki VHS-30D instruction manual