Embraer ERJ-190 Series Installation guide

Embraer ERJ-190 Series (GE CF34) ATA 05 –ATA12

B1.1. and B2 AIRPLANE GENERAL

ISSUE 1, 24 Sep 2014 FOR TRAINING PURPOSES ONLY Page: 1

TRAINING MANUAL

Embraer ERJ-190 Series (GE CF34)

B1.1 and B2 (-sub) categories

AIRPLANE GENERAL

(ATA 05 –ATA12)

Level 1

Embraer ERJ-190 Series (GE CF34) ATA 05 –ATA12

B1.1. and B2 AIRPLANE GENERAL

ISSUE 1, 24 Sep 2014 FOR TRAINING PURPOSES ONLY Page: 2

THIS PAGE IS INTENTIONALLY LEFT BLANK

Embraer ERJ-190 Series (GE CF34) ATA 05 –ATA12

B1.1. and B2 AIRPLANE GENERAL

ISSUE 1, 24 Sep 2014 FOR TRAINING PURPOSES ONLY Page: 3

TABLE OF CONTENTS

DOCUMENTATION .......................................................................................6

INTRODUCTION........................................................................................6

DOCUMENTATION ACCESS ....................................................................8

AMM PART I - SYSTEM DESCRIPTION SYSTEM (SDS)........................10

AMM PART II - MAINTENANCE PRACTICES AND PROCEDURES (MPP)

.................................................................................................................12

MAINTENANCE PRACTICES AND PROCEDURES (MPP).....................14

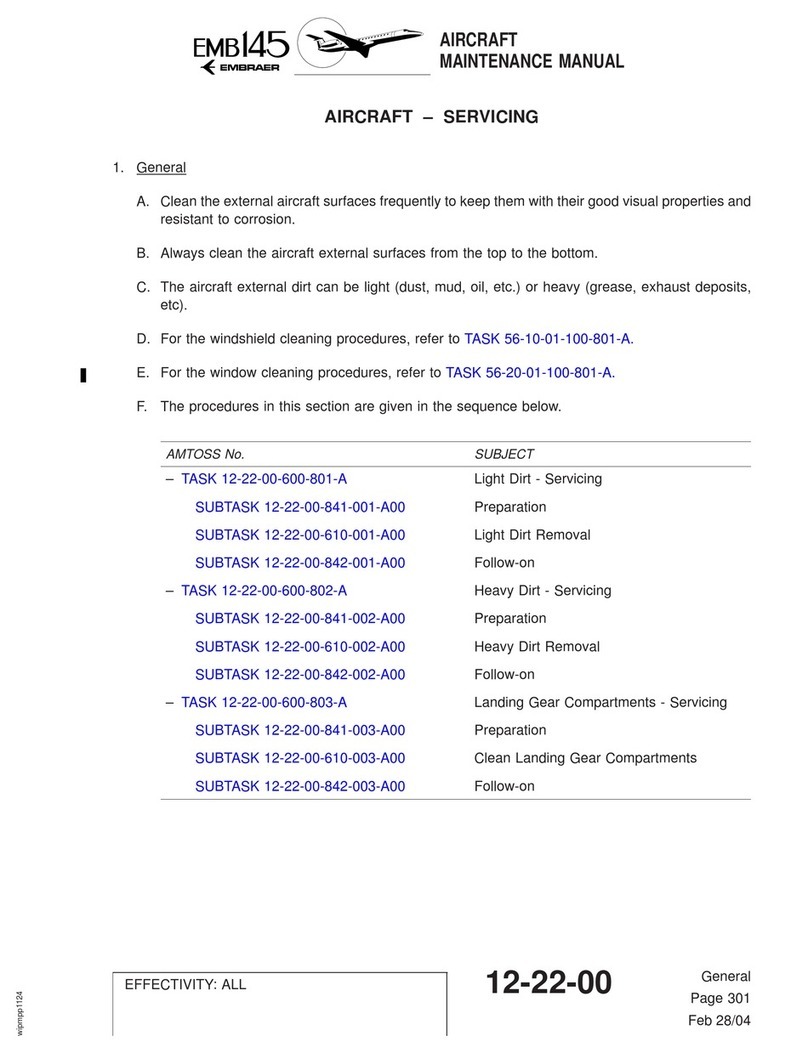

AIRCRAFT MAINTENANCE TASK ORIENTED SUPPORT SYSTEM

(AMTOSS)................................................................................................14

FUNCTION CODES.................................................................................14

AIRCRAFT MAINTENANCE MANUAL.....................................................16

FAULT ISOLATION MANUAL (FIM).........................................................18

RAMP MAINTENANCE MANUAL (RMM).................................................20

COMPONENT MAINTENANCE MANUAL (CMM)....................................20

WIRING MANUAL (WM)...........................................................................22

AIRCRAFT ILLUSTRATED PARTS CATALOGUE (AIPC) .......................24

STRUCTURAL REPAIR MANUAL PART 1 (SRM 1)................................26

STRUCTURAL REPAIR MANUAL PART 2 (SRM 2)................................28

OTHER DOCUMENTATION ....................................................................32

ATA 05 TIME LIMITS AND MAINTENANCE CHECKS................................52

INTRODUCTION......................................................................................52

SCHEDULED MAINTENANCE CHECKS.................................................52

UNSCHEDULED MAINTENANCE CHECKS............................................55

ATA 06 DIMENSIONS AND AREAS............................................................56

INTRODUCTION......................................................................................56

DESCRIPTION.........................................................................................58

ATA 07 AIRCRAFT JACKING......................................................................76

INTRODUCTION......................................................................................76

COMPLETE AIRCRAFT JACKING...........................................................78

BEFORE COMPLETE AIRCRAFT JACKING...........................................80

JACKING POINTS LOCATION.................................................................82

NOSE AND MAIN GEAR JACKING POINTS ...........................................84

ATA 08 LEVELING AND WEIGHING...........................................................86

INTRODUCTION......................................................................................86

WEIGHING THE AIRCRAFT....................................................................88

AIRCRAFT LEVELING.............................................................................90

ATA 09 TOWING AND TAXIING..................................................................92

INTRODUCTION......................................................................................92

TOWING WITH TOWBAR........................................................................94

TOWING OPERATION.............................................................................96

TOWBARLESS TOWING.........................................................................98

TAXIING REGULATIONS.......................................................................100

ATA 10 PARKING AND MOORING ...........................................................102

INTRODUCTION....................................................................................102

MINIMUM DISTANCES..........................................................................104

NORMAL AIRCRAFT PARKING.............................................................106

LONG TERM PARKING .........................................................................110

MOORING THE AIRCRAFT ...................................................................112

ATA 11 PLACARDS AND MARKINGS.......................................................114

INTRODUCTION....................................................................................114

ATA 12 SERVICING...................................................................................116

INTRODUCTION....................................................................................116

REPLENISHING.....................................................................................118

FUEL TANK SERVICING .......................................................................120

HYDRAULIC AND LANDING GEAR SYSTEM SERVICING...................122

ENGINE AND AUXILIARY POWER UNIT SERVICING..........................124

SERVICING WATER/WASTE.................................................................126

GASEOUS SERVICING .........................................................................128

SCHEDULED SERVICING.....................................................................130

UNSCHEDULED SERVICING................................................................132

Embraer ERJ-190 Series (GE CF34) ATA 05 –ATA12

B1.1. and B2 AIRPLANE GENERAL

ISSUE 1, 24 Sep 2014 FOR TRAINING PURPOSES ONLY Page: 4

TABLE OF FIGURES

DOCUMENTATION.......................................................................................7

DOCUMENTATION ACCESS .......................................................................9

AMM PART I –SDS EXAMPLE ..................................................................11

AMM PART II –MPP EXAMPLE.................................................................13

AMTOSS CODES AND SUBDIVISION .......................................................15

AIRCRAFT MAINTENANCE MANUAL.......................................................17

FAULT ISOLATION MANUAL USED AWITH AIRCRAFT CMC (CENTRAL

MAINTENANCE COMPUTER)....................................................................19

RMM AND CMM..........................................................................................21

WIRING MANUAL AND SYSTEM SCHEMATIC MANUAL.........................23

AIRCRAFT ILLUSTRATED PARTS CATALOGUE (AIPC).........................25

SRM 1..........................................................................................................27

SRM 2, DAMAGE REPORT FORM EXAMPLE...........................................29

SRM 2 USAGE............................................................................................31

EXAMPLE OF ARM AND ITEM...................................................................33

EXAMPLE OF NDT MANUAL.....................................................................35

EMB 190 AND 195 ......................................................................................37

FUSELAGE AND AIR CONDITIONING PACKS .........................................39

COCKPIT AND CABIN SECTION...............................................................41

SEAT CAPACITY........................................................................................43

LANDING GEAR .........................................................................................45

TURNING RADIUS......................................................................................47

CF34-10E HIGH BYPASS TURBOFAN ENGINES......................................49

AIRCRAFT DATA........................................................................................51

CHAPTER 05...............................................................................................53

HORIZONTAL MEASUREMENTS ..............................................................57

AIRCRAFT MEASUREMENTS EMB 190....................................................59

AIRCRAFT MEASUREMENTS EMB 195....................................................61

AIRCRAFT DOORS.....................................................................................63

FUSELAGE STATIONS ..............................................................................65

WING STATIONS........................................................................................66

HORIZONTAL STABILIZER STATIONS.....................................................67

VERTICAL STABILIZER STATIONS ..........................................................68

POWERPLANT AND PYLON STATIONS...................................................69

MAJOR AIRCRAFT ZONES........................................................................71

SUB-ZONES................................................................................................73

ACCESS PANELS IDENTIFICATION .........................................................75

LANDING GEAR JACKING , JACKING POINTS........................................77

COMPLETE AIRCRAFT JACKING .............................................................79

CG POSITION..............................................................................................81

JACKING POINTS LOCATION ...................................................................83

MAIN AND NOSE GEAR JACKING POINTS..............................................85

WEIGHING PROCEDURES.........................................................................87

WEIGHING THE AIRCRAFT, WEIGHING KIT AND JACKS OR GROUND

SCALES ......................................................................................................89

AIRCRAFT LEVELING................................................................................91

CHAPTER 9 TOWING AND TAXIING .........................................................93

GROUND TOWING REQUIREMENTS (EXAMPLE)....................................95

BEFORE TOWING.......................................................................................97

TOWBARLESS USING GSE 200 OR GSE 422...........................................99

TAXI REGULATIONS................................................................................101

TYPES OF PARKING................................................................................103

MINIMUM DISTANCES .............................................................................105

NORMAL AIRCRAFT PARKING...............................................................107

NORMAL AICRAFT PARKING IN COLD WEATHER CONDITIONS........109

LONG TERM PARKING ............................................................................111

MOORING THE AIRCRAFT ......................................................................113

EXTERIOR SCREED –PRINTED MARKINGS .........................................115

CHAPTER 12.............................................................................................117

REPLENISHING ........................................................................................119

FUEL TANK SERVICING ..........................................................................121

HYDRAULIC AND LANDING GEAR SYSTEM SERVICING.....................123

ENGINE AND APU SERVICING................................................................125

WATER WASTE SERVICING....................................................................127

GASEOUS SERVICING.............................................................................129

SCHEDULED SERVICING ........................................................................131

UNSCHEDULED SERVICING ...................................................................133

Embraer ERJ-190 Series (GE CF34) ATA 05 –ATA12

B1.1. and B2 AIRPLANE GENERAL

ISSUE 1, 24 Sep 2014 FOR TRAINING PURPOSES ONLY Page: 5

THIS PAGE IS INTENTIONALLY LEFT BLANK

Table of contents

Other Embraer Aircraft manuals