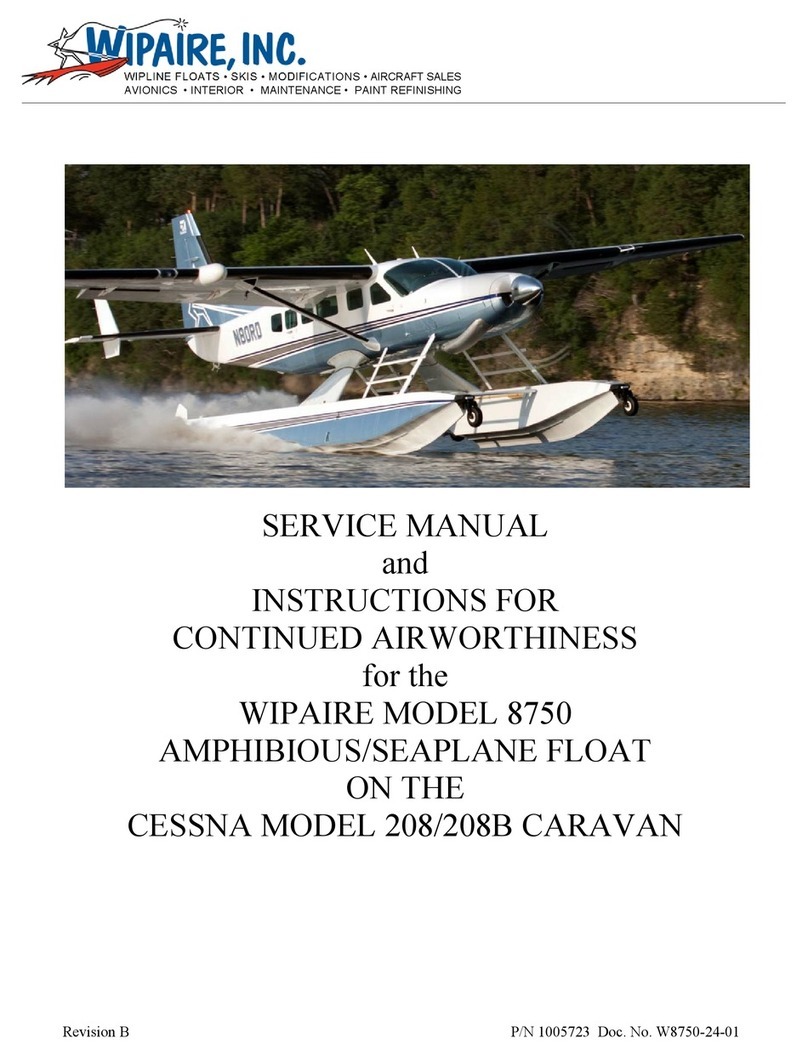

SERVICE MANUAL & ICA

8750 AMPHIBIAN/SEAPLANE FLOATS ON CESSNA 208/208B

Doc. No. W8750-24-01 P/N 1005723 Revision L Page 3

Rev Pages Description Date

IR All Initial Release 7/3/2012

A All Add green grease as an approved grease. 4/18/2013

B All Added 208B eligibility, updated Hydraulic powerpack image. 6/28/2013

C All

Updated Fig 1-8 for new oleo, updated photo p. 25, changes to MLG rigging

procedure, update to inspection procedures, dened water rudder rigging

procedures, remaining pages repaginated, removed p. 107.

5/30/2014

D All

Added Shear Torque chart, PR 1440 C Sealant, Tef-Gel and full contact

info. Removed Warranty Claim Form. Corrected 1200 was 1000, 1400 was

1150 and 1900 was 1300.

5/26/2015

E All Added Dow Corning DC4 and Mobil Aviation Grease SHC 100 to approved

product list. 7/9/2015

F All Added instruction for main gear oil bath system. 9/22/2016

G11 Added reference for Structural Repair Manual part number 1008274 in

introduction. 5/21/2019

H82, 87-

89, 91

Added instructions to oat re-install checklist, changed pylon attachment

inspection intervals, updated oat removal checklist. 8/5/2019

J 84 Added note for Main Landing Gear Axle Shaft in Maintenance Inspection

Checklist. 9/5/2019

K All

Created manual in new software and changed formatting. Added

instructions for Oleo Strut and Tire Servicing. Removed instructions about

annual inspection under Main Gear Oleos in checklist. Added PR 1422 to

approved Float Sealant. Updated Corrosion Limits chart to add extrusions.

Removed Inspector sign o column in maintenance checklist and oat

removal and re-install checklist.

1/9/2020

L

32-33,

35, 37,

67-68,

70, 73-

74

Added note about STA-Lube. Added information for Oil Bath Wheels.

Updated Figure 4-3. Updated title for Figure 4-2A. Added Figure 4-2B.

Added STA-Lube to Brake Caliper Grease. Added information about

corrosion limits. Removed Figure 9.1. Updated details in Maintenance

Checklist for spreader bars and y wires. Added Emergency Gear

Retractions/Extension steps to Maintenance Checklist due to previous

removal. Added Greased Wheel Only procedure in Maintenance Checklist.

Replaced inspector sign o column in oat removal and re-install checklist.

8/3/2020

View most current revision of this ICA at www.wipaire.com.