Seagull IV X-1F Operating manual

SEAGULL®IV X-1F

Drinking Water Purification System

NOTE: Read instructions completely before starting.

General Ecology’s X-1F drinking water purification system is designed to operate at pressures ranging from 25 to 125 psi. If pressure

surges are a possibility (municipal water supplies), install a Pressure Regulator or Surge Protector on the cold water supply line. This

system is intended to be installed to the cold water supply line, downstream of and above the cold water shut-off valve inside the

kitchen sink cabinet (see page 4). Be sure to close supply valves before installation. The Connector Hose will fit an Owner-Supplied

Connector T or our optional Saddle T Assembly or Male Run T shown on page 4. Connector branch of Owner Supplied T must have

aa

aa

a

" Male Compression Thread (

hh

hh

h

" - 24 Thread). The cold water supply line should be clean and free of construction debris. A

pp

pp

p

" to

1½" diameter hole is necessary for mounting the easily installed special Faucet furnished with this unit.

Follow steps 1through 9for installation. Steps Athrough Fare cartridge replacement instructions. An order blank is included for

assistance in obtaining replacement Cartridges. Configuration specifications are shown at the end of this guide.

Installation Instructions

INSTALLATION AND PRODUCT USE GUIDE

supersedes 200712Ax-1f-i&o

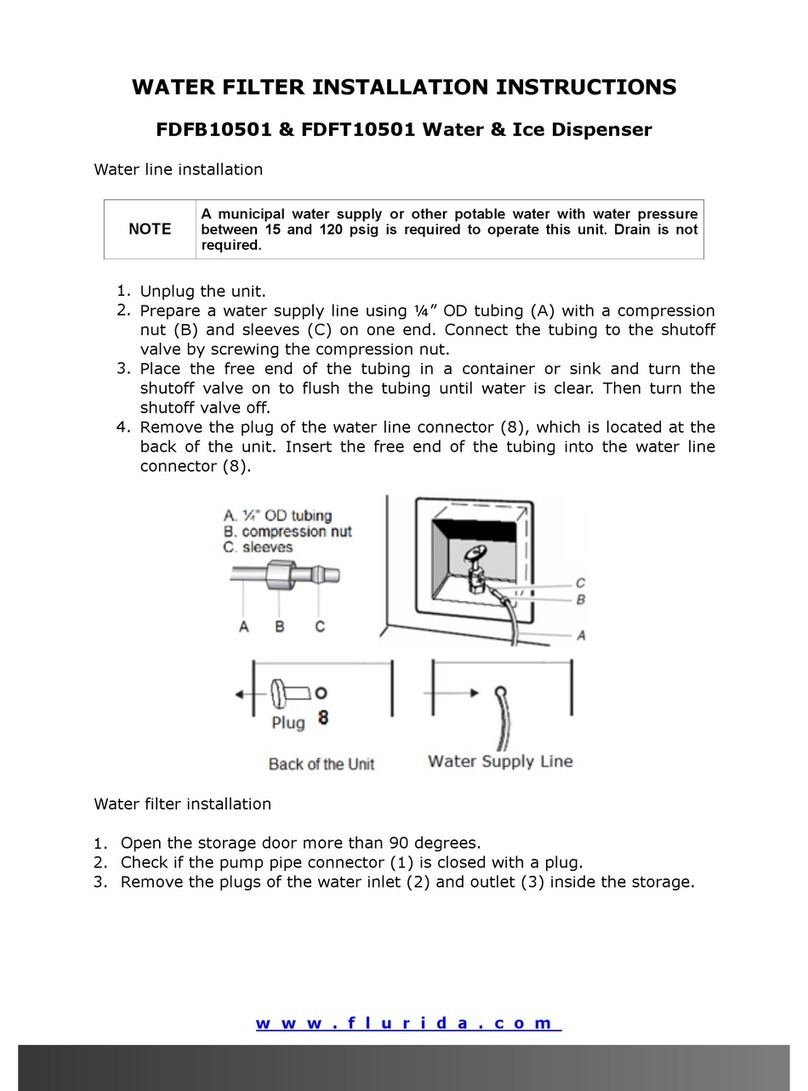

2. Install Cartridge. Thread Cartridge

(Fig.2) into top half of Pressure Vessel

(Be careful not to cross thread.) until

contact is first made with Rubber Seal.

Then tighten 44

44

4turn only. Do not

overtighten. Be sure Pressure Vessel

Flanges and Housing Gasket are clean

and free of dents, nicks or cuts.

3. Reassemble Pressure Vessel. Place

Gasket on Flange of lower half of

Pressure Vessel (Fig.3) and reassemble

V-Clamp, keeping Seagull IV logo

upright. The Wing Nut on the Clamp

shouldbe tightened snugly, by handonly.

Use no tools to tighten.

General Installation Instructions Please retain for future servicing of your SEAGULL®IV Water Purifier

Exclusive Feature — TOP MOUNT FAUCET!

6. ConnectHosedirectly toFaucet Stem

and tighten securely by hand. Do not

overtighten. Insert and thread Spout

into base, Do not over tighten

(figure 5).Drop free end of Connector

Hose through previously prepared

hole and position Faucet in hole.

Figure 4

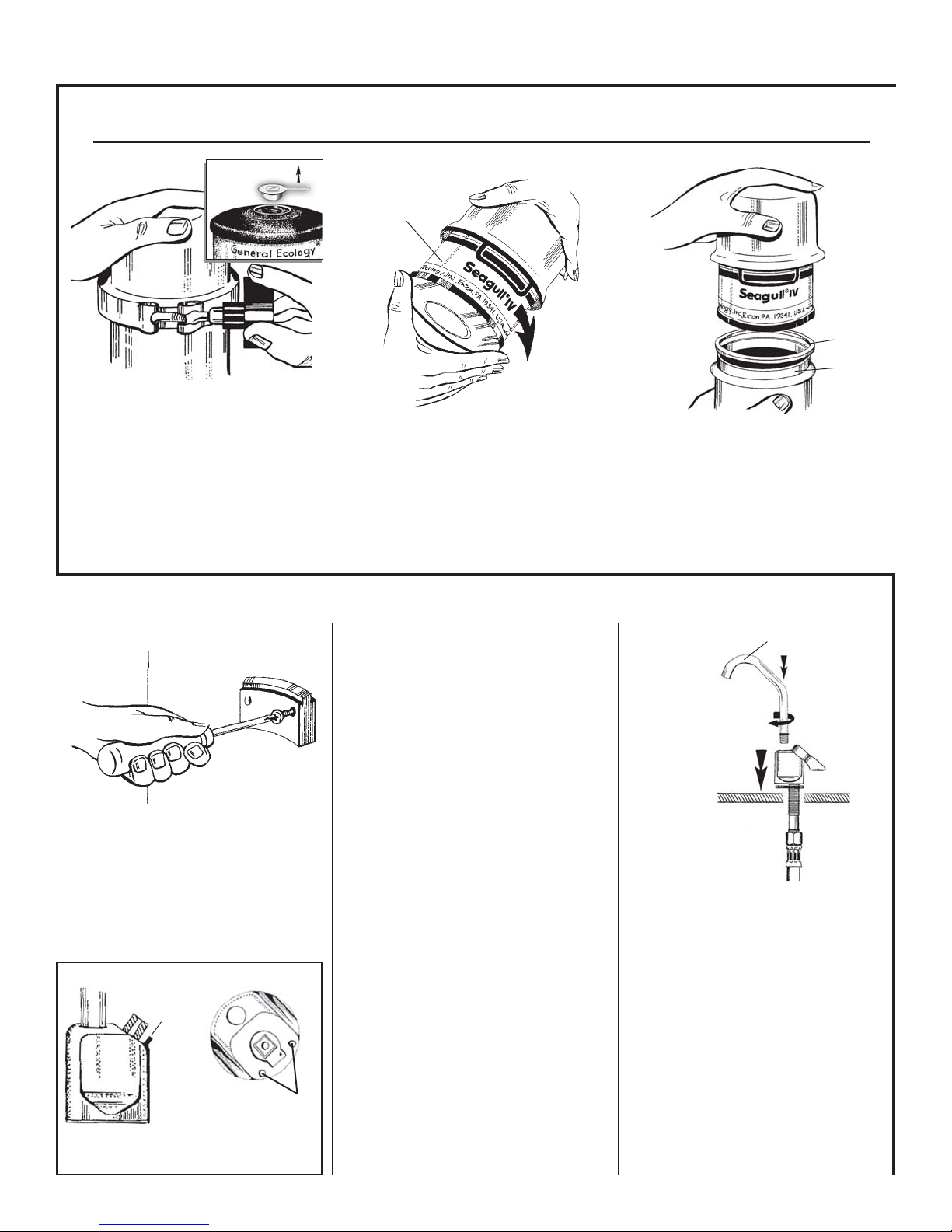

4. Install Mounting Bracket. Position

black Mounting Bracket on the inside

wallof the sink cabinet.Usethe two Self-

Tapping Screws to securely install the

Bracket. Make sure the Bracket location

permits access to the cold water valve

location and easy access for Cartridge

changes.

To change “pull direction” of handle

To change “pull direction” of handle on faucet,

lift handle off stem and reposition stainless steel

pin to alternate location. Reinstall handle.

Stainless

steel pin

Place Pin on right

or left side

5. Install Faucet. The X-1F is furnished

with General Ecology’s exclusive “Top

Mount” Ceramic Disc Faucet. If a

suitable hole isn’t available, prepare a

¾" hole to install your faucet. Cut out

Mounting Pattern supplied on page

number 6 and use for rough positioning.

Tape pattern in place, then for final

positioning place Faucet on pattern on

top of sink and check for correct position

of faucet body, spout and lever. Make

sure of clearance, above and below sink

before drilling mounting hole. Porcelain

sinks require special care. For best

results we suggest you contact your

dealer or others with experience in

making cutout in porcelain sinks. We

have had good success with the

following procedure. First cover the area

being penetrated with masking or duct

tape and from beneath drill a d" pilot

hole upward...a ¼" hole and then a g"

hole and finally the ¾" hole necessary

to mount the faucet. For man-made and

stone products consult counter top

manufacturer’s guidelines. For stainless

steel sinks use a “Greenlee” type punch/

die tool. If you do not have a “Greenlee”

punch and are installing on stainless,

follow the same procedure as on

porcelain/cast iron sinks. Be sure sink

ledge at drill hole is “flat” and burr free.

2

Housing

Gasket

Flange

Figure 3

Cartridge

Figure 2

Figure 5

threaded

spout

Figure 1

1. OpenCanister.Remove V-Clamp and

separate Pressure Vessel upper and

lower halves.

2. Remove Cover. Remove small plastic

protective cover from your new

cartridge by pulling the tab end up

(Fig.1a).

V-Clamp

1a

Preliminary: If needed purchase from local hardware store and install Connector T or Saddle Valve

with a" compression outlet in cold water supply line.

Inlet Line

Outlet Line

Figure 6Figure 7

Cartridge Replacement Instructions

7. MountFaucet. Slideopen side of Faucet

Mounting Nut onto reduced diameter,

un-threaded section of Faucet Stem now

beneath the sink, and slide the Nut

upwards to contact the threads. Then

carefully engage the threads, being

careful to not cross thread. Hand tighten

as necessary to hold the Faucet in place,

but do not use tools and do not

overtighten. Check alignment and

position of Faucet, and adjust as

necessary. (We suggest you practice

threading the Nut to the Stem above the

sink, prior to the actual installation, to

become familiar with the method before

installing Faucet to sink.)

8. ConnectInlet andOutlet lines.Connect

free end of Thermoplastic Connection

Hosefrom Faucet Stemto Outlet (center)

Port on the Pressure Vessel. Tighten

securely. Do not overtighten. Connect

remaining Hose from fitting on cold

water supply line to Inlet (outside) Port

on top of Pressure Vessel. Do not

overtighten.

All Seagull®IV X-1 units employ a RS-1SG Cartridge. The rated average capacity for the RS-1SG

Cartridge is 1,000 gallons. Actual capacity will vary depending on operating conditions and the quality

of the water source. Cartridges should be replaced when the flow rate decreases or when foul tastes or

odors become apparent (evidence of extra heavy loading of sulfur, tannin, iron or contamination), or

annually otherwise. Installing a Cartridge is easily accomplished as follows:

A. Close cold water supply valve.

B. Open X-1F Faucet, and keep it open

until new Cartridge is installed and

operating.

C. Removeunit from Mounting Bracket,

place over a large sauce pan or other

container, remove V-Clamp and drain

loose water from Pressure Vessel. (If

PressureVessel halves remain attached

due to “set,” pull apart manually or

momentarily allow a small amount of

water to flow into the unit with the X-

1F faucet closed to separate the halves.

If X-1F faucet is closed, be sure and

reopen before continuing with next

step).

D. Remove expended Cartridge by

placing plastic bag over it and turning

counter clockwise. Close bag and

discard. Rinse inside of Pressure Vessel

9. Mount unit on Bracket by placing the

V-Clamp over the raised section on top

of the Bracket. Open the X-1F Faucet to

allow air to exhaust slowly. Open Valve

on cold water service line. Check for

leaks. Allow water to run for several

minutes to clear line and system of air

and any loose materials. Please note that

for the first few days you may see

entrapped air bubbles within the water.

This is perfectly normal and will cease

after the unit has processed several

gallons of water. Also, some black

“fines”from inside ofcartridge may flow

with the first few gallons of water.These

are harmless, if consumed, or may be

discarded.

Figure 8

3

Inlet Line

connects

to Cold Water

Supply.

Outlet Line

connects to

Pure Water

Faucet.

QUESTIONS?

Call 1-800-441-8166

for Customer service

with water and wipe clean with paper

towel Be sure thick White Rubber

Cartridge Seal is bonded in place inside

the top of the unit.

E. Align carefully, and being careful not

to cross thread, thread new Cartridge

into place UNTIL CONTACT IS

FIRST MADE WITH SEAL, THEN

TIGHTEN ONE QUARTER TURN

ONLY. DO NOT OVERTIGHTEN.

Please refer to Step 2 and Figure 2.

Reassemble the two stainless steel

halves together, making sure the

rubber Housing Gasket is in

place between the two halves.

IMPORTANT: Make sure Gasket is

not cut or nicked, and be sure

housing has not been dropped or dented

on either of the two mating halves.

F. Refer to Step 9 to place unit back in

service.

HELPFUL

HINTS

Ifyouhavedifficultyseparatingtheupperand

lower halves of the pressure vessel, water

pressure can help. Turn off cold water supply;

remove the V-clamp and close the pure water

faucet. With a pan ready to catch water from

theunit, slowly turnonthewatersupply.Once

the unit begins to separate, turn off the water

supply and proceed according to your

InstallationandOperations instructions.

You may apply a light coating of petroleum

jelly to the housing gasket to assure ease of

openingandclosingofthesystem.

Whenanewcartridgeisputintoservice,you

may see air bubbles and black particles in the

wateruntilthesystemhasstabilized.Theseare

harmless and will be purged from the system

within the first few liters or quarts of water.

1 Female Compression Thread 2 800344

a"Braided Connector Hose

2 Mounting bracket with 2 1 700063

Mounting screws

3 Purification 1 788000

Cartridge RS-1SG

4 X-1 Pressure Vessel 1 N/A

5 Housing Gasket 1 710540

6 V-Clamp for Housing 1 710534

7 Wing Nut for V-Clamp 1 710032

8 Faucet, FP threaded 1 707206

9 Faucet Mounting Nut 1 707106

Optional Accessories Not Included

No. Description Qty. Part No.

SEAGULL®IV X-1F System Parts List

If unable to locate a dealer, cartridges and other parts may be ordered by mailing this form, or fax to our 24

hour fax order line (610) 363-0412 (Please include a daytime phone number.) You may also call 1-800-441-8166

between 8:00 AM - 4:30 PM ET. Please supply the information requested below. No P.O. Boxes, please. U.P.S.

shipping charges and state taxes will be added where applicable.

Convenient Order Form

Name: _________________________________________

Address: _______________________________________

City: __________________________________________

State: ________________________ Zip:___________

Phone: (________ ) ______________________________

Please Print

(Circle One)

Charge my: VISA MasterCard American Express

Part No. Item Quantity

Send To:

GENERALECOLOGY, INC.

151 Sheree Blvd.

Exton, PA 19341 U.S.A.

www.generalecology.com

Expiration Date Signature 4

Manufactured by General Ecology, Inc., Exton, PA 19341

Made in U.S.A.

visit our web site and Order Online at www.generalecology.com

must be filled in

items within

dotted line are

included with

X-1F Purifier

Female a"Stainless Steel

Compression Cap Nut with

Gasket 800349

a"x a"x a" Stainless Steel

Compression T 714358

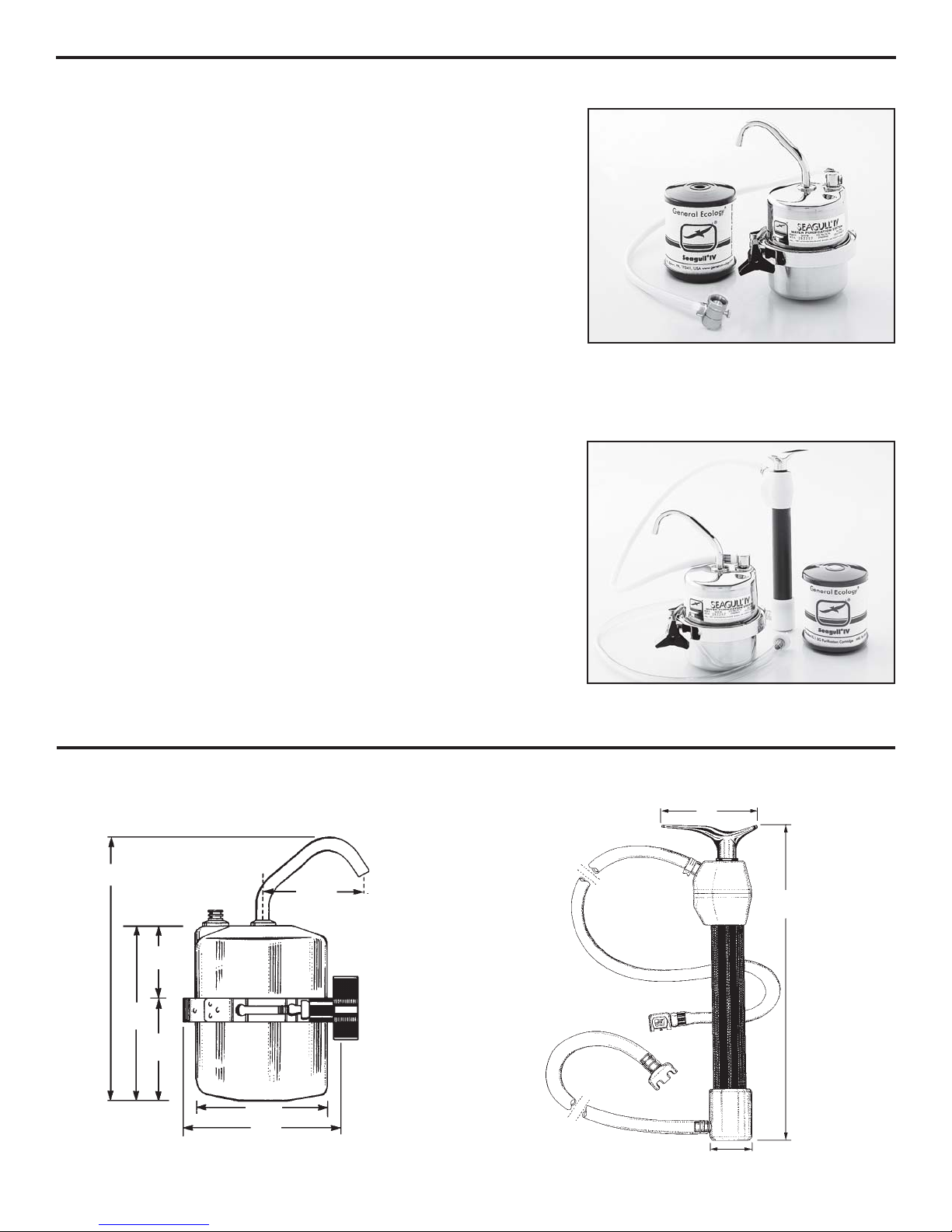

Seagull®IV X-1D Water Purifier

Diverter Configuration - Ideal for apartments,

condominiums or rental properties.

The Seagull IV X-1P configuration has a double acting pump for more water

with less work. Field serviceable pump disassembles for easy cleaning and

permitsthe X-1P water purifier tobe used with gravity feed assistance systems.

"Quick Disconnect" is identical to X-1D configuration for quick and easy

interchangeability.

Easy to install, easy to use. Simply remove aerator from standard kitchen

faucet and connect diverter valve. Attractive "Quick Disconnect" fitting

provides swivel movement of the connector hose, routed at right angles for

easy positioning and less clutter.

Our X-1D configuration includes two adapter bushings, enabling the diverter

to fit approximately 95% of the faucets made in the USA and many overseas.

Seagull®IV X-1P Water Purifier

Manual Pump Configuration - Ideal for camping,

emergency preparedness, and cottages,

anywhere pressurized water is not available.

5

Dimensions of SEAGULL®IV X-1D Vessel and X-1P Pump

4.1"

(10.5 cm)

5"

(12.7 cm)

2.9"

(7.3 cm)

5.4"

(13.7 cm)

2.5"

(6.4 cm)

8.9"

(22.6 cm) 3.5"

(8.9 cm)

1.3"

(3.2 cm)

3.5"

(8.9 cm)

10.5"

(26.7 cm)

X-1P PUMP

X-1D/X-1P PRESSURE VESSEL

1.9"(4.8 cm)

FP FAUCET

PART NUMBER

Chrome 707203

.725" (1.9 cm)

7.4"

(18.8 cm)

6.0"

(15.3 cm)

2.1"

(5.3 cm)

4.1"

(10.4 cm)

Cutoutfaucetbasepatternanduseforroughposition. Tapepattern

in place. Then, for final positioning, place faucet on pattern on top

of sink and check for correct orientation of faucet body, spout and

handle. This final positioning is needed before making your

installationhole.

It is important to note control handle position and “throw” to

insure adequate clearance.

Alsonotethe“swingfeature”of the faucet’sspoutthatallowsmany

different mounting options.

Make sure of all clearances above and below sink before drilling

mountinghole.

Mounting Hole Pattern for

FP Faucet

PATTERN OF BASE OF FP FAUCET SHOWING HOLE

LOCATION (ACTUALSIZE)

Faucet Care Instructions

AllGeneral Ecology,Inc. purifiers featureleadfreeports and faucets.

Faucets are manufactured with the finest components available.

However, they require proper care to keep them looking their best.

If properly cared for, these finishes can provide a lifetime of elegance.

Chromefinishescanbe damaged by abrasive cleaners, inspiteoftheir

hardness. To clean faucet surfaces properly, use a small amount of a

non-abrasiveliquiddetergentandasoftwetcloth.Gentlyrubthesoiled

surface until the dirt is removed. Then rinse clean and wipe with a dry

soft cloth to remove water drops and to prevent spotting. Do not use

any abrasive or pumice type cleansers to clean the surfaces of these

faucets,oryoumaypermanentlyscratchorotherwisedamagethefaucet

coating. Hard water may leave mineral deposits or “water spots”. If

not cleaned regularly, these deposits may resist cleaning with simple

liquiddetergents.These can usuallybe removed using asmallamount

ofvinegarapplied directlyandrubbingwitha softcloth.Heavydeposits

may require repeated applications.

© 2004 General Ecology, Inc. • ®, ™ Trademarks of General Ecology, Inc. • All health claims not in accordance with local or state laws are hereby withdrawn. • 200712 revB 9/07

SEAGULL®IV X-1F Positioning and

Dimension Information

1.9" (4.8 cm)

Base Diameter

.75" (1.9 cm.) Hole Diameter

6

Other Great Products Available

from General Ecology, Inc.

(610) 363-7900 • fax (610) 363-0412 • www.generalecology.com

2.9"

(7.3 cm)

5"

(12.7 cm)

4.1"

(10.5 cm)

5.4"

(13.7 cm)

2.5"

(6.4 cm)

X-1F PRESSURE VESSEL

AS9100, ISO 9001 and FAA Quality Certified PMA Manufacturer

Table of contents

Popular Water Filtration System manuals by other brands

Unilever

Unilever pureit CR5240 instruction manual

Aqua Optima

Aqua Optima Compact Instructions for use

Jandy

Jandy JS Series Installation and operation manual

DeVillbiss Air Power Company

DeVillbiss Air Power Company DAD-504 quick start guide

Wasserhaus

Wasserhaus 12220 manual

Netafim

Netafim SANDSTORM installation manual

REXENER

REXENER Mass Filter Installation and maintenance manual

Vision Aqua

Vision Aqua Verdanium Geo instructions

Kenmore

Kenmore RO-550 owner's manual

Pacific Sun

Pacific Sun AR-PRO S manual

Schmalz

Schmalz STF Series Operating and maintenance instructions

BWT

BWT PERMAQ compact 4 Fitting and operating instructions