2. INTRODUCTION & SPECIFICATIONS

Chuck size:................. 10mm

Free speed: .............. 2500rpm

Air consumption:...............4cfm

Operating pressure: ...........90psi

Air inlet size:.............. 1/4”BSP

Weight: ....................0.95kg

Noise Power: ........... 100.7dB(A)

Noise Pressure: .......... 89.7dB(A)

Vibration Emission Value:.... 0.89m/s²

Uncertainty Value: .......... 1.5m/s²

Original Language Version GSA232 Issue: 1 - 03/06/13

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS,

WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH

IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE OR PERSONAL INJURY AND WILL INVALIDATE THE

WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

3 Follow all workshop health & safety rules, regulations, and conditions when using drill.

p WARNING! Disconnect from air supply before changing accessories or servicing.

3 Maintain the drill in good condition and replace any damaged or worn parts. Use genuine parts

only. Non-authorised parts may be dangerous and will invalidate the warranty.

pWARNING! Check correct air pressure is maintained and not exceeded. We recommended 90 psi.

3Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use

and ensure that all connections are secure.

3Wear approved safety eye protection. If dust is generated wear respiratory protection, and

safety gloves.

3Wear suitable clothing to avoid snagging. DO NOT wear loose jewellery and tie back long hair.

3Keep hands away from rotating chuck and drill bit.

3Keep drill bits clean and sharp for best and safest performance.

3 Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

3Secure non stable work piece with a clamp, vice or other adequate holding device.

3Ensure the chuck is securely fastened to the spindle and the drill bit is secure in the chuck.

3 Keep children and unauthorised persons away from the working area.

8DO NOT get the drill wet or use in damp or wet locations.

8DO NOT apply excessive loads to the drill bit during operation.

8DO NOT hold the workpiece by hand. Use clamps or a vice to secure the workpiece.

7 DO NOT use the drill for a task it is not designed to perform.

pWARNING! DO NOT use drill if damaged or faulty. Contact your local service agent.

pWARNING! Beware of high-reaction torque when breaking through the material being drilled.

7 DO NOT use drill unless you have been instructed in its use by a qualified person.

7 DO NOT drop, throw or abuse the drill.

7 DO NOT carry the drill by the air hose, or yank the hose from the air supply.

7 DO NOT operate drill if you are tired, under the influence of alcohol, drugs or intoxicating

medication.

7 DO NOT carry drill with your hand on the power trigger in order to avoid unintentional starting.

7 DO NOT direct air from the air hose at yourself or others.

3 When not in use disconnect from air supply and store in a safe, dry, childproof location.

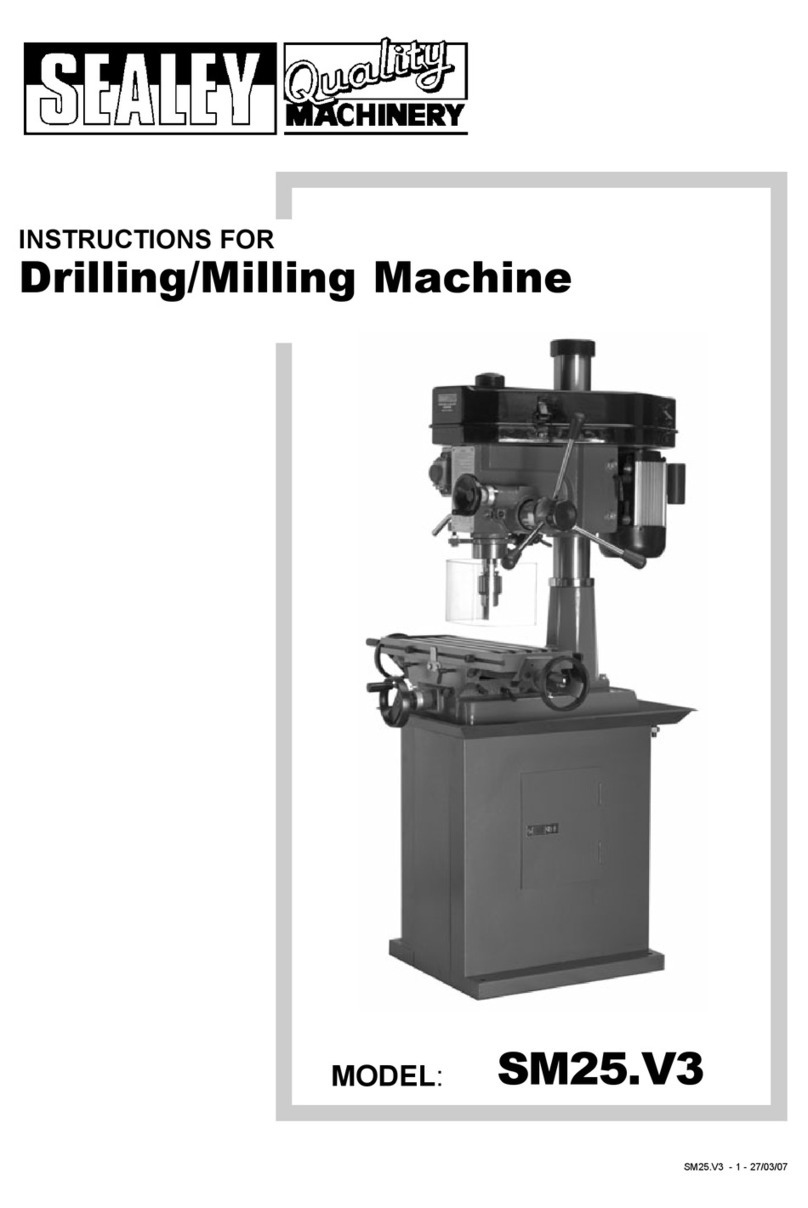

INSTRUCTIONS FOR:

AIR DRILL 10mm STRAIGHT-

KEYLESS CHUCK

MODEL No: GSA232

Textured grip and lightweight aluminium alloy housing provide comfort and control. Powerful air

motor provides smooth operation under load. Exhaust outlet adjusts 360° keeping air flow away

from operator. Fitted with safety release trigger control to prevent accidental operation. Fitted with

Jacob’s keyless chuck for fast bit changes.

© Jack Sealey Limited 2013