8DO NOT use on non magnetic materials.

8DO NOT use on the same steel work as electric welders are being used.

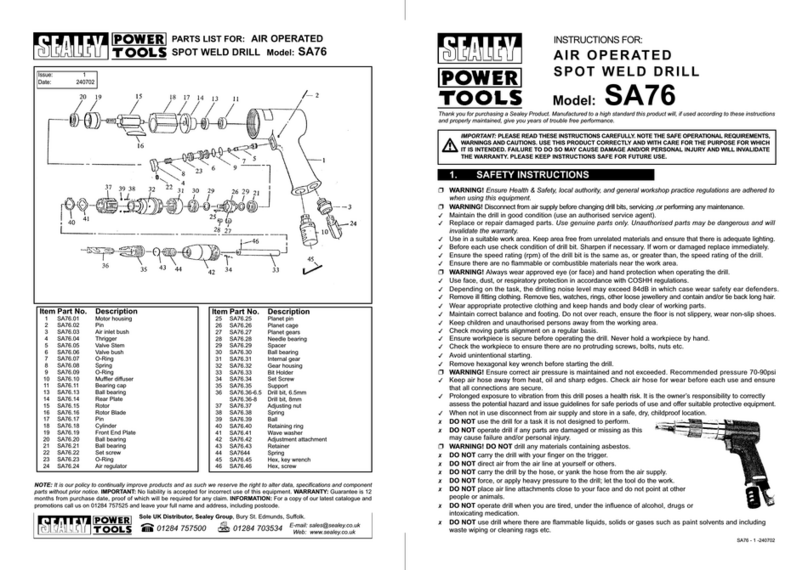

2. INTRODUCTION

Manufactured using high quality components for performance and reliability. Made from heavy-duty die cast magnesium alloy with a variable

speed gearbox for greater accuracy. Fitted with a powerful magnet to ensure unit stays adhered at any angle. Includes safety xing strap and

integrated coolant system to extend the life of cutters and increase the quality of the cut. Can be used with a 16mm twist drill chuck. Designed

for use in fabrication, construction and other applications when drilling ferrous metal.

3. SPECIFICATION

Model No...........................................................MAG60110V

Magnet.......................................................................15800N

Maximum Annular Cutter Capacity............................... 60mm

Maximum Cutter Depth ................................................ 50mm

Core drill diameter........................................................ 60mm

Motor Power................................................................1680W

No Load Speed ...................................................100-470rpm

Stroke length.............................................................. 210mm

Morse taper.....................................................................MT2

Supply................................................................110V ~ 50Hz

Electrical plug type...................................................3-Pin BS

Consumables (not included)

Pilot Pin.................................................................... MAGC.P

Neat Cutting Oil......................................................... NCO/5L

Soluble Cutting Oil .................................................... SCO/5L

4. ASSEMBLY

WARNING! Disconnect from mains supply before performing adjustments.

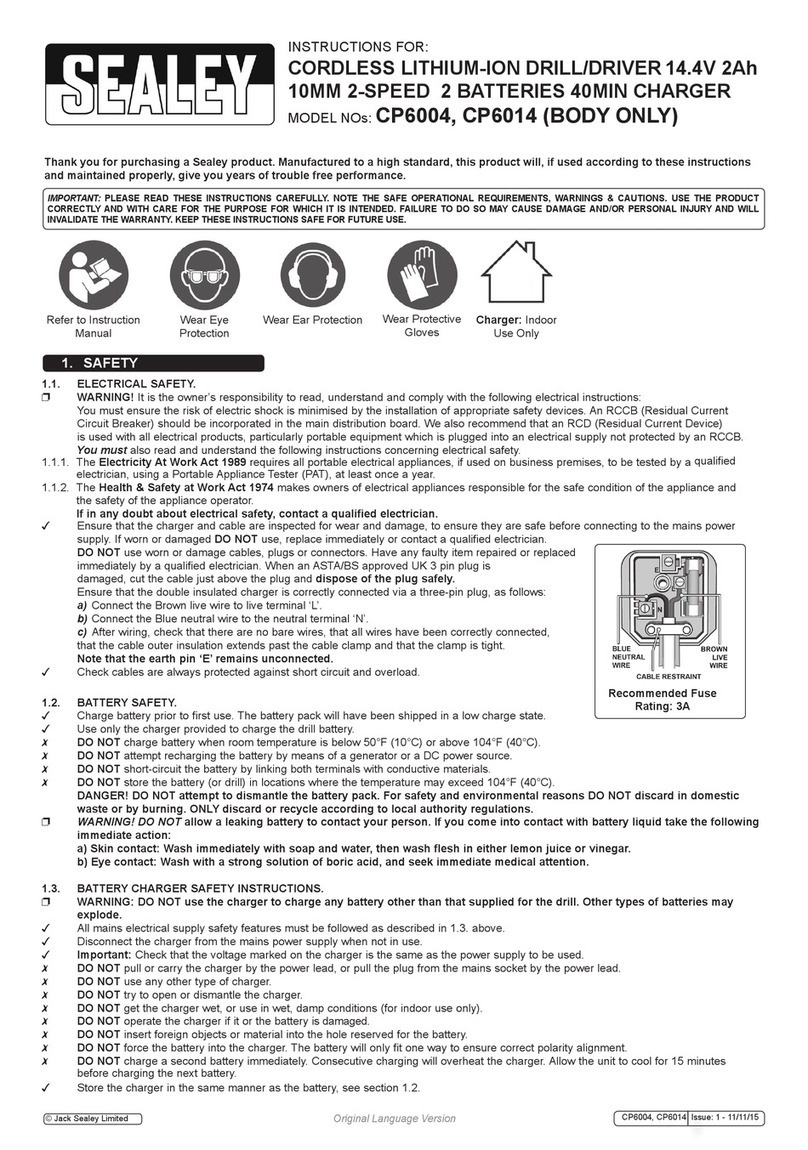

4.1. ATTACH COOLANT BOTTLE (g.1)

4.1.1. Slacken the 2 thumbscrews and slide bottle cage over the thumbscrews.

4.1.2. Tighten thumbscrews.

4.1.3. Connect coolant pipe to the valve on the lubrication ring (g.1). The pipe can be

released by pushing in the blue valve.

4.1.4. Make sure the coolant tap is closed, ll the bottle with appropriate lubricant.

4.1.5. Screw rotation stop (not shown g.1) to lubrication ring to limit rotation

of hose.

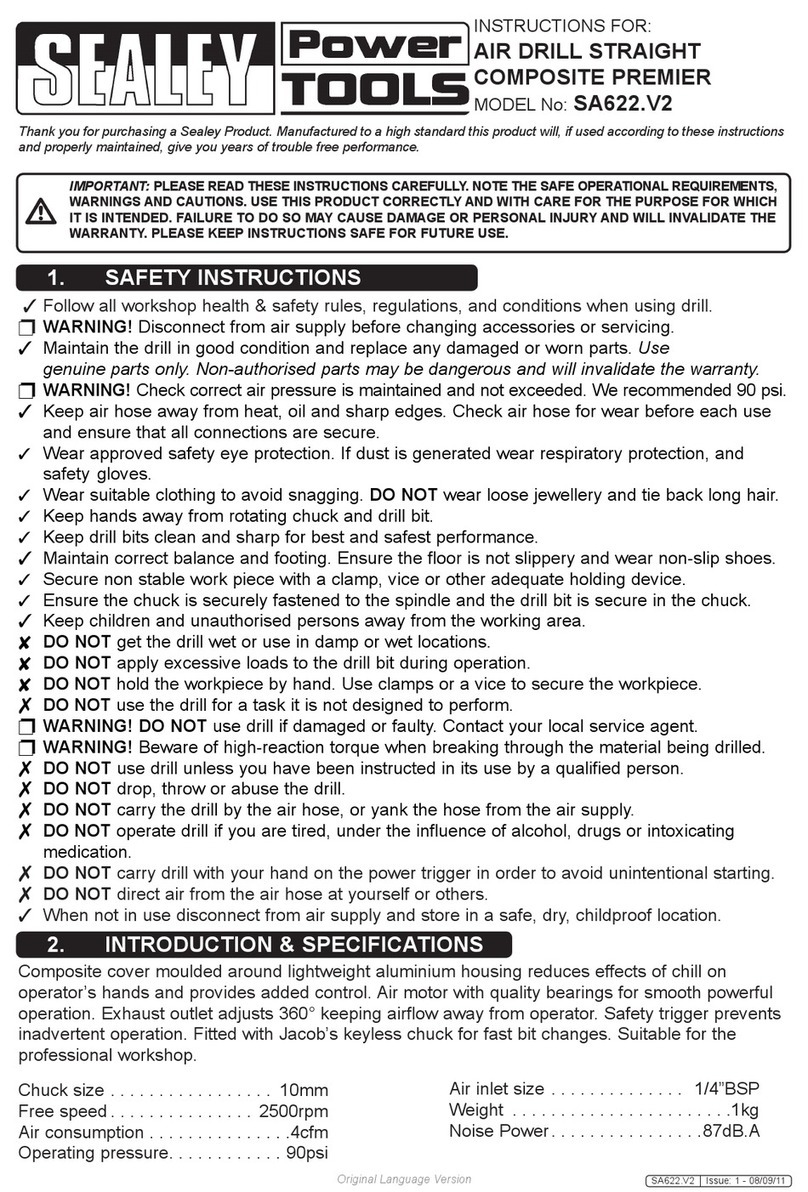

4.2. ADJUSTING THE SLIDES (g.2)

4.3. WARNING! Disconnect from mains supply before performing any adjustments.

4.3.1. To adjust the friction on the drill slide mechanism, remove the drill cutter.

4.3.2. Loosen the 5 slide locknuts and adjust the 2.5mm grub screws until the

required amount of friction on the slides has been achieved.

4.3.3. Tighten the locknuts and test before using the drill.

4.4. REPLACING THE FUSE (g.2)

4.4.1. Undo the fuse cover and replace fuse with one of same rating.

4.5. FIT CUTTING BIT

4.5.1. Wind drill head up to maximum height.

4.5.2. Wind out the two grub screws (g.1), insert the cutting bit aligning the ats with the grub screw locations and tighten.

5. OPERATION

5.1. FIT THE SAFETY STRAP

5.1.1. Securely x the safety strap though the handle of the drill and around the steelwork. Adjust the length of the strap so that if the drill

should fall the drill should not be allowed to swing too far and be damaged.

5.2. POSITION THE DRILL

5.2.1. Connect to the mains supply. Oer drill to workpiece and line up with the previously marked hole.

WARNING! Make sure there is nothing between the magnet and the workpiece BEFORE turning the magnet on.

5.2.2. Ensure the drill head is wound back away from the workpiece before turning the magnet on.

5.3. ATTACH DRILL TO WORKPIECE

5.3.1. Turn the magnet on (g.2). Wind the drill head down to the workpiece and align the cutting head pin (not supplied) with hole

centre marking.

NOTE: In order to ensure sucient magnetic attraction and thus grip to securely hold the drill in place, the workpiece must be at least 10mm

thick.

5.4. FILL COOLANT BOTTLE

5.4.1. Always use the correct cutting oil, refer to Section 3.

5.5. CUTTING THE HOLE

5.5.1. Turn on the coolant bottle tap (g.1).

5.5.2. Back the cutting head away from the workpiece, turn the drill motor on (g.2). Check the drill sounds and is operating normally.

5.5.3. Turn the handle anticlockwise to move the cutting bit towards the workpiece.

5.5.4. Start feeding slowly, with minimal required force to prevent overloading the drill.

CAUTION! Prepare for the cutter bursting through the workpiece.

5.5.5. If the drill suddenly stops, you must turn o the motor switch immediately.

5.5.6. Once the hole has been cut, back the cutting head back out of the hole and switch o the motor.

5.5.7. Turn o the coolant tap.

Original Language Version

© Jack Sealey Limited MAG60110V Issue 1 06/03/20

fig.1

fig.2