INSTRUCTIONS FOR:

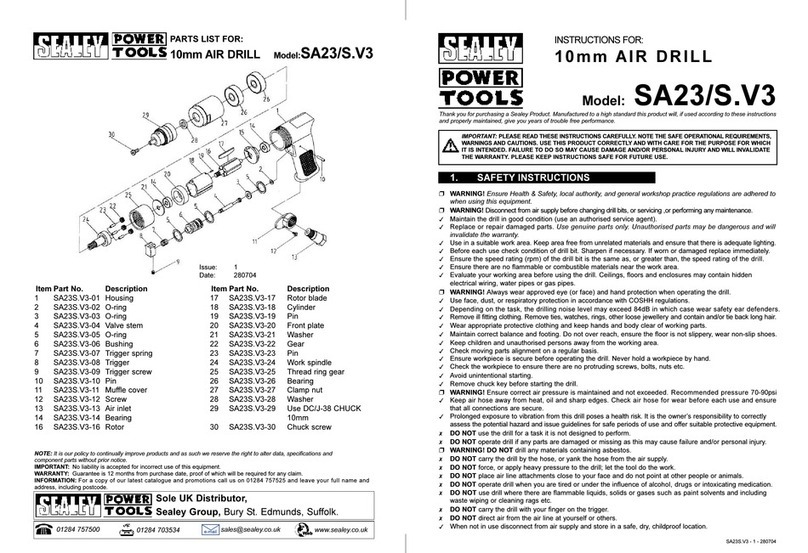

AIR ANGLE DRILL 10MM - KEYLESS CHUCK

MODEL NO: GSA231

1. SAFETY

3. SPECIFICATION

2. INTRODUCTION

GSA231 Issue 1 - 05/11/14

Original Language Version

© Jack Sealey Limited

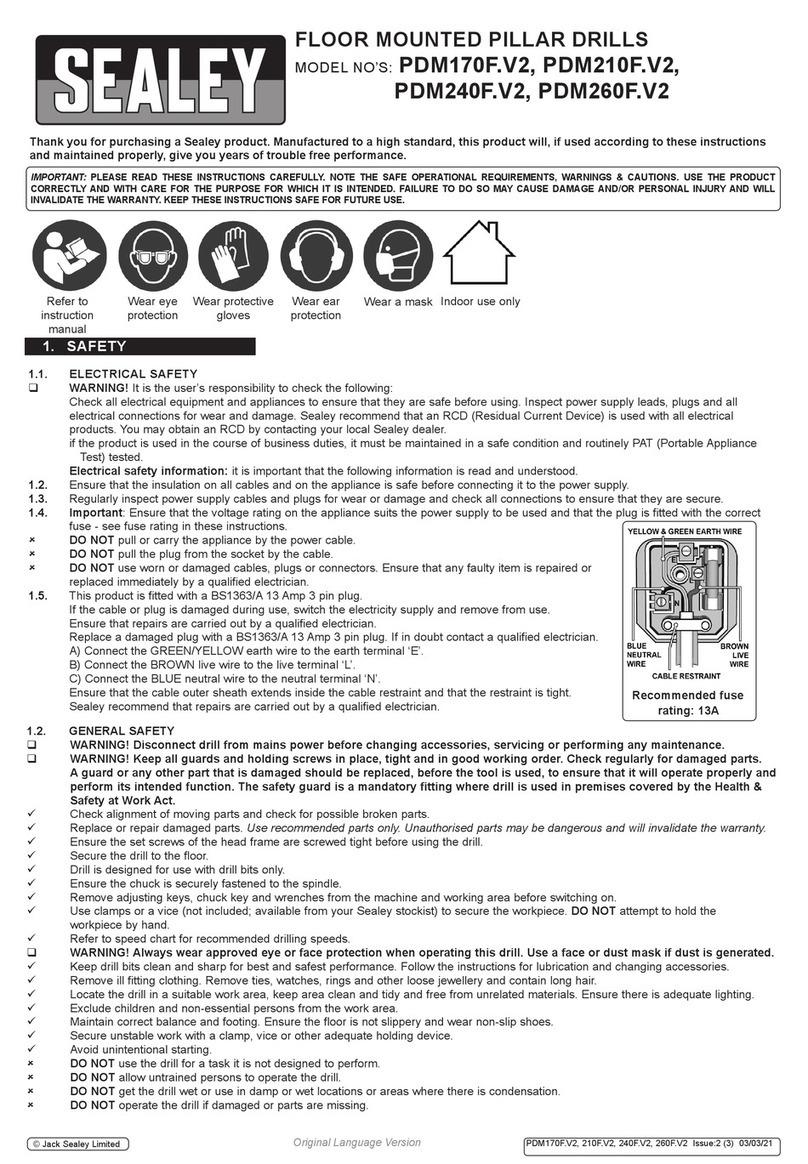

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE

PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL

INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

WARNING! Ensure Health & Safety, local authority and general workshop practice regulations are adhered to when using this equipment.

WARNING! Disconnect from the air supply before servicing or performing maintenance.

WARNING! Always wear approved eye or face and hand protection when operating the drill. If dust is generated wear a mask.

WARNING! Ensure correct air pressure is maintained and not exceeded. Recommended air line pressure is 90psi.

Remove ill fitting clothing. Remove ties, loose jewellery and contain and/or tie back long hair.

Wear appropriate protective clothing and keep hands and body clear of working parts.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

Maintain the tool in good condition (use an authorised service agent).

Replace damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

Use in a suitable clean and tidy work area, free from unrelated materials. Ensure that there is adequate lighting and ventilation.

Keep children and unauthorised persons away from the work area.

Keep hands away from rotating chuck and drill bit.

Ensure the workpiece, chuck and drill bit are secure before operating the drill. Never hold a workpiece in the hand. Use a vice or clamps.

Keep the air hose away from heat, oil and sharp edges. Check air hose for wear before each use and ensure that all connections are

secure.

Prolonged exposure to vibration from this tool poses a health risk. It is the employer’s/owner’s responsibility to correctly assess the hazard

and issue guidelines for safe periods of use and offer suitable protective equipment.

When not in use, disconnect from the air supply and store in a safe, dry, childproof location.

DO NOT operate the drill unless you have been instructed in its use by a qualified person.

DO NOT use any power source except an air compressor.

DO NOT operate the tool near any inflammable substance or on any container that has held an inflammable substance.

DO NOT use the tool for a task it is not designed to perform.

DO NOT operate the tool if any parts are damaged or missing as this may cause failure and/or personal injury.

DO NOT carry the tool by the hose.

WARNING! The warnings, cautions and instructions in this manual cannot cover all possible conditions and situations that

may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be applied by the operator.

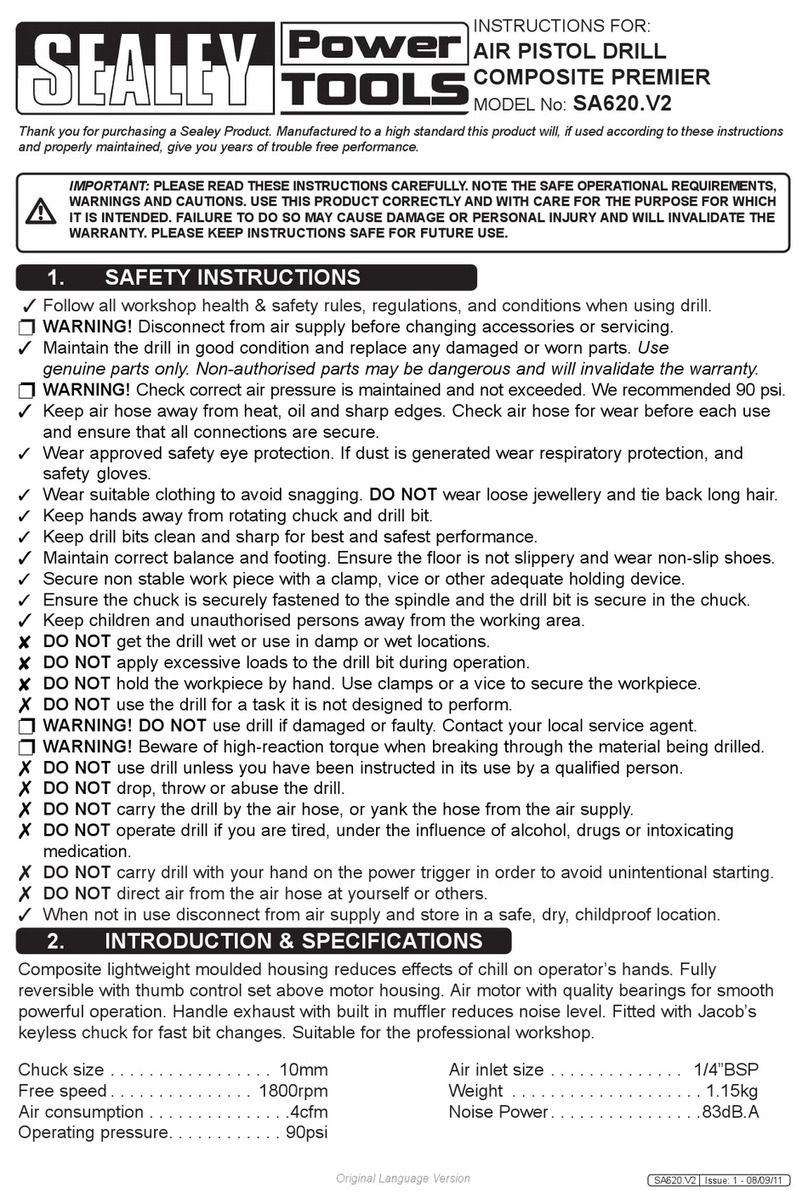

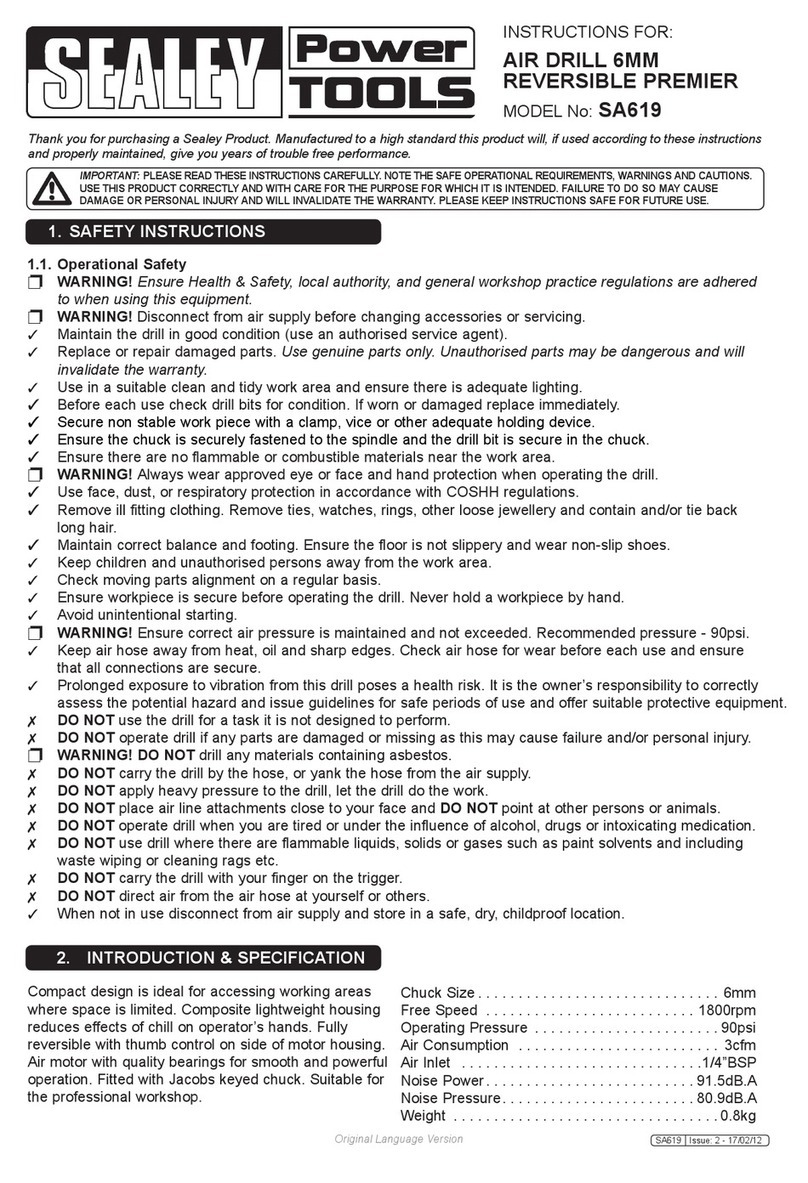

Contoured composite handle reduces effects of chill on operator's hands, provides added control and helps reduce vibration. 90° Angle is ideal

for drilling in hard to reach areas. Directional, low noise air exhaust can be rotated 360° giving operator added protection. Fitted with safety

trigger to prevent inadvertent operation. Supplied with Jacob's keyless chuck for fast bit changes.

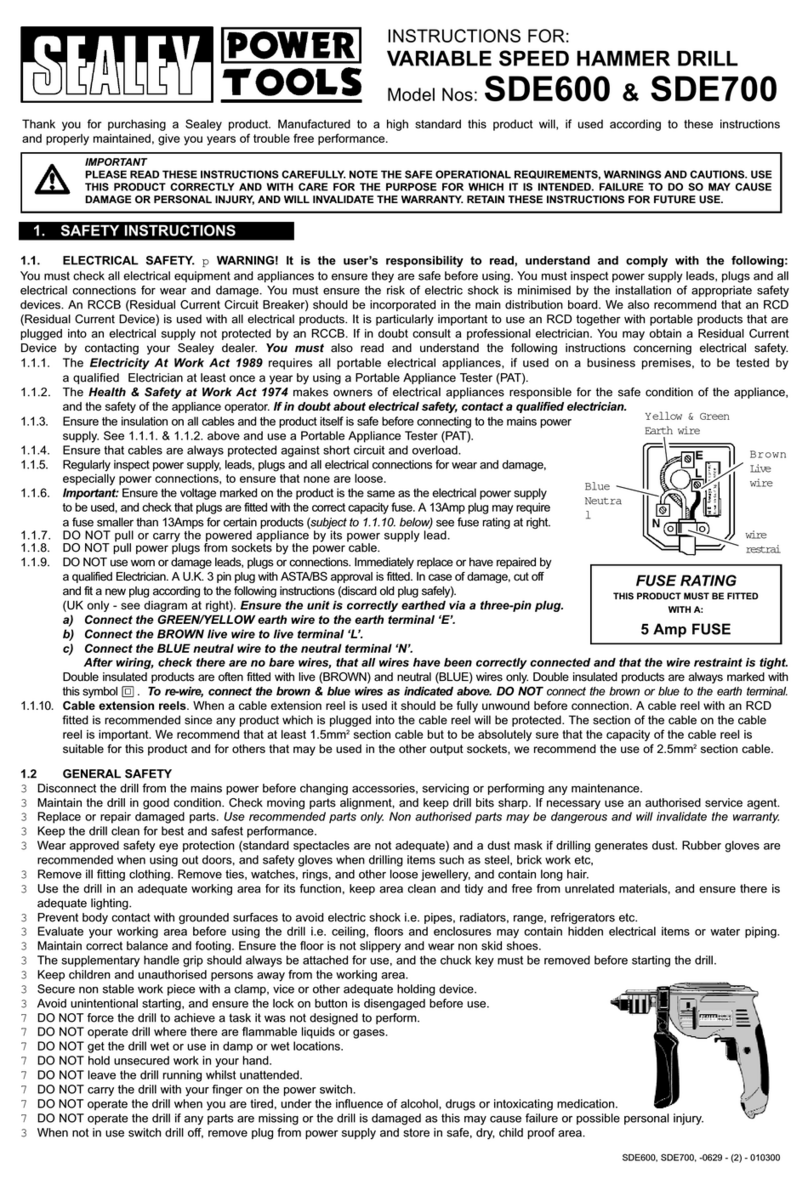

Model No: ........................................GSA231

Chuck Size: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø10.0mm

Air Consumption: ......................................4cfm

Operating Pressure:................................... 90psi

Free Speed:......................................15000rpm

Noise Power: ...................................... 104dBA

Noise Pressure: ..................................... 93dBA

Vibration: ..........................................2.5m/s²

Uncertainty: .......................................1.25m/s²

Air Inlet Size: ......................................1/4"BSP

Weight:............................................ 0.67kg

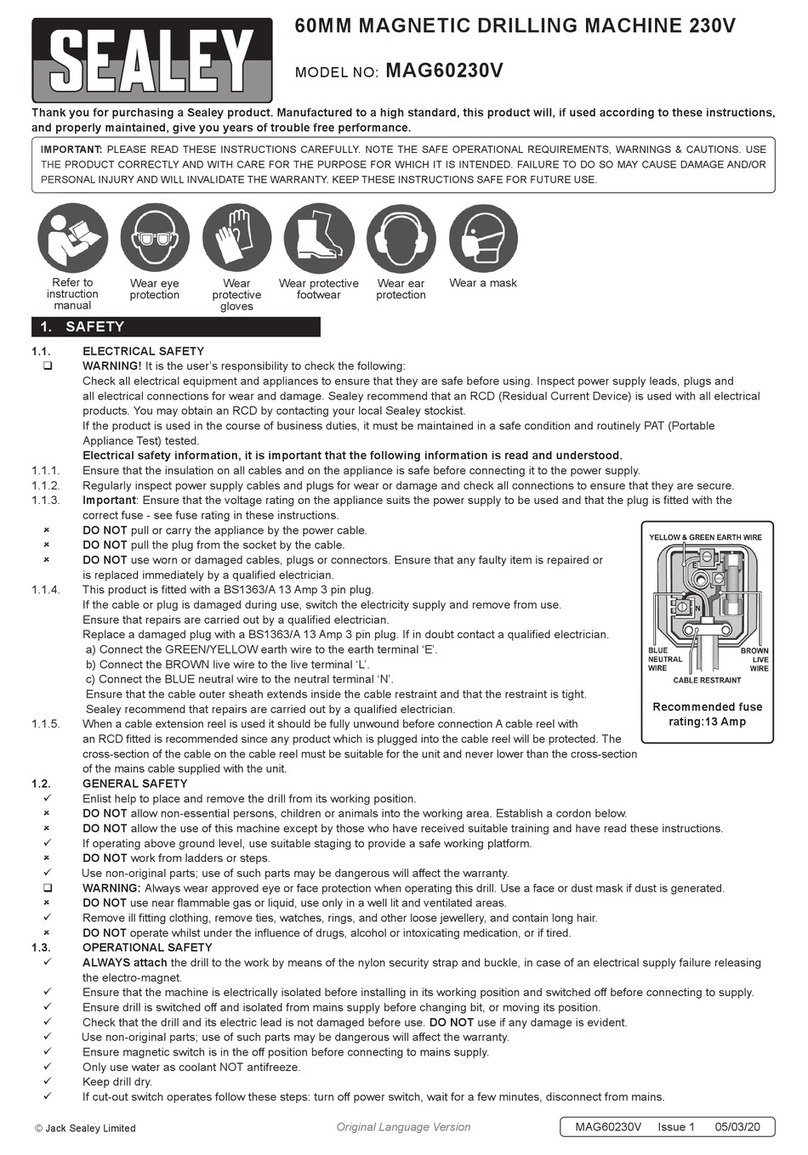

Refer to the

instruction

manual

Wear ear

protection

Wear eye

protection

Wear protective

gloves

Wear a mask