Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT:PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS,

WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH

IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE

THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

SA29/S.V2 - 1 - 191203

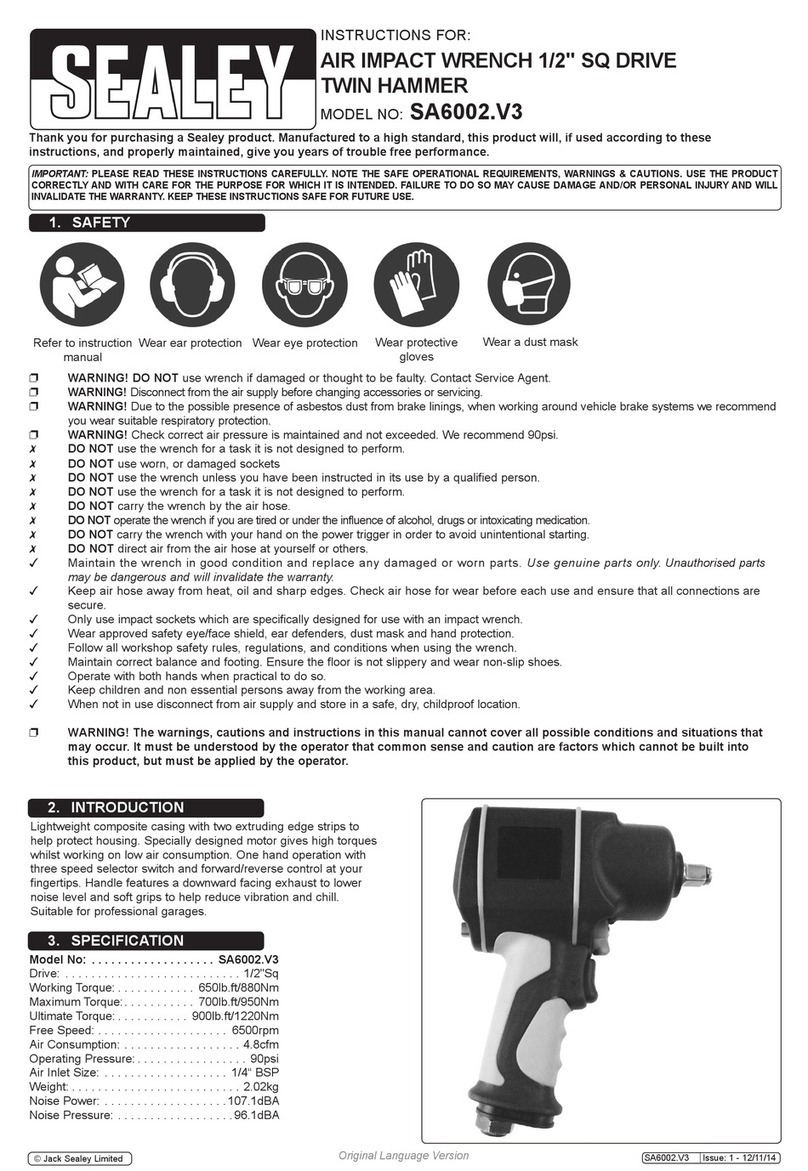

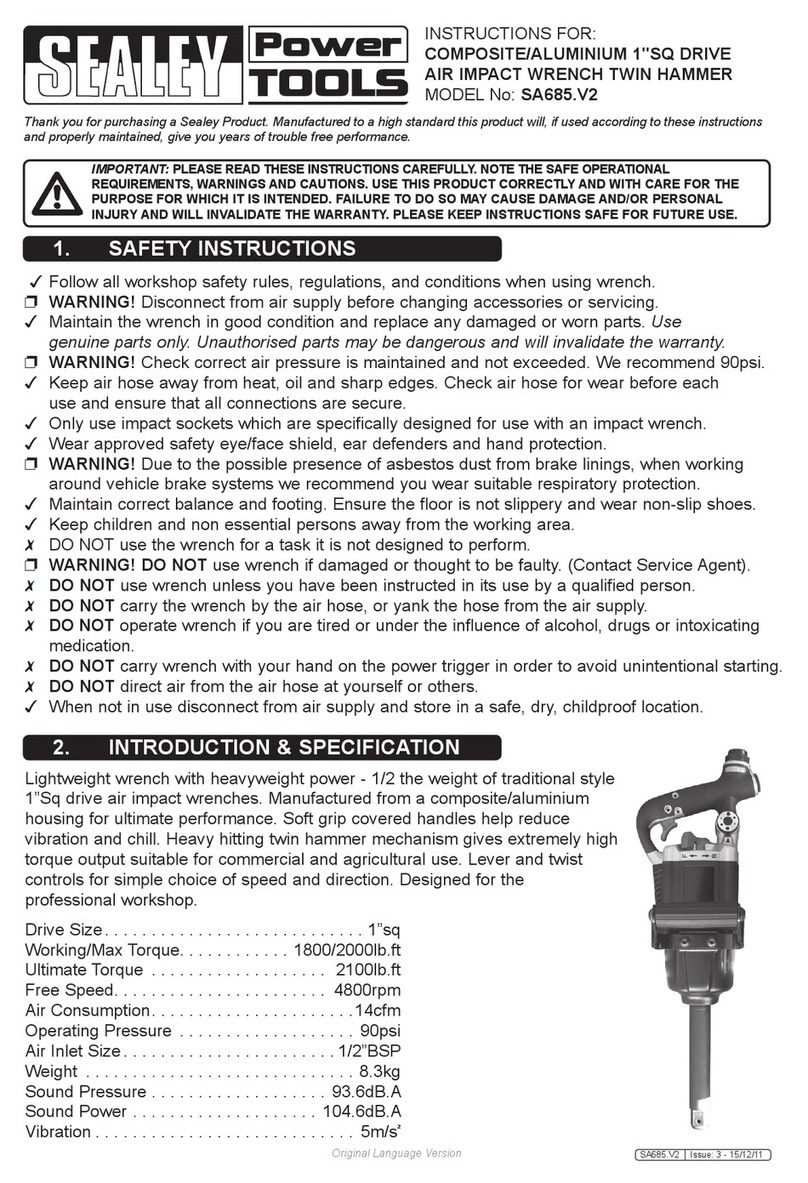

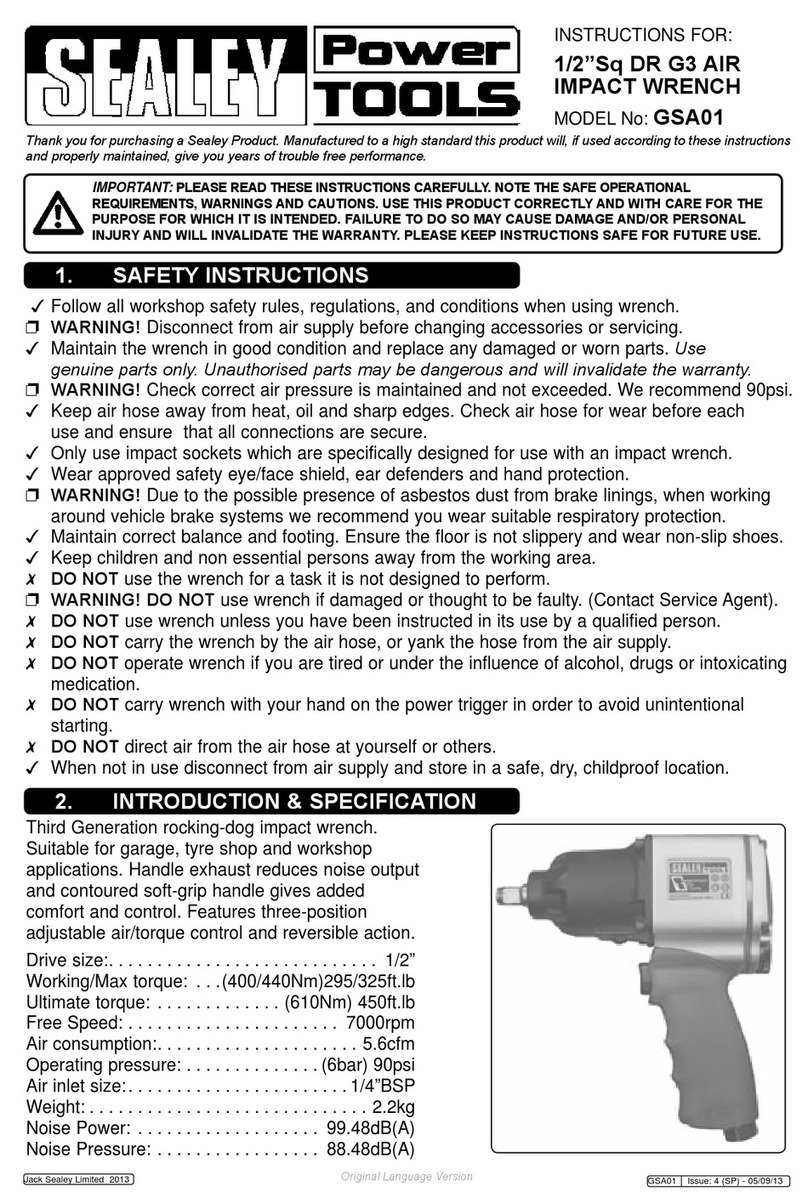

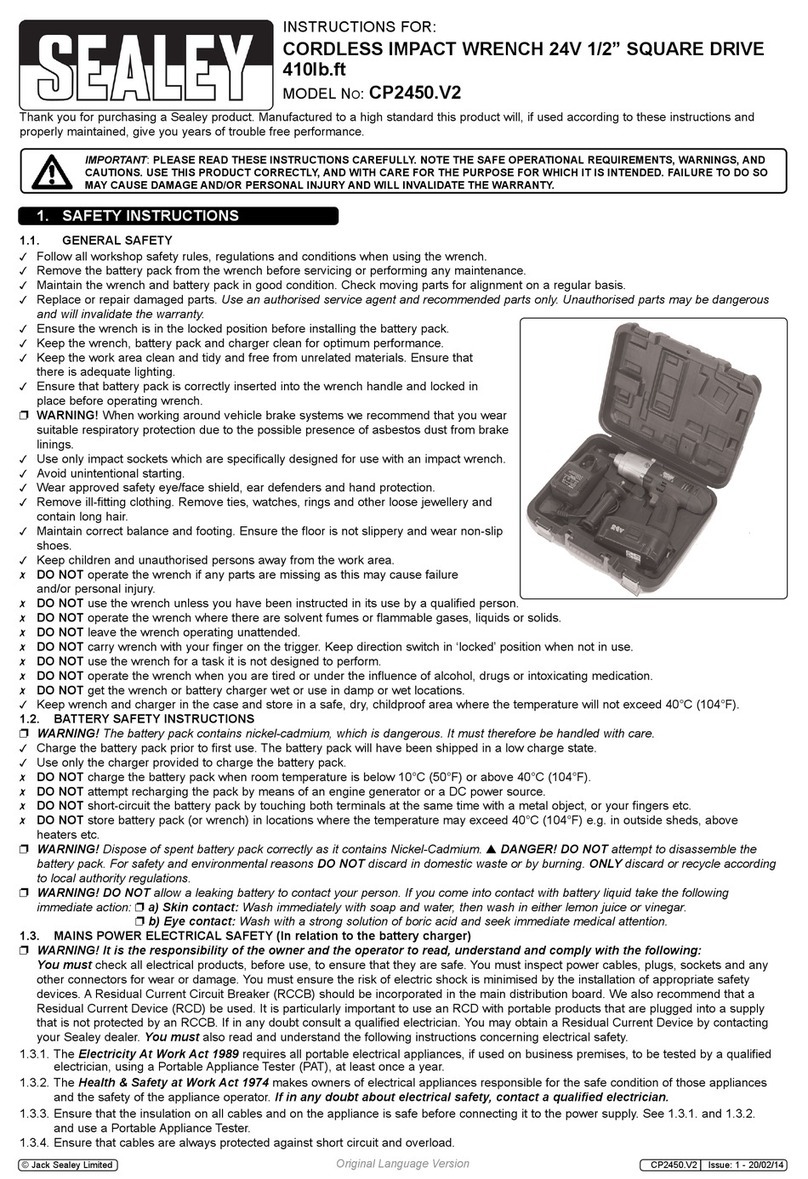

INSTRUCTIONS FOR

1 SQUARE DRIVE

AIR IMPACT WRENCH

Model: SA29/S.V2

01284 757500

E-mail: sales@sealey.co.uk

Web: www.sealey.co.uk

01284 703534

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component

parts without prior notice. IMPORTANT: No liability is accepted for incorrect use of this equipment. WARRANTY: Guarantee is 12

months from purchase date. proof of which will be required for any claim. INFORMATION: Call us for a copy of our latest catalogue

and promotions on 01284 757525 and leave your full name and address including your postcode.

Sole UK Distributor, Sealey Group, Bury St. Edmunds, Suffolk.

2. INTRODUCTION & SPECIFICATIONS

Drive size . . . . . . . . . . . . . . . . . . .1Sq Air inlet size . . . . . . . . . . 1/2 BSP

Working/Max torque . . . . .900/1100ft.lb Ultimate torque . . . . . . . . .1150ft.lb

Operating pressure . . . . . . . . . . .90psi Air consumption . . . . . . . . . 21cfm

Weight . . . . . . . . . . . . . . . . . . . 14.9kg Vibration level . . . . . . . . . .1.5m/s2

Sound pressure . . . . . . . . . . .106.8dB Sound Power . . . . . . . . . .107.5dB

Suitable for commercial and agricultural vehicle use. Long anvil and straight configuration with

rocking-dog clutch for applications with restricted access. Fitted with reverse action. Supplied with

side handle.

Issue : 1

Date : 191203

ITEM PART NO DESCRIPTION

1SA29SX-01 MOTOR HOUSING

2SA29SX-02 REAR COVER

3SA29SX-03 REAR GASKET

4SA29SX-04 SCREW

5SA29SX-05 WASHER

6SA29SX-06 ANVIL BUSHING

7SA29SX-07 OIL SEAL

8SA29SX-08 COVER

9SA29SX-09 SCREW

10 SA29SX-10 CLUTCH HOUSING

11 SA29SX-11FRONT GASKET

12 SA29SX-12 SCREW

13 SA29SX-13 WASHER

14 SA29SX-14 SCREW

15 SA29SX-15 HANDLE DEAD

16 SA29SX-16 SCREW

17 SA29SX-17 TRIGGER

ITEM PART NO DESCRIPTION

35 SA29SX-35 PIN

36 SA29SX-36 CYLINDER

37 SA29SX-37 ROTOR

38 SA29SX-38 ROTOR BLADE

39 SA29SX-39 REAR END PLATE

40 SA29SX-40 PIN

41 SA29SX-41 HAMMER CAGE

42 SA29SX-42 WASHER

43 SA29SX-43 HAMMER PIN

44 SA29SX-44 HAMMER DOG

45 SA29SX-45 DRIVE CAM

46 SA29SX-46 ANVIL

47 SA29SX-47 BUSHING FLANGE

48 SA29SX-48 WASHER

49 SA29SX-49 O-RING

50 SA29SX-50 ANVIL COLLAR

51 SA29SX-51 O-RING

3Follow all workshop safety rules, regulations, and

conditions when using wrench.

pWARNING! Disconnect from air supply before changing

accessories or servicing.

3Maintain the wrench in good condition and replace

any damaged or worn parts. Use

genuine parts only. Unauthorised parts may be

dangerous and will invalidate the warranty.

pWARNING! Check correct air pressure is maintained and not exceeded. We recommend 90psi.

3Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each

use and ensure that all connections are secure.

3Only use impact sockets which are specifically designed for use with an impact wrench.

3Wear approved safety eye/face shield, ear defenders, and hand protection.

pWARNING! Due to the possible presence of asbestos dust from brake linings, when working

around vehicle brake systems we recommend you wear suitable respiratory protection.

3Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

3Keep children and non essential persons away from the working area.

7DO NOT use the wrench for a task it is not designed to perform.

pWARNING! DO NOT use wrench if damaged or thought to be faulty. (Contact Service Agent).

7DO NOT use wrench unless you have been instructed in its use by a qualified person.

7DO NOT carry the wrench by the air hose, or yank the hose from the air supply.

7DO NOT operate wrench if you are tired or under the influence of alcohol, drugs or intoxicating medication.

7DO NOT carry wrench with your hand on the power trigger in order to avoid unintentional starting.

7DO NOT direct air from the air hose at yourself or others.

3When not in use disconnect from air supply and store in a safe, dry, childproof location.

ITEM PART NO DESCRIPTION

18 SA29SX-18 TRIGGER PIN

19 SA29SX-19 BUSHING

20 SA29SX-20 THROTTLE PIN

21 SA29SX-21 O-RING

22 SA29SX-22 RETAINER, O-RING

23 SA29SX-23 SPRING

24 SA29SX-24 SCREEN

25 SA29SX-25 HOSE FITTING

26 SA29SX-26 O-RING

27 SA29SX-27 DUST COVER

28 SA29SX-28 VALVE SLEEVE

29 SA29SX-29 REVERSE VALVE

30 SA29SX-30 LEVER REVERSE

31 SA29SX-31 PIN

32 SA29SX-32 O-RING

33 SA29SX-33 BEARING

34 SA29SX-34 FRONT END PLATE