INSTRUCTIONS FOR

CORDLESS LITHIUM-ION NAIL/STAPLE GUN

18G 18V

MODEL NO: CPNG18

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

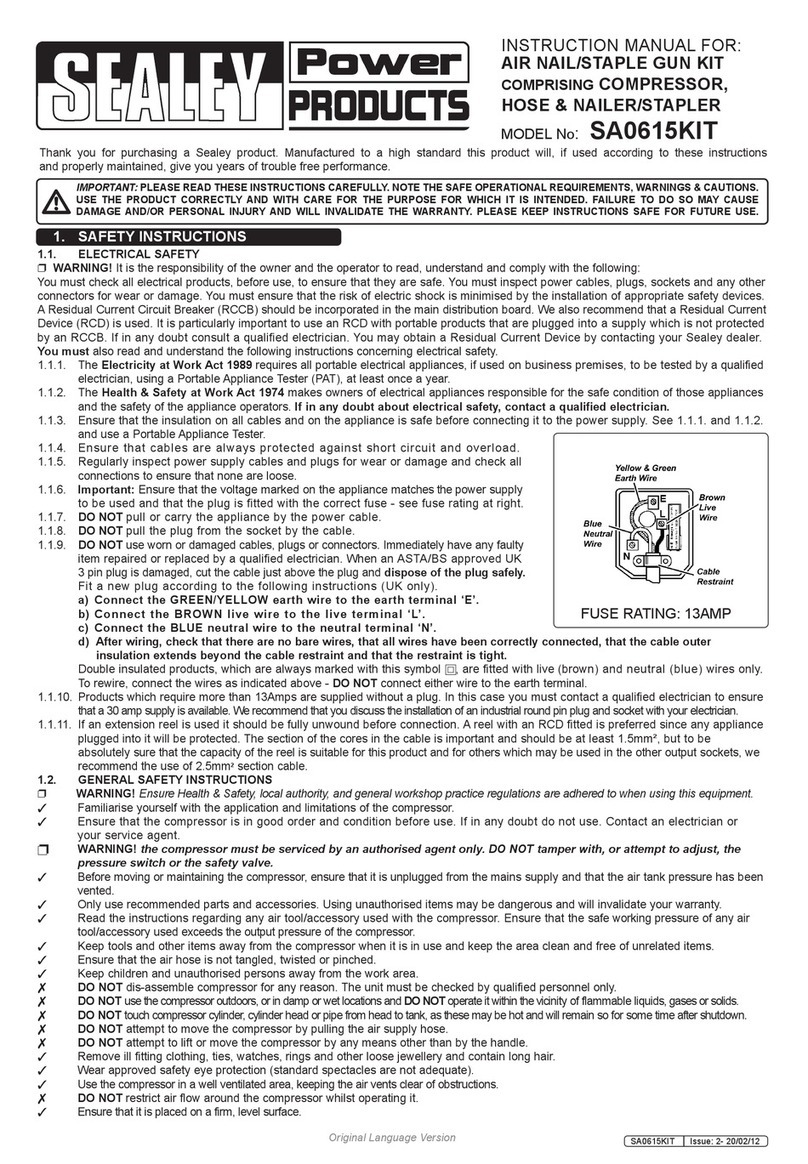

1. SAFETY

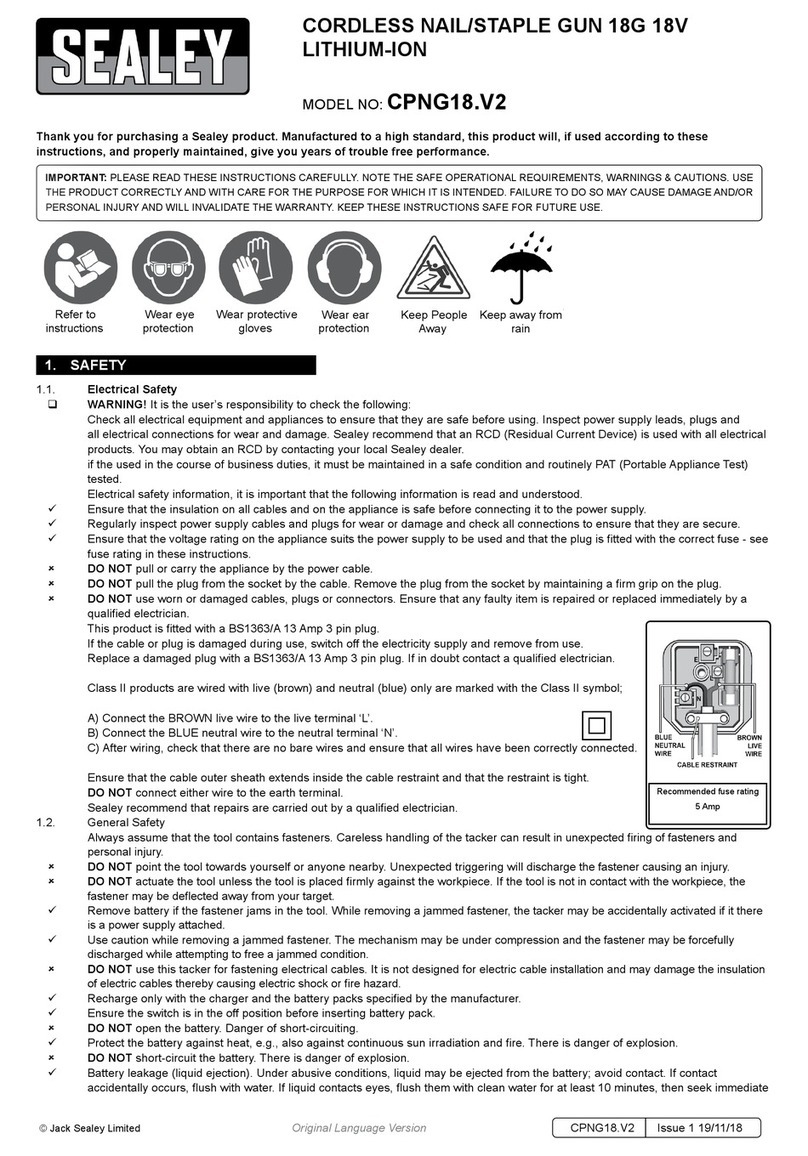

1.1. Electrical Safety

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and

all electrical connections for wear and damage. Sealey recommend that an RCD (Residual Current Device) is used with all electrical

products. You may obtain an RCD by contacting your local Sealey dealer.

if the used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable Appliance Test)

tested.

Electrical safety information, it is important that the following information is read and understood.

9Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

9Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

9Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the correct fuse - see

fuse rating in these instructions.

8DO NOT pull or carry the appliance by the power cable.

8DO NOT pull the plug from the socket by the cable. Remove the plug from the socket by maintaining a rm grip on the plug.

8DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired or replaced immediately by a

qualied electrician.

This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch off the electricity supply and remove from use.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

Class II products are wired with live (brown) and neutral (blue) only are marked with the Class II symbol;

A) Connect the BROWN live wire to the live terminal ‘L’.

B) Connect the BLUE neutral wire to the neutral terminal ‘N’.

C) After wiring, check that there are no bare wires and ensure that all wires have been correctly connected.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

DO NOT connect either wire to the earth terminal.

Sealey recommend that repairs are carried out by a qualied electrician.

1.2. General Safety

Always assume that the tool contains fasteners. Careless handling of the tacker can result in unexpected ring of fasteners and

personal injury.

8DO NOT point the tool towards yourself or anyone nearby. Unexpected triggering will discharge the fastener causing an injury.

8DO NOT actuate the tool unless the tool is placed rmly against the workpiece. If the tool is not in contact with the workpiece, the

fastener may be deected away from your target.

9Remove battery if the fastener jams in the tool. While removing a jammed fastener, the tacker may be accidentally activated if it there

is a power supply attached.

9Use caution while removing a jammed fastener. The mechanism may be under compression and the fastener may be forcefully

discharged while attempting to free a jammed condition.

8DO NOT use this tacker for fastening electrical cables. It is not designed for electric cable installation and may damage the insulation

of electric cables thereby causing electric shock or re hazard.

9 Recharge only with the charger and the battery packs specied by the manufacturer.

9Ensure the switch is in the off position before inserting battery pack.

8DO NOT open the battery. Danger of short-circuiting.

9 Protect the battery against heat, e.g., also against continuous sun irradiation and re. There is danger of explosion.

8DO NOT short-circuit the battery. There is danger of explosion.

9 Battery leakage (liquid ejection). Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentally occurs, ush with water. If liquid contacts eyes, ush them with clean water for at least 10 minutes, then seek immediate

CPNG18 | Issue 1 22/03/17

Original Language Version

© Jack Sealey Limited

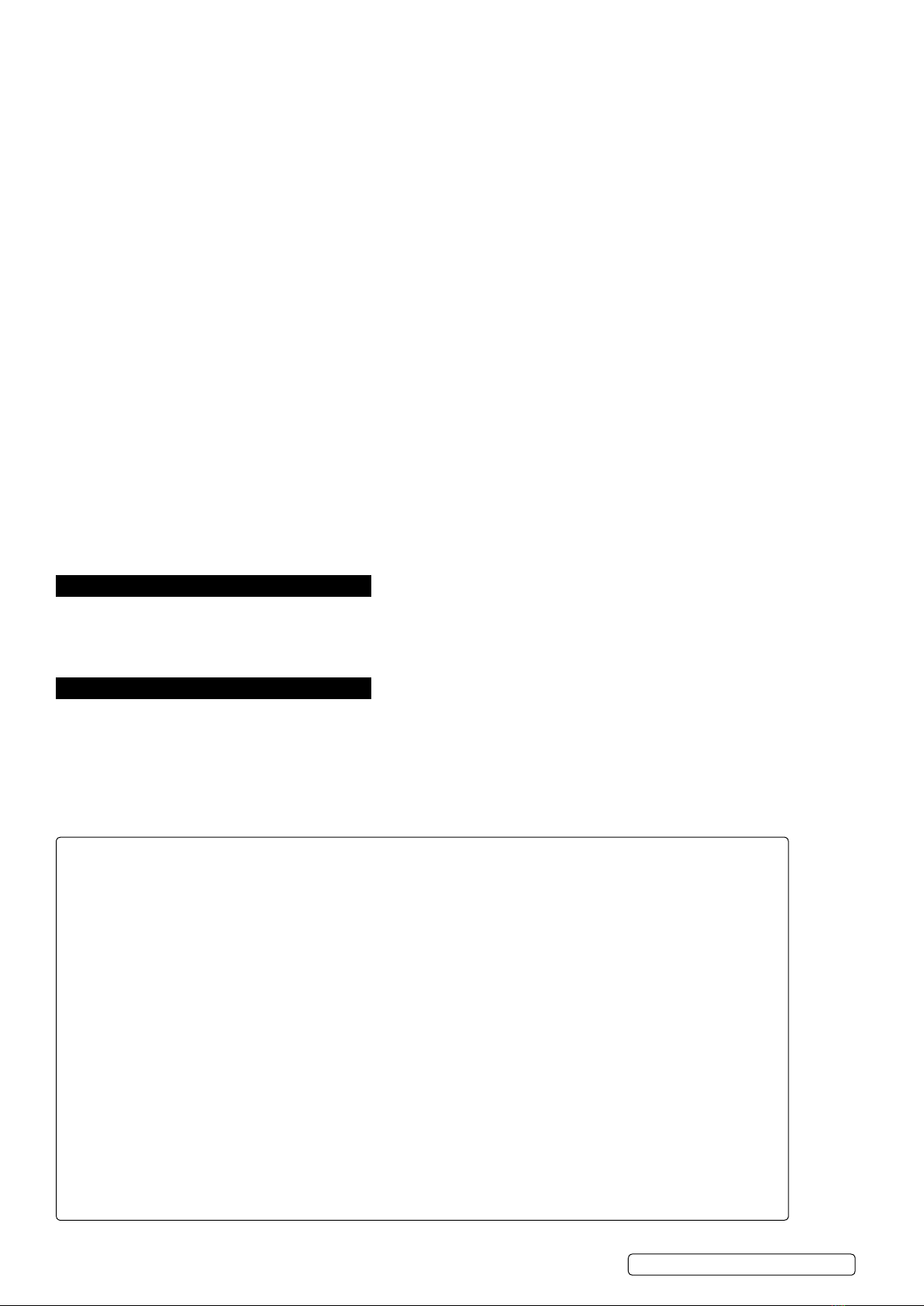

Refer to

instructions

Wear eye

protection

Wear protective

gloves

Wear ear

protection

Keep People

Away

Indoor use

Only

Recommended fuse rating

5 Amp