2. INTRODUCTION & SPECIFICATION

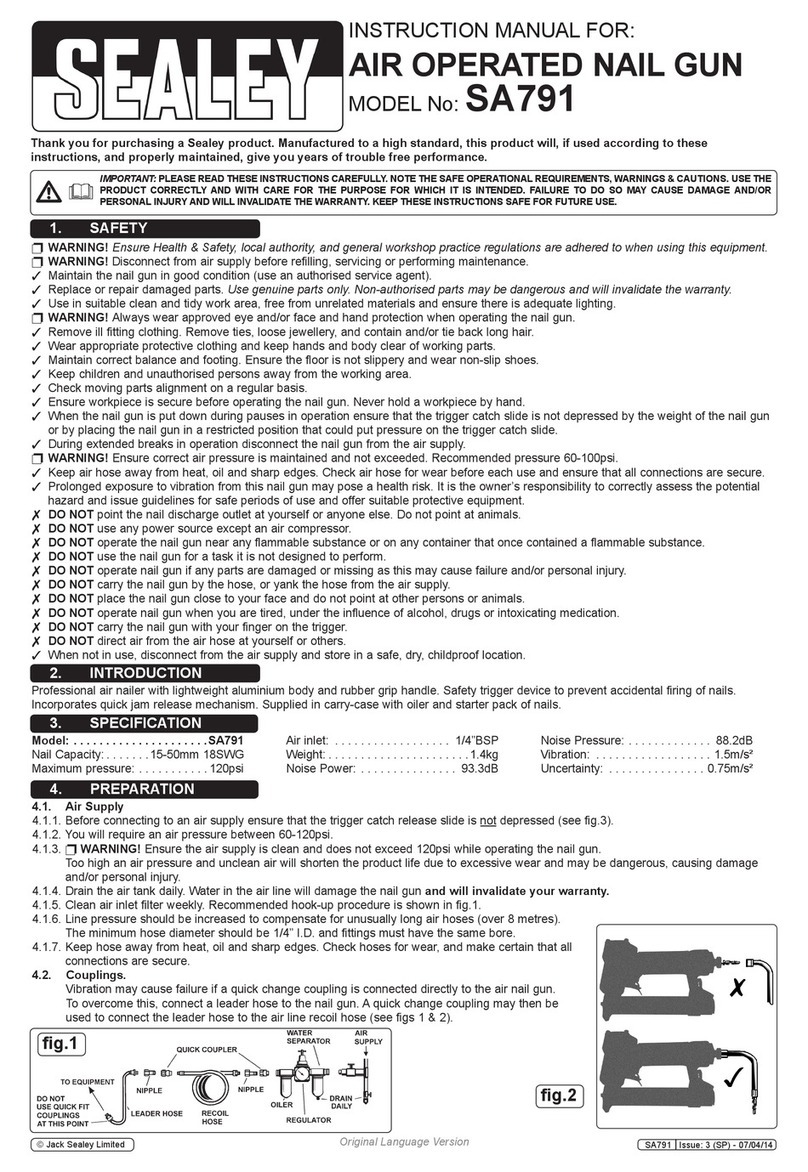

3.1. Air Supply

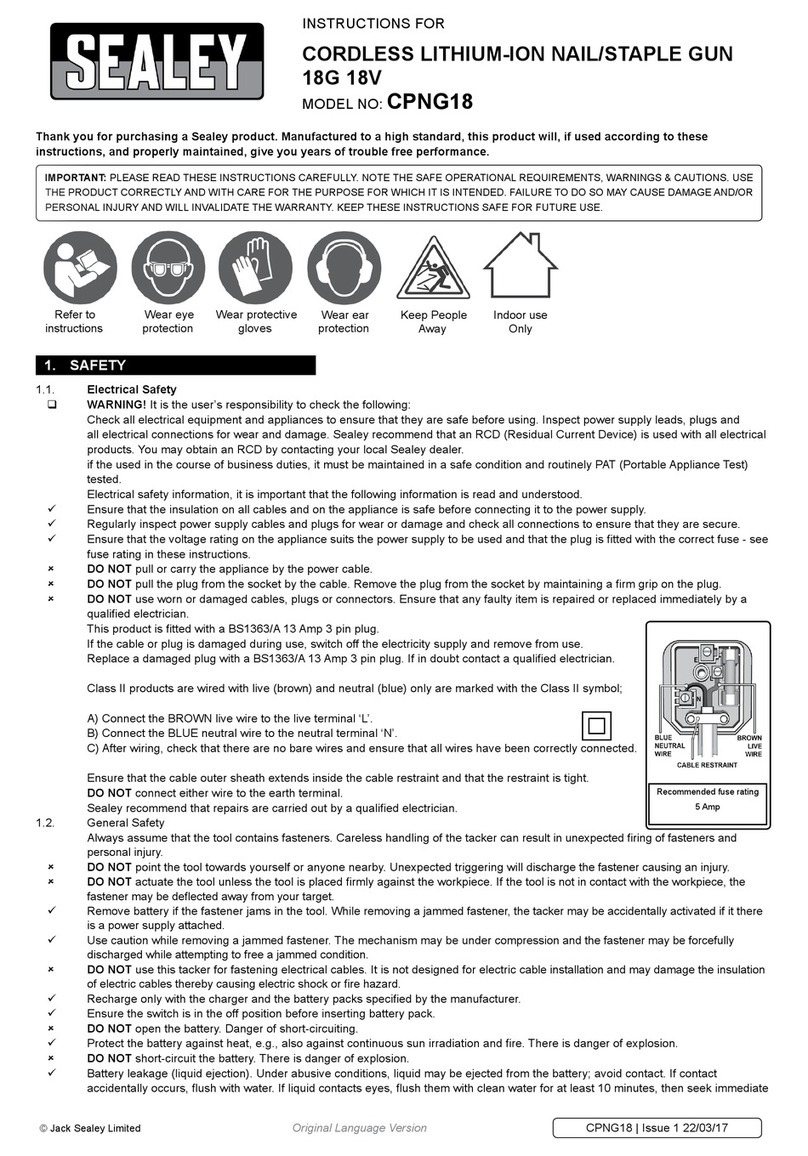

3.1.1. Before connecting to an air supply ensure that the trigger release slide is not depressed (see fig 1).

3.1.2. You will require an air pressure between 60-100psi.

3.1.3. pWARNING! Ensure the air supply is clean and does not exceed 100psi while operating the nail gun.

Too high an air pressure and unclean air will shorten the product life due to excessive wear and may be

dangerous, causing damage and/or personal injury.

3.1.4. Drain the air tank daily. Water in the air line will damage the nail gun and will invalidate your warranty.

3.1.5. Clean air inlet filter weekly. Recommended hook-up procedure is shown in fig 2.

3.1.6. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres).

The minimum hose diameter should be 1/4 I.D. and fittings must have the same bore.

3.1.7. Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all

connections are secure.

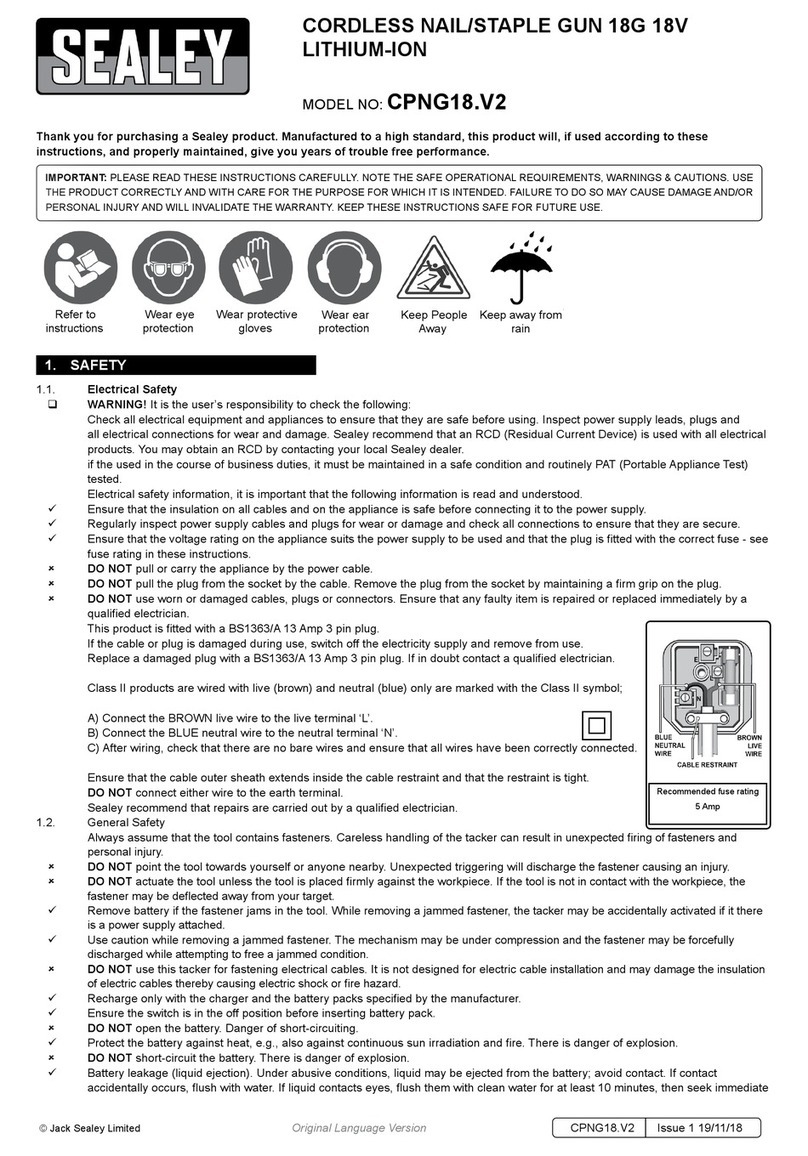

3.2. Couplings.

Vibration may cause failure if a quick change coupling is connected directly

to the air nail gun. To overcome this, connect a leader hose to the nail gun. A

quick change coupling may then be used to connect the leader hose to the

air line recoil hose. See fig 2 & 3.

3. PREPARING NAIL GUN FOR USE

4. OPERATING INSTRUCTIONS

5. MAINTENANCE

p

p

WARNING! Ensure you read, understand and apply safety instructions before use.

4.1 Load the magazine before connecting the airline. To open the magazine, hold the nail gun vertically with

one hand, then with the thumb of your other hand, press the magazine catch upwards and slide the

magazine backwards and open with the forefinger of the same hand. Place a stick of nails into the open

magazine chamber ensuring that all nails have their points resting on the bottom of the chamber.

4.2 Slide the magazine cover shut until it clicks into place behind the catch.

4.3 Before connecting to an air supply, ensure that the trigger catch release slide is not depressed. Connect

the air line to the nail gun as described in Section 3.

4.4 The operating trigger is normally locked and cannot be used until the trigger release slide is

depressed. This happens automatically as you position the nail gun.

4.5 The trigger release slide can be seen protruding downwards just in front of the nail outlet. ( see fig 1 )

Place the tip of the slide onto the material to be nailed and press downwards to bring the nail outlet

into contact with the surface. As the slide retracts the trigger will become free.

4.6 Depress the trigger to fire one nail. To fire another nail, release the trigger, reposition the nail gun at

the next required nailing point and depress the trigger again. Repeat as necessary.

4.7 If you need to put the nail gun down during the course of working ensure that the trigger slide catch is not

depressed against any object.

4.8 When the work is complete or when you have paused for any length of time, disconnect the nail gun from

the air line.

p

p

WARNING! Should a blockage occur, disconnect nail gun from the air supply immediately.

4.9 Open the magazine (as described above)

4.10 Access the blockage by unclipping the driver guide front-plate (see fig 1) using the release catch provided.

4.11Remove the nail and any foreign matter found within the driver guide.

4.12 Replace the driver guide front-plate and set the catch.

4.13 Ensure that all parts of the nail gun are secure and correctly positioned, then reconnect the air supply.

fig 2

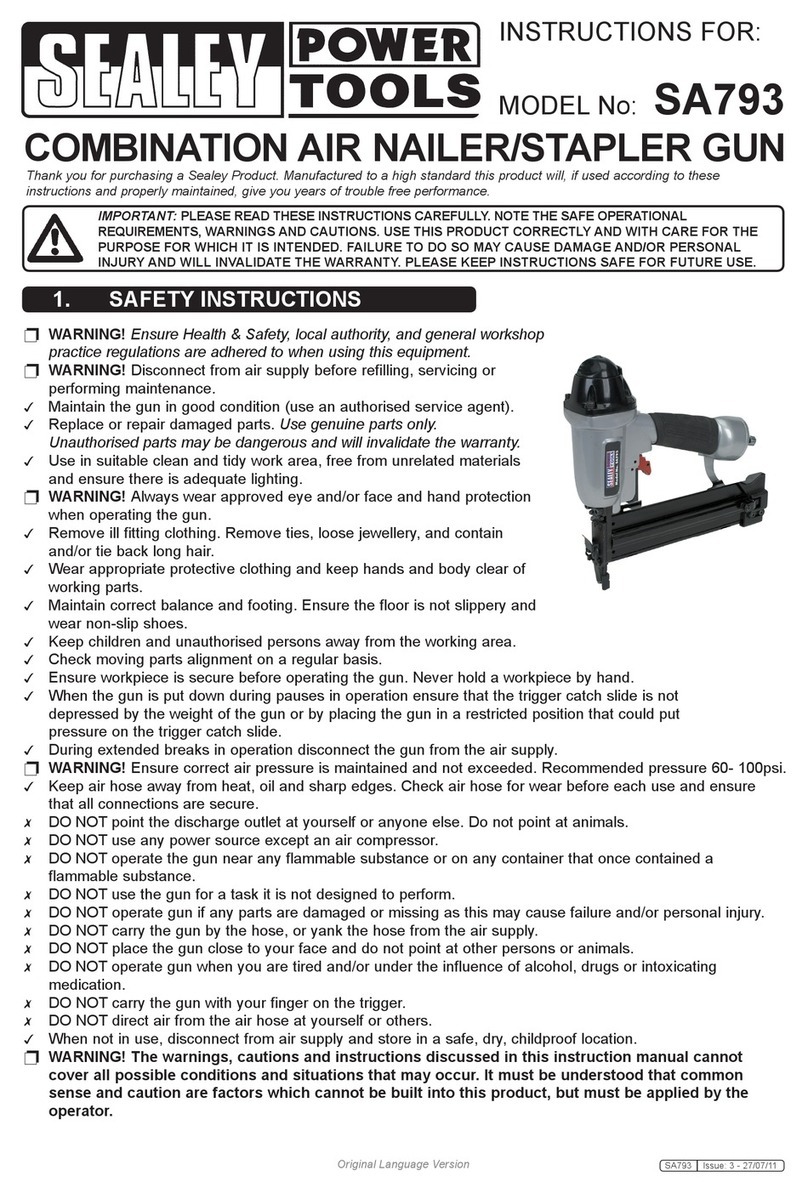

Professional air nailers with lightweight aluminium bodies and rubber grip handles. Both models incorporate a

safety trigger device to prevent accidental firing of nails and a quick jam release mechanism in the head.

Supplied in blow mould case with oil and starter pack of nails.

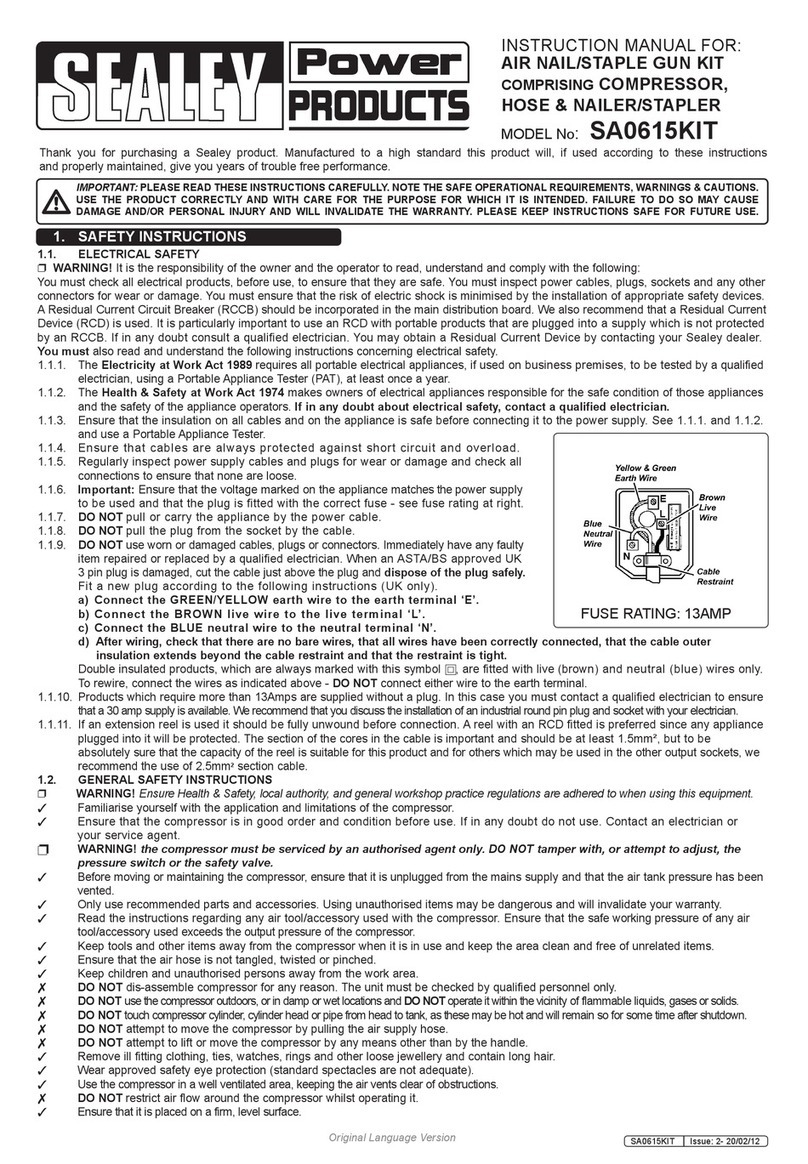

We, the sole importer into the UK, declare that the product listed here is in conformity with the

following EEC standards and directives. The construction files for this product are held by the

Manufacturer and may be inspected, by a national authority, upon request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK

of Sealey Power Products.

Air Operated Nail Gun

Model: SA790

98/37/EC Machinery Directive

93/68/EEC Marking Directive

16TH JUNE 2003

Declaration of Conformity

Signed by Mark Sweetman

fig 3

fig 1

pWARNING! Disconnect nail gun from air supply before refilling with nails, servicing or performing

maintenance. Replace or repair damaged parts.

Use genuine parts only. Non-authorised parts may be dangerous and will invalidate the warranty.

5.1. Lubricate the air nail gun daily with a few drops of the air tool oil supplied, dripped into the air inlet before

use. ( To re-order air tool oil use Sealey part Nos. ATO500S or ATO1000S.)

5.2. Clean the nail gun after use.

5.3. Loss of power or erratic action may be due to the following:

a) Excessive drain on the air line. Moisture or restriction in the air pipe. Incorrect size or type of hose

connectors. To remedy check the air supply and follow instructions in chapter 3.

b) Grit or gum deposits in the nail gun may also reduce performance. Flush the nail gun out with gum

solvent oil or an equal mixture of SAE No 10 oil and kerosene. Allow to dry before use.

If you continue to experience problems, contact your local Sealey service agent.

5.4. For a full service contact your local Sealey service agent.

5.5. When not in use, disconnect from air supply, clean nail gun and store in a safe, dry, childproof location.

5.6 On a weekly basis check the security of the hex bolts holding the driver guide plate in place and tighten if

necessary (see fig 1).

TRIGGER

MAGAZINE

MAGAZINE

CATCH

NAIL OUTLET

TRIGGER

RELEASE

SLIDE

AIR INLET

DRIVER GUIDE

FRONT-PLATE

RELEASE CATCH

DRIVER GUIDE

PLATE HEX BOLTS

Model: SA790

Capacity: 10-32mm 18Ga

Operating pressure: 60-100psi

Air inlet: 1/4 BSP

Weight: 1.2kg

SA790 - 1 - 170603

SA790 - 1 - 170603

Specification:

(Model shown is SA790)