4. OPERATING INSTRUCTIONS

5. MAINTENANCE

WARNING! Ensure you read, understand and apply safety instructions before use.

4.1. Load the magazine before connecting the airline. To open the magazine, hold the nail/staple gun vertically

with one hand, then with the thumb of your other hand, press the magazine catch upwards and

slide the magazine backwards and open with the forefinger of the same hand. Place a “stick” of

nails/staples into the open magazine chamber, ensuring that all have their points resting on the

bottom of the chamber.

4.2. Slide the magazine cover shut until it clicks into place behind the catch.

4.3. Before connecting to an air supply ensure that the trigger release slide is not depressed. Connect

the air line to the nail/staple gun as described in Section 3.

4.4. The operating trigger is normally locked and cannot be used until the trigger release slide is depressed.

This happens automatically as you position the nail/staple gun.

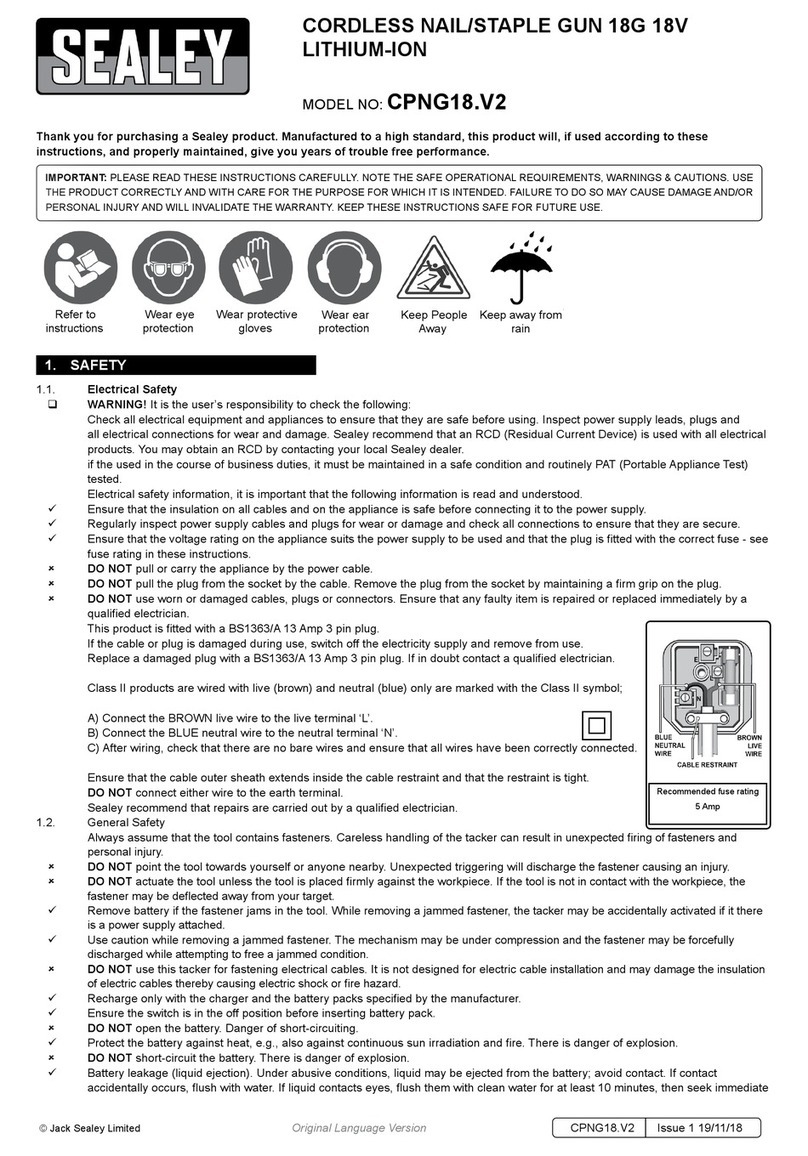

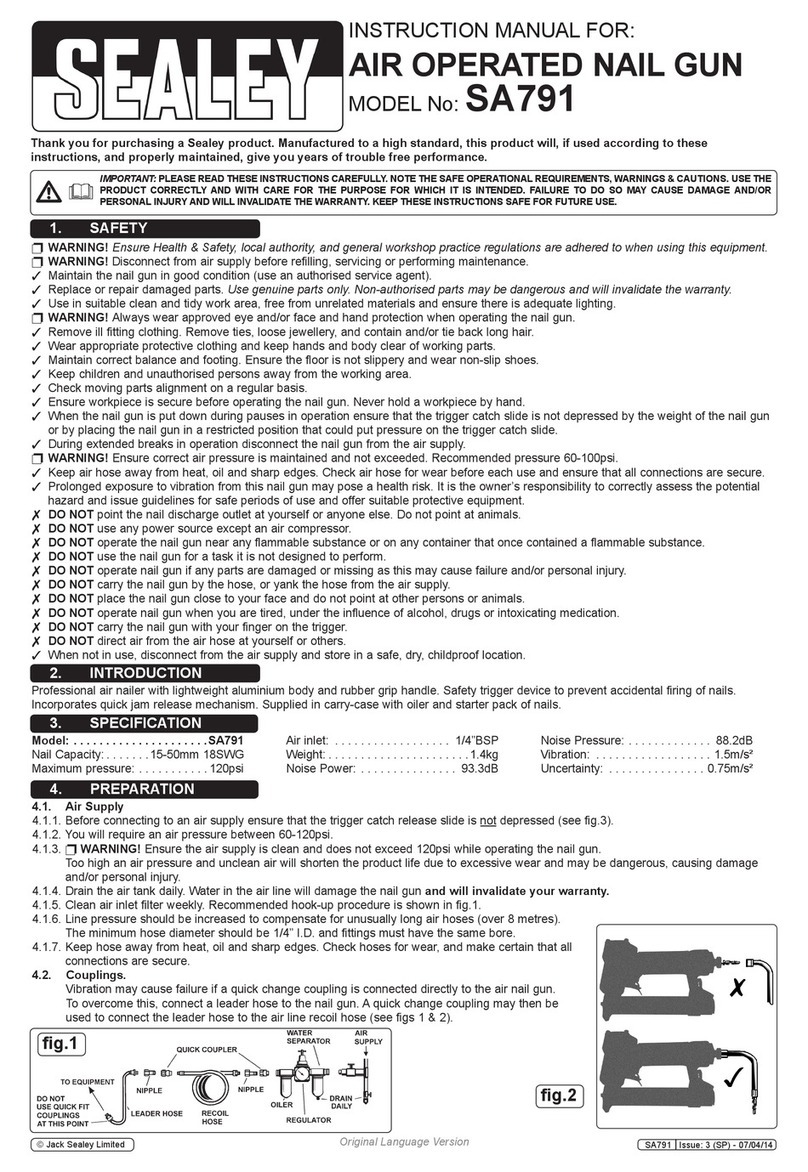

4.5. The trigger release slide can be seen protruding downwards just in front of the nail/staple outlet. (see fig.1)

Place the tip of the slide onto the material to be nailed and press downwards to bring the nail outlet

into contact with the surface. As the slide retracts the trigger will become free.

4.6. Depress the trigger to fire one nail. To fire another nail, release the trigger, reposition the nail/staple gun at

the next required nailing point and depress the trigger again. Repeat as necessary.

4.7. If you need to put the nail/staple gun down during the course of working ensure that the trigger slide

catch is not depressed against any object.

4.8. When the work is complete or when you have paused for any length of time, disconnect the nail/staple

gun from the air line.

WARNING! Should a blockage occur, disconnect nail/staple gun from the air supply immediately.

4.9. Access the blockage by opening the magazine.

4.10. Remove the nail/staple and any foreign matter found blocking the mechanism.

4.11. Close the magazine.

4.12. Ensure that all parts of the nail/staple gun are secure and correctly positioned, then reconnect the air

supply.

WARNING!Disconnect nail/staple gun from air supply before refilling with nails/staples, servicing or

performing maintenance. Replace or repair damanged parts.

Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

5.1. If an air system oiler is not available, lubricate the air nail/staple gun daily with a few drops of the air tool

oil supplied, dripped into the air inlet before use. To re-order air tool oil use Sealey part Nos. ATO500S

or ATO1000S.

5.2. Clean the nail/staple gun after use.

5.3. Loss of power or erratic action may be due to the following:

a) Excessive drain on the air line. Moisture or restriction in the air pipe. Incorrect size or type of hose

connectors. To remedy check the air supply and follow instructions in chapter 3.

b) Grit or gum deposits in the nail/staple gun may also reduce performance. Flush the nail/staple gun

out with gum solvent oil or an equal mixture of SAE No 10 oil and kerosene. Allow to dry before use.

If you continue to experience problems, contact your local Sealey service agent.

5.4. On a weekly basis check the security of the hex bolts holding the driver guide plate in place and tighten if

necessary. (see fig.1)

5.6 For a full service contact your local Sealey Service Agent.

5.5. When not in use, disconnect from air supply, clean nail/staple gun and store in a safe, dry, childproof

location.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

Original Language Version SA792 Issue: 2 - 13/11/09