INSTRUCTIONS FOR: AIR OPERATED

OIL INSTALLATION PUMP

STATION CONSISTING OF:

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

AK4555D - AK4556D - AK4557D - AK4558D - 1 - 090802

2.1. A complete Oil Installation Pump Station may consist of an oil delivery pump AK4555D, a retractable hose reel AK4557D and a delivery

gun AK4558D with digital meter. These parts are available as separate items. In addition the hose reel and dispensing gun are available

together under part No. AK4556D. The system is intended to be installed in medium sized garage workshops to pump new engine oil

from a barrel or tank direct to a vehicle. Where the bulk oil storage is at a distance from the main work area the system can be plumbed

into a correctly specified pipe line. The dispensing gun with digital readout enables the operator to dispense the exact amount of oil

required. The meter also features an accumulative readout enabling a check to be made on the total amount of oil dispensed during any

day / week / month.

2. DESCRIPTION & APPLICATION

3Maintain the pump in good condition (use an authorised service agent).

3Replace or repair damaged parts. Use recommended parts only. Non-authorised parts may be

dangerous and will invalidate the warranty.

3Keep the pump clean for the best and safest performance.

3Wear appropriate protective clothing i.e gloves, safety glasses, overalls.

3Install the pump in an appropriate working area. Keep area clean and tidy, free from unrelated

materials and ensure there is adequate lighting.

3Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

3Keep children and unauthorised persons away from the working area.

pWARNING! Turn off air supply and de-pressurise the output line before removing the pump,

dispensing gun or hose reel from any installation . Failure to comply with this instruction may

damage the units and will invalidate the warranty.

3When not in use ensure the air supply is turned off.

7DO NOT allow unauthorised persons to operate the pump.

pWARNING! DO NOT tamper with, or open, the pump unit. To do so will invalidate the warranty.

7DO NOT point air line at yourself, other persons or animals.

7DO NOT use the pump to draw off any liquids other than oils.

pWARNING! DO NOT allow uncontrolled discharge of fluids thus polluting the environment.

7DO NOT force the pump to achieve a task it was not designed to perform.

7DO NOT operate the pump when you are tired, under the influence of alcohol, drugs or intoxicating medication.

7DO NOT use the pump for pumping flammable or corrosive liquids.

1. SAFETY INSTRUCTIONS

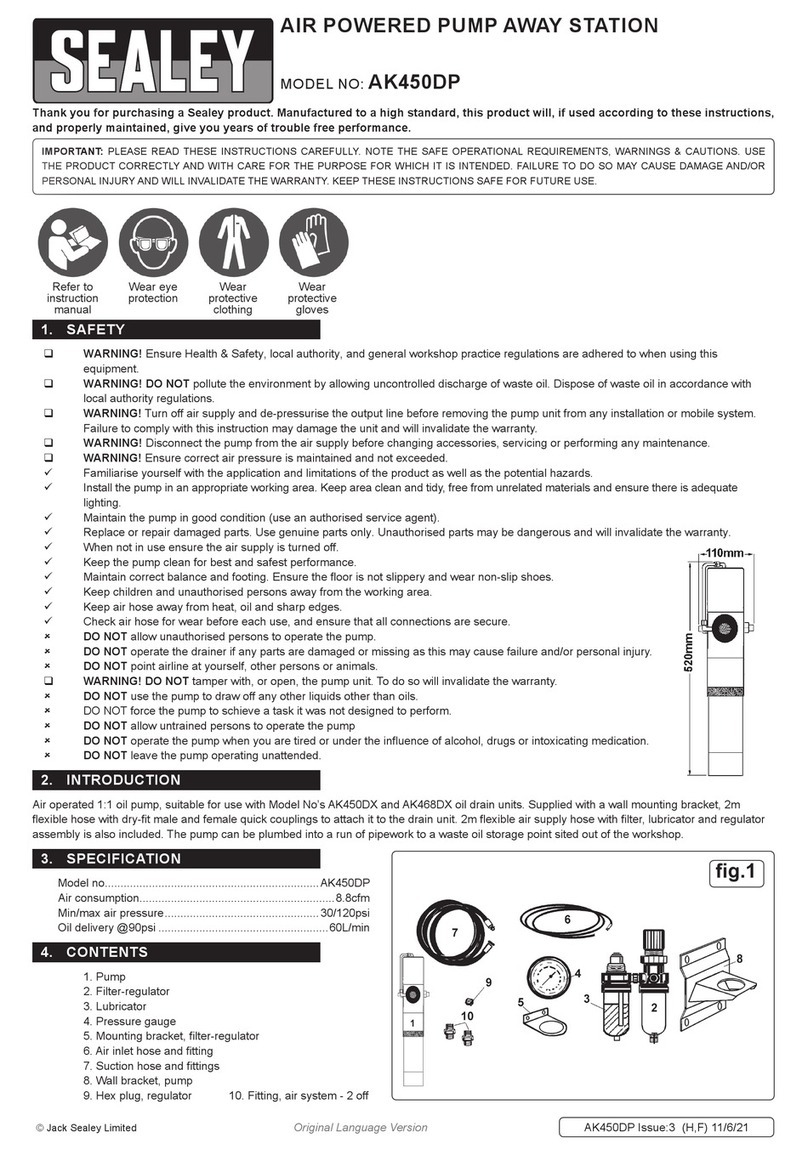

3. SPECIFICATION

Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3:1

Maximum air pressure . . . . . . . . . . . . . . . . .8 bar (120psi)

Operating air pressure . . . . . . . . . . . . . . . . . .6 bar ( 90psi)

Max.output pressure . . . . . . . . . . . . . . . . . . .8 bar (120psi)

Transient peak pressure . . . . . . . . . . . . . . . . . . . . . .38 bar

Max. free flow delivery . . . . . . . . . . . . . . . . . . .14ltr/m

Min. air pressure . . . . . . . . . . . . . . . . . . . . . . . . .3 bar

Air consumption at 6 bar . . . . . . . . . . . . . . . . . . . .9cfm

Air inlet port . . . . . . . . . . . . . . . . . . . . . . . . . .1/4 BSP

Output port . . . . . . . . . . . . . . . . . . . . . . . . . . .1/2 BSP

Suction port . . . . . . . . . . . . . . . . . . . . . . . . . . .1 BSP

Max. sound level at 1m . . . . . . . . . . . . . . . . . .75dB(A)

AK4555D Pump :

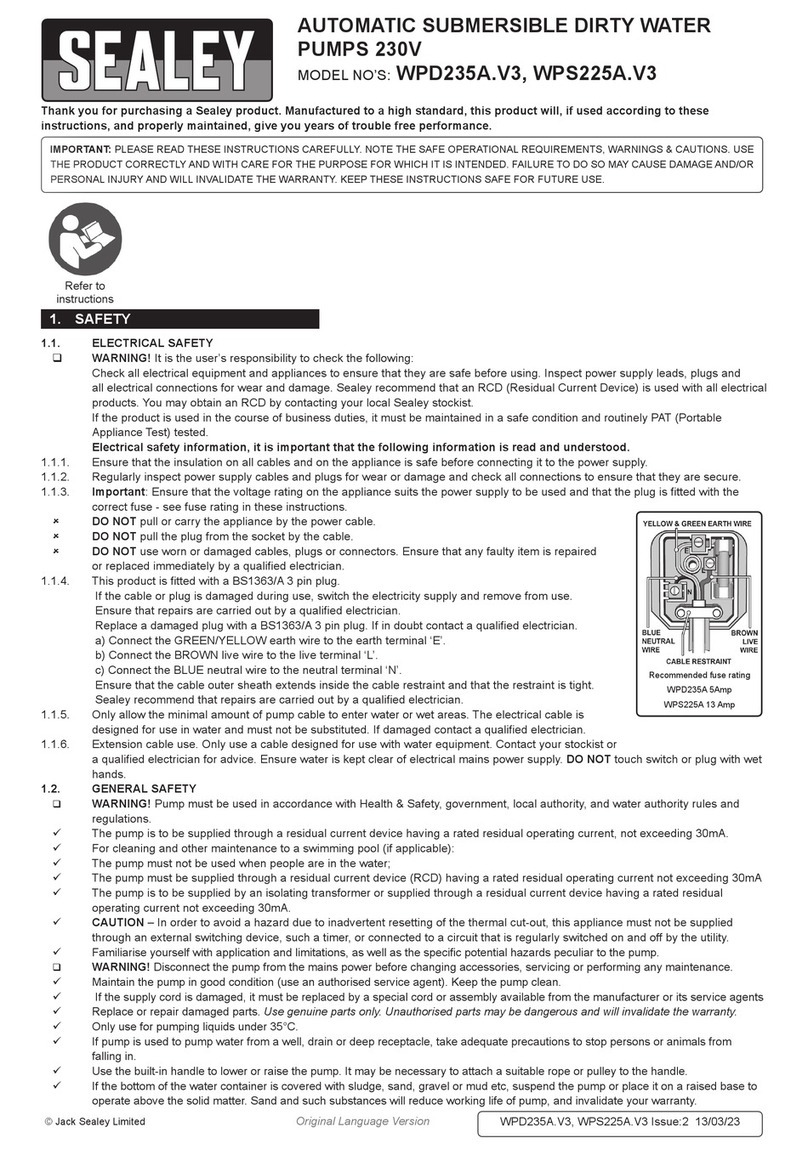

(A) Pump

(B) 2 BSP adaptor for tank or

drum mounting.

(C) Inlet tube (flexible 1) with

filter and non-return valve.

(D) Air supply hose (coiled)

with 1/4 bsp fittings.

(E) Outlet hose ( flexible 1/2)

with shut off valve (F).

(G) Air filter/regulator with 1/4

bsp fittings.

(H) Air lubricator with 1/4 bsp

fittings.

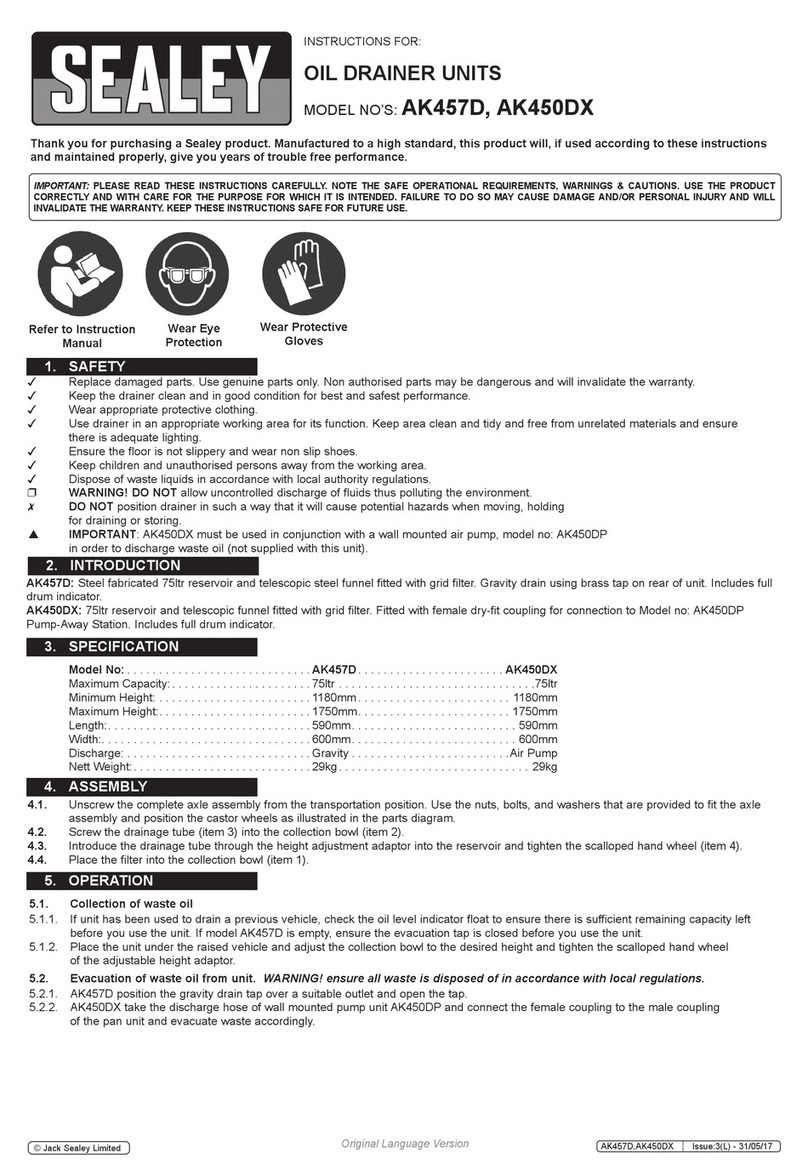

AK4556D Hose Reel + Gun :

(I) Retractable (10 mtr) hose

reel with 1/2 male inlet

fitting.

(J) Inlet hose (flexible 1/2)

(K) Shut off valve.

(L) Drain cock / filter. ( female

fittings ).

(M) Dispensing gun with digital

meter ( male 1/2 inlet

fitting )

AK4557D Hose Reel only :

(I) Retractable (10 mtr) hose

reel with 1/2 male inlet

fitting.

(J) Inlet hose ( flexible 1/2)

(K) Shut off valve.

(L) Drain cock. ( female

fittings ).

AK4558D Digital Gun only :

(M) Dispensing gun with digital

meter ( male 1/2 inlet

fitting )

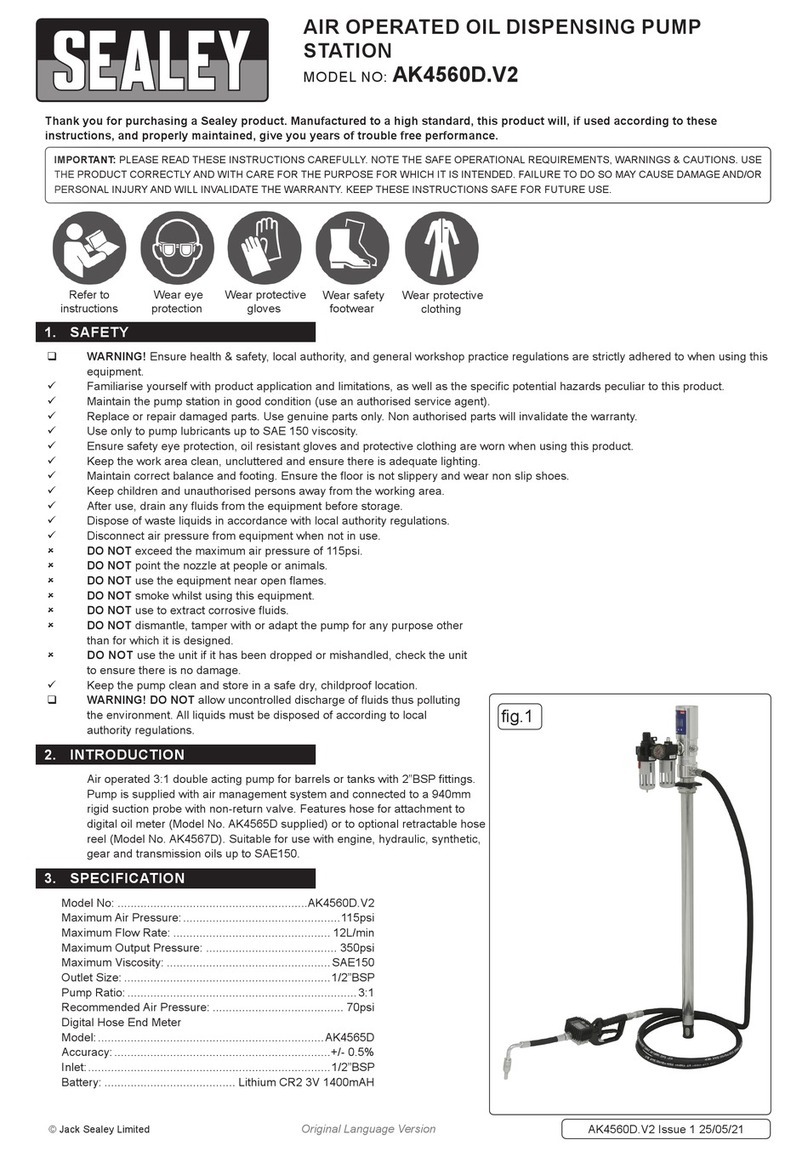

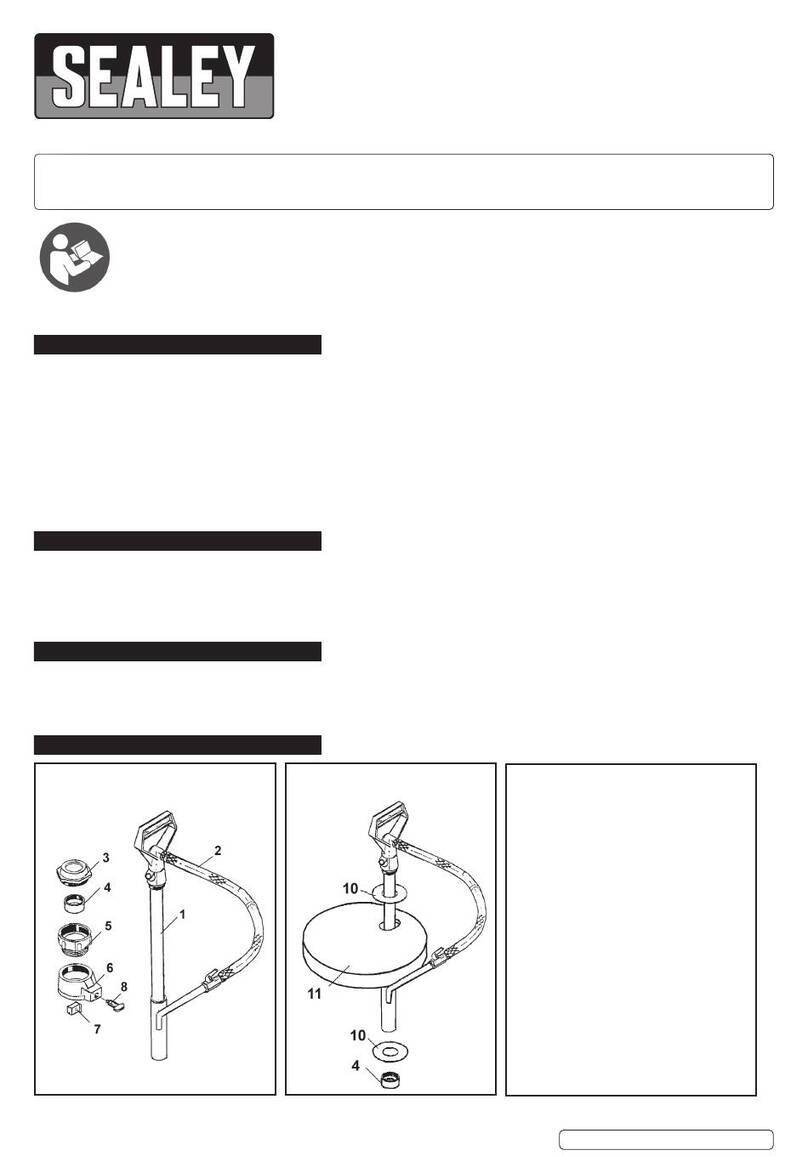

4. CONTENTS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

AK4555D Pump kit AK4556D Hose Reel + Digital meter

Hose Reel available as AK4557D Digital meter available as AK4558D

4.1 Check contents against items in fig.1 and fig.2. Remove items from carton, identify and check pieces for any damage. Contact supplier

immediately if you experience a problem.

AK4555D