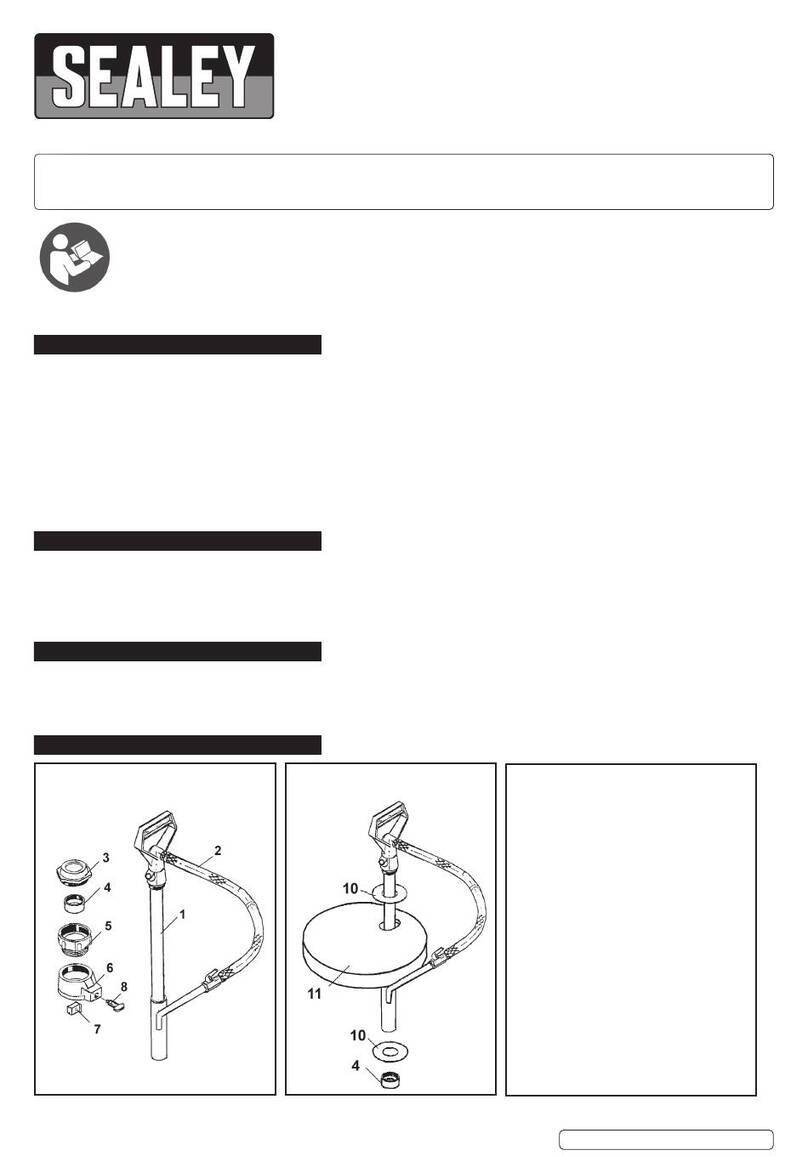

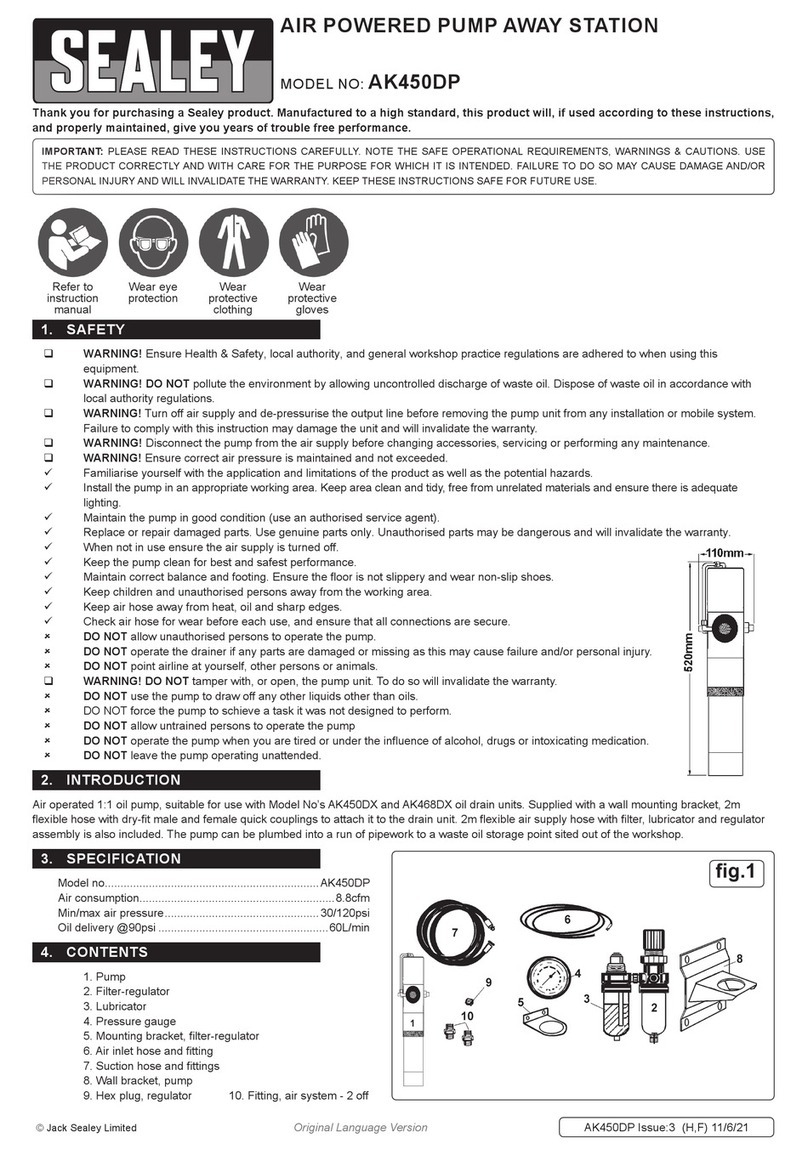

5. INSTALLATION

5.1. The submersible pump is installed as follows:

• In a stationary position with xed pipeline or

• in a stationary position with a exible hose pipe.

NOTE: Never install the pump by suspending it unsupported from its delivery pipe or power cable. The submersible pump must be

suspended from the specially provided handle or be placed on the bottom of the shaft.

5.2. To guarantee that the pump works properly, the bottom of the shaft must be kept free of sludge and dirt of all kinds. If the level of

water sinks too far, any sludge in the shaft will dry out quickly and stop the pump from starting up. Therefore it is necessary to

check the submersible motor pump regularly (by carrying out start-up tests).

5.3. The oat switch must be adjusted in a way that the pump can start immediately.

NOTE: The pump shaft should have minimum dimensions of 40 x 40 x 50 cm, so that the oating switch can move freely.

5.4. MAINS SUPPLY

5.4.1. Submersible pump is equipped with a shock-proof plug according to regulations. The pump is designed to be connected to a 230V - 50

Hz earthed socket. Make sure that the socket is sufciently secured {min. 6 Amp.) and is in excellent condition.

5.4.2. Important Note! If the mains cable or plug suffers any damage from external action, repairs to the cable should be serviced by a

qualied specialist using genuine spare parts.

5.5. Fit appropriate discharge pipe to pump outlet and secure with clip. Ensure the diameter of the discharge pipe is the same as, or

greater than, the outlet diameter. A smaller pipe will adversely effect the pump flow rate.

6. OPERATION

6.1. After having read these instructions carefully, you can set your pump to work, after checking the following:

• Check if the pump rests on the ground of the shaft.

• Check of hose has been attached properly.

• Check if electrical connection is to correct specication.

• Check if socket is in good condition.

• Make sure that water and humidity can never come to the mains supply.

• Avoid pump running dry.

6.2. VENT THE PUMP BEFORE USE

6.2.1. Always ensure that the pump is vented properly before commissioning the pump. Tilting back and forth several times until no more air

bubbles appear, wait at least 15 seconds before starting pump.

6.3. ADJUSTING THE ON/OFF OPERATING POINT

6.3.1. The ON and OFF operating point of the oat switch can be set by adjusting the oat switch in its holder.

6.3.2. Before you put the pump into operation, please check the following:

• The oat switch must be installed so that the level of the ON operating point and the level of the OFF operating point can be reached

easily and with little force. To check this, place the pump in a vessel lled with water, raise the oat switch carefully by hand and then

lower it again. Note whether the pump switches on and off.

• Make sure that the distance between the oat switch head and the holder is not too small. Proper operation is not guaranteed if the

gap is too small.

• When you set the oat switch, make sure that it does not touch the base before the pump switches off.

6.4. CAUTION! RISK OF DRY-RUNNING

6.4.1. The water into which the pump is placed will act as the motor cooling agent. For this reason the pump must remain submerged at all

times. Should the pump have to be used in shallow water DO NOT operate for more than 10 minutes. Failure to follow this rule will

damage the unit and will invalidate your warranty.

This appliance cannot be used by children or people who are physically, mentally or developmentally impaired, or people who lack

experience or knowledge, except in case these people receive instruction from a person responsible for their safety, a supervisor, or by

studying the preceding instructions concerning use of this appliance.

NOTE: Refer to Specification section to determine minimum clearance required if using pump in a restricted area i.e. well, etc.

7. MAINTENANCE

WARNING! With the exception listed below, all pump, float and electrical cable service maintenance and repair must only be

undertaken by an authorised service agent. Failure to observe this rule may be dangerous and will invalidate your warranty.

WARNING! Ensure the pump is disconnected from the mains power supply before attempting any service or maintenance.

7.1. When the pump is often transported in the course of operation, it should be cleaned out with clear water after every use.

7.2. In case of stationary installation, the function of the floating switch should be checked every 3 months.

7.3. All fibrous particles which may have built-up inside the pump housing should be removed with a water jet.

7.4. Every 3 months the shaft ground and as should be cleaned of mud.

7.5. Remove deposits on the floater with clear water.

7.6. CLEANING THE IMPELLER

7.6.1. If excessive deposits collect in the pump case you must dismantle the bottom part of the pump as follows:

1. Remove the intake cage from the pump case.

2. Clean the impeller with clear water.

Important! DO NOT put down or rest the pump on the impeller!

3. Re-assemble in reverse order

8DO NOT dismantle any other part of the unit.

8. STORAGE

8.1. Thoroughly clean the whole machine and its accessories.

8.2. Store out of the reach of children, in a stable and secure position, in a cool and dry place, avoid too high and too low temperatures.

8.3. Protect it from exposure to direct sunlight. Keep it in the dark, if possible.

8DO NOT keep pump in a plastic bag to avoid a build up in humidity.

Original Language Version

© Jack Sealey Limited WPC100.V3, WPC235A.V3, WPC250A.V2 Issue:1 25/10/22