AIR POWERED PUMP AWAY STATION

MODEL NO: AK450DP

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this

equipment.

WARNING! DO NOT pollute the environment by allowing uncontrolled discharge of waste oil. Dispose of waste oil in accordance with

local authority regulations.

WARNING! Turn off air supply and de-pressurise the output line before removing the pump unit from any installation or mobile system.

Failure to comply with this instruction may damage the unit and will invalidate the warranty.

WARNING! Disconnect the pump from the air supply before changing accessories, servicing or performing any maintenance.

WARNING! Ensure correct air pressure is maintained and not exceeded.

9Familiarise yourself with the application and limitations of the product as well as the potential hazards.

9Install the pump in an appropriate working area. Keep area clean and tidy, free from unrelated materials and ensure there is adequate

lighting.

9Maintain the pump in good condition (use an authorised service agent).

9Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9When not in use ensure the air supply is turned off.

9Keep the pump clean for best and safest performance.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9Keep children and unauthorised persons away from the working area.

9Keep air hose away from heat, oil and sharp edges.

9Check air hose for wear before each use, and ensure that all connections are secure.

8DO NOT allow unauthorised persons to operate the pump.

8DO NOT operate the drainer if any parts are damaged or missing as this may cause failure and/or personal injury.

8DO NOT point airline at yourself, other persons or animals.

WARNING! DO NOT tamper with, or open, the pump unit. To do so will invalidate the warranty.

8DO NOT use the pump to draw off any other liquids other than oils.

8DO NOT force the pump to schieve a task it was not designed to perform.

8DO NOT allow untrained persons to operate the pump

8DO NOT operate the pump when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT leave the pump operating unattended.

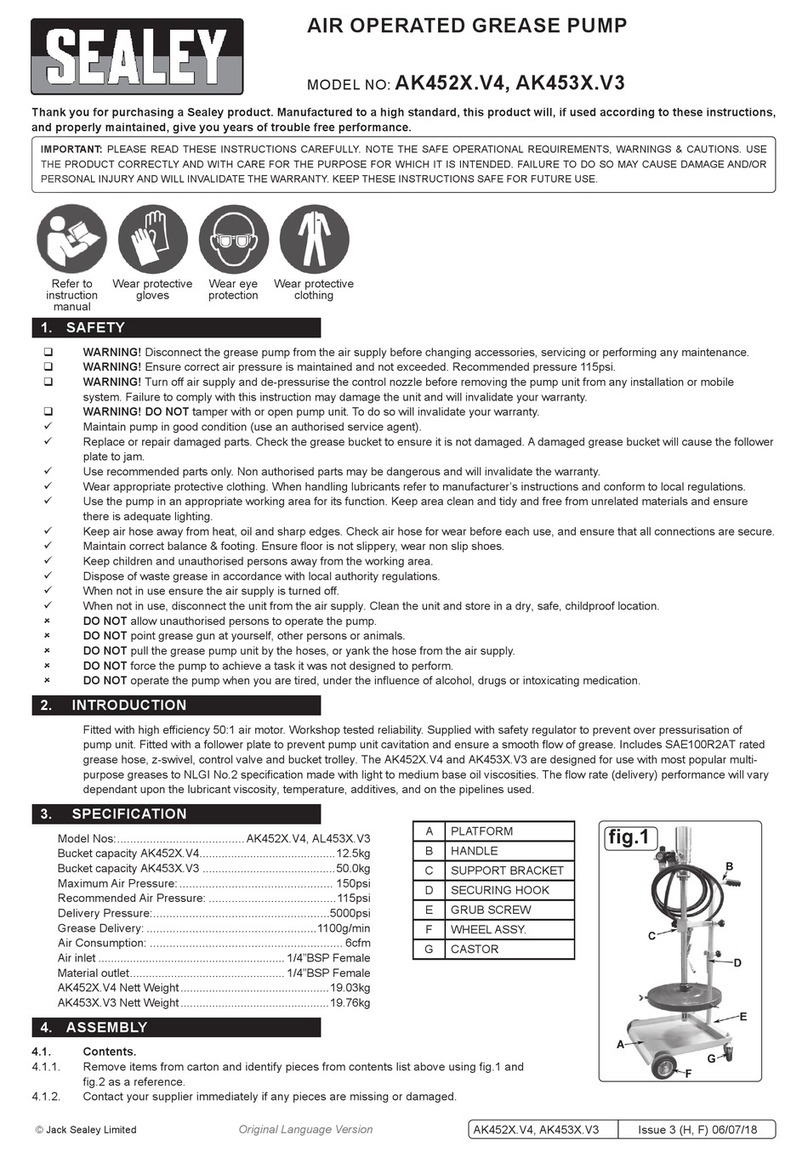

2. INTRODUCTION

Air operated 1:1 oil pump, suitable for use with Model No’s AK450DX and AK468DX oil drain units. Supplied with a wall mounting bracket, 2m

flexible hose with dry-fit male and female quick couplings to attach it to the drain unit. 2m flexible air supply hose with filter, lubricator and regulator

assembly is also included. The pump can be plumbed into a run of pipework to a waste oil storage point sited out of the workshop.

3. SPECIFICATION

Model no....................................................................AK450DP

Air consumption..............................................................8.8cfm

Min/max air pressure................................................. 30/120psi

Oil delivery @90psi ......................................................60L/min

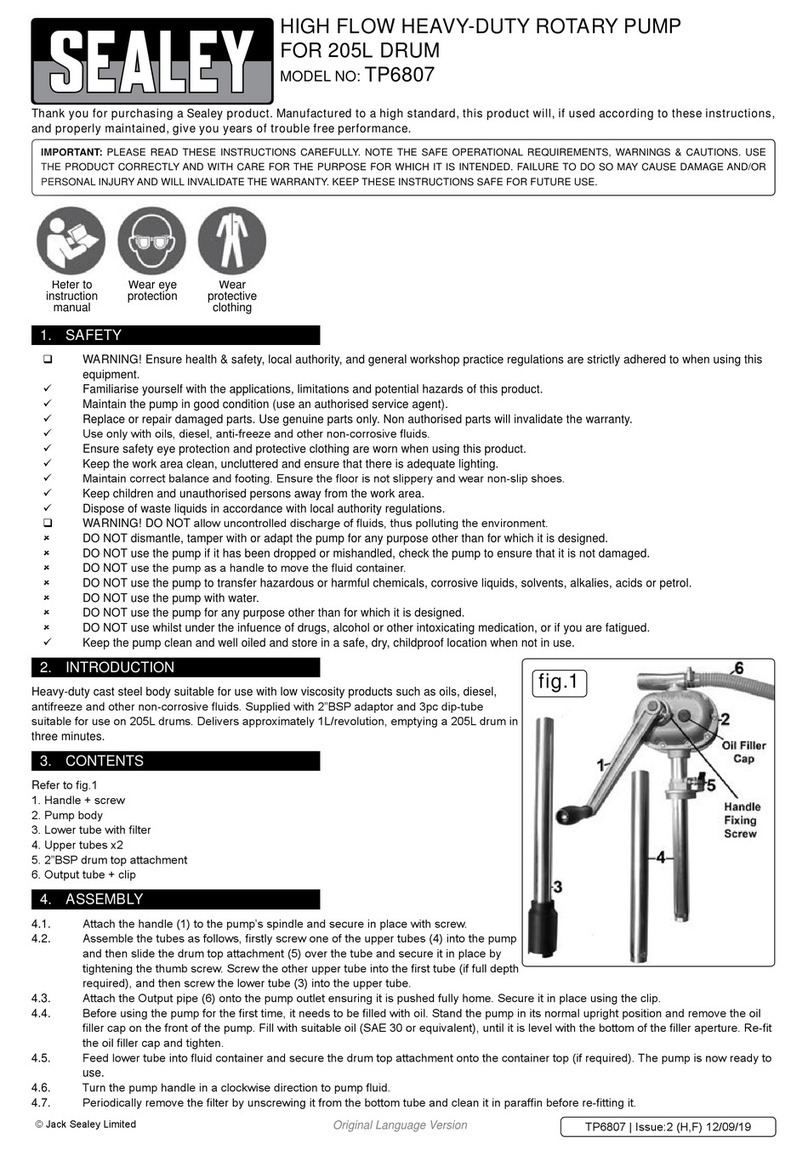

4. CONTENTS

1. Pump

2. Filter-regulator

3. Lubricator

4. Pressure gauge

5. Mounting bracket, filter-regulator

6. Air inlet hose and fitting

7. Suction hose and fittings

8. Wall bracket, pump

9. Hex plug, regulator

Refer to

instruction

manual

Wear eye

protection

Wear

protective

clothing

Wear

protective

gloves

AK450DP Issue:3 (H,F) 11/6/21

Original Language Version

© Jack Sealey Limited

10. Fitting, air system - 2 off

fig.1