Sealy SM18/1 User manual

1. SAFETY INSTRUCTIONS

INSTRUCTIONS FOR:

POWER HACKSAWS

MODEL No: SM16/1, SM17/1, SM18/1

Thank you for purchasing a Sealey quality product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT BEFORE USING THIS PRODUCT, PLEASE READ THE INSTRUCTIONS CAREFULLY. MAKE CAREFUL NOTE OF SAFETY

INSTRUCTIONS, WARNINGS AND CAUTIONS. THIS PRODUCT SHOULD ONLY BE USED FOR ITS INTENDED PURPOSE. FAILURE TO DO SO

MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE.

1.2. GENERAL SAFETY

WARNING! Disconnect the hacksaw from the power source before servicing, changing accessories or performing any other

maintenance.

Familiarise yourself with applications and limitations of the product, as well as the potential hazards.

Maintain the hacksaw in top condition. Keep it clean and keep blades sharp for best and safest performance.

Use original Sealey spare parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

Keep all guards and fixing screws in place, tight and in working order. Check regularly for damaged parts. A guard or any other part

that is damaged should be repaired or replaced before the saw is used further. Check also for proper alignment of moving parts,

loose mountings, or any other condition that could affect the operation of the saw.

Ensure the space allocated for use and maintenance of the machine is adequate, free from unrelated materials and has good lighting.

Remove any adjusting keys and wrenches from the machine before operating.

Wear approved eye and ear protection when operating the machine. If dust is produced, wear an approved face or dust mask.

Keep correct footing and balance at all times.

Always secure the workpiece in the vice.

Keep children and unauthorised persons away from the working area, especially when the saw is in operation.

Ensure that large or oversize workpieces are supported at hachsaw table height. Ensure you use a suitable support for any workpiece

that does not have a flat surface. Be cautious when cutting workpieces which are irregular in cross-section. The saw blade could be

pinched before the cut is completed. Any stock such as frame moulding, must lay flat on the table surface and not be allowed to rock.

WARNING! Rods and tubing have a tendency to roll while being cut and cause the blade to “bite”. DO NOT cut such items without

clamping or blocking the workpiece.

WARNING! Never force the blade through the workpiece.

DO NOT use this machine for anything other than its intended purpose. The machine is designed for light metal cutting work in

engineering workshops, garages, metal fabricators, etc.

1.1. ELECTRICAL SAFETY

WARNING! It is the responsibility of the owner and the operator to read, understand and comply with the following:

You must check all electrical products, before use, to ensure that they are safe. You must inspect power cables, plugs, sockets and any other

connectors for wear or damage. You must ensure that the risk of electric shock is minimised by the installation of appropriate safety devices.

A Residual Current Circuit Breaker (RCCB) should be incorporated in the main distribution board. We also recommend that a Residual Current

Device (RCD) is used. It is particularly important to use an RCD with portable products that are plugged into a supply which is not protected

by an RCCB. If in any doubt consult a qualified electrician. You may obtain a Residual Current Device by contacting your Sealey dealer.

You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity at Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by a qualified

electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of those appliances

and the safety of the appliance operators. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply. See 1.1.1. and 1.1.2.

and use a Portable Appliance Tester.

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply cables and plugs for wear or damage and check all

connections to ensure that none is loose.

1.1.6. Important: Ensure that the voltage marked on the appliance matches the power supply

to be used and that the plug is fitted with the correct fuse - see fuse rating at right.

1.1.7. DO NOT pull or carry the appliance by the power cable.

1.1.8. DO NOT pull the plug from the socket by the cable.

1.1.9. DO NOT use worn or damaged cables, plugs or connectors. Immediately have any faulty

item repaired or replaced by a qualified electrician. When an ASTA/BS approved UK

3 pin plug is damaged, cut the cable just above the plug and dispose of the plug safely.

Fit a new plug according to the following instructions (UK only).

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

d) After wiring, check that there are no bare wires, that all wires have been correctly connected, that the cable outer

insulation extends beyond the cable restraint and that the restraint is tight.

Double insulated products, which are always marked with this symbol , are fitted with live (brown) and neutral (blue) wires only.

To rewire, connect the wires as indicated above - DO NOT connect either wire to the earth terminal.

1.1.10. Products which require more than 13 amps are supplied without a plug. In this case you must contact a qualified electrician to ensure

that a suitably rated supply is available. We recommend that you discuss the installation of an industrial round pin plug and socket

with your electrician.

1.1.11. If an extension reel is used it should be fully unwound before connection. A reel with an RCD fitted is preferred since any appliance

plugged into it will be protected. The cable core section is important and should be at least 1.5mm², but to be absolutely sure that

the capacity of the reel is suitable for this product and for others which may be used in the other output sockets, we recommend the

use of 2.5mm² section cable. If extension reel is to be used outdoors, ensure it is marked for outdoor use.

FUSE RATING 5AMP

Blue

Neutral

Wire

Yellow & Green

Earth Wire

Cable

Restraint

Brown

Live

Wire

Original Language Version SM16/1, SM17/1, SM18/1 Issue: 2 - 08/12/09

3. ASSEMBLY AND SET UP CHECKS

2. INTRODUCTION & SPECIFICATIONS

2.1. Introduction.

The SM16/1, SM17/1 and SM18/1 power hacksaws are manufactured to comply with Supply of Machinery (Safety)

Regulations 1992 (S.I.3073). Cast base with integral mitring vice and setting bar for repetition cutting. Machined

saw arm runners with wear shims for smooth cutting performance. Automatic power cut-off stops machine after

completion of cutting. Fitted with heavy duty 230Volt single phase electric motor and an approved 3 pin safety plug.

SM17/1 and SM18/1 supplied with a belt driven coolant pump system to lubricate and cool the workpiece. Fully

guarded pulley and drive assembly.

WARNING! These hacksaws MUST NOT be used to cut non-metallic materials (including wood) as to do so will invalidate your insurance

cover and your warranty and may cause damage and/or personal injury.

DO NOT wear loose or ill-fitting clothing. Remove ties, watches, rings and other jewellery. Tie up, or adequately cover, long hair.

DO NOT start machine until workpiece is secure and the blade has been lowered to just above the workpiece.

DO NOT use the hacksaw with the blade guard or pulley cover removed.

DO NOT use damaged or deformed hacksaw blades.

Turn the saw off before raising the blade.

DO NOT run the saw with the blade in the raised position.

DO NOT use the machine in wet or damp locations.

DO NOT use the machine in areas where fumes from paint, solvents, or flammable liquids pose a potential hazard. Keep all

flammable materials (including wipers or cleaning rags) away from the saw, and dispose of according to local regulations.

DO NOT stand on the machine.

DO NOT leave machine running unattended. Turn power switch ‘Off’ and do not leave area until machine has come to a complete stop.

DO NOT operate the saw when you are tired, under the influence of alcohol, drugs or intoxicating medication.

2.2. Specifications

Model No SM16/1 SM17/1 SM18/1

Capacity at 90º (mm) 180 X 180 185 X 185 205 X 205

Capacity at 45º (mm) 90 X 180 90 X 185 110 X 205

Motor 375W 230V 375W 230V 375W 230V

Size of blade 400 X 25 X 1.25mm 400 X 25 X 1.25mm 400 X 32 X 1.6mm

Cutting speed 50/70 strokes/min 50/70 strokes/min 60/80 strokes/min

Working floor area required 1020 X 350mm 1020 X 350mm 1050 X 370mm

Weight 110kg 115kg 140kg

Note: Letters in brackets refer to Fig.1.

3.1. Glass oiler

3.1.1. The glass oiler ensures constant lubrication between the bow saw and the saw arm.

3.1.2. Screw the glass oiler into the mounting on the saw bow, as shown in (A).

3.1.3. Fill the oiler with light machine oil.

3.1.4. Adjust the rate of flow by turning the serrated collar on the top of the oiler.

3.2. Oil caps

3.2.1. There are five oil caps fitted to the saw, (B1 - B5).

3.2.2. Remove the six self tapping screws in the guard, (C, only two shown) and fold it

down.

3.2.3. Identify the two oil caps on the frame support (B1 & B2) and the two on the saw

arm, (B3 & B4).

3.2.4. Lift each cap in turn and fill the cups with light machine oil. Allow time for the oil

to penetrate and refill as necessary.

3.2.5. Fold the guard into position and refit the six screws removed in paragraph 3.2.2.

3.2.6. The fifth oil cap is fitted on the connecting rod, (B5). Lift the cap and fill the cup

with light machine oil.

3.3. Length bar

3.3.1. When cutting multiple same length pieces, the length bar and length plate can be

fitted to save the operator having to measure the item to be cut each time.

3.3.2. Screw the length bar (D) into the side of the saw bed and tighten the locking nut.

3.3.3. Adjust the length plate (E) to the required position and lock in place by

tightening the “T” head bolt (F).

3.4. Blade tension

3.4.1. Check the blade tension by flicking the blade. The blade should make a sharp

pining sound if it is properly adjusted.

3.4.2. If the blade needs adjusting, refer to paragraph 5.3.

3.5. Coolant tank (Models SM17/1 and SM18/1 only)

3.5.1. Fill the cooling tank, attached to the underside of the saw bed, with cutting oil

Fig.1.

by pouring through the slots in the saw bed into the coolant tank. Ensure the supply tap at the base of the coolant pipe is turned off.

Note: Neat cutting oil, part no NCO/5L and soluble cutting oil SCO/5L are available from your local Sealey dealer.

3.6. Saw arm weight

3.6.1. Fit the saw arm weight, (G) onto the saw arm to increase the cutting weight if required.

Original Language Version SM16/1, SM17/1, SM18/1 Issue: 2 - 08/12/09

WARNING! Before operating the hacksaw ensure that you read, understand and apply the safety instructions in Section 1.

NOTE: Before operating the machine certain checks and adjustments will need to be carried out. It is very important that

these instructions are followed carefully in order that the machine is set up safely and correctly.

WARNING! The machine is designed for the cutting of light metal in engineering workshops, garages, metal fabricators, etc. The

SM16/1, SM17/1 & SM18/1 must not be used to cut any other materials (including wood). To do so will invalidate your insurance

cover and your warranty and may cause damage and/or personal injury.

WARNING! Ensure that the saw is disconnected from the power supply before making any adjustments.

4.1. Set up checks

4.1.1. Check the saw thoroughly before using it. Ensure the guards are correctly fitted and that the moving parts are secure and in working

order.

4.1.2. Raise the saw arm as far as possible.

4.1.3. Place the work piece in the vice, set the length bar as required and clamp the work piece securely. For angled cutting, see 4.2.

4.1.4. If cutting mild steel, turn on the coolant supply tap (models SM17/1 and SM18/1 only) and direct the coolant nozzle towards the area of

the workpiece that will be cut.

Note: Ensure the oiler is correctly set and tha t oil has been applied to the five oil caps before starting the saw.

4.1.4. Connect the machine to the mains power supply.

4.1.5. Start the machine and the arm will automatically lower and start cutting.

4.1.6. When sawing is completed the saw will switch off automatically, disconnect from the power supply, raise blade and remove workpiece.

Never raise blade when machine is running .

4. OPERATION

4.2. Vice setting

4.2.1. The vice is locked at 0º but can be set to any angle up to 45º.

4.2.2. To set an angle on the vice, remove the centre bolt fig.2.C and vice clamp bolt

fig.2.D.

4.2.3. Loosen the vice swivel bolt fig.2.A and the vice clamp bolt fig.2.B.

4.2.4. Set the vice to the required angle and tighten vice swivel bolt fig.2.A and the vice

clamp bolt fig.2.B.

4.2.5. Loosen the free vice clamp bolt fig.2.E.

4.2.6. Place the work piece in the vice and wind the free vice closed until it grips the

workpiece.

4.2.7. Tighten the free vice clamp bolt fig.2.E and ensure the workpiece is securely

clamped.

4.2.8. Where the length of the workpiece to be secured is half the width if the vice, or less,

adjust the bolt on the free vice so that it touches the fixed vice face, as shown in

fig.3.

4.2.9. The saw bed provides an alternative pair of mounting holes for the fixed side of the

vice. o use these holes, remove the centre bolt fig2.C, the vice clamp bolts

fig.2.B & D and the vice swivel bolt fig.2.A.

4.2.10. Position the fixed side of the vice on the saw bed such that the vice swivel bolt fig.2.A

is located through the vice and into the mounting hole fig.2.F.

4.2.11. Fit one of the vice clamp bolts fig.2.B or D through the vice and into mounting hole

fig.2.G.

Note: When using these alternative mounting holes, the fixed vice does not have a 0º lock

facility. It is the responsibility of the operator to ensure that the fixed vice is at the

correct angle.

4.2.12. Set the vice to the required angle and secure by tightening the vice swivel fig.2.A and

clamp bolt fig.2.D.

Note: Use of these alternative mounting holes can lengthen the life of the saw blades.

Fig.2.

Fig.3.

Fig.4.

5. MAINTENANCE & ADJUSTMENTS

WARNING! BEFORE CARRYING OUT ANY MAINENANCE OR MAKING ANY

ADJUSTMENTS, DISCONNECT SAW FROM POWER SUPPLY.

5.1. Cleaning

5.1.1. Clean saw after each operation and smear unpainted surfaces with oil to prevent

rusting.

5.2. Replacing the saw blade

We recommend you keep a small supply of commonly used saw blades to hand.

Change saw blades frequently for best results. Ensure you choose a blade with a

pitch suitable for workpiece to be cut.

5.2.1. Disconnect the machine from the power supply.

5.2.2. Loosen the two screws, fig.4.A, holding the fixed plate on.

5.2.3. Undo the two locking nuts, fig.4.B and release the tension in the blade.

5.2.4. Undo the two blade retaining screws, fig.4.C and remove the blade.

5.2.5. Fitting the new blade is the reverse of the procedure in paragraphs 5.4.1. to 5.4.3.

5.2.6. Tension the blade as described in paragraph 5.5.

5.3. Blade tension

5.3.1. Test the blade tension by flicking the blade. The blade should make a sharp pinging

sound if it is correctly adjusted.

5.3.2. To adjust the blade tension, turn the lock nuts fig.4.B. Do not over tighten.

5.4. Blade stroke adjustment

5.4.1. Disconnect the machine from the power supply.

5.4.2. The sawblade stroke can be adjusted ±60mm.

5.4.3. Remove the six self tapping screws in the guard, fig.1.C and fold it down.

5.4.4. Loosen the nut on the inside of the gear wheel, fig.5.

Fig.5.

Original Language Version SM16/1, SM17/1, SM18/1 Issue: 2 - 08/12/09

5.4.5. To shorten the stroke, slide the bow saw towards the centre of the gear wheel and

to lengthen the stroke, slide the bow saw towards the outside of the gear wheel.

5.4.6. Tighten the nut on the inside of the gear wheel, fig.5.

5.4.7. When satisfied that the adjustment is accurate, carefully turn the pulley by hand to

see if the blade snags or rubs at any point. Readjust stroke if necessary.

5.4.8. Fold the guard into position and refit the six screws removed in paragraph 5.4.3.

5.5. Hydraulic pump - oil change

5.5.1 The oil in the hydraulic pump should be changed every 6 months.

5.5.2. Remove the six self tapping screws in the guard, fig.1.C and fold it down.

5.5.3. Remove the cotter pin, fig.6.A and the compression arm retaining pin, fig.6.B.

5.5.4. Lift off the compression arm, fig.6. C.

5.5.5. Remove the cotter pin, fig.6. D and the swing bolt retaining pin, fig.6.E.

5.5.6. Loosen the two hydraulic pump retaining bolts, fig.6.F and lift out the hydraulic

pump.

5.5.7. Undo the four screws in the hydraulic pump top plate (not shown), lift the plate off

and empty the oil into a suitable container and dispose of according to local

regulations.

5.5.8. Refill the pump with oil.

Note: Use a good quality jack oil, such as SEALEY HYDRAULIC JACK OIL.

5.5.9. Assembly and fitting instructions are the reverse of paragraphs 5.5.2. to 5.5.7.

above.

5.6. Bow saw & saw arm adjustment

5.6.1. Play between the bow saw and the saw arm can be removed by adjusting the three

tensioning bolts shown in fig.7.

5.6.2. Loosen the three lock nuts and tighten the tensioning bolts until the play has been

removed.

5.6.3. Tighten the three lock nuts.

Note: Do not over tighten the tensioning bolts as this will cause excessive wear.

5.7. Vibration

5.7.1. If the saw arm shakes, vibrates excessively or apears otherwise insecure it may be

necessary to tighten the support frame,fig.8 to the gear shaft or tighten the saw

arm to the support frame fig.9.

5.7.2. To tighten the support, remove the six self tapping screws in the guard, fig.1.C and

fold it down.

5.7.3. Loosen the lock nuts and tighten the bolts fig.8 such that any movement on the

gear shaft is significantly reduced.

5.7.4. Tighten the lock nuts.

5.7.5. Fold the guard into position and refit the six screws removed in paragraph 5.7.2.

Note: Do not over tighten the bolts as this will cause excessive wear.

5.7.6 To tighten the support, remove the six self tapping screws in the guard, fig.1.C and

fold it down.

5.7.7. Loosen the outer lock nut, fig.9, tighten the inner lock nut and tighten the outer lock

nut.

5.7.8. Fold the guard into position and refit the six screws removed in paragraph 5.7.6.

5.7. Adjusting rate of decent of the saw arm

5.7.1. The rate of decent of the saw arm can be adjusted by altering the effective length of

the compressing bracket.

5.7.2. Remove the six self tapping screws in the guard, fig.1.C and fold it down.

5.7.3. To increase the rate of decent of the saw arm, loosen lock nut “A”, fig.10, and

tighten lock nut “B”, fig.10 shortening the effective length of the compressing

bracket.

5.7.4. To decrease the rate of decent of the saw arm, loosen lock nut “B”, fig.10 and

tighten lock nut “A”, fig.10 increasing the effective length of the compressing

bracket.

5.7.5. Fold the guard into position and refit the six screws removed in paragraph 5.7.2.

Note: Fine adjustment of the rate of decent of the saw arm is possible using the fine

adjuster, fig.11, on the hydraulic pump (SM18/1 only).

Fig.6.

Fig.7.

Fig.8.

Fig.9.

Fig.10. Fig.11.

Original Language Version SM16/1, SM17/1, SM18/1 Issue: 2 - 08/12/09

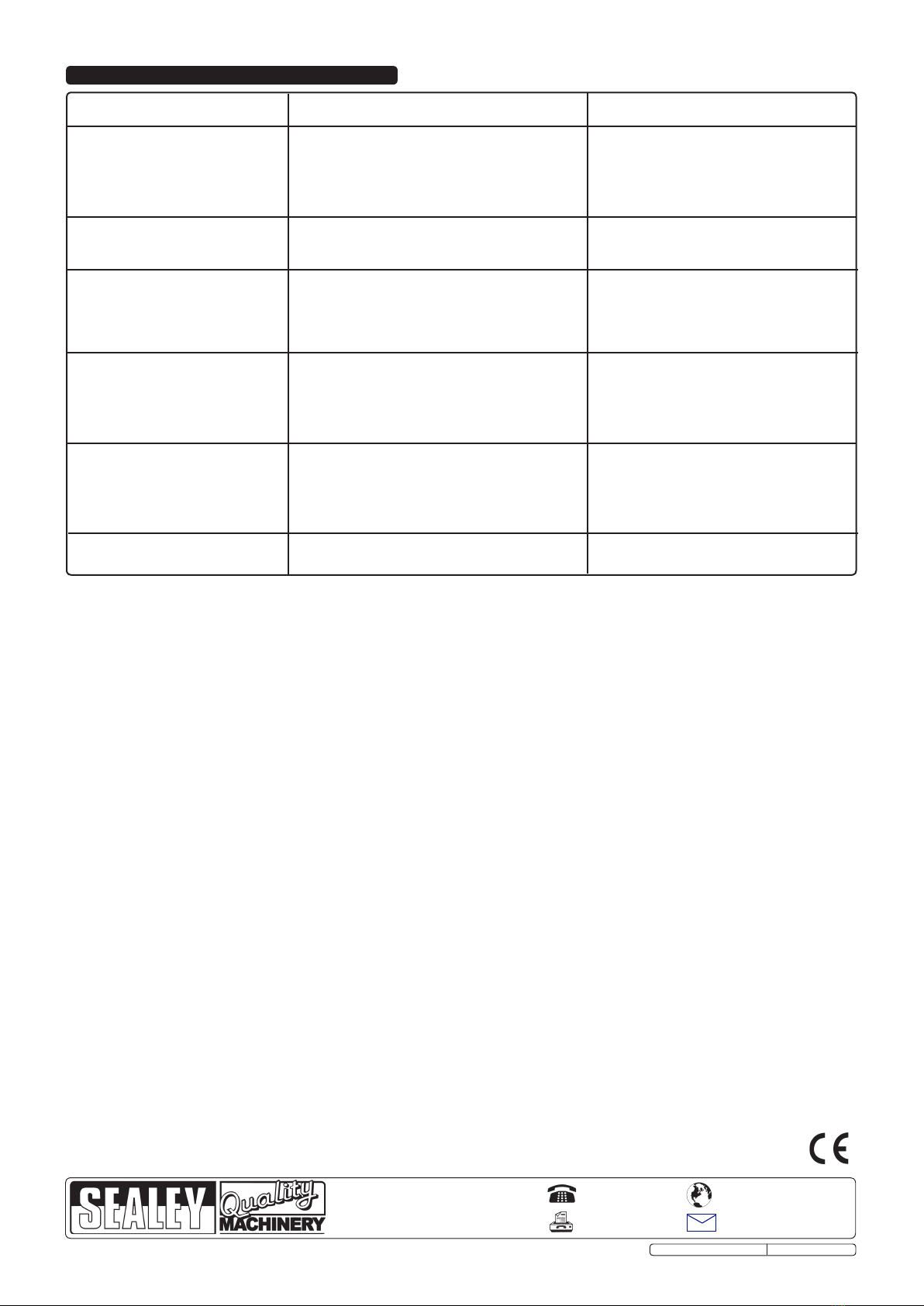

6. TROUBLESHOOTING

Problem Possible Cause Solution

The angle of the cut is inaccurate. 1. The tensioning bolts on the bow are loose. 1. Tighten the bolts.

2. The blade is not tight. 2. Tighten the blade.

3. The blade is dull. 3. Replace the blade.

4. The setting on the vice is inaccurate. 4. Set the vice at 0 using a right angle

and adjust the pointer to match.

No power 1. Oil level is low. 1. Check oil and fill up as required.

2. The tensioning bolts are loose. 2. Tighten the bolts.

Saw is not cutting efficiently. 1. Pressure from the saw arm is too light. 1. Attach a heavier weight to the arm.

2. The stroke of the blade is incorrect. 2. Adjust the stroke.

3. Saw blade is the wrong type. 3. Use a different TPI blade.

4. Saw blade is worn. 4. Replace the blade.

Saw blade does not rise when cutting. 1. Hydraulic pressure is low. 1. Check the pressure. Refill if needed.

2. Compressing arm is too low. 2. Adjust the compressing bracket to a

higher position.

3. The cam is loose. 3. Tighten the cam.

4. Air is in the hydraulic system. 4. Pump the arm a few times manually.

Excessive noise. 1. The saw is low on lubricant. 1. Check lubricant and refill as required.

2. The pulley is touching the pulley guard. 2. Adjust the pulley so that it does not touch

the guard.

3. The gears are worn out. 3. Replace the gears.

4. Screws, bolts or other moving parts are loose. 4. Tighten loose parts as required.

Coolant delivery is weak. 1. Sediment may have collected in the cooling 1. Clean the cooling tank .

tank.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

Original Language Version SM16/1, SM17/1, SM18/1 Issue: 2 - 08/12/09

This manual suits for next models

2

Table of contents