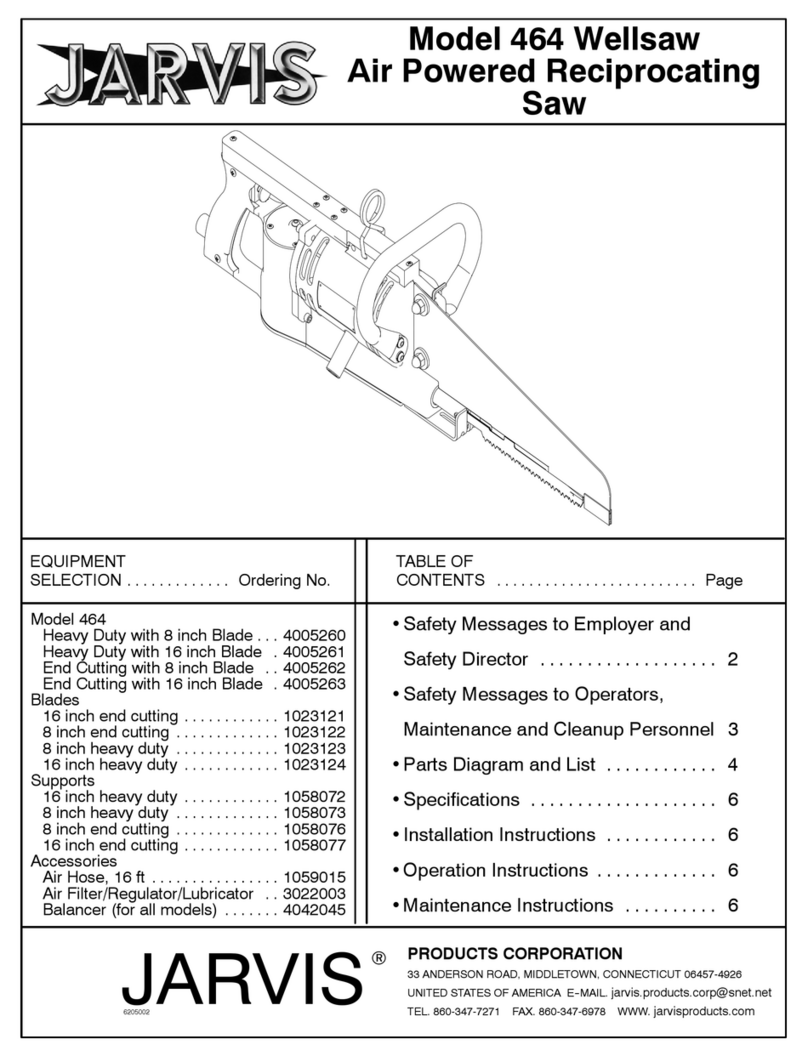

parts diagram and list

Model SHC 140, 165, 165B, 165G, 165GT and 205

page 4 of 20

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457-4926

UNITED STATES OF AMERICA E--MAIL.

sales@ arvisproducts.com

TEL. 860-347-7271 FAX. 860-347-6978 WWW.

arvisproducts.com

JARVIS

6207016::::.

1 1055905 Cheese Head Screw 1

2 1004020 Washer 1

3 3025010 Depth Gage Assy, RH 165 1

3025012 Depth Gage Assy, LH 165

3025015 Depth Gage Assy, RH 140

3025016 Depth Gage Assy, LH 140

4 1004001 Washer 1

5 1004021 Washer 1

6 1055954* Hex Head Screw 2

7 1036130* Auxiliary Handle Bushing 1

8 1019197* Auxiliary Handle, RH 1

1019198* Auxiliary Handle, LH

9 1024154 Blade Guard, RH 165 1

1024174 Blade Guard, LH 165

1024190 Blade Guard, RH 140

1024192 Blade Guard, LH 140

10 1054140 Blade Retaining Screw, RH 1

1054148 Blade Retaining Screw, LH

11 1004292 Blade Retaining Washer 1

12 1023324 Blade, 140 Teeth (165mm) 1

1023362 Blade, 120 Teeth (140mm)

1023308 Blade, 60 Teeth (165mm)

1023363 Blade, 60 Teeth (140mm)

13 1004293 Slinger 1

14 1035474 Oil Seal 1

15 1055899 Flat Head Screw 3

16 1002355 Gear Housing Cover, RH 1

1002373 Gear Housing Cover, LH 1

17 1021372 Ball Bearing 1

18 1026171 Crown Gear, RH 1

1026184 Crown Gear, LH

19 1021081 Ball Bearing 1

20 1038006 Grease Fitting 1

21 3016301 Gear Housing, RH 1

3016320 Gear Housing, LH

with items 20 and 22

3016304 Housing & Gear Assy, RH

3016319 Housing & Gear Assy, LH

(items 10, 11 and 13--27)

ITEM PART NO. PART NAME QTY

22 1021373 Needle Bearing 1

23 1026170 Pinion Gear, RH 1

1026183 Pinion Gear, LH

24 1021374 Bearing Race 1

25 1011300 Coupling 1

26 1021155 Ball Bearing 1

27 1013232 Internal Retaining Ring 1

28 1035164 O--ring 1

29 1032420 Adapter Plate, RH 1

1032453 Adapter Plate, LH

30 1042395 Hanger Bracket 1

31 1009153 Hanger Sleeve 1

32 1055742 Socket Head Cap Screw 4

33 3008172 Hydraulic Motor Assy, RH 1

3008189 Hydraulic Motor Assy, LH

(item 152, 157--160, 164--179)

34 1024155 Trigger Guard 1

35 1055725 Pan Head Screw 2

36 1032479GGuard Mounting Plate 1

37 1024023GBlade Guard (Brisket) 1

38 1055918GFlat Head Screw 1

39 1058153GBlade Guide (Brisket) 1

40 8039099 Blade Locking Pin 1

41 1019001 Straight Handle 1

42 1004003 Lock Washer 1

43 1055802 Hex Head Screw 1

44 1055835 Flat Head Screw 2

45 1033012 Depth Gage Index 1

46 1055901 Oval Head Screw 2

3024035 Guard & Gage Assy, RH 165

3024037 Guard & Gage Assy, LH 165

3024039 Guard & Gage Assy, RH 140

3024040 Guard & Gage Assy, LH 140

(items 1--5, 9, 45 and 46)

3024041 Guard Assembly (Brisket)

(items 36--39)

3019218* T--Handle Kit, RH (items 6--8)

3019217* T--Handle Kit, LH (items 6--8)

ITEM PART NO. PART NAME QTY

*

*

*

G

G

G

G

F gure A

SHC--140, 165 and 165B

a= 20 lbf--ft (27 Nm)

a

* optional -- must remove helical insert

in blade guard to install “T” handle.

** special tool 8039152 is available

GUsed on model SHC 165B brisket saw

**