Sears, Roebuck and Co. 103.22160 Use and care manual

r

-_/

\

OPERATING INSTRUCTIONS

AND PARTS- LIST FOR

..

BENCH

8 INCH

SAW

rIi

I

Model Number 103.22160

The model number of your Bench Saw will be found on

a plate on the rear of the Base. Alwaysmention this

model number when communicating with us regarding

your Bench Saw or when ordering parts.

-=tnstf'uctions

rqr

OrderIng Parts

All parts listed herein must be ordered through a Sears

retail store or mail order house. Parts are shipped

prepaid. When ordering repair parts, always give the

followinginformation:

1. The Part Number.

2. The Part Name and Price.

3. The ModelNumber 103.22160.

This list is valuable. It will assure your being able to

obtain proper parts service. Wesuggest you keep it with

other valuable papers.

SEARS, ROEBUCK and CO.

LITHOGRAPHED IN U. S. A.

SOURCE FORM 37979

..

OPERATING

INSTRUCTIO~S

AND PARTS LIST FOR

8 INCH BENCH SAW

Model 103 22160

FIGURE 2

Insert with clips

Install in opening provided in table top. See Fig. 4.

INSTALLATION OF SAW:

There are four 5/16 diameter holes provided in

the base of the saw through which the tool should

be fastened securely with screws or bolts to a well

built work bench. A large hole in the bench below

the blade will allow sawdust to escape.

The Motor Mount Bracket should be installed as

shown in Fig. 2.

I. Set the saw at 0 inches elevation and 0 degrees

tilt. (See paragraph headed "Controls".)

FIGURE

-r

Careful planning, preCISIOn machining, and rigid Motor Mount

inspection have all contributed toward maintaining Install as shown in Fig. 2 and outlined under "Instal-

the high standard of quality found in this tool. We lation of Saw".

are confident that you will find it satisfactory in

every respect.

To increase the versatility of this saw beyond the

normal range of bench saw operations, various

attachments "are readily available.

To prevent damage in shipment some of the parts

were disassembled from the tool. These parts are

listed below. Be sure they are all accounted for be-

fore discarding any of the packing material.

I. Fence; item II I.

2. Miter gage assembly; item I23.

3. Motor alignment rod; item 17.

4. Motor mount complete; item 26.

5. Insert with clips; items 12, 13, 14 and 15.

6. Motor pulley; item 64.

7. V-belt; item 62.

ASSEMBLY:

Fence and Miter Gage

Install as shown in Fig. I.

Motor Alignment Rod

The 5/1 6 x 4 1/2 inch motor alignment rod, No. I7,

fits into the hole in the back of the splitter bracket.

Insert the rod as far as it will go into the bracket

and tighte:n the set screw.

2

r

•

2. Draw a line on the bench 5 inches from the

rear of the Saw base. (Measure at two points

12 inches apart to be sure that the line is par-

allel to the rear of base. )

3. Place the bracket, No. 22, on the bench as

follows; The end with the elongated hole 4 5/8

inches in from the left side of saw base and the

front edge on the line drawn previously.

Fasten it securely in this position.

4. Assemble motor rail, No. 2 I, and motor rail

guide and plate, No. 18, to the motor rail

bracket as shown. The grooved end of the

motor rail to be placed in end of bracket with

elongated hole.

5. Bolt your motor to the mount so that the motor

pulley will be in line with the saw pulley when

the motor alignment rod is through the slot in

the motor rail guide and plate.

Check before Operation

I

1. The motor alignment rod must project at

least 1/4 inch through the mount slot with the

blade retracted and tilted 45 degrees. This

setting should be checked often during opera-

tion. As the belt wears or stretches, loosen

the set screw and pull the alignment rod out

of the bracket the amount needed.

2. The motor mount must not strike the motor

mount bracket at either end of the motor rail

at 0 or 45 degrees tilt.

3. Be sure that the teeth of the blade point

toward the front of the saw and the top of

the blade turns toward the front.

MOTO,,:

For general home workshop use, a 1/2 horsepower

3450 RP.M. motor will provide adequate speed and

power. However, to enable you to take full advan-

tage of the rugged performance features and full

cutting efficiency of this saw, especially for heavy

duty work, a 3/4 horsepower 3450 RP.M. motor

should be used.

SPEED:

The motor pulley, No. 64, installed on a 3450 RP.M.

motor with a 1/2 inch diameter shaft will drive the

saw at the recommended speed-4500 RP.M.

BELT:

If your motor shaft is approximately 4 inches from

the bottom of the base of the motor, the V-belt, No.

62, should fit the installation previously described.

LUBRICATION:

The precision ball bearing assembly used on the saw

arbor has been packed with lubricant and sealed at

the factory. It should require no further attention for

the life of the bearing assembly.

To maintain the smooth, easy operation of the

controls, oil the following points occasionally;

1. The guide, No. 48, at the front cif the arbor

support.

2. The guide ways of the front and rear trun-

nions, Nos. 80 and 96.

3

3. The elevation screw, No. 76.

4. The motor rail, No. 21.

CONTROLS:

The Control Knob raises the saw from 0 to 2 1/2

inches above the table level when pushed in and

turned. It tilts the saw 0 to 45 degrees when pulled

out and turned.

The Angle of Tilt is shown by a pointer on the

scale just below the control knob.

The Depth of Cut Gauge and Pointer c~n be seen

through the curved slot to the left of the control

knob.

The Miter Protrador face is a guide surface for.

cross cutting or diagonal cutting to a definite angle.

The protractor may be used on either side of the

blade at any angle or depth of cut setting. The angle

is shown by the pointer on the calibrated scale on

the protractor head. The lock knob clamps the head

in the selected position.

CAUTION:

This saw has an extra long spindle for greater dado

capacity. If the blade is extended more than 2 3/8

inches according to the depth of cut gauge, the spindle

will strike the table insert when the saw blade is

tilted.

The Fence Lock Handle when down clamps the

fence at both ends of the table. Raise the handle to

unlock and by grasping the front fence end move

the fence to any point across the table. T~ make

sure that the fence~l rpendicular to the I lbfe, push

down on fence as you lock it.

/

TIGHTEN LOCK NUTS

AFTER ADJUSTMENT

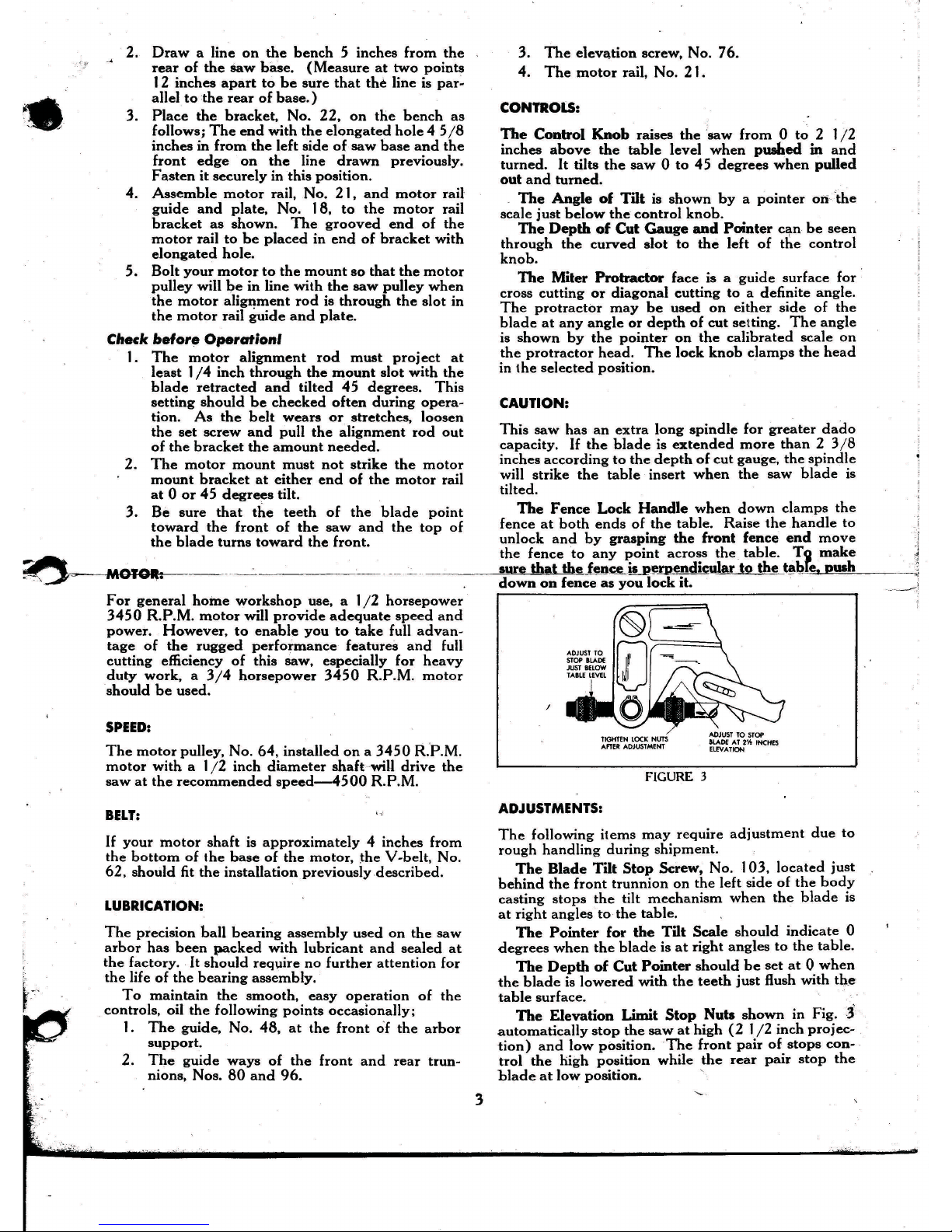

FIGURE 3

ADJUSTMENTS:

The following items may require adjustment due to

rough handling during shipment.

The Blade Tilt Stop Screw, No. 103, located just

behind the front trunnion on the left side of the body

casting stops the tilt mechanism when the blade is

at right angles to the table.

The Pointer for the Tilt Scale should indicate 0

degrees when the blade is at right angles to the table.

The Depth of Cut Pointer should be set at 0 when

the blade is lowered with the teeth just flush with the

table surface.

The Elevation Limit Stop Nuts shown in Fig."

automatically stop the saw at high (2 1/2 inch projec-

tion) and low position. The front pair of stops con-

trol the high position while the rear pair stop the

blade at low position.

IAISE .LADE

,'AI

INC"S

DISTANCE'SHOULD

BE EOUAL.

TURN BLADE-

MEASURE FROM

SAME TOOTH AT

TABlE LEVEL

FENCEMUST LOCK

PARALLEL WITH

MITER SLOTS

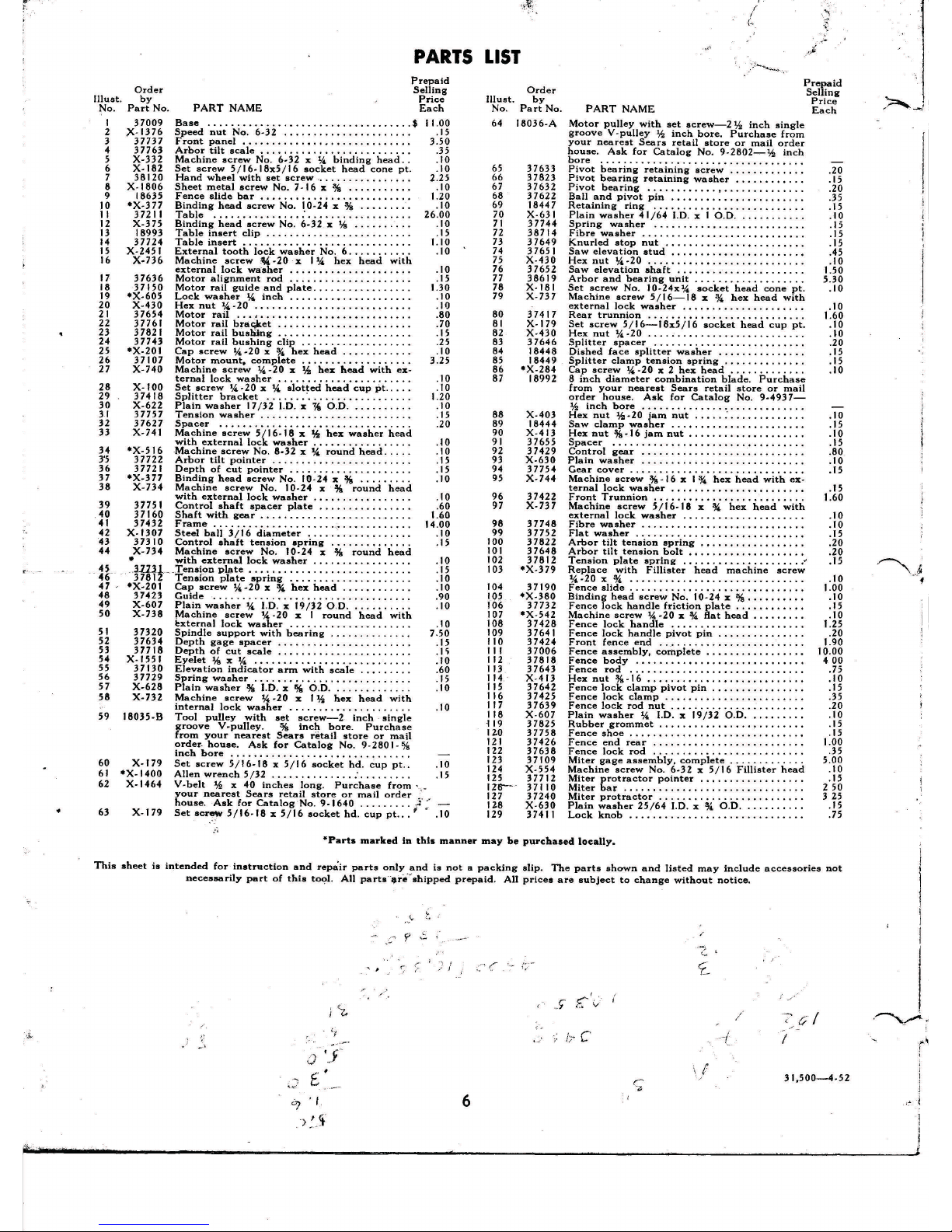

FIGURE 4

The Blade Must Be Parallel with the Miter Slots

in the Table to Get a Straight Cut. (See Fig. 4).

Adjustment, if necessary, may be made as follows;

1. Raise the blade to 2 1/2 inches depth of cut

and set at right angle (0 degrees) to table.

2. Measure accurately from a raker tooth on the

blade to an edge of either miter slot, as ex-

plained and shown in Fig. 4.

3. Loosen the bolts, Nos. 79 and 97. holding each

trunnion, Nos. 80 and 96. to the lower table

surface. (4 bolts total.)

4. Shift the complete under-table mechanism until

the blade is parallel with the miter slot.

5. Re-tighten the four trunnion screws. front pair

first.

6. Check this adjustment as previously explained

fa

be

eel

lain it is correct-after re-assembly is

complete.

The Fence Must Lock Parallel with the Miter Slots.

Using one hand on the front end of the fence, slide

the fence to the edge of the miter slot. Push the lock

handle down slowly. If fence isn't parallel to miter

slot adjust as follows;

1. Loosen the two screws, NO.,1

OS;

,onthe under-

side of the front fence end. '

2. Release the fence lock handle.

3. Hold the fence flush to the edge of the miter

slot. Turn both screws up just snug. Then

tighten each one securely.

4. Check the adjustment by sliding the fence

away from the slot and returning several times

to see if it locks parallel each time.

The Fence Must Be Square with the Table Surface.

Adjust by loosening the screws, No. 10, holding the

fence slide bar to the table. Slide the bar up or down

at either end to square the face of the fence with the

table. Re-tighten the screws.

The Arbor Tilt Tension Spring, No. 100, provides

tension to keep the mechanism tilted at any angle,

thus eliminating the need for a manual control lock.

After

tlie,;tbol

is "broken in." you may find it neces-

sary to.lncr~~se this tension. Loosen the lock nut.

No. 90. and turn the bolt, No. 101, until enough ten-

sion has been applied. Re-tighten the lock nut.

Note: After a few hours of operation. tightep all

pulley set screws.

CARE OF THE BLADE:

Keep the blade teeth sharp and properly set.

To sharpen the blade;

1. Lower the blade until an oil stone laid on the

table will just touch the teeth. Rotate the

blade backward by hand until the ends of all

the small cutting teeth have been touched.

2. File the gullets (space between teeth) of all

teeth of the same shape to a uniform depth

and width. Maintain' the original shape,

bevels. and dimensions. Avoid sharp corners

or nicks in the gullets between the teeth.

3. The top one-quarter of each cutting tooth

should be set at an angle of approximately 10

degrees. The set should be uniform and should

alternate from left to right on successive teeth.

The large raker teeth require no set-they

should be kept approximately 1/64 inch

shorter than the cutting teeth.

4. File the bevel of each cuttingtooth-15 to 20

degree bevel on the inside front face of each

tooth. Maintain the original bevel angle and

be careful not to shorten the teeth.

Blade Wobble is often noticed at slow speeds

when starting or stopping the saw. If this does not

disappear at full speed, check the saw blade and

clamp washers for dirt or saw dust on the clamping

surfaces.

Gummy' residue can generally be removed with

kerosene. '

OPERATION:

- • <

The blade provided with this saw may be used for

Doth cross-cutling and ripping.

For proper chip clearance and best general results,

the blade should project through the work-piece ap-

proximately 1/4 inch.

Do not force material into the blade too fast. Use

a straight, direct, steady feed which does not over-

tax the cutting capacity of the blade.

To eliminate creep of your work when making a

miter cut, clamp the work piece to the.miter gage.

Support long work as it leaves the.re~of the table.

SAFETY:

While the bench saw is one of the most widely used

woodshop power tools, it is by nature of its general

design. one of the most dangerous in the hands of ,

inexperienced or careless operators. The bench saw -

is not, however. an unsafe tool when used with com-

mon sense and good judgment.

Use a push block rather than letting the hands get

closer than 3 inches to the blade on narrow cuts.

Never hold the hands over the blade when making

blind groove type cuts. Stand to one side when com-

pleting a cut. A loose piece caught J.)ythe blade can

fly back with surprising force.

Always stop the saw when removing waste stock

from near the blade, when making adjustments, or

when changing settings.

Donat wear dangling neck ties, loose baggy

sleeves, etc.• while operating power tools.

103

J-;-

102

126

122

9-

129

_128

127

26

MOTOR MOUNT

COMPlETE

17

16 /, 18

,/ ,/ j -

19

32_.~, ,.... _ /.--20

7

l ••

3130IJ/

29 28 27 ./

l

25

I

23

24

41

ITER GAGE ASSY.

M COMPLETE

123

5

55

FENCE ASSY.

COMPLETE

111

,

106

r

(

i

(,.

PARTS LIST

.20

.15

.20

.35

.\5

.10

.15

.15

. I 5

45

.10

1.50

5.30

.10

.10

1.60

.10

.10

.20

. I 5

.15

.10

.10

. I 5

.10

.15

.80

.10

.15

.15

1.60

.10

.10

• I 5

.20

.20

• I 5

.10

1.00

.10

.15

.10

1.25

.20

1.90

10.00

400

75

.10

.15

35

.20

.10

. 15

. I 5

1.00

.35

5.00

.\0

. I 5

2 50

3 25

.15

.75

Prepaid

Selling

Pric

Each

PART NAME

Motor pulley with set screw-2 % inch single

groove V-pulley % inch bore. Purchase from

your n ar st S ars r tail stor or mail ord r

house. Ask for Catalog No. 9-2802-% inch

bor .

Pivot b aring r taining scr w .

Pivot b aring r taining wash r .

Pivot b aring , .

Ball and pivot pin ..................•....

R taining ring .

Plain washer 4 I/64 J.D. x I

0.0 .

Spring wash r .

Fibr wash r .

Knurled stop nut ..............•.........

Saw l vation stud .

Hex nut %-20 .....•.....................

Saw elevation shaft ..............•.......

Arbor and bearing unit .

Set screw No. 10-24x',4 socket head cone pt.

Machine screw 5/16- I8 x

*

hex head with

xt rnal lock wash r .

R ar trunnion .

Set screw 5/1 6- I8x5 / I6 socket head cup pt .

Hex nut % .20 .......••..................

Splitter spacer .

Dish d fac splitt r wash r .

Splitt r clamp t nsion spring .

Cap screw %.20 x 2 hex head .

8 inch diameter combination blade. Purchase

from your n ar st S ars r tail stor or mail

order house. Ask for Catalog No. 9.4937-

'h inch bore ..•...................•....•

Hex nut %.20 jam nut : .

Saw clamp wash r .

Hex nut %.16 jam nut .

Spacer ..............•..................

Control gear .

Plain washer .

G ar cov r .

Machine screw % - 16 x I

*

hex head with ex.

ternal lock washer ......................•

Front Trunnion .

Machine screw 5/16. I8 x

*

hex head with

xt rnal lock wash r .

Fibre washer ........•...................

Flat washer ............•.....•...•.....•

Arbor tilt tension spring .

Arbor tilt tension bolt .•..................

T nsion plat spring .

Replace with Fillister head machine screw

%.20 x

* .

Fence slide .....................•.......•

Binding head screw No. 10-24 x

% .

Fence lock handle friction plate ....•.......

Machine screw % .20 x

*

flat head .

Fence lock handle ..•....•...............

Fence lock handle pivot pin .

Front fence end .

Fence assembly, complete ..•.............•

Fence body ..............•..............

F nc rod .

Hex nut %.16 .............•.............

F nc lock clamp pivot pin .

Fence lock clamp ..•.....................

Fence lock rod nut .

Plain washer % J.D. x 19/32

0.0 .

Rubber grommet .

F nc sho .

F nc nd r ar .

Fence lock rod .

Mit r gag ass mbly, compl t .

Machine screw No. 6.32 x 5/16 Fillister head

Mit r protractor point r .

Miter bar ..........•....................

Mit r protractor .

Plain washer 25/64 J.D. x

*

0.0 .

Lock knob .....•........................

37748

37752

37822

37648

37812

.X.379

37190

.X-380

37732

.X-542

37428

37641

37424

37006

37818

37643

X-413

37642

37425

37639

X-607

37825

37758

37426

37638

37109

X-554

37712

37110

37240

X-630

37411

65 37633

66 37823

67 37632

68 37622

69 18447

70 X-63 I

71 37744

72 38714

73 37649

74 37651

75 X-430

76 37652

77 38619

78 X.181

79 X-737

80 37417

81 X-I79

82 X.430

83 37646

84 18448

85 18449

86 .X.284

87 18992

Order

Illust. by

No. Part No.

64 18036-A

88 X-403

89 18444

90 X-413

91 37655

92 37429

93 X.630

94 37754

95 X.744

96 37422

97 X.737

98

99

100

101

f02

103

104

105

106

107

108

109

110

III

112

113

114

115

116

117

118

119

120

121

122

123

124

125

12 6 -'

127

128

129

.10

.10

.15

.15

.10

.10

.10

. I 5

.10

. I 5

.10

.10

.90

.10

.10

.10

1.20

.10

.15

.20

.10

.15

1.30

.10

.10

.80

.70

• I 5

.25

.10

3.25

.10

7.50

. I 5

.10;

.10

.60

.15

.10

.10

.60

1.60

14.00

.10

• I 5

X.179

Order

by

Part No.

Prepaid

Selling

Price

PART NAME Each

37009 Base ........•.....•.......•...•........ $ 11.00

X-1376 Speed nut No. 6.32 .15

37737 Front panel............................. 3.50

37763 Arbor tilt scale. ... . .. . .. . .. .. .. . . . . . . . . . .35

X.332 Machine screw No. 6.32 x % binding head. . .10

X.182 Set screw 5/16. I8x5 /16 socket head cone pt. .10

38120 Hand wheel with set screw,................ 2.25

X.1806 Sheet metal screw No. 7.16 x % .10

18635 Fence slide bar ..•....................... 1.20

.X-377 Binding head screw No. 10.24 x % .10

37211 Table ..•............ :.................. 26.00

X-375 Binding head screw No. 6.32 x

'AI ••••••.•••.

10

18993 Table insert clip . . . . .I5

37724 Table insert I. 10

X.245 I External tooth lock washer No.6. . . . . . . . . . . .I0

X.736 Machine screw ~.20x 1% hex head with

xt rnal lock wa'sh r .

37636 Motor alignment rod .....•.........•.....

37150 Motor rail guide and plate .

.X.605 Lock washer % inch ........•............

X.430 Hex nut %.20 ...........•...............

37654 Motor rail ... , ...•........•...•.........

37761 Motor rail brac;ket .•......•..............

3782 I Motor rail bushing ....•......•...•......•

37743 Motor rail bushing clip .

.X.20 1 Cap screw %.20 x

*

hex head .

37 I07 Motor mount. complete .

X.740 Machine screw %.20 x % hex head with ex.

ternal lock washer .

X- 100 Set screw % -20 x % slotted head cup pt .

374 18 Splitter bracket ...............•..........

X-622 Plain washer 17/32 J.D. x

%

0.0 .

37757 Tension washer ......•...................

37627 Spacer .

X. 741 Machine screw 5/16.18 x % hex washer head

with external lock washer .

.X-516 Machine screw No. 8.32 x % round head .

37722 Arbor tilt pointer ................•.......

37721 Depth of cut pointer .

.X.377 Binding head screw No. 10.24 x % .

X.734 Machine screw No. 10.24 x % round head

with external lock washer ...•.............

37751 Control shaft spacer plate .

37 I60 Shaft with gear .............••...........

37432 Frame ....•................ ,. ..•.........

X.f307 Steel ball 3/16 diameter .

373 10 Control shaft tension spring .

X.734 Machine screw No. 10.24 x % round head

• with xt rnal lock wash r .

111378.1121.,Tensionplate .

TenSion plate spring .

.X.20 1 Cap screw %-20 x

*

hex head .•..•.......

37423 Guide .

X-607 Plain washer %

1.0.

x 19/32

0,0 .

X.738 Machine screw % -20 x I round head with

~xternal

lock wash r ~ .

37320 Spindle support with bearing .

37634 Depth gage spacer .

37718 Depth of cut scale ..•....................

X-15H Eyelet

'AI

x % .

37 I30 Elevation indicator arm with scale .

37729 Spring washer .................•.........

X-628 Plain washer % J.D. x

%

0.0 .

X.732 Machine screw % .20 x 1% hex head with

int rnal lock wash r .

18035.B Tool pulley with set screw-2 inch single

groove V.pulley.

%

inch bore. Purchase

from your n ar st S ars

r tail

stor or

mail

order, house. Ask for Catalog No. 9-280 I-

%

inch bor .

Set screw 5/16.18 x 5/16 socket hd. cup pt ..

Allen wrench 5/32 ......•.................

V-belt 'h x 40 inches long. Purchase from ',_

your n ar st S ars r tail stor or mail ord r

house. Ask for Catalog No. 9.1640

j' :'

Set scr~ 5/16.18 x 5/16 socket hd. cup pt ' .. 10

X.179

.X-1400

X.1464

I

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

3'5

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

Illust.

No.

'Parts marked in this manner may be purchased locally.

This sh t is int nd d for. instruction and r pair parts only and is not a packing slip. Th parts shown and list d may includ acc ssori s not

necessarily part of this tool. All parts ',r. ' shipped prepaid. All prices are subject to change without notice .

.

~

6

b C

I

3 1,500-4.52

1

I

t

Table of contents

Other Sears, Roebuck and Co. Saw manuals

Popular Saw manuals by other brands

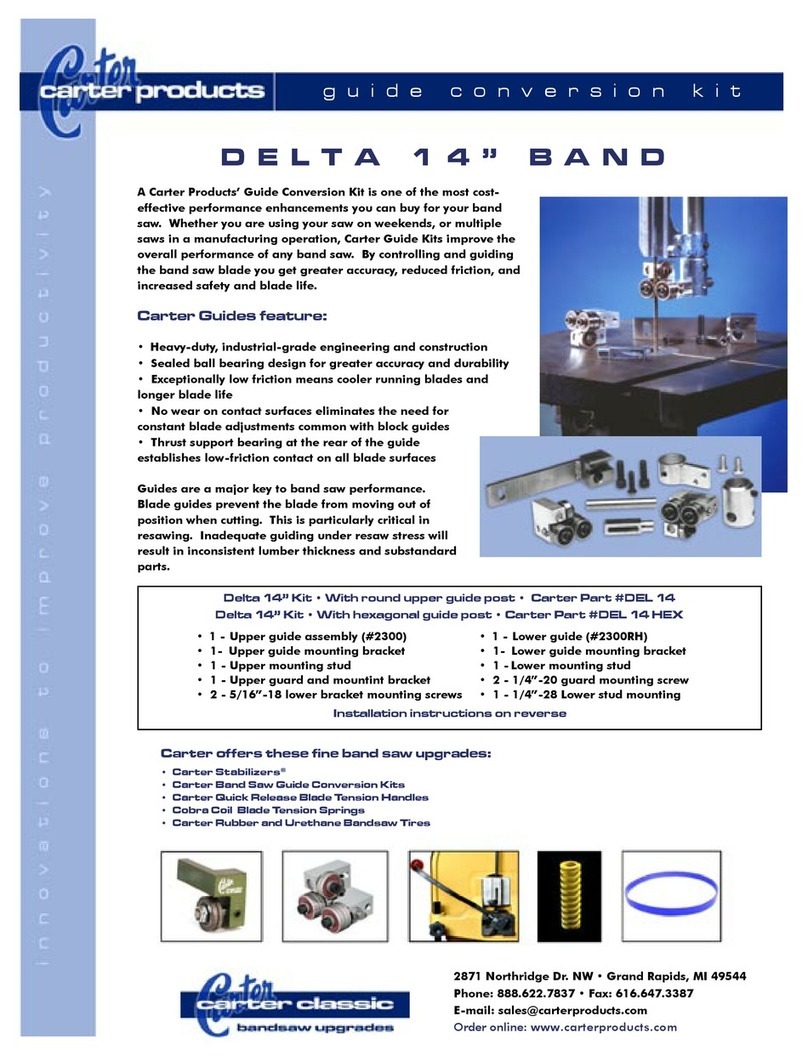

Carter Products

Carter Products DELTA Series manual

Scheppach

Scheppach HM90SL Translation of original instruction manual

GRABBER

GRABBER GR871 instruction manual

Hitachi

Hitachi C 12YB Handling instructions

Axminster

Axminster Hobby MS210S instructions

Clarke

Clarke CTS800C Operation & maintenance instructions