FULL ONE YEAR WARRANTY ON CRAFTSMAN HAND GRINDER

lf this Craftsman Hand Grinder fails to give complete satisfaction within one year f rom the date of

purchase, return it to the nearest Sears store throughout the United States and Sears will replace it,

free of charge.

lf this hand grinder is used for commercial or rental purposes this warranty applies for only 90 days

from the date of purchase.

This warranty gives you specif ic legal rights, and you may also have other rights which vary from

state to state. SEARS, ROEBUCK AND CO.

BSC41-3

SEARS TOWER

CHICAGO, IL 60684

INTRODUCTION

DOUBLE INSULATION is.a.concept il_s{-ely_,.il IMp9RTANT-Servicing of a toot with doubte in-

electric p9w9r tools, which eliminates ll"-19_"d-Lo-f sutation requires extrerie care and knowtedgJoi tne

the usual three wire grou.nded po.we-r- 9"19-^?lq system and'shoutd be performed onty by a fiuatified

grounded supply system. Wherever there-is 9l-":trl9 ierrice technician. F6r service wd suggest you

current in the tool there are two. .9orql:l9..tTI return the toot to your nearest Sears Stordior replir.

insulation to protect the user. All expo-sef lglll et*ays use original factory reptacement parts when

parts are isolated from the internal metal motor serricing.

components with protecting insulation.

VARIABLE SPEED

Your new hand grinder will run at various speeds.

The speed of the grinder is controlled by turning the

knurled knob on grinder. The lower speeds are ideal

for working on wood or soft metals and the higher

speeds are better for working on hard metals.

Your Grinder is a compact, powerful tool packed

with a wealth of usef ulness for professional tool and

die makers and home "handYmen."

R,ULES FOR SAFE OPER,ATION

1 . KNOW YOUR POWER TOOL - Read owner's manual carelully. Learn its applications and limitations as well

as the specif ic potential hazards peculiar to this tool.

2. GROUND ALL TOOLS - UNLESS DOUBLE-INSULATED. lf lool is equipped with three-prong plug, it should

be plugged into a three-hole electrical receptacle. lf adapter is used to accommodate two-prong receptacle,

the adafter wire must be attached to a known ground. (Usually the screw securing receptacle cover plate).

Never remove third prong.

3. KEEP GUARDS lN PLACE and in working order.

4. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

5. AVOID DANGEROUS ENVIRONMENT. Don't use power tool in damp or wet locations or expose to rain. Keep

work area well lit.

6. KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

7. STORE IDLE TOOLS. When not in use, tools should be stored in dry, high or locked-up place-out of reach

of children.

DON'T FORCE TOOL. lt will do the job better and safer at the rate for which it was designed.

USE RIGHT TOOL. Don't force small tool or attachment to do the job of a heavy duty tool.

WEAR PROPER APPAREL. No loose clothing or jewelry to get caught in moving parts. Rubber gloves and

footwear are recommended when working out(pors.

USE SAFETY GLASSES with most tools. Also face or dgst mask if cutting operation is dusty.

DON'T ABUSE CORD. Never carry tool by cord or yank it to disconnect from receptacle. Keep cord lrom heat,

oil and sharp edges.

13. SECURE WORK. iJse clamps or a vise to hold work. lt's safer than using your hand and it f rees both hands to

operate tool.

14. DON'T OVERREACH. Keep proper footing and balance at all times.

15. MAINTAIN TOOLS WITH bARE. Keep tobls sharp at all times, and clean lor best and safest performance.

Follow instructions for lubricating and changing accessories.

16. D|SCONNECTTOOLSwhennotlnuse,beforeservicing;whenchangingattachments,blades,bits,

cutters, etc.

17. REMOVE ADJUSTING KEYS AND WRENCHES. Form

wrenches are removed from tool before turning it on.

18. AVOID ACCIDENTAL STARTING. Don't carry plugged-in tools

when plugging in.

19. OUTDOOR USE EXTENSION CORDS. When tool is used outdoors,

outdoors and so marked.

Simply grabp the tool with one hand and maneuver it

like you would a pencil with only enough pressure to

do the job.

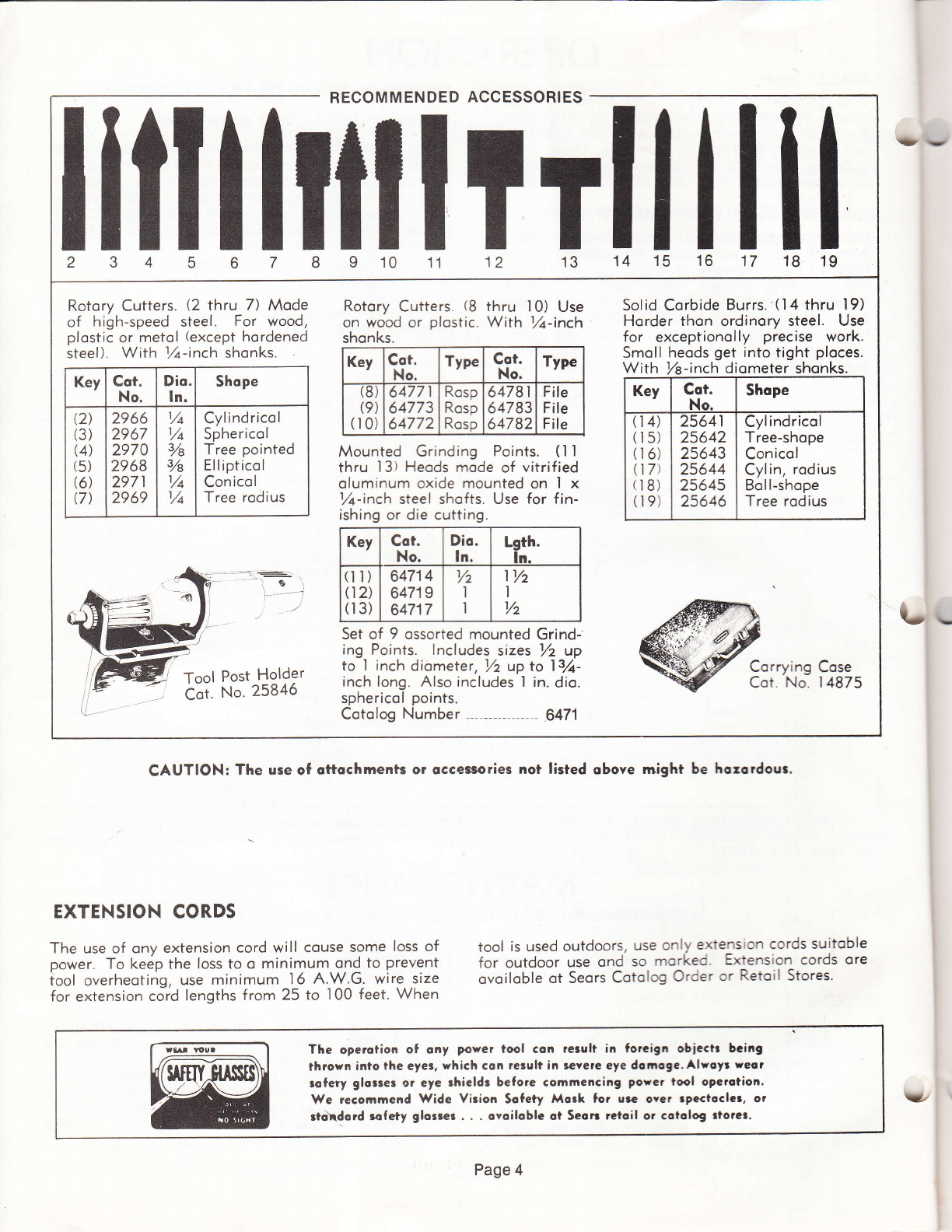

There is a wide variety of cutters, grinding wheels,

mounted wheels and points, carbide cutters, burrs,

etc., available at'your Sears Catalog Order or Retail

Store. With these accessories you can carve, rout,

sharpen, grind, mill, f ile, rasp, and deburr.

The results of work that can be done with your

Grinder are limited only by the skill of the operator.

For specif ic uses, refer to errclosed grinder booklet.

habit of checking to see that keys and adjusting

with finger on switch. Be sure switch is off

8.

9.

10.

11.

12.

Page 2

use only extension cords suitable for use