operotion

BATTERY AND CHARGING SYSTEM TESTS

Ni#+ffi'S{!"t".

c't' \ ,m.;:ll,:r"t o; -+q,

(D

c# ilF

-rI

YO[' o

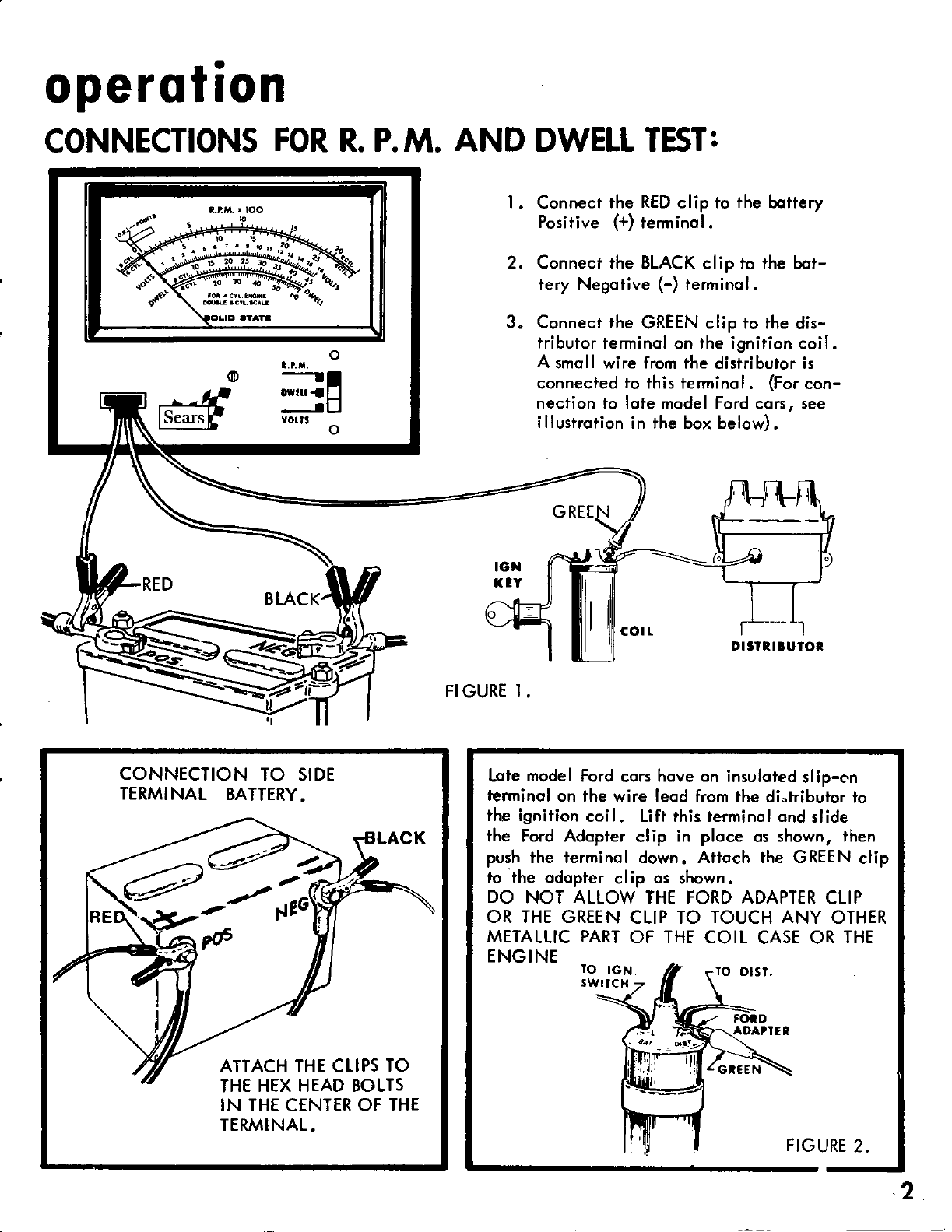

Connecf the test leods os ehown in FIGURE I

on Poge 2.

NOTE: Voltoge reodings con olso be mode

with the GREEN leod connecied os shown in

FIGURE 'I .

Slide the selector knob to the VOLTS position.

Observe voltoge reodings on the 0-16 D. C.

VOLTS scole. Eoch division on this scole rep-

resents .2 volts.

CONSULT THE OPERATING MANUAL

OF THE VEHICLE BEING TESTED FOR

SPECIFIC VOLTAGES AND TEST

PROCEDURES:

The following iniormotion wi ll serve os o

generol guide for moking chorging system

tests.

BEFORE MAKING ANY ELECTRICAL

TESTS, MAKE THE FOLLOWTNG VISUAL

CHECKS:

Check the fon belt -- it should be tight ond

in good condition .

Check the generotor or olternotor pulley ond

mounting bolts. They should be tight.

/rr'loke sure thot the chorging syslem wiring ond

the bottery cobles ore in good condition ond

thot connections ore fight. lvloke sure the

boftery is cleon ond thof the liquid level in

eoch ce I I is obove the plotes. When woter is

odded to ony cell, chorge the bottery ot 15 -

25 omps for 15 minutes to mix the woter with

electrolyte.

The engine ond oll ports of the chorging

system should be ot normol operoting temper-

oture before moking ony electricol tests. lf

ihe engine is cold, operote the engine ot idle

for 15 minutes before moking ony tests.

ENGINE OFF

Wifh the engine off, o 12 volt bottery will

normolly reod between 12.2 ond 12.8 volts

ond o 6 volt bottery will reod between 6.1

ond 6.4 volts. Reodings higher thon these

figures indicote fhot the boitery is holding

o surfoce chorge. lf the heodlights ore turned

on for o few minutes or fhe engine cronked,

the surfoce chorge wi I I be disipoted.

STARTING

A fully chorged l2 volt bottery should not

drop below 9.6 volts ond o 6 volt bottery

should not drop below 4.8 volts when cronk-

ing. Reodings below these figures indicote

trouble in the bottery or storting circuit ond

fhe bottery ond storting circuit should be

checked corefully to defermine fhe couse.

CHARGING

Stort the engine .With the engine wormed up

ond running ot 1500 RfM, the rneter should

reod within the specified volfoge ronge for

fhe vehicle. Reodings lower thon specified

indicote either o worn out or dischorged bot-

teryrdefective generotor or defective or im-

properly odiusted vo lfoge regu lotor. Reodings

higher fhon specfied indicofe o defective or

improperly odiusted voltoge regulofor or ex-

cessive resistonce in the voltoge sensing leod. 6