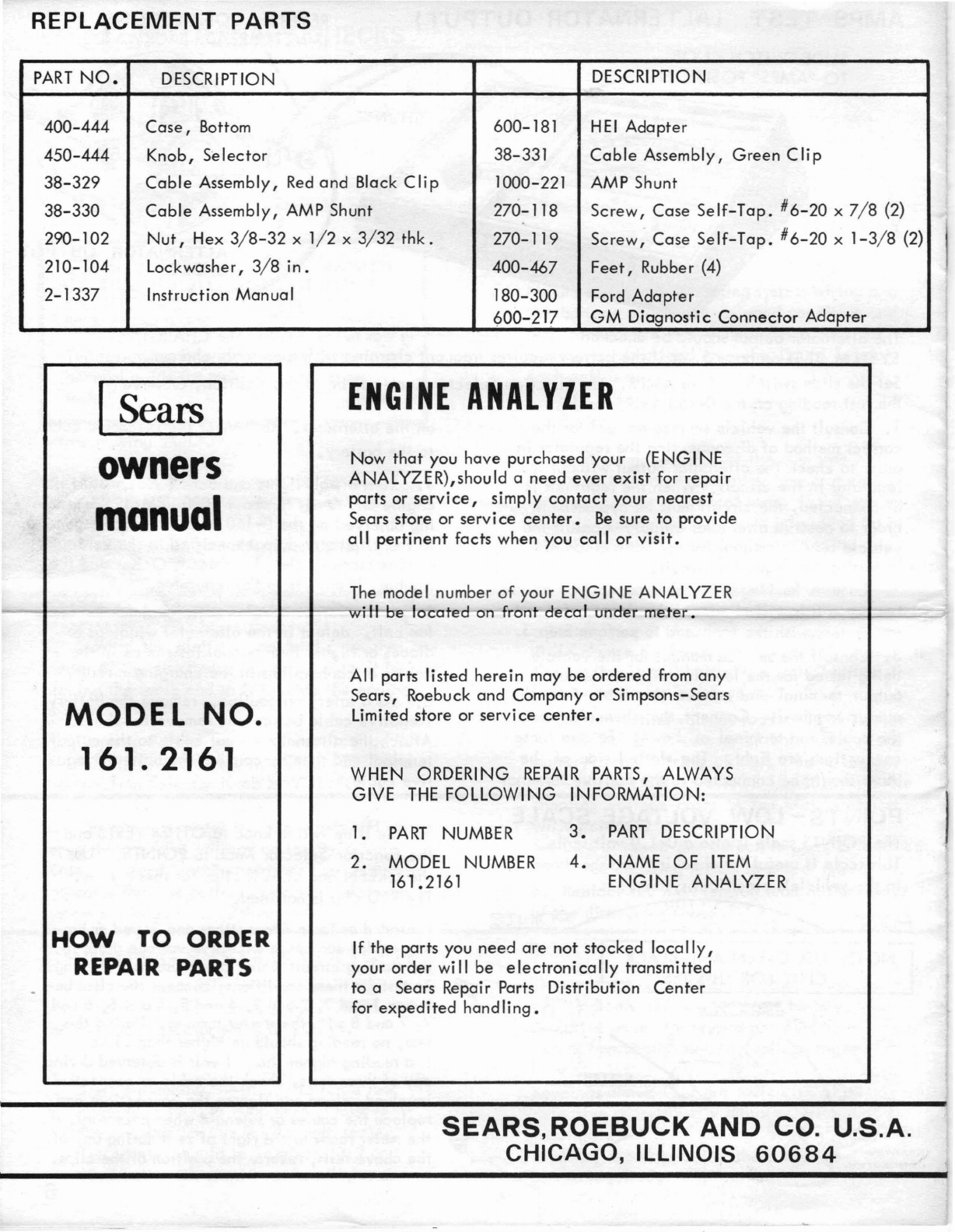

REPLACEMENT

PARTS

PART

NO.

DESCRIPTION DESCRIPTION

400-444

Case,

Bottom

600-181

HEI

Adapter

450-444 Knob, Selector 38-331 Cable Assembly, Green C

Ii

P

38-329 Cable Assembly,

Red

and Black Clip 1000-221

AMP

Shunt

38-330 Cable Assembly,

AMP

Shunt 270-118 Screw, Case

Se

If-Tap. #6-20 x

7/8

(2)

290-102

Nut,

Hex

3/8-32

x

1/2

x

3/32

thk.

270-119 Screw, Case Self-Tap.

#6-20

x

1-3/8

(2)

210-104 Lockwasher,

3/8

in.

400-467

Feet,

Rubber

(4)

2-1337 Instruction Manual 180-300

Ford

Adapter

(>00-217 GM DiagnosticConnector Adapter

ISears I

owners

manual

ENGINE

ANALYZER

Now

that you have purchased your

(E

NG

I

NE

ANALYZER),should aneed ever exist

for

repair

parts or

service,

simply contact your nearest

Sears store or service

center.

Be

sure to provide

all

pertinent facts when you call or

visit.

The

model number of your ENGINE

ANALYZER

lo---I----------lI--I--wfV+tt-"h

u,e-~ocate

on

front decaIunder meter. !

MODEL

NO.

161.2161

A

II

parts listed herein

may

be ordered

from

any

Sears, Roebuck and Company or Simpsons-Sears

Limited store or service

center.

WHEN

ORDERING

REPAIR

PARTS,

ALWAYS

GIVE

THE

FOLLOWING INFORMATION:

1.

PART

NUMBER

2.

MODEL

NUMBER

161.2161

3.

PART

DESCRIPTION

4.

NAME

OF

ITEM

ENGINE ANALYZER

HOW

TO

ORDER

REPAIR PARTS

If

the parts

you

need are not stocked loco IIy,

your order

wi"

be electronico

IIy

transmitted

to aSears Repair Parts Distribution Center

for

expedited handling.

SEARS,ROEBUCK

AND

CO. U.S.A.

CHICAGO, ILLINOIS

60684