Sears 911.47890C2 User manual

Other Sears Oven manuals

Sears

Sears 790.42003604 Manual

Sears

Sears 8101 P590-60 User manual

Sears

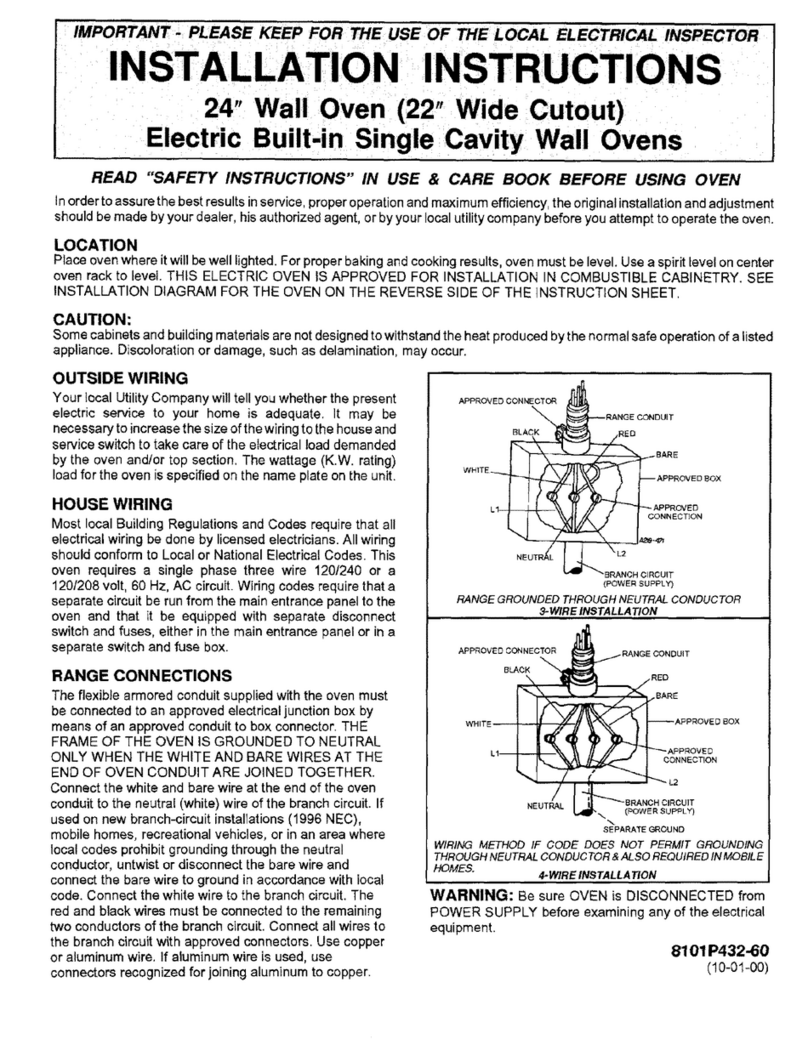

Sears 8101 P432-60 User manual

Sears

Sears 790.40192402 Manual

Sears

Sears WB44K5013 User manual

Sears

Sears 790.48902000 Manual

Sears

Sears Kenmore SR10251 Use Installation instructions

Sears

Sears 24 User manual

Sears

Sears Kenmore C970-418823 User manual

Sears

Sears Kenmore 911.30168 User manual