CONTENTS

INTRODUCTION

...

............

.

.....

...

.. .. ..

. .

.......

...

...

..

..

.............

....

.

...

..

....

...

. . 2

\....../

Sears

Airless

Sprayer

.......

....

.

......

.

........

..

.....

.

...

..

...

.

.......

.............

...........

2

Safety

Precautions

..............................................................................

2

BEFORE

PAINTING

..

....

..........

..

....

.........

.

..

....

.......

.

.......

...........

.

..

..........

..

2

PREPARING

PAINT

FOR

SPRAYING

.

...............

........

.

............

..

.

....

.

.....

............

3

OPERATION

.....

.

..

. . . .

......

...

.

.............

.

.....

...

........

. .

...............................

3

Setting

Delivery

Rate

........................

.

..................................

.

................

3

Spraying

Techniques

........

.

...

....

......

.

.....

....

...

...

.....

..

....

..........

.

..

........

.....

3

USEFUL

ACCESSORIES

.

.............

...

.

........

........

..

.

...

.....

.............................

4

CLEANING

PROCEDURES

.......

.

......

.

..

.........

.

......

.

..........

.

....

......

. .

..........

.....

4

TROUBLESHOOTING

....

.

...

.......

...

.....

....

......

....

..

.....

.

..........

.

..

......

...........

. 5

Seized

("Frozen

") Piston

........................................................................

5

Troubleshooting

Guide

................................

...

...............

........

..........

...

...

6

Replacement

of

Wear Parts . . . . . . .. . . . . . . . . . . . . .. . . . . . . .. . . . . . . .. . . . . .. . . .. . . .. . . . . .. . . . . . . .. . . .. 7

Minor

Repairs

........................................................................

.....

...

. . 7

Major

Repairs

....

.....

.......

...

.....

..

....

................

..

....

..........

......

. . .

...

....

.

....

7

PARTS

LIST

...

.

.....

.

....

.

........

..

....

...

...........

.

.......

....

..

.....

....

..

.

.....

.....

.

..

. .

..

9

ASSEMBLY

INSTRUCTIONS

5'

SUCTION

TUBE

. .

....

....

.

.....

..............

..

.

........

. .

..

..

...

10

THINNING

RECOMMENDATIONS

.....

..

...............

.........

.

.....

.....

.

..

. .

.......

........

..

11

ACCESSORIES

..

..........

....

.....................

. .

....

...

.......

............

...

. .

....

.....

...

12

WARRANTY

....

. .

...

.......

.

...

...

...

. . .

..........

. .

.....

.

.....

......

................

. .

.........

13

HOW

TO

ORDER REPAIR

PARTS

................................

......

...

.

....

.

..

....

. .

Back

Cover

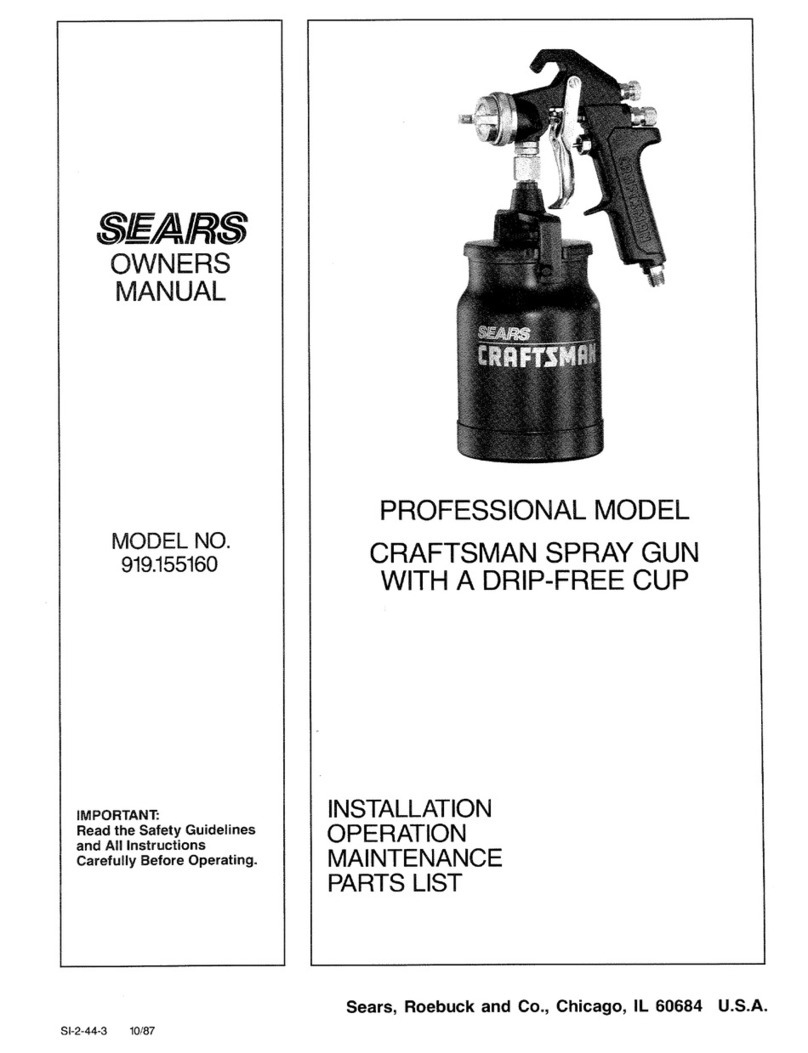

CONTAINER-----+\

FILTER

CONTROL

:..----

KNOB

•~---

HANDLE

3-WIRE

GROUNDED)

PLUG