5

GENERAL INFORMATION

INSTALLATION

(Figure 1) Attach nut of paint cup

assemblyto1/4"NPTfluidinletnipple

onspraygun. Tightenonlyuntil snug.

Position yoke at right angle to gun

body with cam toward front of gun.

Connect atomization air line to air

compressor.

OPERATION

This Craftsman Detail Touch-up gun should be flushed

with solvent prior to spraying with paint.

A. Adjust air pressure to approximately 30 P.S.I. The

use of an air regulator assures clean, dry air.

B. Turn needle adjustment screw out until first

thread shows. This places the tip and needle in a full

open position which gives maximum tip and needle

life. Never turn all the way in, as trigger cam will

break.

C. Turnfan adjusting screwout until first thread shows.

D. Press trigger and adjust needle adjusting screw for

desired material flow.

E. Press trigger and observe atomization of fluid. If it is

too great, decrease air pressure at regulator. If it is

not enough, increase air pressure at regulator.

F. Press trigger and adjust fan adjusting screw until

desired pattern is obtained. A perfect pattern is a

full, even coat from end to end. Each time needle

adjusting screw is adjusted Step E should be re-

peated.

PREPARING PAINT

Be sure the surface to be sprayed is dry

and free of all dirt, grease, oil and loose

paint. Mix and prepare paint in accor-

dance with the manufacturer's instruc-

tions. Strain material to be sprayed

througha60to90meshscreenorequiva-

lent.

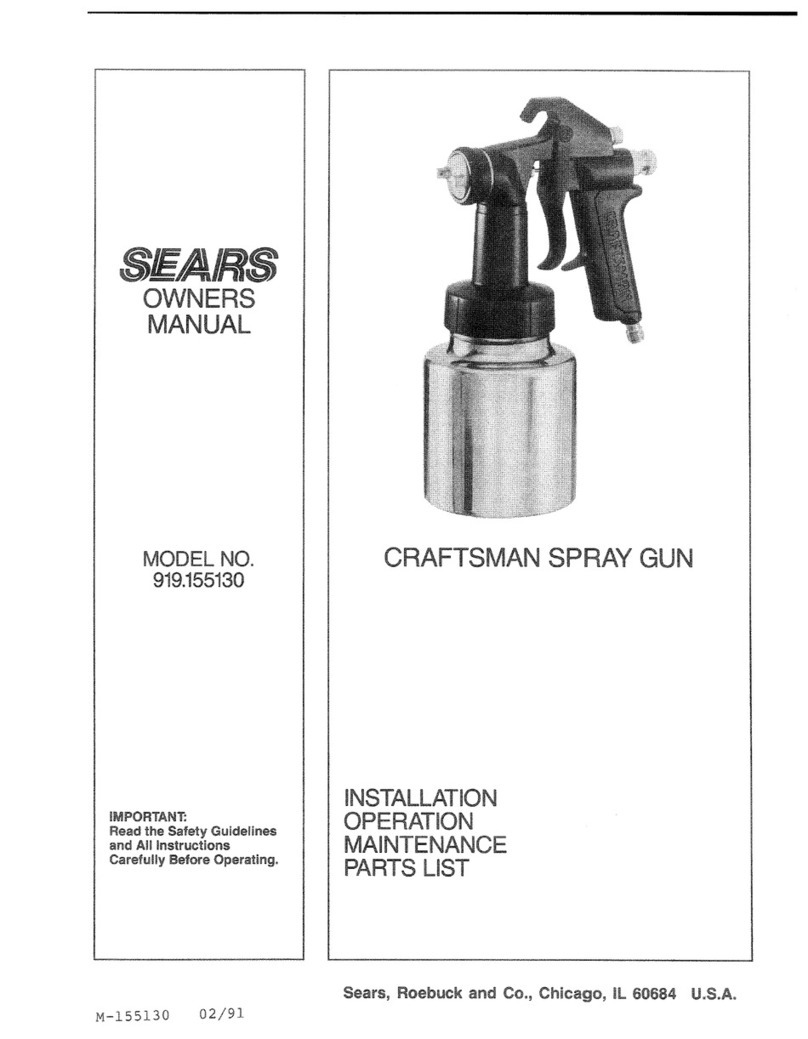

CONTROLLING THE FAN SPRAY

(Figure2)Thefan spray foranexternal

mix nozzle set up is easily controlled

by means of the fan adjusting screw.

Byturningtothe right (clockwise)until

it is closed will give a rounded spray;

turning it to the left (counterclock-

wise) will widen the spray into a fan

shape of any width desired. The di-

rection of the fan spray (horizontal or

vertical) is obtained by turning the air

nozzle to the desired position, then

tightening the air cap/retaining ring.

Tighten only finger tight. Do not use

pliers or wrench to tighten or loosen.

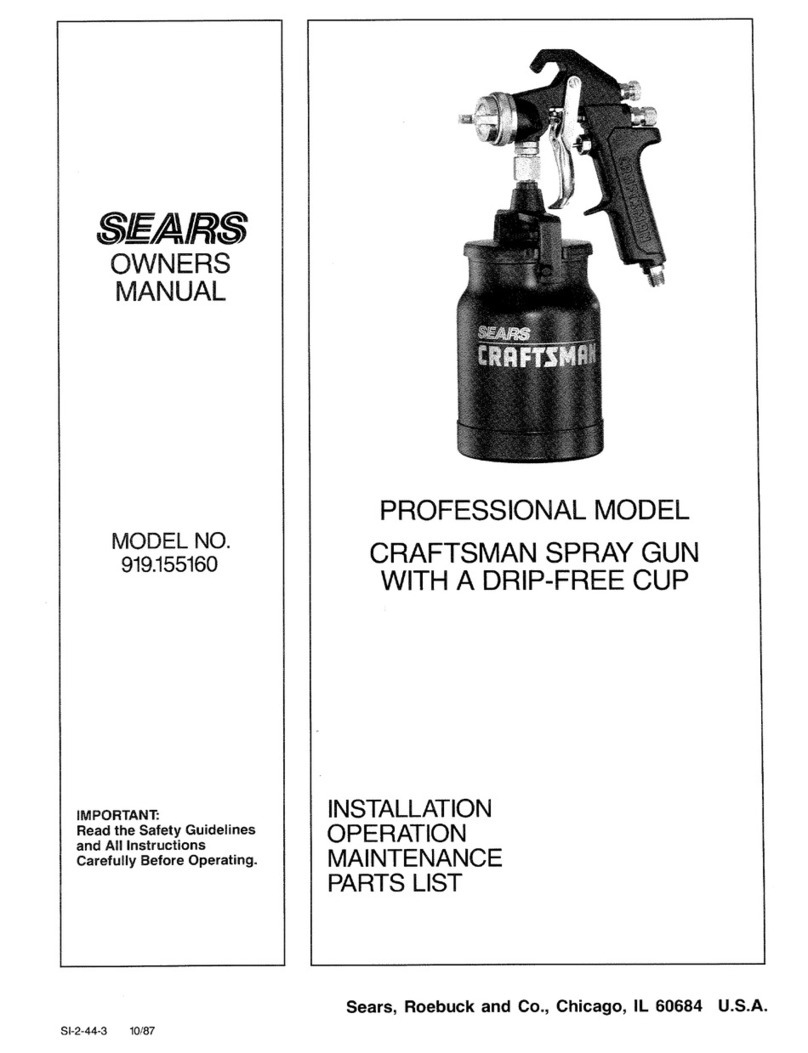

FIGURE 1

DESCRIPTION

The Craftsman Detail Touch-Up Gun is the only spray gun of its type that can be simply converted for use by a left

or right handed sprayer, by simply unscrewing the trigger screw, turning the trigger over and re-inserting the trigger

screw. The complete Craftsman Detail Touch-Up Gun consists of a detail touch-up gun and 8 oz. (240 cc) suction cup

assembled. The detail touch-up gun is a non-bleeder, suction feed, external mix type. The cup has a one half pint

capacity.

FIGURE 2

NOTE: This spray gun is designed to spray stains, acrylics, lacquers, primers, automotive metallics and

other light and medium viscosity finishes. Most unreduced latex or other heavy bodied materials require

the use of a pressure feed paint tank. If used with corrosive, rust-inducing, or highly abrasive materials,

frequent and thorough cleaning will be required and/or may increase the need for replacement parts.